8

3. Heating Surfaces

3.1. Water Heating Surface

The Airmaster air handling unit DV 1000 can be tted with

an external water heating surface. AM 300, 500, 800,

900, 1000 and 1200 can be tted with an internal water

heating surface.

The water heating surface for the DV 1000 is also used to

protect against the formation of ice in the heat exchanger.

The “Virtual Preheat” function is used for this purpose.

Further details are available in the Operator’s Manual.

For this option, a motorised valve and an automatic heat

retention thermostat are tted on the heating surface. The

water heating surface is leakage tested and nal inspection

performed according to standards and rules in eect.

The heating unit’s delivery ow is connected to the con-

nection tting marked FREM (“DELIVERY”) and the return

ow to the connection tting marked RETUR (“RETURN”).

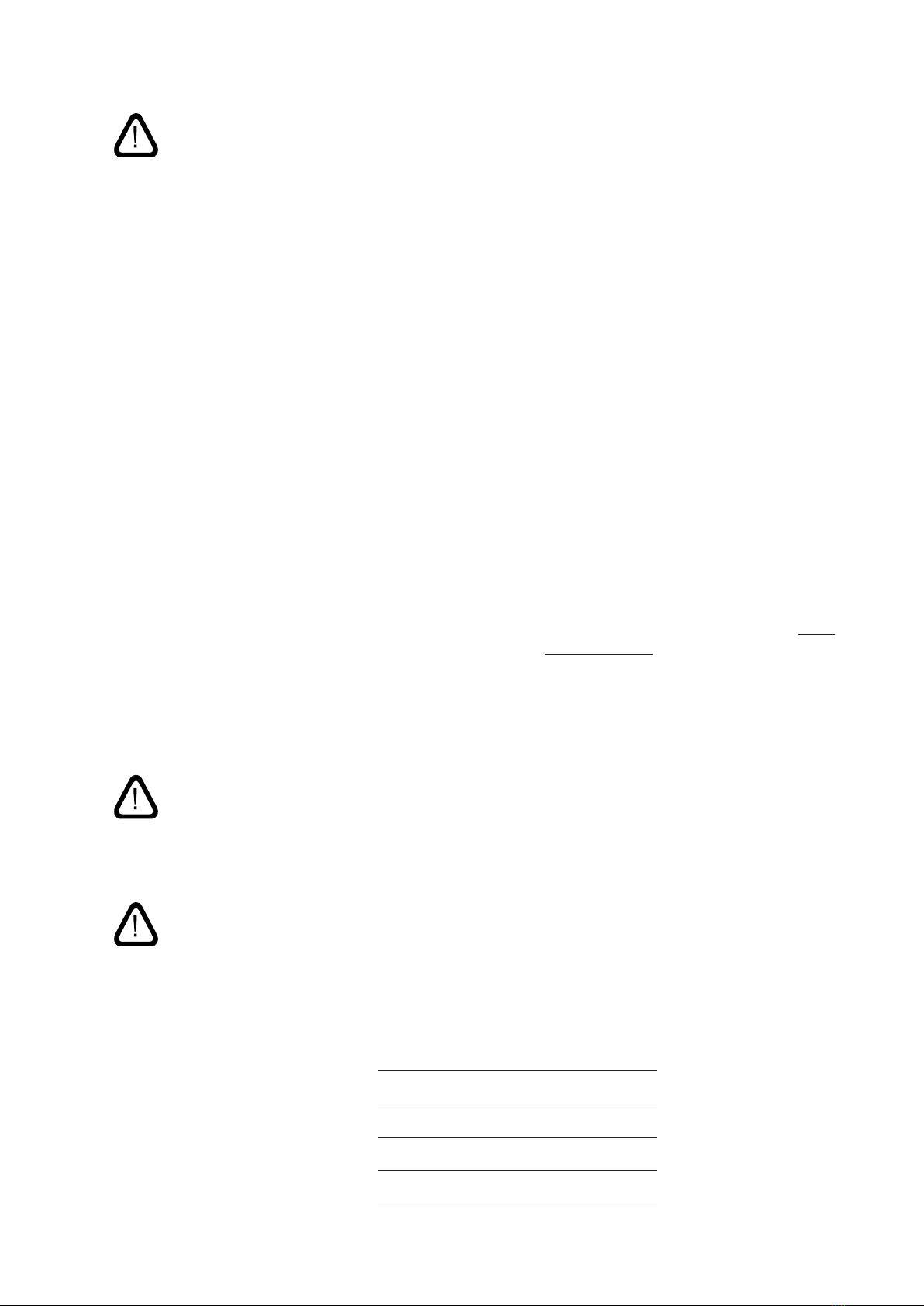

NB! The dimensioning of pipes and valves and

connection of water to the unit must always be carried

out by an authorised specialist in accordance with

current legislation and regulations.

NB! There must be clean water in the installation for

the internal valves in the water comfort heater to be

able to function optimally without problems.

It is recommended that shut-o valves, a dirt lter and

a line regulating valve be tted in accordance with the

“External connection” block diagram. It is also recommended

to mount the bleed valve and drain cock for commissioning

and service.

It may be necessary (e.g. in the case of a district heating unit)

to install a pressure dierential regulator if the pressure

dierence ∆ps exceeds 40 kPa (10 kPa = 0,1 bar). If the

dierential pressure ∆p rises above the internal construction

above 40 kPa, the risk of noise from the control valve to the

heating surface increases.

External connection:

Δp

Δps

D

BC

G

A

E

TD

F

A Internal assembly (supplied by Airmaster).

B Shut-o valve (supplied by installation contractor).

C Dirt lter (supplied by installation contractor).

D Line regulating valve (supplied by installation contractor).

E Pressure dierential regulator (supplied by installation

contractor).

F Bleed valve (supplied by installation contractor).

G Drain cock (supplied by installation contractor).

Internal construction:

In the case of DV 1000, the internal assembly is installed on

the inside of the external heating surface. In the case of AM

products, the unit must be opened for any connection work.

M

TC

1

2

3

45

6

6

1 Return connection. (Delivery connection for the AM 800.)

2 Delivery connection. (Return connection for the AM 800.)

3 Frost protection valve (Comap D3803S) with remote

temperature sensor (Comap Senso RI).

4 Control valve (Comap D3803S) with electric On/O valve

(Ballerox 43600012).

5 Water heating surface.

6 Airow.

3.1.1. Bleeding

Open the water throughow and bleed the system using

the bleed valve (F). After a short time any air noise in the

water throughow should cease.

NB! The unit must be bled with fully open valves (3 + 4).