INSTALLATION AND CALIBRATION

4 – 20 mA SENSOR / TRANSMITTER MODEL TR-1000

INSTALLATION:

1. Locate a flat surface to mount the enclosure so that the sensor can face

downward. If the rear power entry is to be used, remove the plug before

mounting the enclosure. The second power entry is at the end opposite

the sensor.

2. Remove the cover of the enclosure by removing the 4 screws in the

corners. Be careful here since the circuit board is connected to the cover.

The circuit board is connected to the sensor, so the cover will hang from

these wires when removed. Remove the plug from the end power entry if it

is to be used.

3. Connect the electrical fittings to the enclosure and bring in the electrical

wires. NOTE: BE SURE WIRING IS DONE ACCORDING TO THE LOCAL

ELECTRICAL CODE REQUIREMENTS. NOTE: To prevent shorting

problems do not leave ground wire to box bare (if one is used) – cover

with electrical tape.

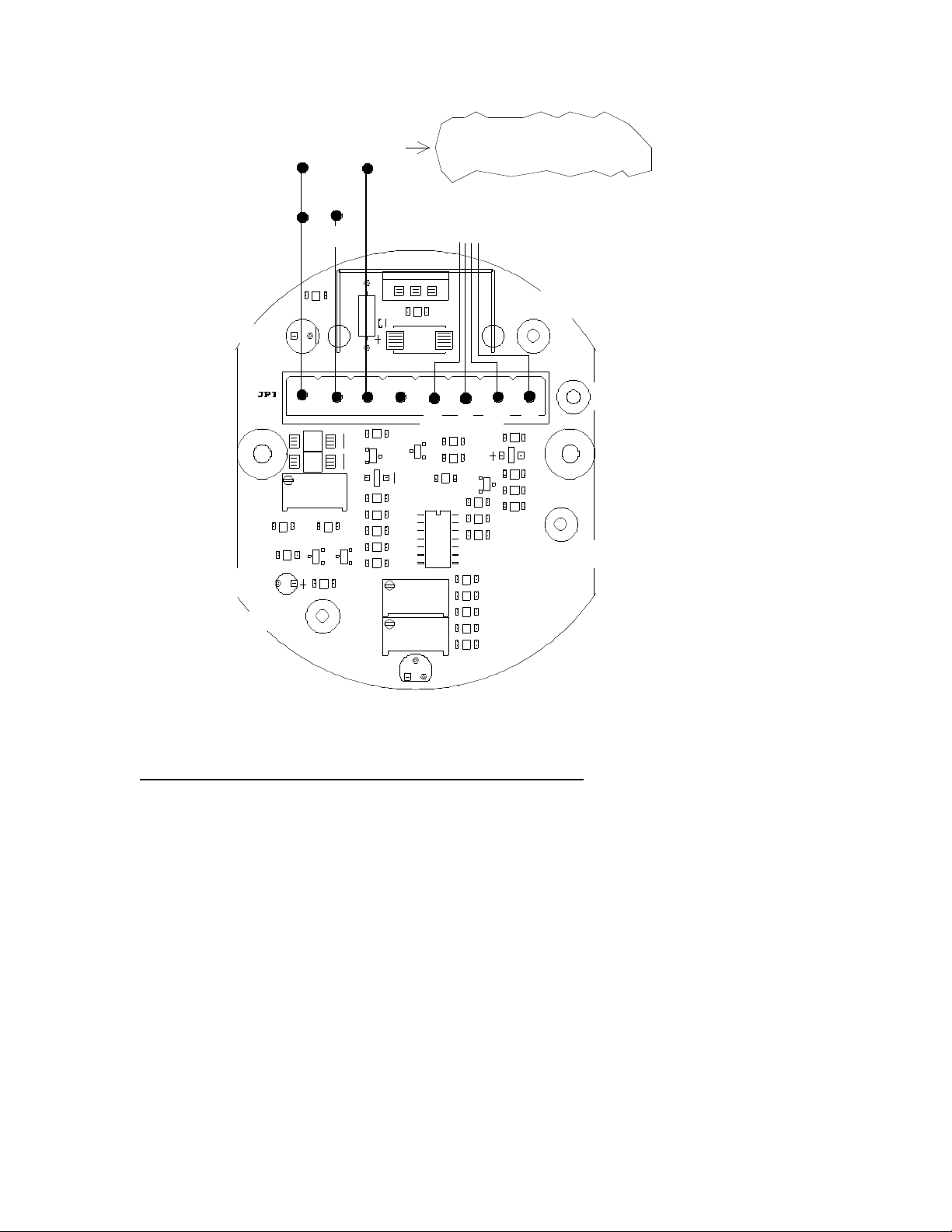

4. Connect the wires to the removable connector block as shown on the

wiring drawing. (See Fig.1)

CALIBRATION - SOLID STATE SENSORS:

The TR-1000 has been factory calibrated for a range of 0 – 400 ppm CO and is

ready for use. If however there is a level of background gases, it should be

calibrated on site. If the range is to be changed, the TR-1000 must be re-

calibrated.

1. Connect power and signal return wires to a suitable controller that will provide

sensor excitation and signal processing. (See Fig.1)

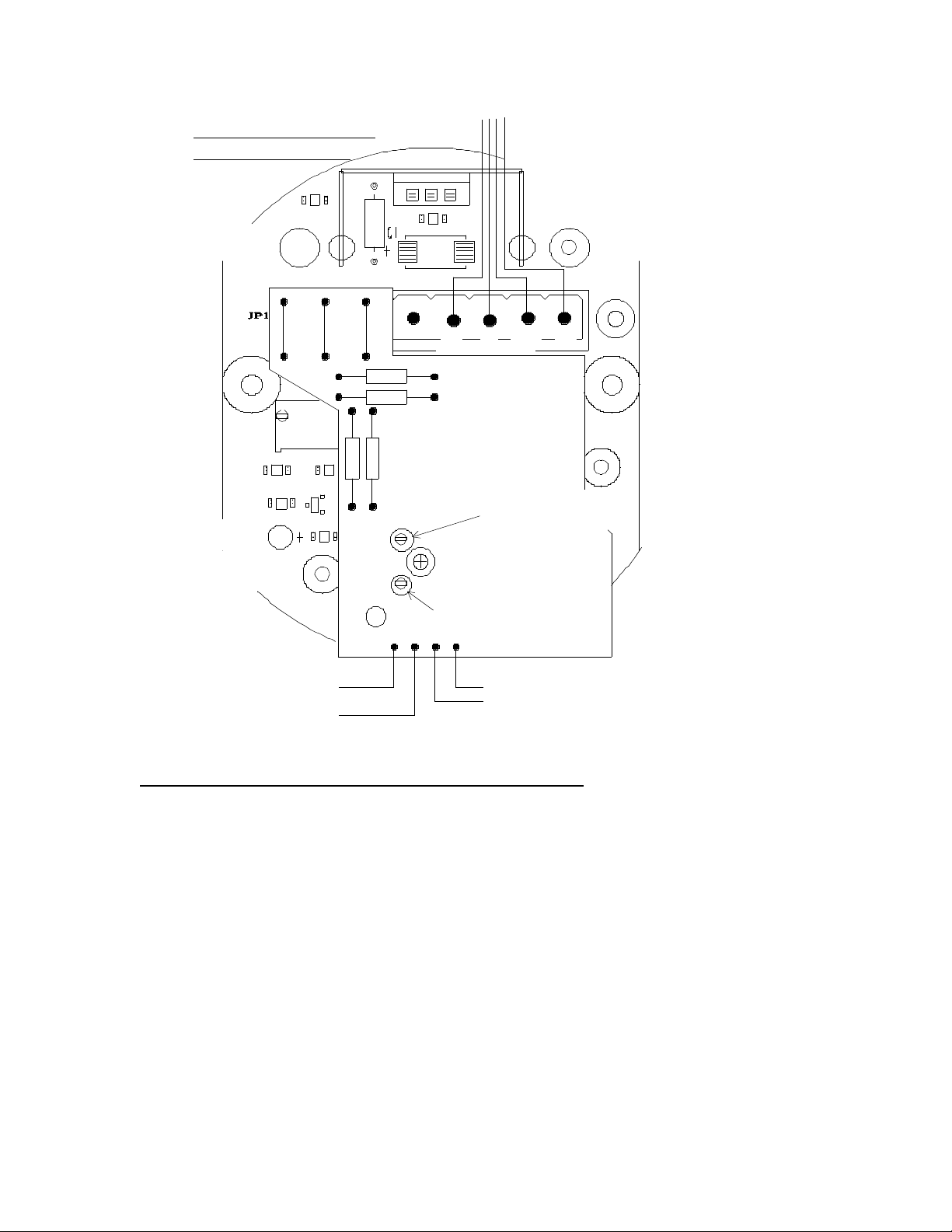

For all the following readings TP1 (RED) is the COMMON POSITIVE jack.

2. Power up the unit, the ready light will come on in 10 seconds. Check TP2

(Black) for correct voltage of 5.0V ±0.1V. If it is satisfactory let the sensor

burn-in for 24 hours. If voltage is unsatisfactory the board is faulty and must

be serviced.

3. TO SET ZERO

Adjust the ZERO potentiometer, RV1, until the ACTIVE LED (YELLOW) just

goes off.