1.2 How the airwell pump works

Compressed air is a particularly useful means of transferring energy to pump water. Air compressed at an existing

power source can be carried significant distances through MDPE polyethylene pipe with limited loss of pressure,

saving a costly power installation to the water source, whilst allowing the compressor to be used for multiple

pumps, or other local purposes.

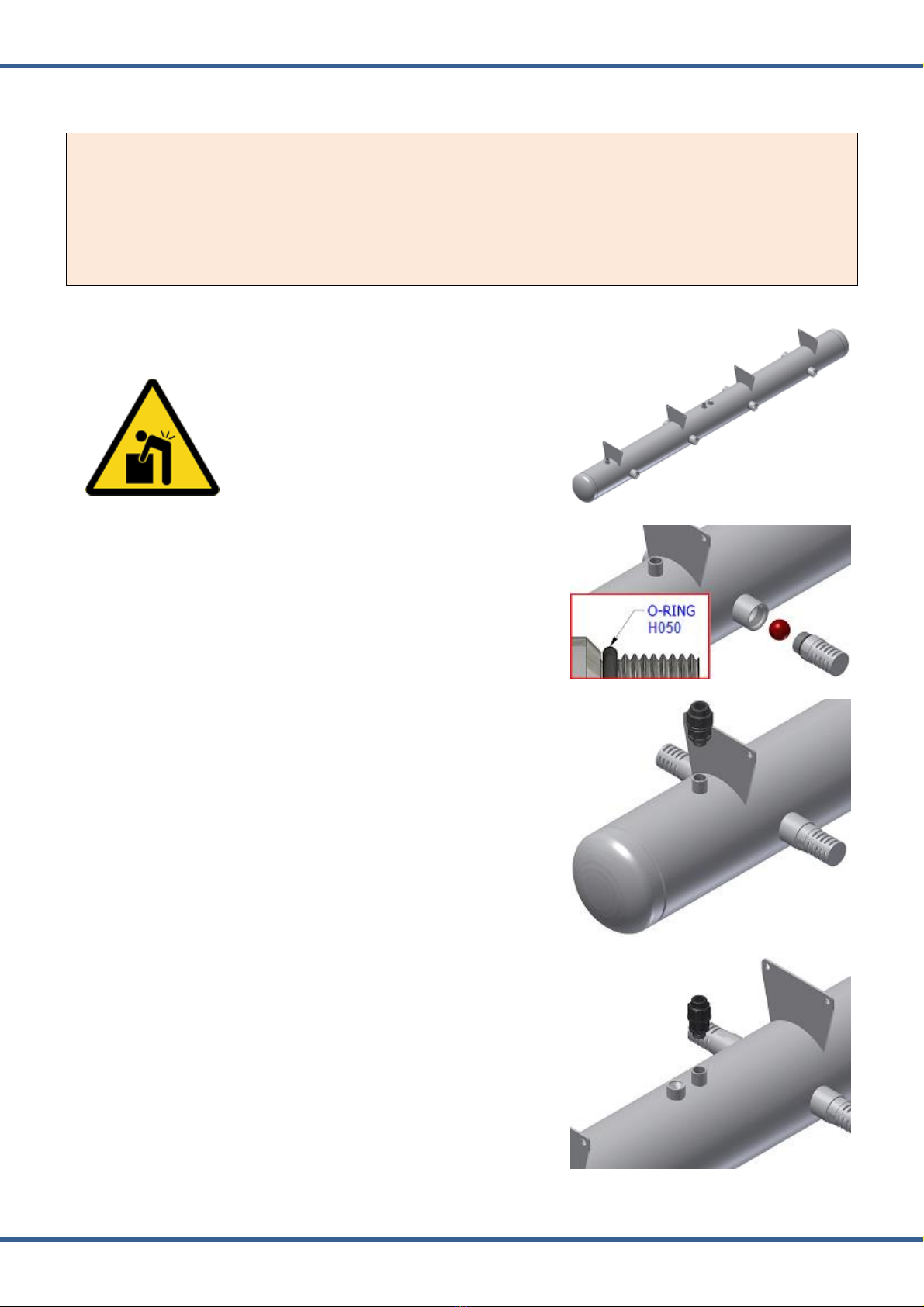

The Airwell pump component is a 316L grade stainless steel tube that can be manufactured in varying forms and

sizes to suit a variety of different applications. The tube is enclosed at each end and incorporates a foot valve(s) to

allow the submerged vessel to fill with water and a check valve on the outlet preventing the return of the

expelled water. The valves are our own design and incorporate special features to provide exceptional ability to

handle silt and sand, whilst keeping a very simple, maintenance free construction. The clean, hard valve seats

provided for the polyurethane balls to close on are kept clean by the circulation of the water and are raised above

the bottom of the pump to minimise contamination.

Within our most popular pumps there are two level (conductivity) probes; one long enough to reach the bottom

of the pump to detect when the pump is empty, and one short one to detect when it’s full. This is the key to the

automatic function of the pump. We use the conductivity of water to monitor the high and low fluid levels in the

pump. This means that a ‘contact’ is made when the water rises to the height of the short probe at the top of the

vessel, (now both probes are wet) and is ‘broken’ when the water level falls below the lower probe at the bottom

of the pump, (when both probes are dry).

An electronic circuit in the control unit detects this making and breaking of water contact, and subsequently

changes the state of a 3-way solenoid valve, allowing compressed air to the pump when a ‘full’ signal is received,

forcing the water up the discharge pipe, and then exhausting the air pressure to allow the pump to refill when the

‘empty’ signal is seen. The result of this is that the Airwell Pump will only cycle when a 'full' or 'empty' signal is

received, regardless of this being every few seconds, minutes, hours, weeks or years.

The control unit is located close to the pump, but above water level. Besides carrying the 3-way valve for the air

and the electronic control circuit, it also houses a 4.5 Amp/hour dry cell battery to power the system, which in

turn is recharged by the solar panel on the lid of the controller. Mains powered systems are available for those

applications where power is close to the water source, as are multiple pump controllers, flow monitoring and flow

control options.

It should be noted that the solenoid valve is a ‘latching’ type valve and requires a short pulse of power (60

milliseconds) in one direction to change state and will stay that way until a pulse in the opposite direction

changes it. A conventional solenoid requires permanent energisation to maintain either an open or closed state.

Should power be lost to the microprocessor, upon reconnection, the system will initialise on pressure, expelling

any water in the pump, and regaining a reference for the controller. The water delivered by an Airwell system

comes in surges, not a continuous flow like that of most electric pumps. Flow rates from the Airwell pump vary

dependant on many factors.