SVH

Sunfab Hydraulics AB, Box 1094, SE-824 12 Hudiksvall, Sweden. Tel: +46 650-367 00, Fax: +46 650-367 27, E-mail: sunfab@sunfab.se Web: www.sunfab.com

2

D

LS

© Copyright 2020 Sunfab Hydraulics AB. All Rights Reserved.

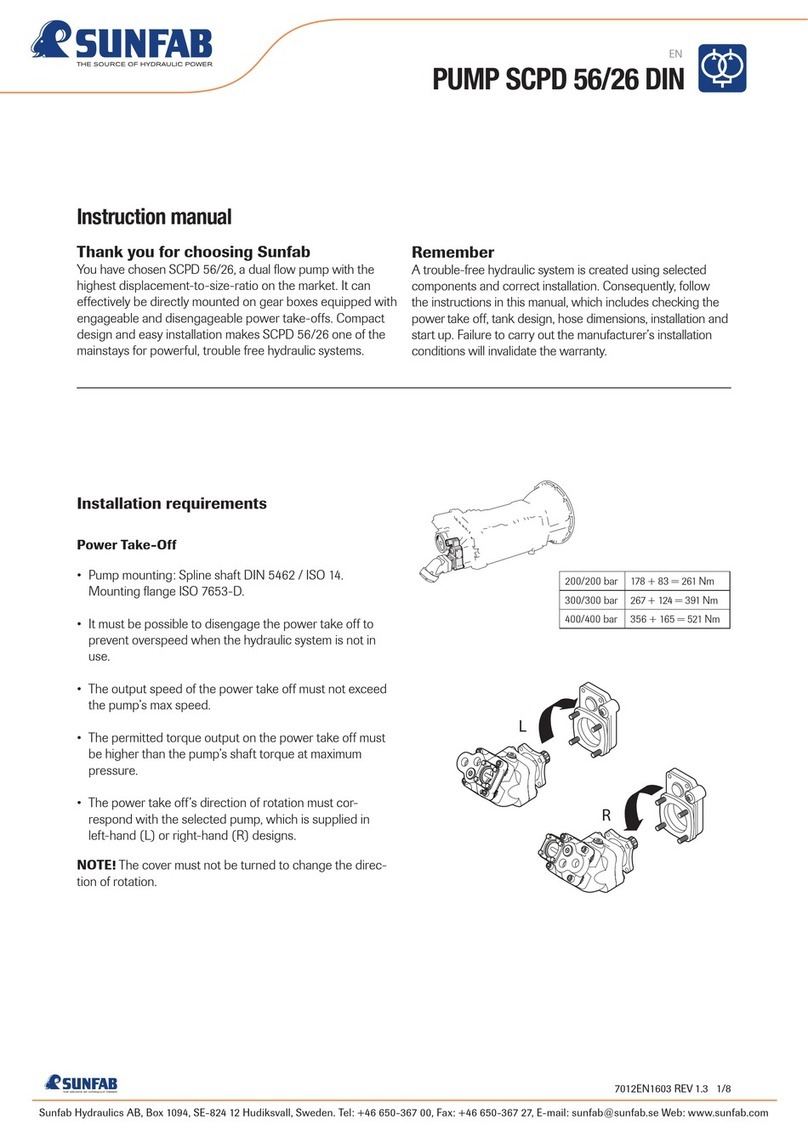

Drainage line D

Route a drainage pipe of at least 19 mm directly between the pump and

tank. The drainage pipe’s connection to the tank should lie in between the

lowest oil level and the bottom of the tank.

The pump housing must be filled with new hydraulic fluid before the hydrau-

lic pump is commissioned.

Signal line LS

The capacity of the LS signal line should be adapted to the relevant hydraulic

system. The speed and damping for the signal is optimal when the LS signal

line has a capacity of 10 % of the capacity for the pressure line between the

pump and directional control valve. If both lines are the same length, the

inside diameter of the signal line should be 1⁄3 of the pressure line’s internal

diameter I.E.¼–½”. The signal line should ideally be a hose.

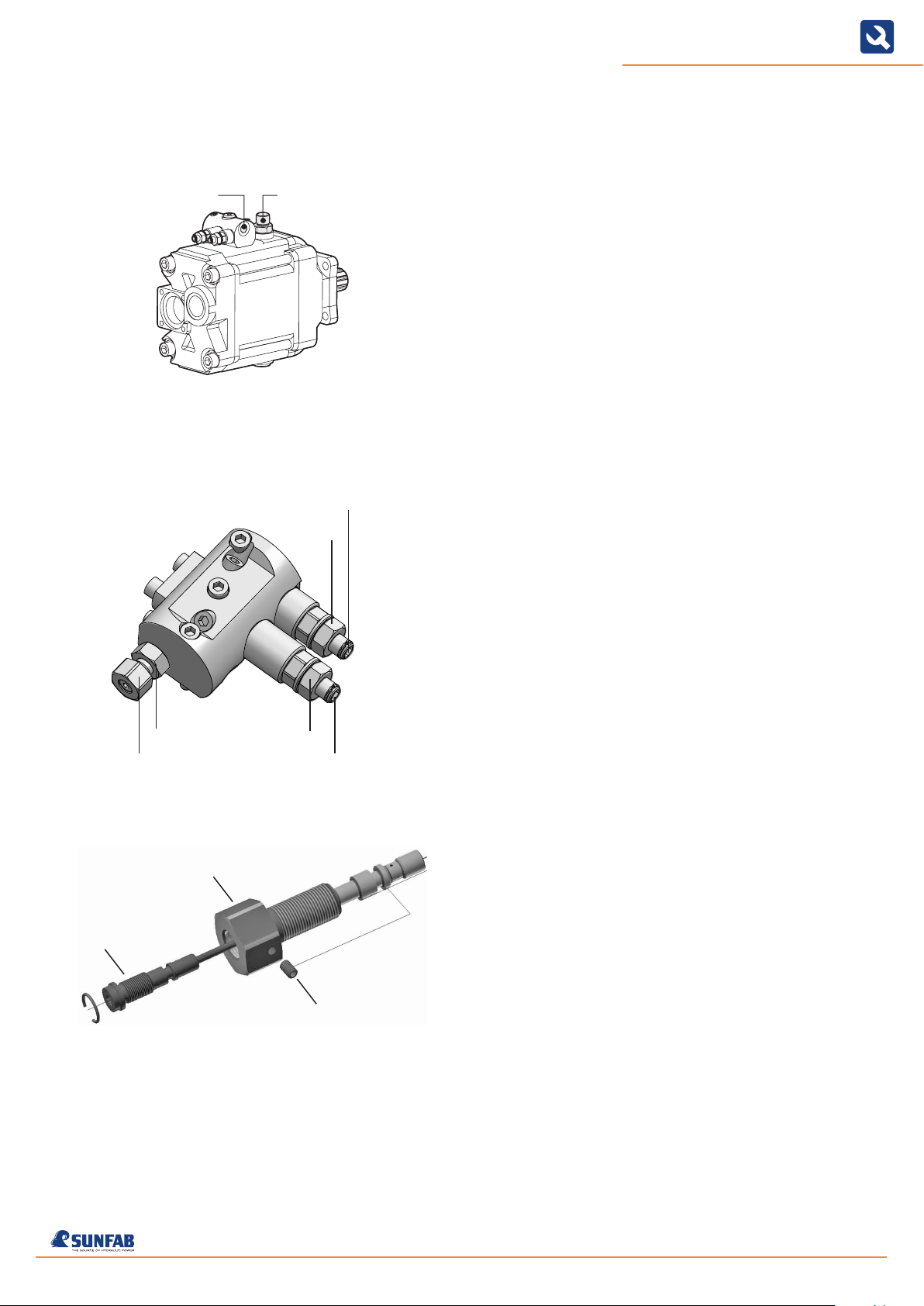

Load sensing regulator LSP

Adjust the differential pressure Δp = system pressure minus the signal pres-

sure. The regulation range is 20-55 bar. Preset to 27 bar. 1 turn of the

adjuster screw corresponds to 10 bar. Clockwise increases the differential

pressure, counterclockwise decreases.

Adjust the max. system pressure between 20 and 350 bar. The value preset

at the factory is 350 bar. 1 turn of the adjuster screw corresponds to 50

bar. Clockwise increases the maximum system pressure, counterclockwise

decreases.

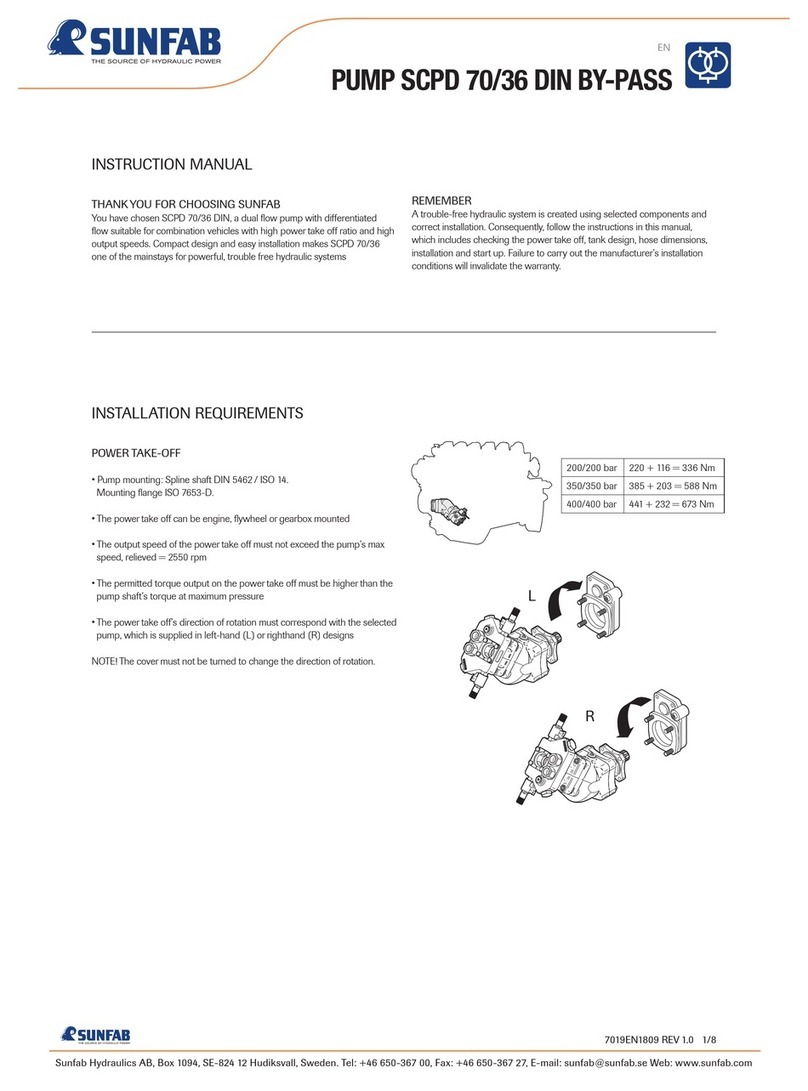

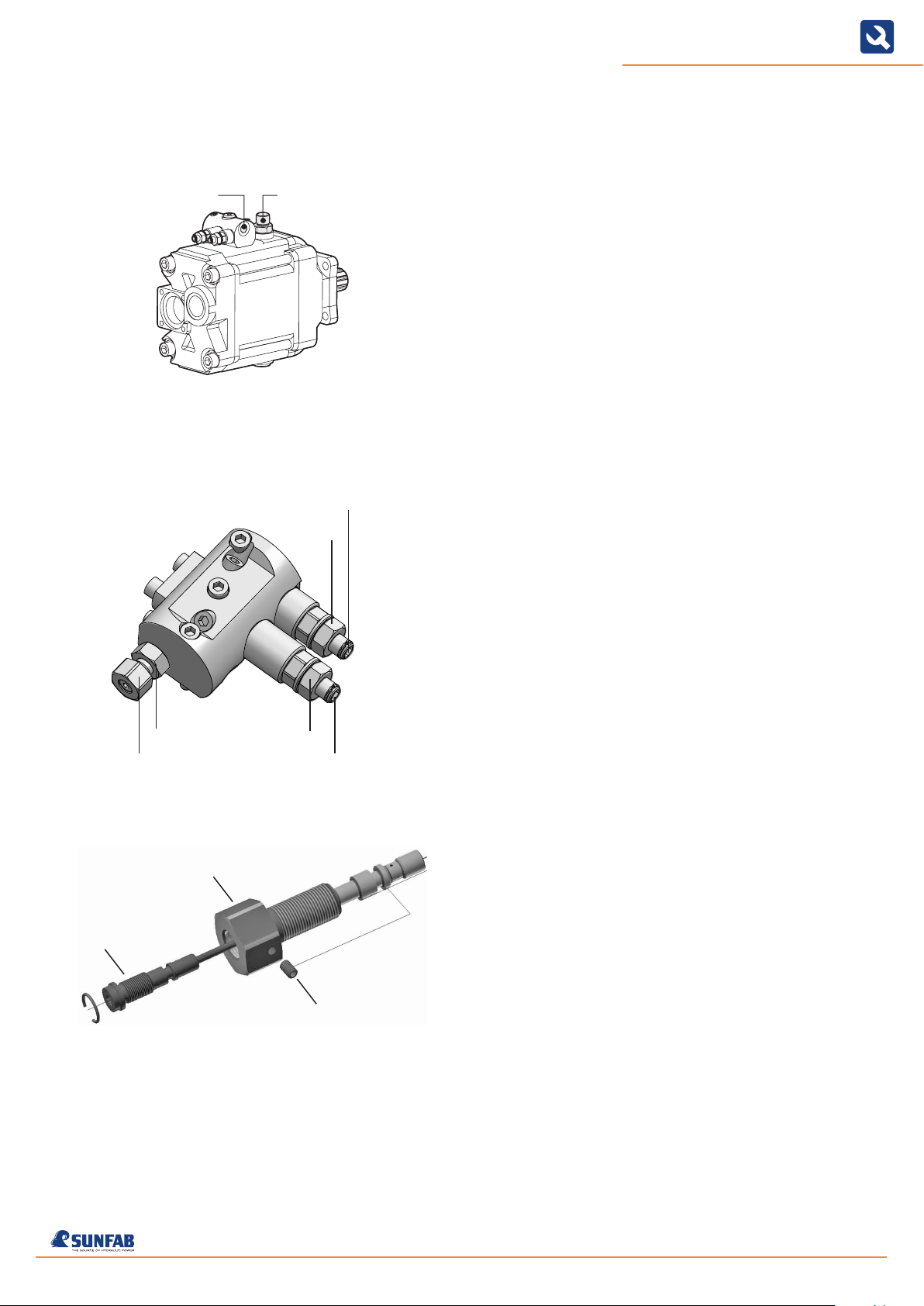

Description of the two-part damping

screw on the LSP-controller

With the return flow throttle you can adjust the onstroke

time for bringing the pump from Vgmin to Vgmax.

• Unscrewing the screw reduces the dampening and accelerates the

vonstroke time.

• Screwing in the screw increases the dampening and slows down the

onstroke time.

• Adjustment range: ca. 5.5 revolutions resp. 4 mm

With the bypass throttle you can adjust the destroke time

for bringing the pump from Vgmax to Vgmin.

• Unscrewing the screw increases the dampening and slows down the

destroke time

• Screwing in the screw reduces the dampening and accelerates the

destroke time

• Adjustment range: ca. 4 revolutions resp. 2 mm

System pressure

Damping screw Differential pressure Δp

20 Nm

20 Nm 20 Nm

7015EN2008 Rev 1.4

Sunfab reserves the right to make changes in design and dimensions without notice. Printing and typesetting errors reserved.

Bypass throttle

Return flow throttle

Allen screw