•Drain the Electric Ladder Pipe monitor and nozzle after use to prevent “freeze damage”.

•Ensure that the thread in the nozzle swivel matches the thread on the Ladder Pipe outlet. Do not overtighten

the nozzle onto the Ladder Pipe.

•The Electric Ladder Pipe monitor, nozzle, logic box, control boxes, auxiliary battery, are made for optimal

performance. Do not alter in any manner.

•Do not install shutoffs on the outlet of the Ladder Pipe.

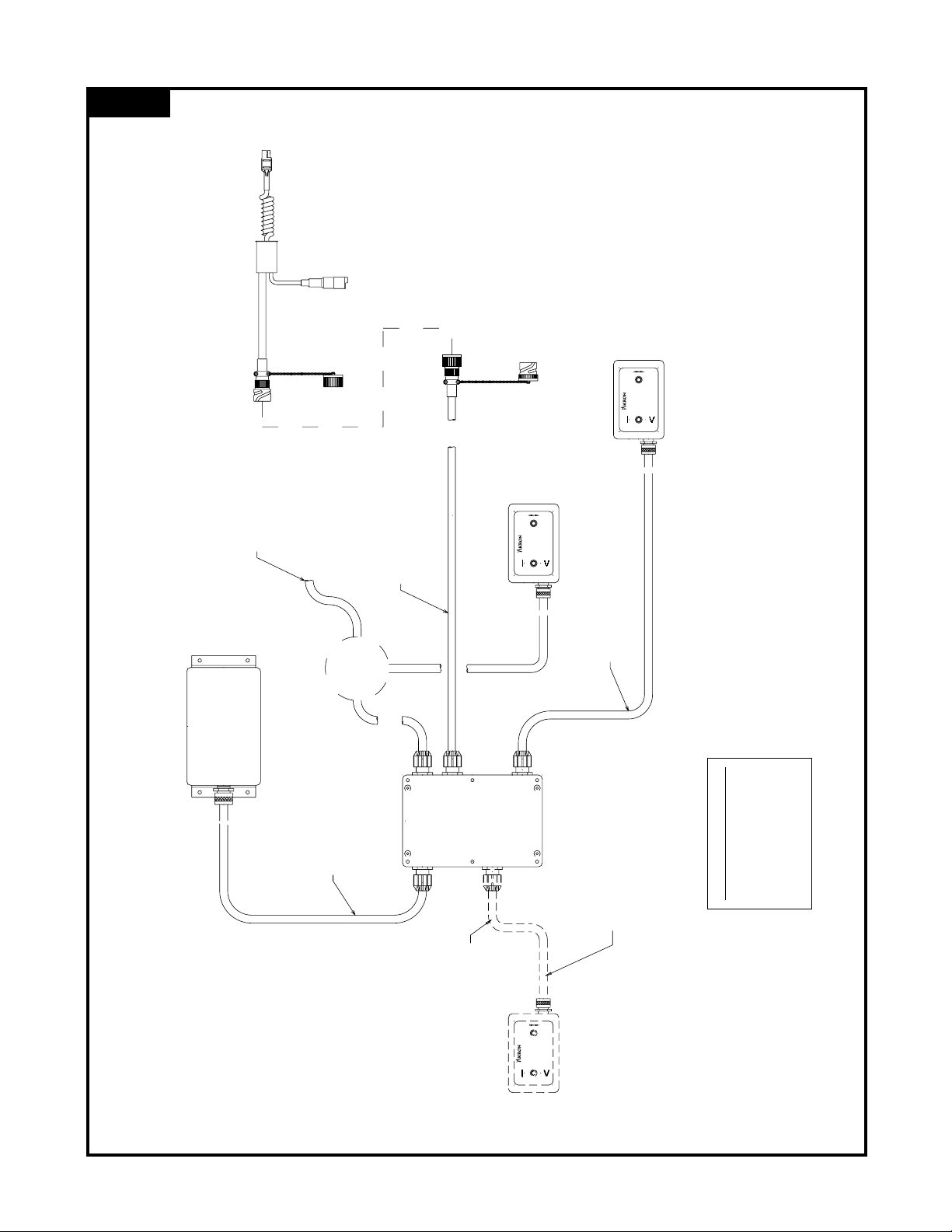

•Mount the logic box, control boxes and auxiliary battery out of Danger Zone (Figure 3).

ELECTRICAL INSTALLATION INSTRUCTIONS FOR ELECTRIC LADDER PIPE

A. CONTROL BOX WIRING AND ATTACHMENT

The Electric Ladder Pipe optional upper and lower controls use the same control box. The following steps

will prepare either one or both control boxes for attachment to the logic box.

STEP 1 If the control box includes an attached cable skip to STEP 6.

STEP 2 Determine the length of #20-7 cable needed, add 10 inches, then cut. For example, if a five

foot length of cable is needed, add 10 inches and cut the cable 5 foot 10 inches long.

STEP 3 Remove the cable grip nut and washer from the control box and put it on the cable with the

threads facing the box. On the same end of the cable remove 4 inches of the outer casing of

the cable and strip back 3/8 inch from each of the 7 wires.

STEP 4 Take the 7 ring terminals from the plastic bag and crimp them on the 7 wires. Remove the four

control box cover screws and set the control box cover

aside. Thread the 7 wires through the cable grip attached to

the control box and attach them to the proper terminals.

Tighten the cable grip nut and washer on the cable to the

cable grip on the control box to secure the cable. Reattach

control box cover and secure with the four screws.

STEP 5 Remove the cable grip nut from the plastic bag and put it on

the other end of the cable with the threads facing out.

Remove 6 inches of the outer cover and strip back 3/8 inch

from each of the 7 wires.

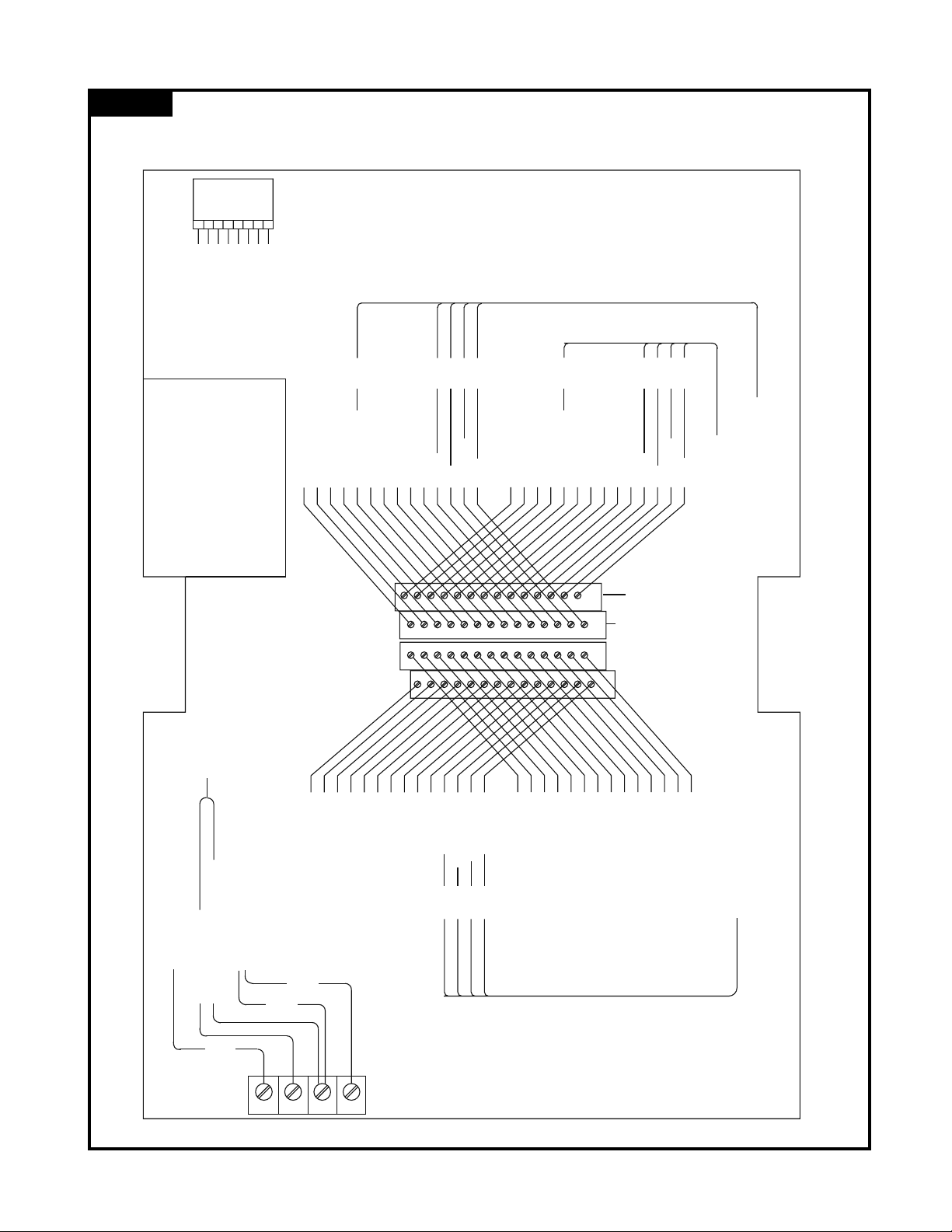

STEP 6 Remove the 6 logic box cover screws and set the logic box cover aside. Thread the 7 wires

through the upper or lower control hole in the logic box (see component layout, Figure 5).

Thread the cable grip washer and cable grip nut with the threads facing the box on the cable.

Pull enough cable through the cable grip to ensure a good fit. Tighten the cable grip nut and

attach the individual wires to the proper terminals (see wiring diagram Figure 6). Reattach the

logic box cover and secure with the 6 screws.

NOTE: The lower control and upper control wires must be attached to the correct terminals for

the lower control to override the upper control. The one attached to the Master terminal will

have the overriding capabilities.

B. LOGIC BOX / MONITOR WIRING HARNESS ATTACHMENT

These instructions are to attach the logic box / monitor wiring harness to the logic box.

STEP 7 Disconnect the logic box wiring harness from the monitor wiring harness (Figure 3). Remove the

cable grip nut from the logic box and put it on the wiring harness (#16-4) cable with the threads

facing out. Thread the wires through the appropriate cable grip hole on the logic box (Figure 3).

Pull enough cable through the cable grip to ensure a good fit. Tighten the cable grip nut and

attach the individual wires to the proper terminals (Figure 2).

NOTE: Do not extend the wiring harness. To ensure proper voltage, attach the supplied wiring

harness directly to logic box.

C. AUXILIARY BATTERY ATTACHMENT

The battery connections should be the last connection made.

Page 4