Subject to changes in line with technical progress. 3

3059570

Table of contents

1 About this manual..........................................................................................5

1.1 Explanation of symbols ..............................................................................................................................5

1.1.1 Safety instructions......................................................................................................................................5

1.2 Safety symbols...........................................................................................................................................6

1.2.1 Abbreviations..............................................................................................................................................7

1.3 Legal notices .............................................................................................................................................. 7

2 Safety instructions .........................................................................................8

2.1 Intended use...............................................................................................................................................8

2.2 Foreseeable misuse .................................................................................................................................... 8

2.3 General safety instructions .........................................................................................................................8

2.3.1 Safety instructions for operation ..............................................................................................................10

2.3.2 Safety instructions for maintenance .........................................................................................................10

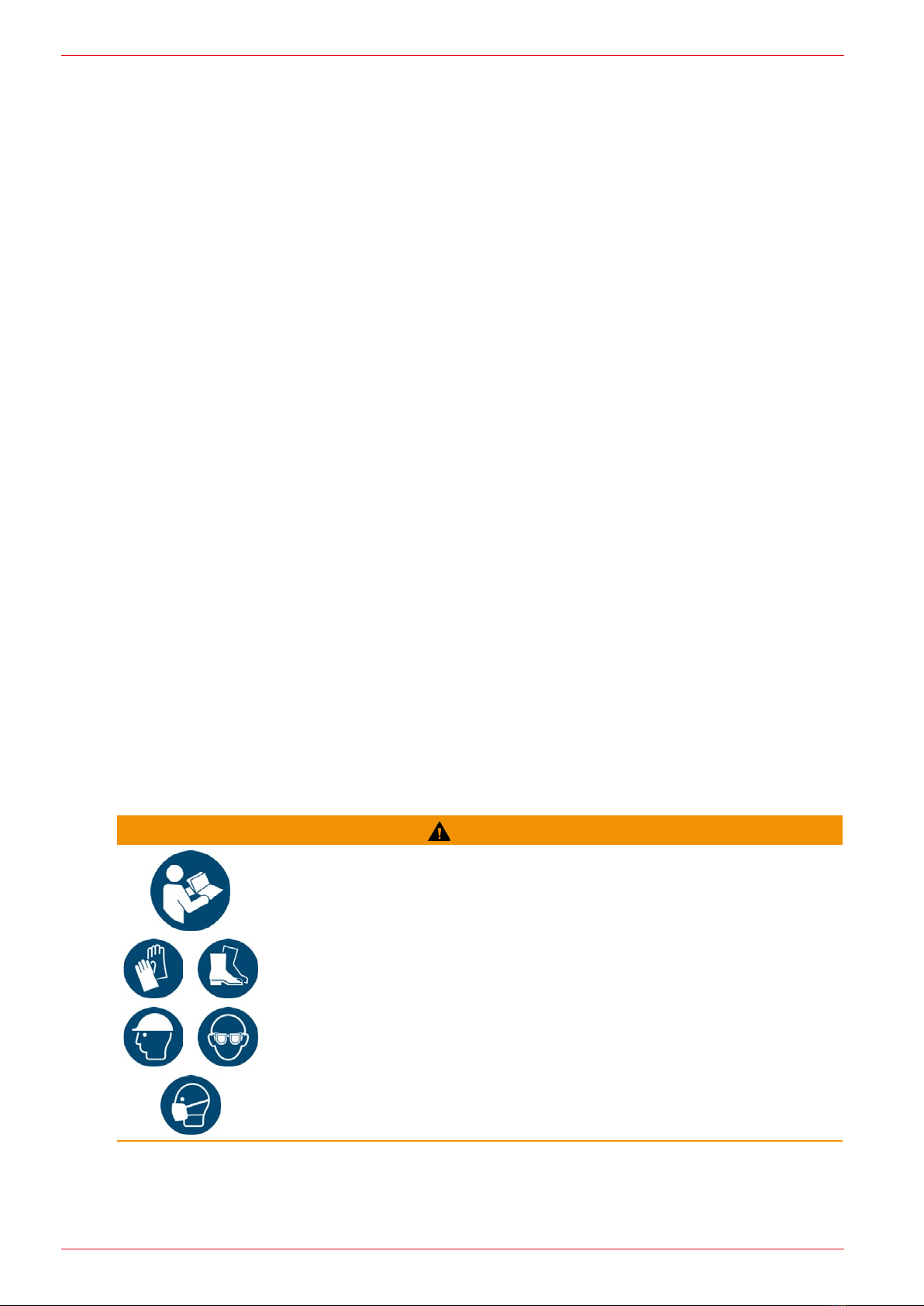

2.3.3 Personal safety instructions .....................................................................................................................10

2.4 Residual dangers...................................................................................................................................... 10

2.5 Training ....................................................................................................................................................11

3 Product description ...................................................................................... 12

3.1 Functional description .............................................................................................................................. 12

3.2 Technical and electrical data .....................................................................................................................14

3.2.1 EF supply and exhaust unit....................................................................................................................... 15

3.2.2 GF supply and exhaust unit with countercurrent plate heat exchanger..................................................... 15

3.2.3 Vibration values of the fan impeller ..........................................................................................................16

3.3 Example type plate for EASYAIR®at ........................................................................................................16

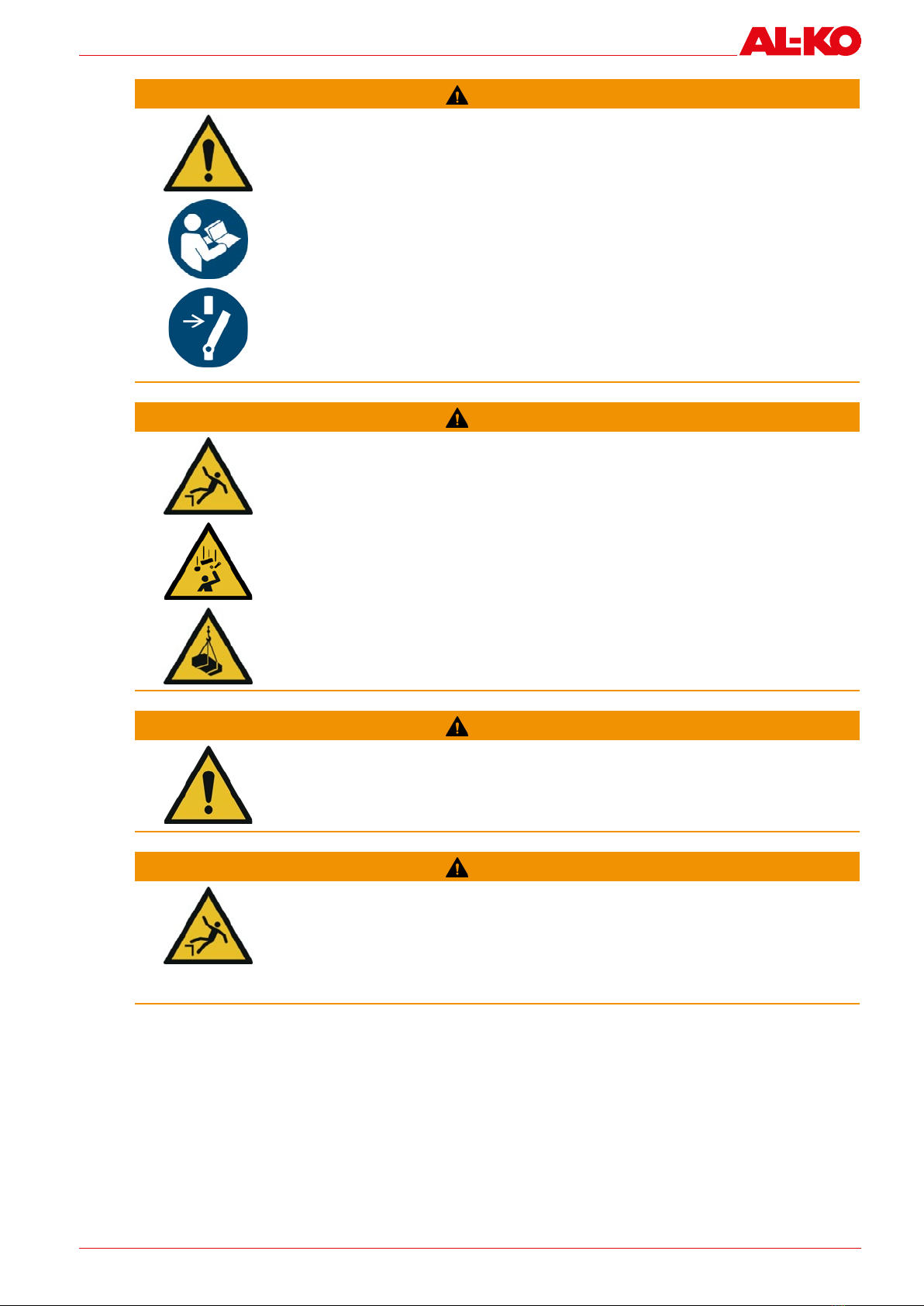

4 Transport .................................................................................................. 17

4.1 Delivery ....................................................................................................................................................17

4.2 Storage prior to assembly ........................................................................................................................17

4.3 Transport ..................................................................................................................................................17

4.4 Transportunderdifcultconditions.......................................................................................................... 18

4.5 Disposal of packaging ..............................................................................................................................19

5 Assembly .................................................................................................. 20

5.1 General information.................................................................................................................................. 20

5.2 Preparations .............................................................................................................................................21

5.3 Ceiling construction..................................................................................................................................22

5.4 Opening/removing the maintenance panel................................................................................................23

5.4.1 Disassembly of the maintenance panel for individual modules.................................................................23

5.4.2 Disassembly of the maintenance panel for countercurrent exchanger module.........................................24

5.4.3 Assembly of the maintenance panel for the countercurrent exchanger module........................................25

5.5 Assembly of the modules .........................................................................................................................27

5.5.1 Work steps ...............................................................................................................................................27

5.5.2 Removability of the components ..............................................................................................................30

5.5.3 Duct connection ....................................................................................................................................... 32

5.5.4 Siphon connection....................................................................................................................................34

5.6 Electrical connection.................................................................................................................................34

5.6.1 Cable lists.................................................................................................................................................35

5.6.2 Cablefromtheswitchcabinettotheelddevices....................................................................................35

5.6.3 Cable from unit switch cabinet to the electric fan heater ..........................................................................36

5.6.4 Connectionoftheelddevicestothecontrol...........................................................................................36

5.6.5 Assembly/connection of supply air, outdoor air, extract air temperature sensor ......................................36

5.6.6 Connection of electric air heater (ELE option) ..........................................................................................37

Table of contents