10

AL-KO BRAKING SYSTEM ADJUSTMENT

1. Ensure the towing shaft with coupling head is pulled

FULLY FORWARD. (Fig 11).

2. Release the handbrake to the FULLY OFF position. If the

handbrake will not go down the whole way because of

the fairing or any other obstruction; then the fairing must

be cut away and/or the obstruction removed to achieve

this desired position. It will not be possible to set up the

braking system properly when the handbrake is not in the

FULLY OFF position. (Fig 11).

3. Jack up one side of the caravan, using the AL-KO Side

Lift Jack System. (See Jack Operating Instructions).

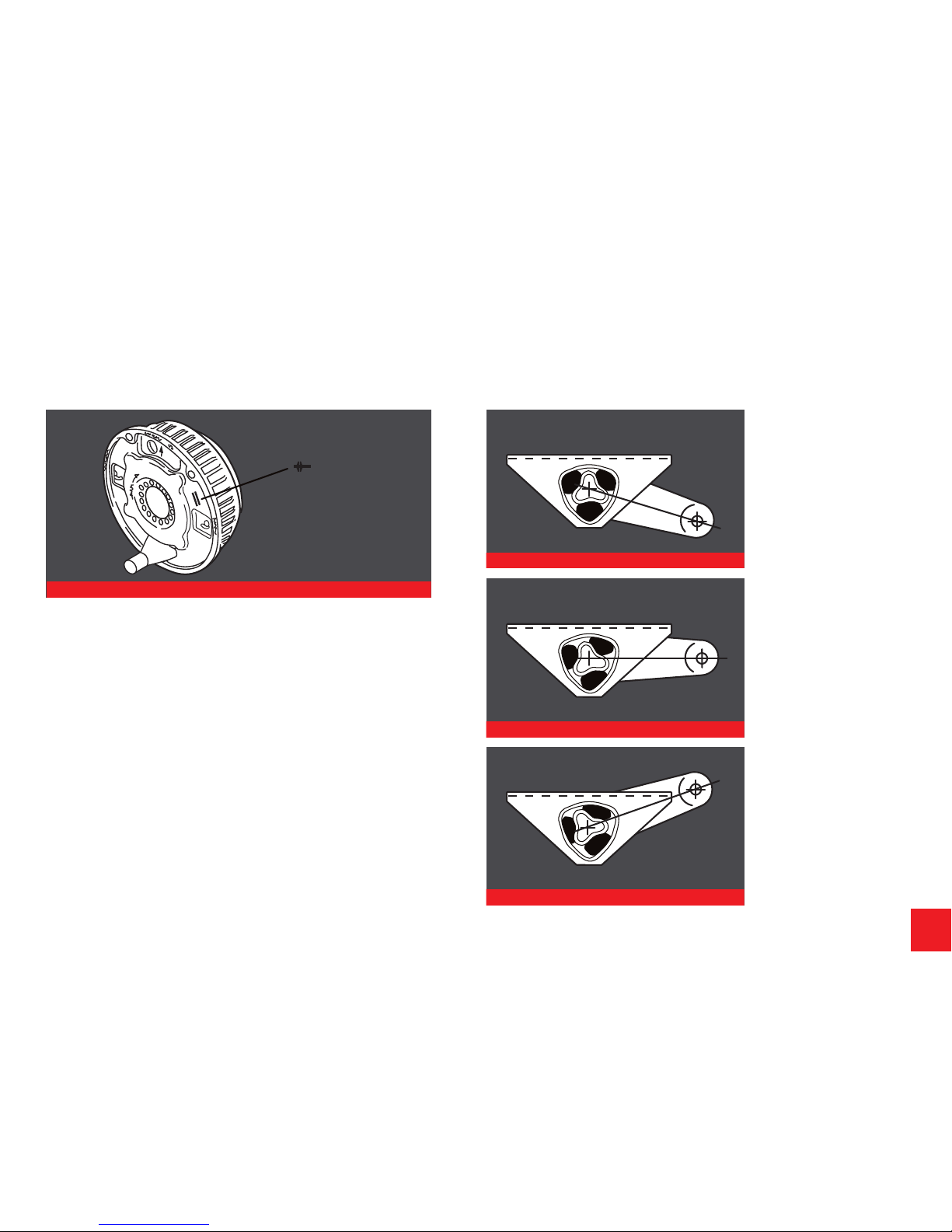

4. Remove the inner plastic bung from the backplate to

expose the ‘starwheel’ adjuster access. (Figs 11 & 12).

5. ALWAYS rotating the road wheel in the forward direction

- NEVER backwards; adjust the starwheel with a suitable

screwdriver, in the direction of the arrow embossed

on the backplate until there is resistance in the wheel

rotation. (Fig 12).

6. Slacken off the starwheel adjuster until the road wheel

turns freely in the FORWARD direction. (Fig 12).

7. Check the adjustment at the end of the brake cable where it

is secured to the abutment (bracket), welded to the centre of

the axle. When the inner cable is pulled out it should extend

between 5 and 8 mm. (Fig 13a\b). (On tandem axles a double

abutment (bracket) is tted to the front axle ONLY).

8. Repeat for other wheel or wheels.

9. On tandem axles the brake cables from the rear axle should

pass over this axle and cross over each other before being

connected to the abutment (bracket) on the front axle. Where

ATC is tted to a tandem axle caravan, the brake cables

SHOULD NOT be crossed over.

10. Ensure the balance bar (compensator) is being pulled evenly

(Figs 11 & 13a\b). Excessive movement to this bar (double on

tandem axles) would indicate possible incorrect adjustment

(if appropriate, repeat step No. 7 - Fig 13a\b).

11. Check the brake rod support bracket, (xed to the oor) IS

supporting the brake rod evenly. The brake rod MUST ALWAYS

run straight, NEVER bent or curved under any ttings. On

tandem axles, using the double balance bar, a brake rod

support tube (Part No. 228827) MUST ALWAYS be tted on the

end of the brake rod, passing through the centre aperture on

the abutment.