Caution The enclosure must have a door or cover accessible only by the use of a

tool.

Electromagnetic Compatibility Guidelines

This product was tested and complies with the regulatory requirements and limits for

electromagnetic compatibility (EMC) stated in the product specifications. These requirements

and limits provide reasonable protection against harmful interference when the product is

operated in the intended operational electromagnetic environment.

This product is intended for use in industrial locations. However, harmful interference may

occur in some installations, when the product is connected to a peripheral device or test object,

or if the product is used in residential or commercial areas. To minimize interference with

radio and television reception and prevent unacceptable performance degradation, install and

use this product in strict accordance with the instructions in the product documentation.

Furthermore, any changes or modifications to the product not expressly approved by National

Instruments could void your authority to operate it under your local regulatory rules.

Special Conditions for Marine Applications

Some products are Lloyd’s Register (LR) Type Approved for marine (shipboard) applications.

To verify Lloyd’s Register certification for a product, visit ni.com/certification and search for

the LR certificate, or look for the Lloyd’s Register mark on the product.

Caution In order to meet the EMC requirements for marine applications, install the

product in a shielded enclosure with shielded and/or filtered power and input/output

ports. In addition, take precautions when designing, selecting, and installing

measurement probes and cables to ensure that the desired EMC performance is

attained.

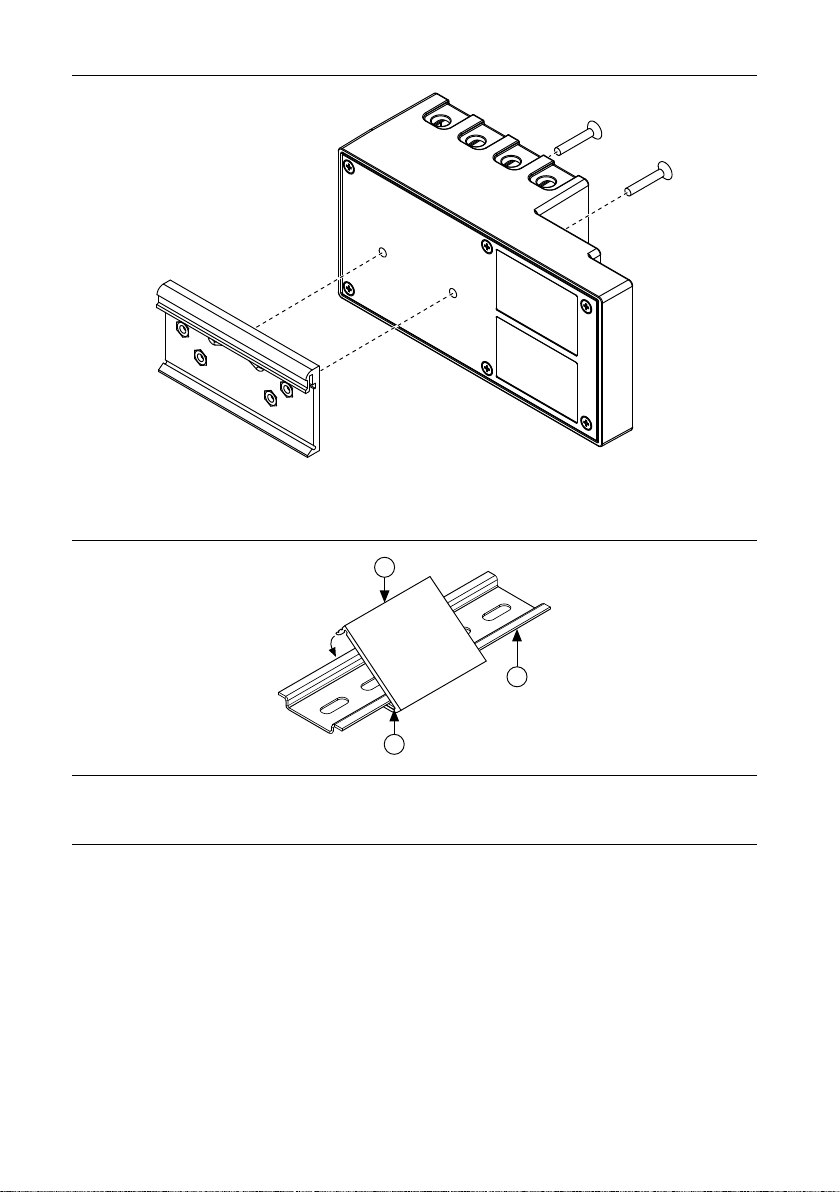

What You Need to Install CompactRIO

Reconfigurable Embedded Hardware

• FIRST Robotics Competition kit, including cRIO-FRC II and FRC software

• C Series I/O modules

• DIN rail mount kit (for DIN rail mounting only)

• Panel mount kit (for panel mounting only)

• Two M4 or number 8 flathead screws (for mounting the chassis without one of the listed

mounting kits)

• A number 2 Phillips screwdriver

• Power supply

• Ethernet cable

NI cRIO-FRC II User Manual and Specifications | © National Instruments | 3

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com