Alaris Medical Systems imed Gemini PC-1 User manual

MEDICAL SYSTEMS

dx

ALARIS'

m

Ur

:

imeci

Gemn

Pc-1*

VOLUMETRIC

INFUSION

PUMP/CONTROLLER

MAINTENANCE

MANUAL

PC-1

WARNINGS,

CAUTIONS

AND

NOTICES

CAUTION:

FEDERAL

(USA)

LAW

RESTRICTS

THIS

DEVICE

TO

SALE

BY

OR ON

THE

ORDER

OF

A

PHYSICIAN.

USE

ONLY

HOSPITAL

GRADE

POWER

SUPPLY

CORD

TO

INSURE

PROPER

GROUNDING.

GROUNDING

RELIABILITY

CAN

ONLY

BE

ACHIEVED

BY

CONNECTION

TO

A

RECEPTACLE

MARKED

"HOSPITAL

GRADE".

DANGER:

EXPLOSION

HAZARD,

DO

NOT

USE

IN

THE

PRESENCE

OF

FLAMMABLE

ANESTHETICS.

©

7

WARNING:

TO

PREVENT

UNRESTRICTED

FLOW,

CLOSE

CLAMP

WHEN

FLO-STOP

IS

OPEN.

REMOVE

COVER

OR

BACK.

REFER

SERVICING

TO

'

CAUTION:

TO

REDUCE

RISK

OF

ELECTRICAL

SHOCK,

DO

NOT

QUALIFIED

SERVICE

PERSONNEL.

WARNING:

REPLACE

FUSE

AS

MARKED.

CAUTION:

|

BEFORE

CONNECTING

"REFER

TO

MANUAL"

|

NOTE

TO

MAXIMIZE

THE

SERVICE

LIFE

OF

THE

INSTALLED

BATTERY,

IT

IS

RECOMMENDED

THAT

THIS

INSTRUMENT

BE

STORED

AND

OPERATED

IN

AN

ENVIRONMENT

THAT

IS

TEMPERATURE

CONTROLLED

BETWEEN

68°F

(20°C)

AND

77°F

(25°C).

WARNING

IN

THE

EVENT

THE

INSTRUMENT

IS

DROPPED

AT

ANY

TIME,

IT

MUST

BE

CHECKED

BY

A

BIOMEDICAL

TECHNICIAN

PRIOR

TO

USE FOR

PATIENT

CARE.

PC-1

WARNING

AND

CAUTION

NOTICES

em

WARNING:

TO

PREVENT

UNRESTRICTED

FLOW,

CLOSE

ROLLER

CLAMP

WHEN

FLO-STOP®

MECHANISM

IS

OPEN.

/

|

CAUTION:

REFER

TO

MANUAL

TYPE

CF

(Equipment

useable

for

direct

cardiac

applications)

CLASS

1

ALTERNATING

CURRENT

-

REPLACE

FUSE

ONLY

WITH

SAME

TYPE

AND

RATING

|

EQUIPOTENTIAL

GROUND

POINT:

IF

THE

INTEGRITY

OF

THE

EQUIPOTENTIAL

(CY

EARTH

CONNECTION

OR

HOSPITAL

EARTH

SYSTEM

IS IN

QUESTION,

OPERATE

THE

INSTRUMENT

USING

INTERNAL

BATTERY

POWER.

IPX1

DRIP

PROOF

WARNING

tf

the

PC-1

pump/controtler

is

dropped

at

any

time,

have

the

instrument

checked

by

the

Biomedical

Department

prior

to

further

use.

一

iv

PC-1

NOTICE

Product

design

and/or

specifications

are

subject

to

None

of

the

information

contained

herein

may

be

change

without

notice.

The

information

contained

duplicated

nor

may

it

be

utilized

in

any

manner

in

this

manual

is

current

as

of

the

date

of

issue.

other

than

for

the

repair

and

maintenance

of

ALARIS

Medical

infusion

pump/controllers

and

the

This

publication

contains

ALARIS

Medical

component

parts

thereof.

Any

unauthorized

use

of

Systems,”

Inc.

("ALARIS

Medical")

proprietary

the

information

contained

herein

may

subject

the

data

provided

solely

for

the

use

of

technical

user

to

substantial

liability.

personnel

in

repairing

ALARIS

Medical

infusion

pump/controllers.

This

manual

may

not,

in

whole

or

in

part,

be

copied,

photocopied,

reproduced,

translated,

or

converted

to

any

electronic

or

machine-readable

form

without

prior

written

consent

of

ALARIS

Medical

Systems,

Inc.

ALARIS

Medical

Systems,

inc.

Copyright

2000

ALARIS

Medical

Systems,

Inc.

All

Rights

Reserved

10221

Wateridge

Circle

Printed

in

USA

(858)

458-7000

San

Diego,

CA

92121

USA

U.S.

Patents

4,617,014;

4,689,043;

4,690,673;

4,725,205;

4,728,265; 4,836,752;

4,909,710;

4,920,336;

4,954,046;

4,859,927;

5,219,330;

D305,

151;

D308,946;

D312,879,

AU

646,216;

580,184;

586,594;

590,179; 601,664; 607,112;

622,088;

604,477.

CA

1,235,033;

1,258,212;

1,300,977; 1,280,647;

1,296,791;

2,020,926;

1,238,832.

AT

0,225,158.

BE

0,225,158.

FR

0,225,158;

283,614;

315,312;

0,431,726;

0,238,277.

GB

0,225,158;

283,614;

315,312;

0,431,726; 0,238,277.

NL

0,225,158;

283,614.

IT

0,225,158;

283,614.

SE

0,225,158;

283,614.

CH

0,225,158.

DE

P3686558.3;

P3772,556.9;

3871721T2;

P6908208;

P3774598.

TW

UM52721.

JP

###1754470%.###1

8

16872##%##1902387%:

###19671685,8##17931195;##*173039585.

Other

US

and

Foreign

Patents Issued and

Pending.

IMED®,

Gemini

PC-1®,

Flo-Stop®,

VersaTaper®,

AutoTaper®,

are

registered

trademarks

of

ALARIS

Medical

Systems™.

PC-1

PREFACE

This

manual

contains

operation

and

maintenance

instructions

for

the

IMEDº

GEMINI

PC-1º

Volumetric

Infusion

Pump/Controller

(“PC-1").

The

information

provided

herein

is

intended

for

use

by

technical

personnel

responsible

for

servicing

this

product.

The

material

is

divided

into

six

sections

and

is

presented

as

follows:

Section

1

-

Descriptive

Information;

Section

2

-

Preparation

for

Use;

Section

3

-

Operating

Instructions;

Section

4

-

Functional

Description

and

Schematic.

Diagrams;

Section

5

-

Maintenance

Instructions;

Section.

6

-

Parts

Lists

and

Assembly

Drawings;

Section

7

-

Calibration

and

Preventive

Maintenance.

Additional

copies

of

this

manual

may

be

obtained

by

contacting

ALARIS

Medical's

Customer

Service

Department.

This

manual

supersedes

PC-1

Maintenance

Manuals

1310-9251-00

and

1310-9261-00

and

1310-9261-00

and

PC-1

International

Addendum

P/N

1310-9028-00.

The

features

of

the

220V

model

of

the

PC-1

pump/controller

have

been

incorporated

into

this

manual.

Text

or

graphics

that

are

related

exclusively

to

the

220V

model

are

identified

with

*

a

EM

symbol.

In

addition,

some

features

are

for

the

110V

model

of

the

PC-1

pump/controlier

only

and

are

identified

with

a

symbol.

vi

PC-1

TABLE

OF

CONTENTS

SECTION

1

-

DESCRIPTION

ーー

©

NO

UP

Wh

+

introduction

..........

ーー

1-1

Operating

Characteristics

-

Operating

Condifion

enveree

User

Interface

...............,.....,............,,.....,.........

Physical

Description

................................

0.

eee

Product

History

...................................

Operating

Specifications

` ・

Accessories

.ee

SECTION

2

-

PREPARATION

FOR

USE

2.1

Iniroduclon

eee

enn

--

2-1

2.2

Pre-Operational

Mechanical

Inspection

......:.................,.,.,.......

2-1

2.3

OperationalPerformanceCheck

........................................

23

2.3.1

Pre-operationalCheckBatteyCharge

...................................

2-3

232

Pre-operational

Electrical

Inspectiion

..

enene

2-3

2.3.2.1

Electrical

Leakage

Test

......................,.....

P

2-3

2.3.2.2

Electrical

Ground

Test

...........................,..........,.........

2-3

2.8.3

Abbreviated

Operational

Performance

Test

...............................

2-3

2.3.3.1

Тез!

Ведийетет$

...............

ω

ων

εννοώ

νοκ

εννεενε

ον

ενω

νοκ

ώ ο

ων

2-3

2.3.3.2

TestProcedures.............................

1

e

lisa

2-4

SECTION

3

-

OPERATION

8.1

Introduction

..............

Z

ο

κώνο

νο

ον

3-1

3.2

Controls

and

Indicators

..........,.........,,....,..........,.,...,...

3-1

3.3

Operating

Conditions

..............

rr

3-9

3.3.1

NormalandComputerOperation........................................

3-9

3.3.1.1

Ритр

апа

СогигоНег

Модез

...........

i

3-9

3.3.1.2

VersaTaper*/AutoTaper®

Mode

Operation

................................

3-17

3.3.1.3

Battery

Powered

Operation

.....................

i

3-23

3.3.2

Maintenance/Diagnostic

Mode

..............,...............,.........

3-24

3.4

Operator

Information

Display

and

Alarm

Response

Procedures

.....,.........

3-25

3.5

Audio

Alert

Sysiem

k

3-25

SECTION

4

-

PRINCIPLES

OF

OPERATION

4.1

42

4.2.1

4.2.1.1

421.2

42.2

4.2.2.1

4.2.2.2

4.3

4.3.1

4.3.2

jntroduciion

..

ee

n

4-1

Mechanical

Operation

................,.................,...,..4...2

41

Physical

Description

...............

a

41

Pumping

Mechanism

.......................,....,.......,...,...,...

4-1

Strain

Beam

(Pressure

Transducer)

...........,..........,.........,....

4-1

Functional

Operation

..........................

..

.

1...

laa

4-1

Pumping

Mechanism

..............................

0.

00

cence

eeae

41

Strain

Beam

(Pressure

Transducer)

....................................

4-5

Electrical/Electronic

Operation

.

................................:.,.....

4-5

Functional

Description

......................,,,.....,,....,..,.....

4-5

Functional

Operation

............................

2...

아이다

4-8

5.5.3.4a

Charger

Adapter

CCA

Removal

(Instruments

with

Dual

State

Charger

Modification

Kit

installed)

.

............................................

5-39

5.5.3.5

Power

Supply

Board

Removal

......,..................................

5-39

5.5.3.6

Pole

Clamp Assembly

Removal

and

Disassembly

(Figure

6-18)

..............

5-40

5.5.3.7

Removal

of

the

Power

Cord

Strap

(Figure

6-1c)

...........................

5-40

5.5.3.8

GroundingStudRemoval:.......................................

5-40

5.6

Reassembiy

........

erre

se

5-40

SECTION

6

-

ILLUSTRATED

PARTS

BREAKDOWN

6.1

Introduction

eee.

6-1

SECTION

7

-

CALIBRATION

AND

PREVENTIVE

MAINTENANCE

7.1

Introduction

に

に

に に に に に に

に

ーー

に

ーー

トト

に

に に

トト

トト

トー

トー トト トト トト

トト

て

レレ

トト

トレ

トト

トト

トー

トレ

レー

ッッ ここ

7-1

7.2

Preventive

Maintenance

.....................,...................,..,.

71

73

Calibration

Procedures

.....,........................,.........,...,..

7-1

7.3.1

Strain

Beam

Calibration..................................

0...

7-1

7.3.1.4

Calibration

Equipment

Requirements

..............,.....................

7-1

7.3.1.2

Calibration

Procedures

...............................................

7-2

7.3.2

AllDetectorCalibration....................................

...

0...

7-3

7.4

Comprehensive

Operational

Performance

Test

............................

7-4

7.4.1

Electrical

Inspection

.......

EE

と

と と と と

と

に

ez

7-4

7.4.1.1

Electrical

Leakage

Test

..

eee

eee

7-4

7.4.1.2

Electrical

Ground

Test

...........................,.............,......

7-4

7.4.4.3

Dielectric

Test

(Optional)

..................................

0...

00

7-4

7.4.1.4

Battery

Voltage

Check

.............................,.................

7-4

7.4.1.5

Battery

Care

and

Maintenance

..........................,,..,,.........

7-4

7.4.2

Qualitative

Operational

Performance

Test

................................

7-5

7421

Operational

PerformanceTest..............................

Lon

75

7.4.2.2

VTBI

Display

Validity

Check

....................,......................

7-5

7.4.3

Quantitative

Operational

Performance

Test

...............................

7-5

7.4.3.1

Equipment

Requirements

.............................

0.00

κ

νο

ος

ον

7-5

7.4.3.2

Initialization

Setup

....................

ーー

7-5

7.4.3.3

Pump

Mode

Tests

......................................,............

7-7

WARRANTY

NOTES

SALES

AND

SERVICE

OFFICES

TECHNICAL

SERVICE

MANUAL

SUPPLEMENTS

PC-1

Figure

1-2

2-1

2-2

2-3

2-4

3-1

3-1а

3-2

4-1

4-2

4-2а

4-3

4-4а

4-5

4-6

4-7

4-8

4-8а

4-9

4-10

4-11

4-12

4-12а

4-12b

4-12b

4-12c

4-126

4-13

4-14

4-15

4-16

417

4-18a

4-18b

4-18¢

4-18d

4-19

4-20

4-20a

4-20b

4-20c

4-20c

4-21

4-22

4-22a

LIST

OF

FIGURES

Title

Page

IMED®

Gemini

PC-1°

Volumetric

Infusion

Pump/Controller.

...................

xiii

Audio

Characteristics.

.............................

0.1.0111

1-8

PC-1

Front

and

Rear

Operating

Features.

..................

eee

eee

2-2

Communications

Emulator

Plug.

.........,....,.............

ーー

2-4

Aïir-In-Line

Simulator.

.....................................,,....,.28.

2-8

PC-1

Test

Data

Sheet.

し

ーー

ュ

に

に

に

に

に

に

に に

レー

に

に に

に

ーー

に

ーー

トト トト トー

て

トト

て て

ーー

スーーー

ト

ーー

2-9

PC-1

Front

Panel

Controis

and

Indicators.

..............,......,.........

3-2

PG-1

Titration

Front

Panel

Controlsandindicators..........................

3-3

PC-1

Rear

Panel

Controls

and

Indicators.

...............................

3-4

PC-1

Pumping

Mechanism

................................,..,,....,

42

Functional

Block

Diagram

[v2.x/5.xx/6.xx]

.............

se

4-3

Functional

Block

Diagram

[V7.xx]

eee

en

4-4

CrossSectionofStranBeamAssembiy.................................

4-5

PC-1

Interconnect

Diagram

0

e.

4-6

PC-1

(220V)

interconnect

Diagram

κκ

κος

4-7

Microprocessor

TimingWaveforms

.....................................

4-8

Power

ON/OFF,

Auto

Power

On

and

Sensor

Signal

Functional

Schematic

№2.хх/5.хх/б.хх]

..-.-

ーー

4-10

5

Volt

Protected

Circuit

Functional

Schematic

[v2200520/8.xx]

...............

4-11

+12

Volt

Power

Supply

Functional

Schematic

[V2.xx/5.xx/6.xx]

.

..........,....

4-14

Charger

Adapter

Board

Schematic

(with

Mod.Kit

installed)

..................

4-14

System

Reset

Functional

Schematic

[v2.xx/5.xx/6.xx]

......................

4-16

Stator

Polarity

Change

as

a

Function

of

Phase

Excitation.

...................

4-37

Relationship

of

Stator

and

Rotor

Teeth

with

the

A

Phase

Energized.

..........

4-17

Battery

Charger

Functional

Schematic

(without

Dual

State

Charger).

..........

4-19

Battery

Charger

Functional

Schematic

Pwr

Sup

Brd

(Dual

State

Charger).

....

4-21

Power

Supply

CCA

[v7.xx]

(Sheet

1)

.....

本

4-23

Power

Supply

CCA

[V7.xx]

(Sheet

2)

...........,............,........,..

4-25

Power

Supply

CCA

with

Crowbar/Timer

(PC-1CE

V8.xx)

(Sheet

1).

...........

4-27

Power

Supply

CCA

with

Crowbar/Timer

(PC-1CE

V8.xx)

(Sheet

2).

...........

4-29

Pumping

Mechanism

Functional

Schematic

[V2.xx/5.x%/6.xx]

................

4-31

input

Signal

Pulses

and

Change

in

Phase

Excitation

of

Unipolar

Drive.

........

4-32

Strain

Beam

Functional

Schematic

[V2.x4\5.2046.xx]

.

..................,....

4-33

AlL

Detector

Cross

Section

..........,............,.......,...........

4-34

Slide

Clamp

Detector

Cross

Section

............................

ーー

4-35

Hybrid

AlU/SCDBoardSchematic......................................

4-35

ALSCD

PCB

Sechemag

kenene

4-36

AIL/SCD

Schematic

...............,,..............,....,..,....,2.

4-36

AIL/SCD

PCB

Schematic

................,......................,.....

4-37

PC-1

Audio

Subsystem

[V2.x45.x4u6.xx]

.

…...............................

4-39

Display

CCA

Schernatic

IM2.xyv5

ーー

4-41

Display

GCA

Schematic

[V6.xx]

.....................

k

4-43

Display

CCA

Schematic

[V7.XX]

enke

nnesnenes

4-45

Display

CCA

Schematic

[PC-1CE

v8.xx]

(Sheet

1)

................,,.....:

4-47

Display

CCA

Schematic

[PC-1CE

v8.xx]

(Sheet

2)

........................

4-49

Communicatons

Interface

Functional

Schematic

..........................

4-51

ECD

Schematiic

..

rr

rr

4-53

ECD

(Universal)

Schematic

...............................,,.........,

4-54

Microprocessor

Interface

Schematic

[V2.xx/5.xx/6.xx]

(Sheet

1)

..............

4-55

Microprocessor

Interface

Schematic

[v2.xx/5.xx/6.xx]

(Sheet

2)

..............

4-57

Microprocessor

Interface

Schematic

[V2.xx/5.xx/6.xx]

(Sheet

3)

..............

4-59

Logic

CCA

Schematic

[v7.xx]

(Sheet

1)

.................................

4-61

Logic

CCA

Schematic

[V7.xx]

(Sheet

2)

.................................

4-63

Logic

CCA

Schematic

[v7.xx]

(Sheet

3)

.................................

4-65

Logic/Analog

CCA

Schematic

[PC-1CE

v8.xx]

(Sheet

1)

....................

4-67

Logic/Analog

CCA

Schematic

[PC-1CE

v8.xx]

(Sheet

2)

...:................

4-69

Logic/Analog

CCA

Schematic

[PC-1CE

v8.xx]

(Sheet

3)

....................

4-71

Parts

Identification

PC-1

Final

Assembly

Parts

Identification

PC-1

Final

Assembly

Parts

Identification

PC-1

Final

Assembly

Parts

Identification

Front

Case

Assembly

Parts

Identification

Front

Case

Assembly

Parts

Identification

Front

Case

Assembly

Parts

Identification

Door

Assembly

......,..............................

Parts

Identification

Logic

CCA

[V7.xx]

...........,....:.....,............

Parts

Identification

Logic

CCA

[V8.13]

........................,...........

Parts

Identification

Display

Circuit

Card

Assembly

[V7.xx]

...................

6-23

Parts

identification

Display

Circuit

Assembly

[V8.13]

.......................

6-24

Parts

Identification

Rear

CaseAssembiy

................................

6-26

Parts

Identification

Power

Supply

CCA

[V7.xxX]

0.0002.

o

6-32

Parts

Identification

Power

Supply

CCA

[V8.13]

............................

6-33

Universal

Test

Station

Setup

.........................................,

7-10

Air-In-Line

Simulator

ーー

7-11

PC-1

Test

Data

Sheet

................,....,...................,.....

7-12

xi

PC-1

LIST

OF

TABLES

Table

Title

Page

1-1

Product

History

..............

ーー

1-5

1-2

Operating

Requirements

.......

本

1-6

1-3

Performance

Specifications

..............................,....

ーー

1-6

1-4.

Accessories

eee

n

1-9

3-1

PC-1

Controls

and

indicators

я

изн

зените

3-5

3-2

PC-1

Status/Alarm

Displays

.............

ーー

k

3-26

4-1

RS-232-C

Communications

Data

Port

Signal

Definitions

.

..........,............,

4-32

5-1

(o

TroubleshootinyaultisolationGuilde.........................

ーー

5-10

5-2

PC-1

Error

Log

Codes

(V2.xx,

V5.xx,

V6.xx,

and

V6.3X/4x)

.......................

5-14

5-2а

PC-ErmorlogCodes(V7X)........................

eee

5-21

5-2b

PC-tErorlogCodes(V8XxX).......................

1...

resen

5-29

5-2z

PC-1

Maintenance

Mode

Error

Codes

(v5.xx/v6.xx/V7.xx/v8.xx)

.................,.

5-35

5-3

TableoflorgueValues....................................

0.

een

5-41

6-1

Parts

List

-

PC-1

Final

Assembly

..

iii

6-2

6-1a

'

Parts

List

-

PC-1

Final

Assembly

....................,.,............,...,..,.

6-3

6-2

Parts

List

-

Front

Case

Assembly

....................,.....,......,,........

6-8

6-3

Partslist-DoorAssembiy

..............................

0.00.

ea

6-13

6-4

Parts

List

-

Logic

Circuit

Card

Assembly

[v7.xx

&

subsequent]

...........,........

6-15

6-5

Parts

List

-

Display

Circuit

Card

Assembly

[v7.xx

&

subsequent]

........:..........

6-21

6-6

Parts

List

-

Rear

Case

Assembly.

..............................,............

6-25

6-7

Parts

List

-

Power

Supply

Circuit

Card

Assembly

for

[V7.xx

&

subsequent]

.

..........

6-27

xii

PC-1

に

D

το

τν

=

Integer

Keypad

απ

|

|

Em

Fractional

Keypad

B

=

l

Titration

Keypad

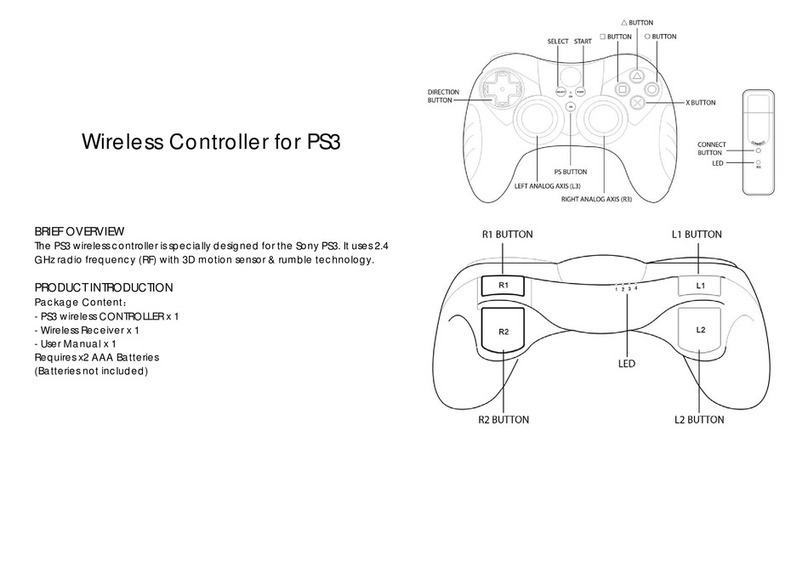

Figure

1-1

IMED®

GEMINI

PC-1®

Volumetric

Infusion

Pump/Controller

xiii

PC-1

SECTION

1

-

DESCRIPTION

1.1

INTRODUCTION

This

section

includes

general

operating

characteristics,

physical

description

and

operating

specifications

for

the

IMED®

GEMINI

PC-1®

Volumetric

Infusion

Pump/Controller

("PC-1").

1.2

OPERATING

CHARACTERISTICS

The

PC-1

instrument

is

a

single

channel

volumetric

infusion

pump/controller

used

for

the

administration

of

intravenous

drugs

and

fluids.

The

instrument

can

be

operated

as

either

a

Pump

or

Controller.

A

lockout

feature

is

incorporated

which

allows

the

instrument

to

be

preset

as

either

a

Pump

or

Controller.

Secondary

(piggyback)

infusions

can

be

administered

using

infusion

parameters

independent

of

the

Primary

infusion.

An

Empty

Container

Detector

(ECD)

is

available,

as

an

option

(All

except

PC-1CE

v8.xx

220V),

to

permit

infusing

ihe

eniire

contents

of

an

IV

solution

container.

The

instrument

is

compatible

with

remote

computer

operation

when

the

communication

option

is

installed.

An

integral

maintenance

mode

is

‘

incorporated

to

monitor

instrument

performance,

identify

and

document

instrument

malfunctions

and

assist

technical

personnel

in

troubleshooting

and

repair.

Fractional

Keypad/Series

V5.xx

&

Subsequent

Software

`

A

VersaTaper®

Mode

is

incorporated

to

facilitate

administration

of

!V

fluids

that

require

non-linear

delivery

(rate

and/or

VTBI)

during

the

period

of

medication.

Twenty,

manually

input,

independent

steps

(rate

and

VTBI

combinations)

are

available

to

set

up

a

tapered

infusion

program.

Titration

Keypad/Series

V7.xx

&

Sub.

Software

An

AutoTaper“

Mode

is

incorporated

to

automate

infusion

setup

and

delivery

of

ramp-up/taper-down

cyclic

parenteral

nutrition

applications.

The

PC-1

pumping

mechanism

employs

linear

peristaltic

action

to

deliver

a

continuous

flow

of

infusion

products

reliably,

accurately

and

safely.

In

the

controller

mode,

the

instrument

will

deliver

fluid

at

a

pressure

equal

to

the

pressure

created

by

the

head

height

of

the

IV

solution

container

+12

inches

(30

cm).

In

the

pump

mode,

the

instrument

delivers

fluid

at

a

pressure

up

to a

maximum

of

10

+2

psi

(69

+14

kPa;

517

+103

mmHg).

Above

these

pressures,

the

instrument

will

occlude.

Integer

Keypad/Series

V2.xx

Software

infusion

rate

is

selectable

between

1

and

999

mL/hr

in

1

mL/hr

increments.

Volume

to

be

infused

(VTBI)

is

selectable

between

1

and

9999

mL

in

1

mL

increments.

When

an

infusion

is

complete,

the

instrument

automatically

switches

to

the

KVO

rate

of

1

mL/hr.

Fractional

Keypad/Series

V5.xx

&

Sub.

Software

infusion

rate

and

VTB!

are

dependent

on

the

selected

instrument

operating

mode

-

Micro,

Macro

or

Universal.

Available

parameters

are

as

follows:

MICRO

(mic)

-

Rate

is

selectable

between

0.1

and

99.9

mU/hr

in

0.1

mL/hr

increments;

VTBl

is

selectable

between

0.1

and

999.9

mL

in

0.1

mL

increments.

MACRO

(mac)

-

Rate

is

selectable

between

1

and

999

mL/hr

in

1

mL/hr

increments;

VTBI

is

selectable

between

1

and

9999

mL

in

1

mL

increments.

UNIVERSAL

(mic/mac)

-

Rate

is

selectable

in

0.1

mL/hr

increments

between

0.1

and

99.9

and

in

1

mi/nr

increments

between

100

and

999

mL/hr;

VTBI

is

selectable

in

0.1

mL

increments

between

0.1

and

999.9,

when

the

Rate

is

fractional,

and

otherwise

in

1

mL

increments

between

1

and

9999

mL.

When

an

infusion

is

complete,

the

instrument

automatically

switches

to a

KVO

rate

of

1

mL/hr

for

delivery

rates

>1

mL/hr

or

a

rate

equal

to

the

set

delivery

rate

for

rates

<1.0

mL/hr.

PC-1

This

version

of

the

PC-1

pump/controller

incorporates

a

feature

that

allows

the

instrument

to

be

preset

in

either

the

Micro

(mic),

Macro

(mac)

or

Universal

(mic/mac)

mode.

Rate

Titration

Keypad/Series

v7.xx

E

The

Rate

Titration

feature

allows

the

rate

to

be’

increased

or

decreased

1

mL/hr

(MACRO

mode)

or

0.04

mL/hr

(MICRO

mode)

with

each

press

of

the

or

(©

control,

then

press

START

to

accept

the

new

rate.

Greater

rate

changes

can

be

achieved

by

pressing

and

holding

the

appropriate

BB

controls

until

the

desired

rate

is

obtained,

then

press

START

to

accept

the

new

rate.

The

PC-1

pump/controller

does

not

require

any

pre-

operational

warm

up.

An

internally

mounted

battery

provides

normal

operation

for

a

limited

period

to

enable

use

when

AC

power

is

not

available

or

the

external

power

source

is

interrupted.

The

PC-1

pump/controller's

user

interface

consists

of

a

front

panel

tactile

keypad

and

the

rear

panel

Audio

Control

potentiometer.

Tamper

resistant

operation

is

provided

through

the

requirement

to

utilize

a

prescribed

key

press

sequence

to

enter

or

change

infusion

parameters.

Basic

operating

instructions

are

printed

on

the

right

side

of

the

instrument

case.

Functional

control

is

provided

by

a

16

bit

microprocessor

using

a

stored

program

that

includes

a

diagnostic

routine

that

monitors

pump

performance,

provides

audio

and

visual

signals

to

ensure

proper

sequencing

of

normal

operations

and

initiates

an

alarm

in

the

event

a

software

or

hardware

malfunction

is

detected.

_

Sufficient

disposable

configurations

are

available

to

provide

the

user

with

a

full

range

of

set-up

combinations

(see

Section

1.7).

The

Flo-Stop®

on

the

GEMINI

administration

set's

pumping

segment

prevents

free

flow

in

the

event

the

tubing

set

is

removed

from

the

instrument

following

initial

installation.

Free

flow,

as

a

result

of

deliberate

operator

action,

is

possible

when

using

the

set

to

perform

a

gravity

infusion

in

accordance

with

the

instructions

provided

in

the

set

package.

1.3

OPERATING

CONDITION

The

PC-1

pump/controller

can

be

operated

independently

(Normal

Operation)

or,

when

configured

with

a

communication

data

port,

as

a

computer

controlled

device

(Computer

Operation).

Normal

operation

includes

the

Controller

and

Pump

modes

plus

the

Maintenance

mode.

Computer

operation

includes

the

Monitor

and

Computer

Control

modes.

NORMAL

OPERATION

—.

SETUP

MODE

V7.xx

and

subsequent

software

The

Titration

keypad

instruments

utilize

the

Setup

Mode

(refer

to

Section

2.3.3.2)

to

configure

the

instrument

for

specific infusion

regimes,

language

selection

and

communication

(serial

port)

parameters.

CONTROLLER

MODE

In

the

CONTROLLER

mode,

the

PC-1

pump/controller

is

programmed

to

control

the

infusion

of

a

specific

volume

of

IV

solution.

The

instrument

senses

and

responds

to

container

height

and

patient-side

pressure

in

a

manner

similar

to

a

gravity

infusion.

The

instrument's

pressure

sensor

measures

the

hydrostatic

pressure

from

the

fluid

container

and

compares

that

pressure

against

distal

tubing

in-line

pressure.

When

in-line

pressure

exceeds

pump

input

pressure,

an

occlusion

condition

exists

and

an

alarm

is

initiated.

Actual

delivery

pressure

is

directly

proportional

to

container

height;

increasing

container

height

raises

and

decreasing

the

height

reduces

occlusion

pressure.

Controller

mode

occlusion

pressure

tolerance

is

+12

inches

(30.54

cm)

from

the

fluid

container

height.

Transient

surges

in

patient-side

pressure

above

the

occlusion

threshold

of

<60

seconds

duration

will

produce

a

LOW

FLOW

condition

which

stops

the

infusion

while

the

pressure

is

above

the

occlusion

threshold.

Pressure

transients

above

the

occlusion

threshold

for

periods

longer

than

60

seconds

duration

or

cumulative

time

required

to

compensate

for

volumeiric

deficiency

in

excess

of

30

minutes

will

initiate

an

occlusion

alarm.

À

ペー

ジ

PC-1

Roe

PUMP

MODE

In

the

PUMP

made

of

operation,

the

instrument

employs

a

preset

occlusion

pressure

limit

of

10

+2

psi

(69

+14

kPa;

517

+103

mmHg)

predicated

on

a

nominal

container

height

of

24

inches

(61

cm)

and

a

delivery

rate

>30

mL/nr.

For

delivery

rates

<30

mL/hr,

the

occlusion

pressure

is

rate-dependent

to

ensure

timely

detection

of

occlusion

conditions.

Any

transient

distal

in-line

pressure

above

this

limit

will

generate

a

patient-side

occlusion

alarm.

Software

Release

V6.xx

and

Subsequent

These

instruments

can

be

locked

into

a

rate-

independent

(10

psi)

occlusion

pressure

mode.

This

mode

will

result

in

significantly

increased

time-to-

occlusion

for

rates

<30

mL/hr.

Software

Release

v8.13

only

These

instruments

can

be

locked

into

a

rate-

independent

(517

mmHg)

occlusion

pressure

mode.

This

mode

will

result

in

significantly

increased

time-to-occlusion

for

rates

<30

mL/hr.

MAINTENANCE/DIAGNOSTIC

MODE

Integer/Fractional

Keypad

Instruments

The

Maintenance

mode

is

intended

solely

for

use

by

biomedical

technicians

to

perform

servicing

and

maintenance

actions

and

must

NEVER

be

used

when

the

PC-1

pump/controller

is

connected

to

a

patient.

The

maintenance

mode

provides

biomedical

service

personnel

access

to

the

closed

loop

diagnostic

test

routines

and

allows

the

pumping

mechanism

to

be

operated

unencumbered

by

stoppages

resulting

from

alarm

and

maifunction

conditions.

Specific

sub-routines

are

incorporated

in

the

maintenance

test

sequence

to

permit

configuring

the

instrument

for

non-English

language

and

computer

operation

(see

Section

5.3

for

detailed

operation).

Titration

Keypad

Instruments

The

Diagnostic

mode

provides

biomedical

service

personnel

access

to

the

closed

loop

diagnostic

routines,

allows

the

pumping

mechanism

to

be

operated

uninterrupted

by

stoppages

resulting

from

alarm

conditions

and

maintains

a

log

of

the

24

most

recent

error

codes

(see

Section

5.3

for

detailed

operation).

COMPUTER

OPERATION

Fractional/Titration

Keypads

with

Software

Release

V6.xx

and

Subsequent

ONLY

MONITOR

MODE

The

Monitor

mode

allows

a

host

computer

to

monitor

infusion

status

and

instrument

performance.

Monitor

mode

is

enabled

when

a

host

computer

is

connected

to

the

PC-1

pump/controller

through

the

Communications

Data

Port

(RS-232-C)

and

the

Monitor

indicator

is

illuminated.

COMPUTER

CONTROL

The

Computer

Control

mode

allows

an

infusion,

once

set

up,

to

be

controlled

and

monitored

by

a

host

computer

installation.

Computer

controlled

operation

is

selected

by

actuating

the

COMPUTER

CONTROL/MONITOR

switch

after

Monitor

mode

has

been

established.

Computer

controlled

operation

is

confirmed

by

the

computer

control

indicator

presentation

changing

from

flashing

to

a

steady

illumination.

1.4

USER

INTERFACE

The

front

Control!

and

Display

panel

incorporates

a

tactile

keypad

for

operator

use

in

programming

an

infusion.

Delivery

mode

(if

not

locked),

Rate

and

Volume

to

be

Infused

are

each

selected

for

Primary

infusions.

A

SEC/PIGGYBACK

(Secondary)

key

permits

independent

selection

of

Rate and

VTBI

for

a

sequential

secondary

infusion.

Separate

registers

are

provided

to

accumulate

Total

and

Secondary

volume

infused

quantities.

Fhe

PAUSE/STOP

control

allows

an

infusion

to

be

"paused"

and

then

resumed

or

stopped.

Rate and

VTBI

infusion

parameters

for

the

Primary

or

Secondary

are

displayed

digitally

in

the

respective

displays.

The

operator

information

display

presents

visual

prompts,

advisories,

alarms

and/or

malfunctions

messages

as

appropriate

to

assist

the

operation

in

programming

and

operating

the

instrument.

Fractional

Keypad/Series

V5.xx

&

Sub.

Software

The

0.1,

10,

100,

VTBI,

Vi,

PC

and

CLEAR/SILENCE

keys

have

a

secondary

function

during

instrument

power

up

to

enable

or

clear

PC-1

discrete

delivery

mode

selections

available

on

these

versions

of

the

PC-1

pump/controller.

Titration

Keypad/Series

V7.xx

&

Sub.

Software

The

keypad

adds

the

rate

titration

controls

&

and

E

which

enable

the

user

to

quickly

increase

or

decrease

the

rate

parameter.

A

tamper

resistance

feature

is

enabled

in

the

SETUP

mode

and

implemented

using

the

push

actuation

of

the

Audio/

Tamper

Resistance

Control

on

the

rear

panel.

The

requirement

to

properly

install

the

administration

set's

integral

Flo-Stop

before

the

door

will

close

and

latch

prevents

inadvertent

"free

flow,"

inhibits

premature

operation

of

the

pump

and

prohibits

use

of

an

unauthorized

set.

The

Door

Open

and

Air-in-Line

sensors

are

provided

to

stop

pump

operation

if

either

of

these

conditions

occur

during

an

infusion.

A

strain

relief

fitting

is

provided

in

the

instrument's

handle

support

to

prevent

kinking

of

the

proximal

tubing.

The

rear

panel

of

the

PC-1

pump/controller

is

configured

with

an

audio

volume

contro!

and

an

ECD

connection

(ECD

connection

-

All

except

PC-1CE

v8.xx

220V).

A

RS-232-C

data

port

connector

is

incorporated

on

the

power

supply

board

for

the

Fractional

Keypad

instruments.

Software

releases

V6.xx

and

subsequent

enable

the

PC-1

pump/controller

for

computer

controlled

operation.

IMED®

GEMINI

Series

disposable

administration

sets

are

required

for

use

with

the

GEMINI

family

of

Infusion

Pump/Controllers.

Sufficient

set

types

are

available

to

support

a

broad

range

of

infusion

types

and

configurations.

1.5

PHYSICAL

DESCRIPTION

The

PC-1

instrument

has

the

following

physical

characteristics:

Height:

10.8

inches

(27.5

cm)

Width:

8.4

inches

(21.3

cm)

w/pole

clamp

Depth:

6.5

inches

(16.5

cm)

w/pole

clamp

Weight:

11.1

pounds

(5.1

kg)

The PC-1

instrument

consists

of

two

major

assemblies:

the

front

and

rear

case.

FRONT

CASE

The

front

case

assembly

consists

of

a

high-impact,

injection

molded,

plastic

case/insert

assembly

with

an

Electro-Static

Discharge

(ESD)

coating,

which

houses

and

supports

the

pumping chamber

access

door,

the

peristaltic

pumping

mechanism,

pressure

transducer

(strain

beam),

Air-in-line

and

slide

clamp

detectors,

the

multi-card

assembly,

keypad

and

front

case

ESD

components.

REAR

CASE

The

rear

case

assembly

consists

of

a

die-cast

aluminum

shell

which

mounts

and

supports

intern-

ally

the

battery,

transformer,

power

supply

board

(with

sonalert),

ECD

connector

(except

PC-1CE

v8.xx

220V),

audio

control

potentiometer

and

RS-

232-C

connector)

and

power

entry

module.

The

exterior

of

the

rear

case

supports

the

pole

clamp,

ECD

storage

fitting,

power

cord

retention

strap

and

power

cord

retainer.

only.

The

exterior

of

the

rear

case

supports

the

220V

AC

power

entry

module

plus

the.

equipotentiality

grounding

point.

The

power

entry

module

includes

fuses

for.

both

input

leads

and

a

220V

AC

power

interrupt

switch

(where

applicable).

1.6

PRODUCT

HISTORY

The

initial

release

of

the

Gemini

PC-1°

Infusion

Pump/Controller

was

in

October

1988. Since

that

time

a

number

of

changes

have

occurred.

The

initial

release

PC-1

is

an

“Integer”

Infusion

Pump/

Controller,

it

delivers

fluids

in

whole

number

increments

only.

The

next

iteration

of

PC-1

delivered

fluid

in

whole

and

fractional

increments

and

incorporated

“VersaTaper®

an

intravenous

feeding

algorithm.

Then

the

PC-1

was

updated

to

interface

with

the

RS-232

bus.

The

last

major

change

incorporated

“Rate

Titration”

keys

which

allows

the

user

to

increase/decrease

the

rate

by

small

increments

with

a

minimum

number

of

key

presses.

This

model

also

incorporated

AutoTaper®

which

is

a

predefined

intravenous

feeding

algorithm.

These

instruments

can

be

identified

by

their

keypads,

The

Keypad

without

a

fractional

key

is

the

“Integer”

model.

The

Keypad

with

a

fractional

key

is

the

“Fractional”

model.

The

Keypad

with

1 /

keys

is

the

“Titration/Fractional”

model.

Refer

to

Table

1-1

for

product

history.

1-4

PC-1

1.7

OPERATING

SPECIFICATIONS

1.8

ACCESSORIES

The

PC-1

Operating

Specifications

are

The

accessories

approved

for

use

with

the

PC-1

subordinated

into

Operating

Requirements

and

pump/controller

are

listed

in

Table

1-4.

Performance

Specifications

which

are

delineated

in

Tables

1-2

and

1-3,

respectively.

Table

1-1.

Product

History

Model

History

Integer

PC-1

・

Initial

release

of

product

Software

version

2.xx.

Fractional

PC-1

・

Fractional

rate,

VersaTaper®

introduced

Software

version

5.xx.

Fractional

PC-1

・

RS-232

interface

enhanced

10psi

mode

introduced.

Software

version

6.xx.

Titration/Fractional

+

Rate

Titration,

Tamper

mode

and

AutoTaper®

introduced.

This

unit

has

a

Configuration

Setup

Mode

that

can

be

accessed

by

holding

the

“Volume

Infused”

key

at

Power

Up.

Software

version

7.xx.

International

PC-1

*

This

unit

was

developed

to

meet

international

requirements.

Software

version

8.xx.

n

Matrix:

Revision

#

PC-1

X

Revision

“A”

-

Initial

Revision

Revision

“B"-

Software

Upgrade

for

International

Units

to

enhance

operation.

Revision

“C"-

Software

Upgrade

to

change

“PSI”

to

“mm/hg”.

Revision

“D”

-

Mandatory

Upgrade

to

incorporate

“Crowbar”

circuit

for

2.xx

units.

This

circuit

will

cause

the

line

fuse

to

blow

if

the

battery

is

in

an

overcharge

condition.

Revision

“E"-

Not

used.

Revision

“F”-

Mandatory

Upgrade

to

incorporate

“Crowbar”

circuit

for

5.xx

and

6.xx

units.

This

circuit

will

cause

the

line

fuse

to

blow

if

the

battery

is

in

an

overcharge

condition.

Note’:

xx

= a

number

associated

with

a

particular

software

version,

i.e.,

2.xx

could

be

2.09

or

2.13

or

2.16

etc.

Notez:

All

PG-1's

have

a

Maintenance

or

Diagnostic

Mode.

To

access

this

mode:

hold

in

the

Computer

key

at

Power

Up;

press

the

“Computer”

button

to

step

through;

press

the

“Start”

button

to

access

each

function...

CAUTION:

The

“Fractional”

and

“integer”

Pumping

Mechanisms

are

not

interchangeable.

PC-1

Table

1-2.

Operating

Requirements

ui

Parameter

Specification

Power

Required:

Non-Dual

State

Charger

instruments

90-132

VAC,

current

draw

0.2

Amps

maximum

(25

watts),

0.1

Amps

nominal

(12

watts),

fused

at

0.4A,

50-60

Hz,

3

wire,

Single

4

Dual

State

Charger

Instruments

90-132

VAC,

current

draw

0.3

Amps

maximum

(35

watts),

0.1

Amps

nominal

(12

watts),

fused

at

0.5A,

50-60

Hz,

3

wire

single

d

ED

180-264V

AC

0.15

Amps

nominal,

Fused

at

0.315

A,

50-60

Hz,

3

wire,

Single

中

Battery:

Sealed

Lead-acid,

6

VDC,

7.2

Amp-Hr

Operating

Temperature

Range:

40°F

(5°C)

to

104°F

(40°C)

Operating

Humidity

Range:

0%

to

95%

Relative

Humidity,

non-condensing

Storage/Transport

Temperature:

.

-40°F

(-40°C)

to

158°F

(70°C)

Storage/Transport

Humidity:

0%

to

95%

Relative

Humidity,

non-condensing

Table

1-3.

Performance

Specifications

Parameter

Specification

Operating

Principle:

Linear

Peristaltic

Operating

Range:

}

Pump

and

Controller

modes:

. .

Integer

Keypad/Series

V2.xx

Software

Rate:

1-999

mL/hr

in

1

mL/hr

increments

(CONTROLLER

Mode

maximum

recommended

rate

is

500

mL/hr)

Volume-to-be-Infused:

.

1-9999

mL

or

ALL

(with

external

ECD)

Keep

Vein

Open

(KVO)

Rate:

1

mU/hr

Fractional/Titration

Keypad/Series

V5.xx

&

Subsequent

Software

Rate:

MICRO:

0.1-99.9

mL/hr

in

0.1

mL/hr

increments

MACRO:

1-999

ml/hr

in

1

mL/hr

increments

UNIVERSAL:

0.1-99.9

mL/hr

in.0.1

mL/hr

increments;

100-999

mL/hr

in

1

mi/hr

increments

(CONTROLLER

Mode

maximum

recommended

rate

is

500

mL/hr)

Volume-to-be-infused:

MICRO:

0.1-999.9

mL

in.0.1

mL

increments

MACRO:

41-9999

mL

in

1

mL

increments

UNIVERSAL:

0.1-999.9

mL

in

0.1

mL

increments;

1000-9999

mL

in

1

mL

increments

Ni

Le,

Table of contents

Popular Controllers manuals by other brands

Link4

Link4 iGrow 1800 Installation and user guide

KMC Controls

KMC Controls MCP-1160 Series installation guide

Bosch

Bosch Rexroth IndraDrive M Project planning manual

MOULDPRO

MOULDPRO Flosense 3.0 user guide

Motortech

Motortech DetCon series operating manual

Kärcher

Kärcher Water Controller Duo Smart manual