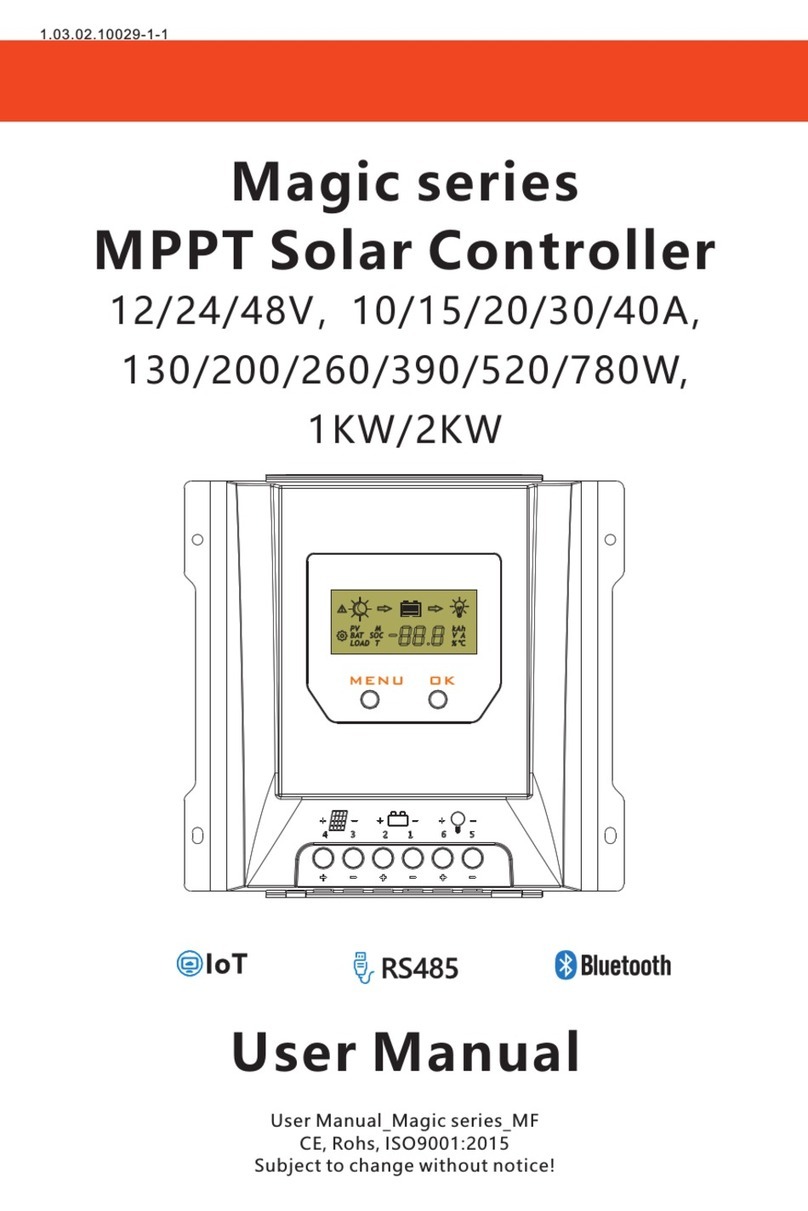

Innovative Max Power Point Tracking(MPPT) technology, tracking efficiency >99.9%

Full digital technology, high charge conversion efficiency up to 98%

LCD display design, read operating data and working condition easily

LCD can display lastest daily/monthly/yearly charging data, total 5 years

12/24/48V automatic recognition

Liquid, Gel, AGM and Lithium battery for selection

The separate ports for remote temperature sensor and voltage sensor, make battery temperature

compensation and voltage detection more accurate

Automatic power reduction when over-temperature

Relay control the switching signals of external loads and chargers for hybrid power supply system

like solar energy with utility electricity or gas generation

Dual automatic restriction function when exceeding rated charging power and charging current

5-year memory battery voltage and historical charging data

Android APP version for Bluetooth communication

IoT wireless or RS485 communication functions optional

Monthly charging data can be calculated and displayed by grouping and graphs

Modbus protocol based on RS485 standard for remote communication need

Multi-functional AUX port can meet customized requirements

Common positive design, suitable for telecom applications

Perfect EMC & thermal design

Full automatic electronic protect function

Magic series solar controller is based on an advanced maximum power point tracking (MPPT)

technology developed, dedicated to the solar system, the controller conversion efficiency up to

98%. The controller can rapidly track the maximum power point(MPP) of PV array to obtain the

maximum energy of the panel, especially in case of a clouded sky, when light intensity is changing

continuously, an ultra fast MPPT controller will improve energy harvest by up to 30% compared to

PWM charge controllers.

The limitation function of the charging power and current, and automatic power reduction

function fully ensure the stability when works with oversize PV modules and operate under high

temperature environment.

2.1 Outstanding features

2.2 MPPT

MPPT profile

The full name of the MPPT is maximum power point tracking. It is an advanced charging way

which could detect the real-time power of the solar Modulel and the maximum point of the I-V

curve that make the highest battery charging efficiency.

Current Boost

Under most conditions, MPPT technology will "boost" the solar charge current.

MPPT Charging:Power Into the controller (Pmax)=Power out of the controller (Pout)

Iin x Vmp= Iout x Vout

* Assuming 100% efficiency. Actually, the losses in wiring and conversion exist.

If the solar module's maximum power voltage (Vmp) is greater than the battery voltage, it follows

that the battery current must be proportionally greater than the solar input current so that input

and output power are balanced. The greater the difference between the Vmp and battery voltage,

the greater the current boost. Current boost can be substantial in systems where the solar array is

of a higher nominal voltage than the battery as described in the next section.

3

2, Product Overview