4

1:1 MAINTAINING THE HEATING SYSTEM

Check the heating system’s uid level regularly in the expan-

sion vessel. The level should be approximately 1cm above the

Min mark when the system is cold. The heating system should

be lled with a mixture of water and glycol. For preference, use

high quality pre-mixed glycol (with inhibitor) intended for use in

aluminium heating systems.

If using concentrated glycol, the mixture should consist of 60%

water and 40% glycol. If the heating system will be exposed

to temperatures below –25°C, the glycol content must be

increased, but not to more than 50%.

Any vessels used in handling the liquid must be spotlessly

clean, and the pipes in the heating system must be free of

contamination. This will prevent the growth of bacteria in the

system. The glycol mixture should be changed every second

year, since its ability to protect against corrosion, for example,

will deteriorate. The glycol content should be checked before

topping up with new liquid. This will ensure that the concentra-

tion of glycol in the mixture is not too high.

If the uid level in the expansion tank falls for reasons other

than evaporation, check all joints, drain cocks and bleeder

screws to ensure that they are not leaking. If the glycol-water

mixture leaks out, rinse with water and wipe up.

Never allow the heating system to stand empty of glycol uid.

Adding liquid:

Ensure that the vehicle is standing level, and check that the

bleeder screws and drain cocks are closed. Release the plastic

nut on the circulation pump, located on the expansion vessel,

and lift out the pump. Pour the glycol mixture slowly into the

expansion vessel, using a watering can. When the system is

being lled, air pockets may form, depending on how the pipe-

system has been installed. A good indication that there is air

in the system is when the heat only travels a few metres along

the pipe from the boiler, despite the fact that the circulation

pump is operating.

To make relling and bleeding easier, we recommend using

the Alde lling pump which quickly both lls and bleeds the

system automatically.

Bleeding a caravan heating system (manually):

The LPG boiler must be switched on and the circulation pump

switched off. Start by opening the bleeder screws (please refer

to the vehicle instruction book for their location). Leave them

open until liquid escapes through the spout at the air screw.

Switch on the circulation pump and let it run for a while. Check

whether the pipes and radiators all around the caravan are

warm.

If air still remains in the system, try the following:

The LPG must be switched on and the circulation pump

switched off. Lower the front of the caravan as far as possible

using the jockey wheel. Leave it in this position for several

minutes, to allow any air to rise to the highest point in the

system. Open the bleeder screw at the highest point and keep

it open until all the air has escaped.

Then raise the front of the caravan as high as possible using

the jockey wheel, and repeat the process.

Return the caravan to a horizontal position and start the

circulation pump.

Check that the heat is circulating all around the caravan. When

bleeding a trailer or a motor caravan, it is easier to park on a

steep slope, or raise the vehicle using a jack.

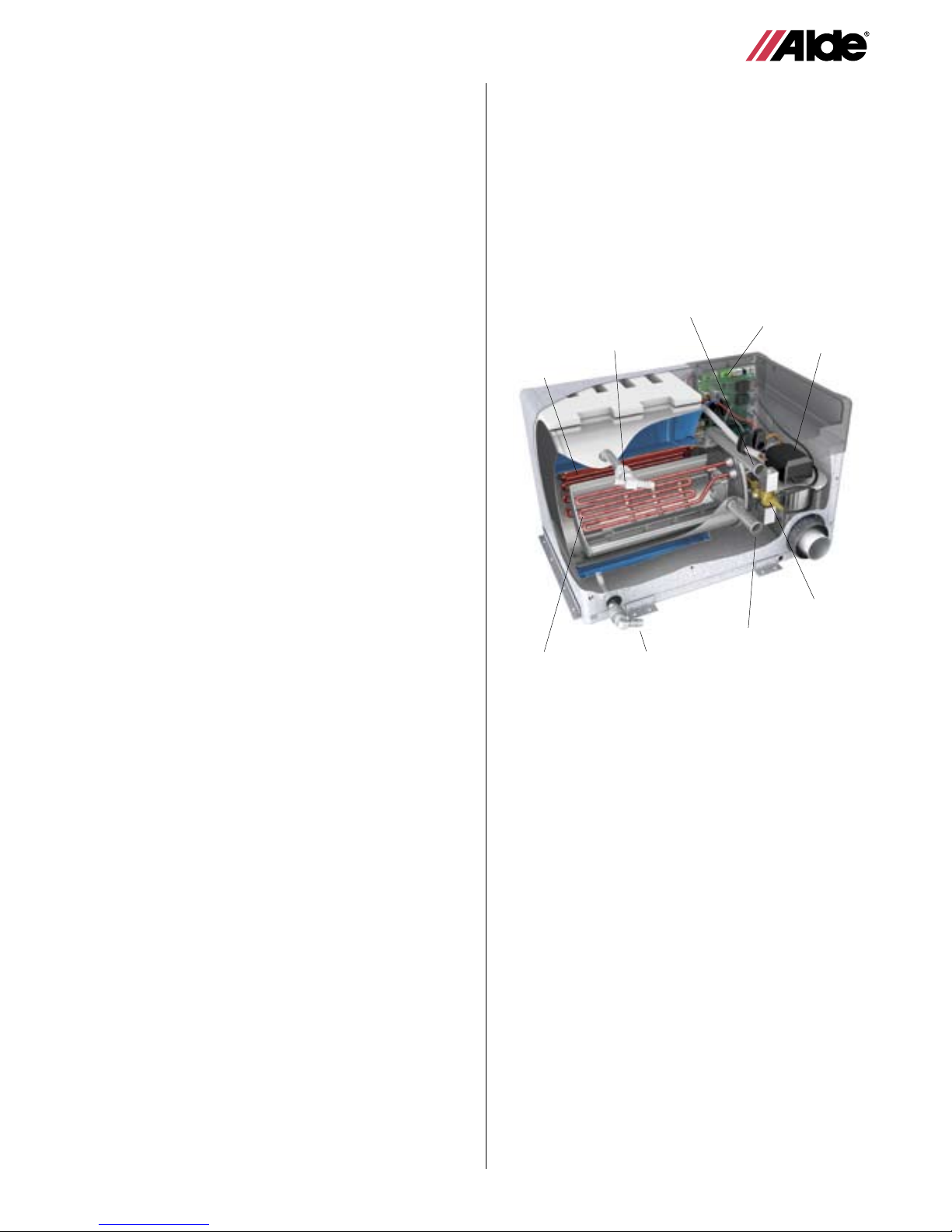

2:0 ABOUT THE COMPACT 3010

The set-up of the boiler.

The boiler consists of three eccentrically-tted pipes. The

innermost pipe is a heat exchanger made from extruded alu-

minium. This is surrounded by a water jacket containing a 40%

glycol mixture which is the uid for the heating system.

The fresh-water heater is located outside the water jacket. The

two outer pipes, as well as their ends and connections, are

made from stainless steel.

The heat exchanger is divided into two semicircular parts by a

u-shaped bafe plate.

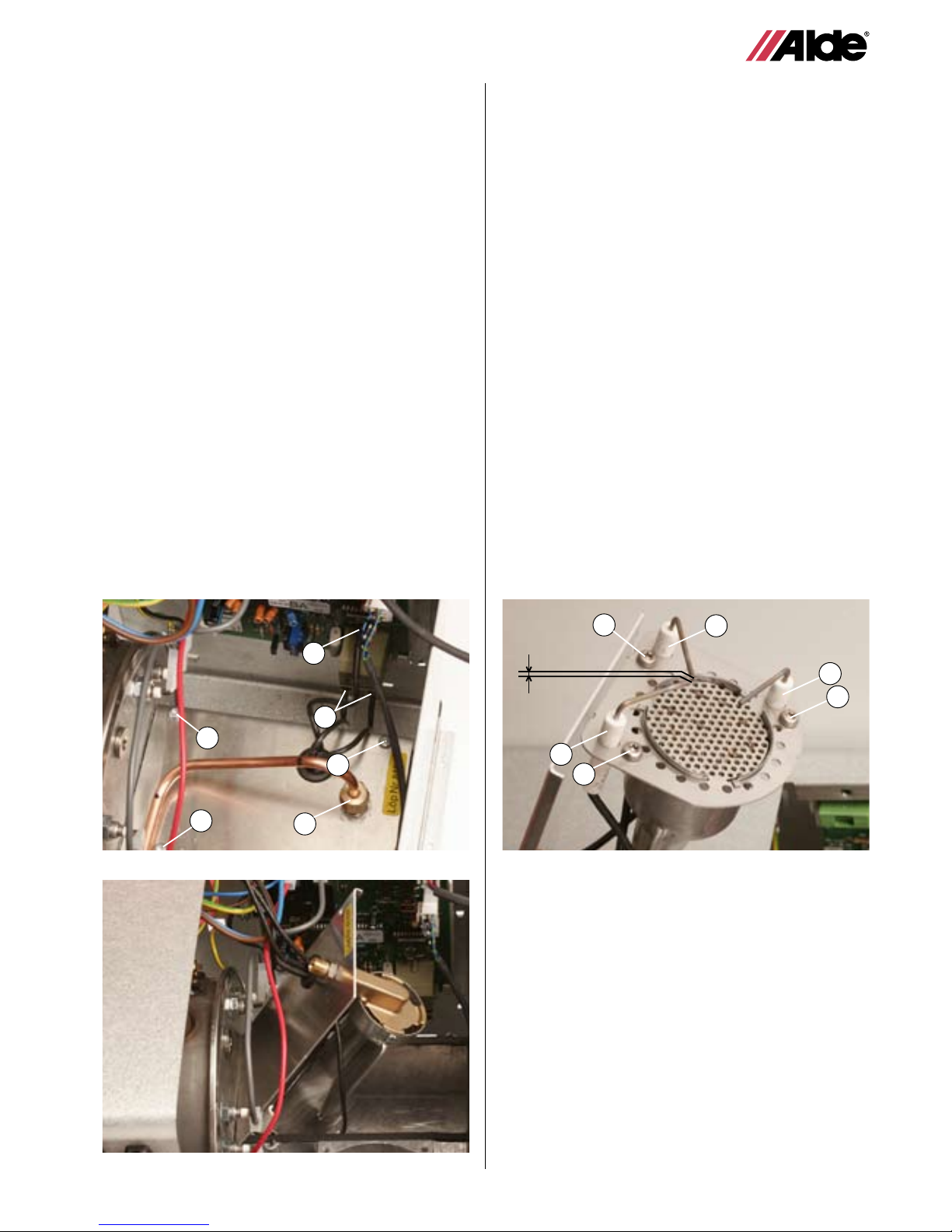

The burner is located in the upper semicircle, the combustion

chamber. The bafe plate leads the ue gases back into the

lower part of the section, which constitutes the convection part.

The burner housing is tted on the end of the heat exchan-

ger. On the burner housing is a fan, burner, solenoid valve

and intake/exhaust connections. The exhaust gases escape

through the inner tube, and fresh air enters through the outer

tube. The exhaust fumes exit the vehicle via a hose and ue

tted either to the roof or to the wall. Fresh air enters via the

same ue (balanced draft).

2 electrical heating cartridges are tted to the upper part of the

water jacket. The maximum output of the cartridges is either

2kW or 3kW depending on boiler model.

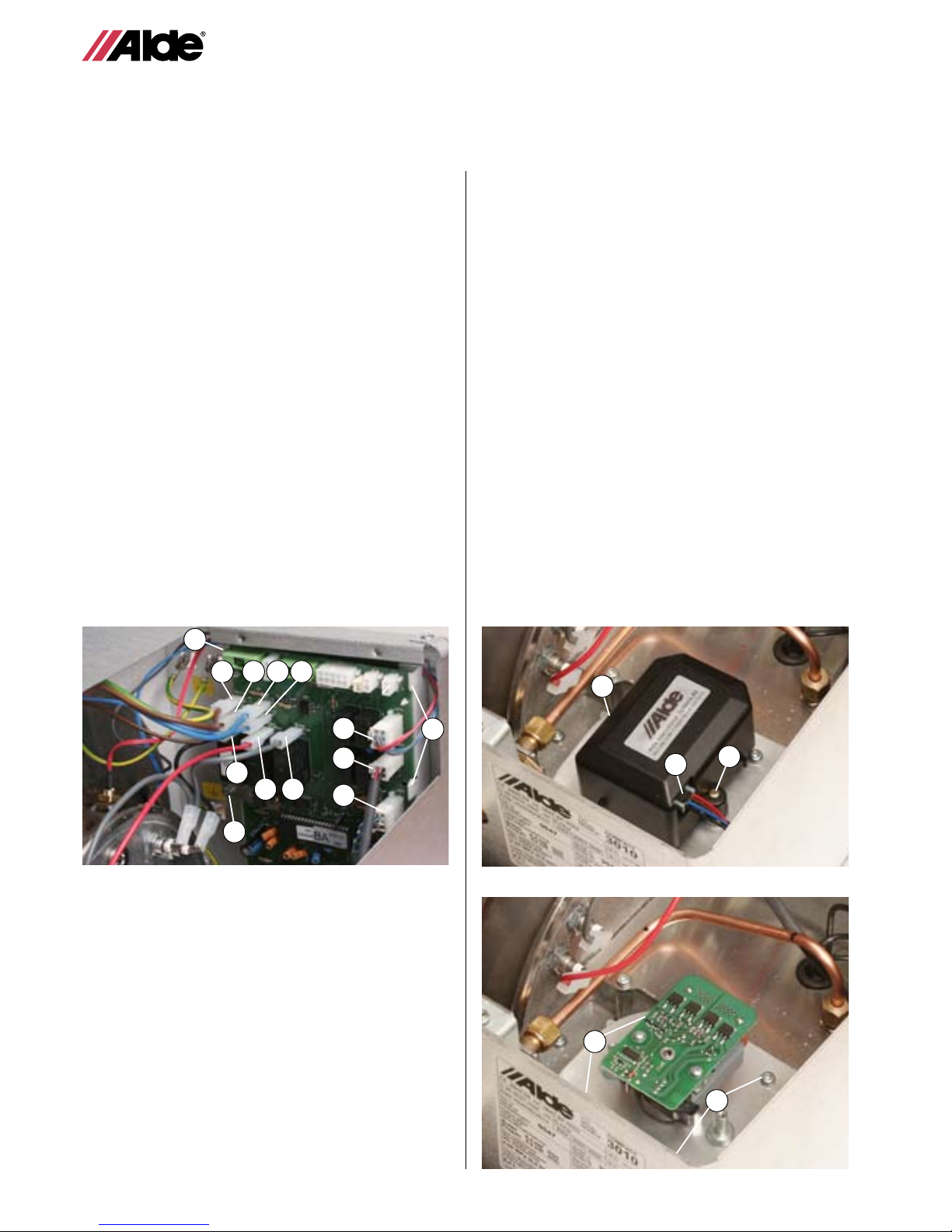

2:1 HOW THE BOILER WORKS

The boiler is a combined unit for producing heat and hot water.

Electricity, LPG or a combination of both are used as energy

source. The electrical elements, of which there are two, have

an output of 1kW and 2kW respectively. The output is control-

led via a relay on a printed circuit board, and depending on

the model of the card, the maximum output is 2kW or 3kW

respectively. When starting, not all the power is connected in

at the same time, but connecting-in goes in two or three steps

with a few seconds delay between them. The LPG heater has

a burner that works in two steps. The lower of the two steps is

3kW, and the higher is 5.5kW. The power step that the heater

works on is determined by the requirement for heat in the

vehicle. Functions are also connected to the printed circuit

board that are required for monitoring and controlling the

heater.

They can be divided into the following units:

• Monitoring and regulating the speed of the fan at the two

different power steps.

• Opening the different power steps of the gas valve at the

right point of time. The ignition sparks the burner via the two

spark electrodes mounted on the burner.

• Monitoring of the ame through ionised sensing via ame

sensor pin mounted on the burner.

• Control and monitoring of radiator temperature via sensor

mounted on the boiler body.

Control of warm water temperature via sensor mounted on

the heater.

• Regulation of room temperature in the vehicle via sensors

in the panel or sensors connected to the panel.

Filling pump

Art no 1900 811