Page 2 | RDF Installation Supplement

Caution

FOR GENERALVENTILATING USEONLY.DO NOT USETO EXHAUST

HAZARDOUS OR EXPLOSIVE MATERIALS AND VAPORS.

Warning

TO REDUCETHE RISK OF FIRE, ELECTRIC SHOCK, OR INJURYTO

PERSONS, OBSERVE THE FOLLOWING:

1. Usethisunitonlyinthemannerintendedbythemanufacturer.

If you have any questions, contact the manufacturer.

2. Beforeservicingorcleaningtheunit,switchpoweroatservice

panel and lock service panel to prevent power from being

switched on accidentally. When the service disconnecting

means cannot belocked, securelyfasten a prominent warning

device, such as a tag, to the service panel.

In addition to the following manufacturer’s instructions, it is

necessary to comply with federal, state, and local government

codes. Your purchase of this ALDES North America system

represents an investment in the health and comfort of occupants,

as well as an investment in the protection of the building from the

damaging eects of excessive indoor humidity.

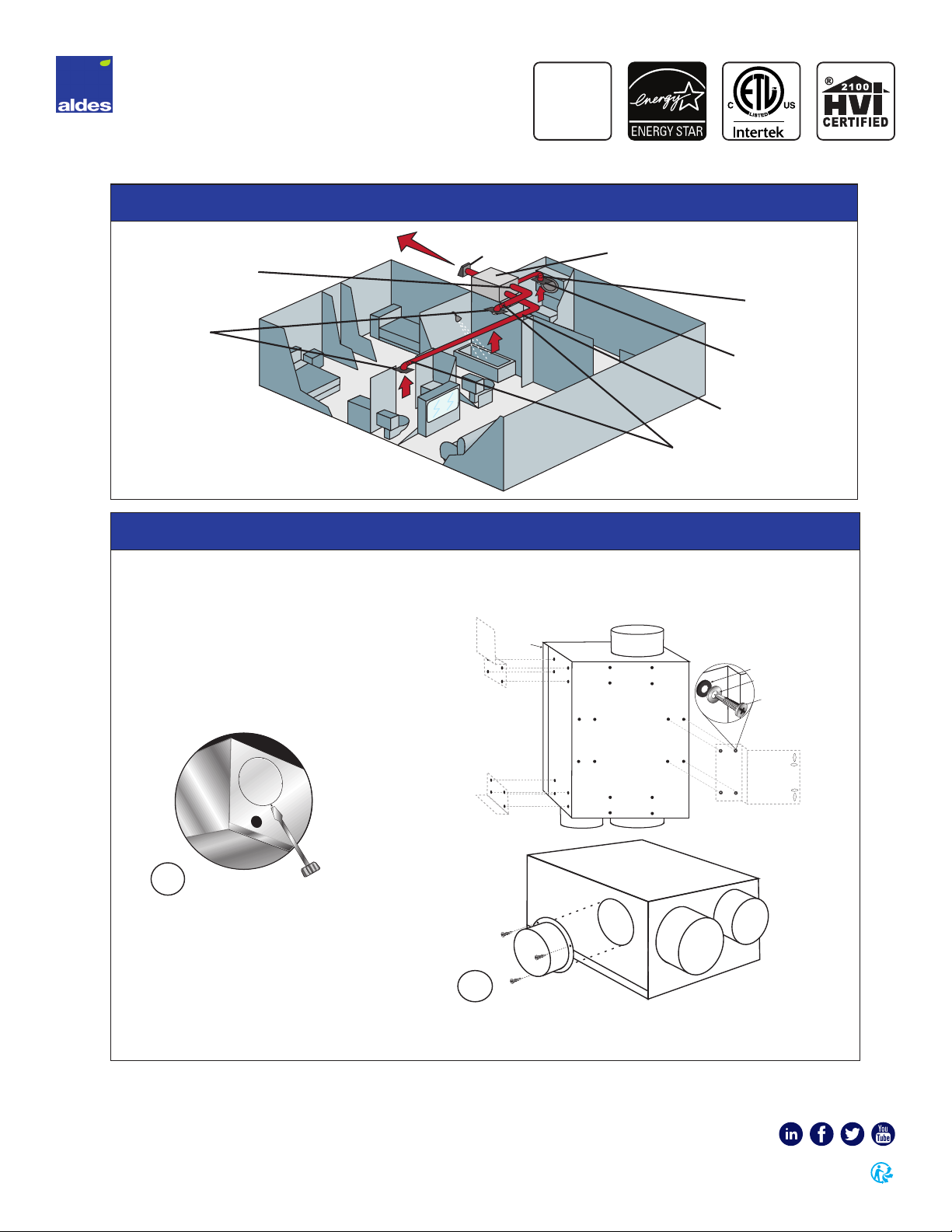

This model of centrifugal fan is designed for multiple purposes. It

may be used as an in-line rectangular duct fan (Model RDF) or a

manifolded, multi-port fan for multiple exhaust or supply points.

It may be installed in a remote location such as an attic space,

mechanical room, above a drop ceiling, in a closet or in a laundry

room, to provide quiet exhaust of stale, humid, or otherwise

polluted air from bathrooms, kitchens, laundry rooms, or storage

rooms via exhaust grilles and ducting to the centrally located

fan, which is ducted to the outdoors. With small return grilles

in bedrooms and other areas, and one duct connection to the

outdoors, such as the BVS models, it may also be used as a supply

ventilator or recirculating central ventilator for the introduction

of outdoor air, raising the temperature of the fresh air by

mixing with recirculated indoor air. When used with adjustable

balancing grilles or ALDES Constant Airow Regulators (CAR) and

compatible roof/wall caps, ducting, etc., the fan is the heart of a

complete pre-engineered ventilation system.

System Design

Satisfactory performance of a central ventilation system requires

the proper integration of all the components:

• Fan selection for airow, pressure and acoustic properties,

vibration characteristics and mounting method, and mode of

operation (continuous, manually or automatically controlled)

• Proper duct design for friction losses, with compatible supply

or exhaust grilles (airow and acoustic properties of the supply/

exhaust grilles), and compatible wall/roof caps

• Method of balancing airows of multi-point ventilation systems

• Consideration for potential condensation in the ducting or fan

housing (installation in an unheated space)

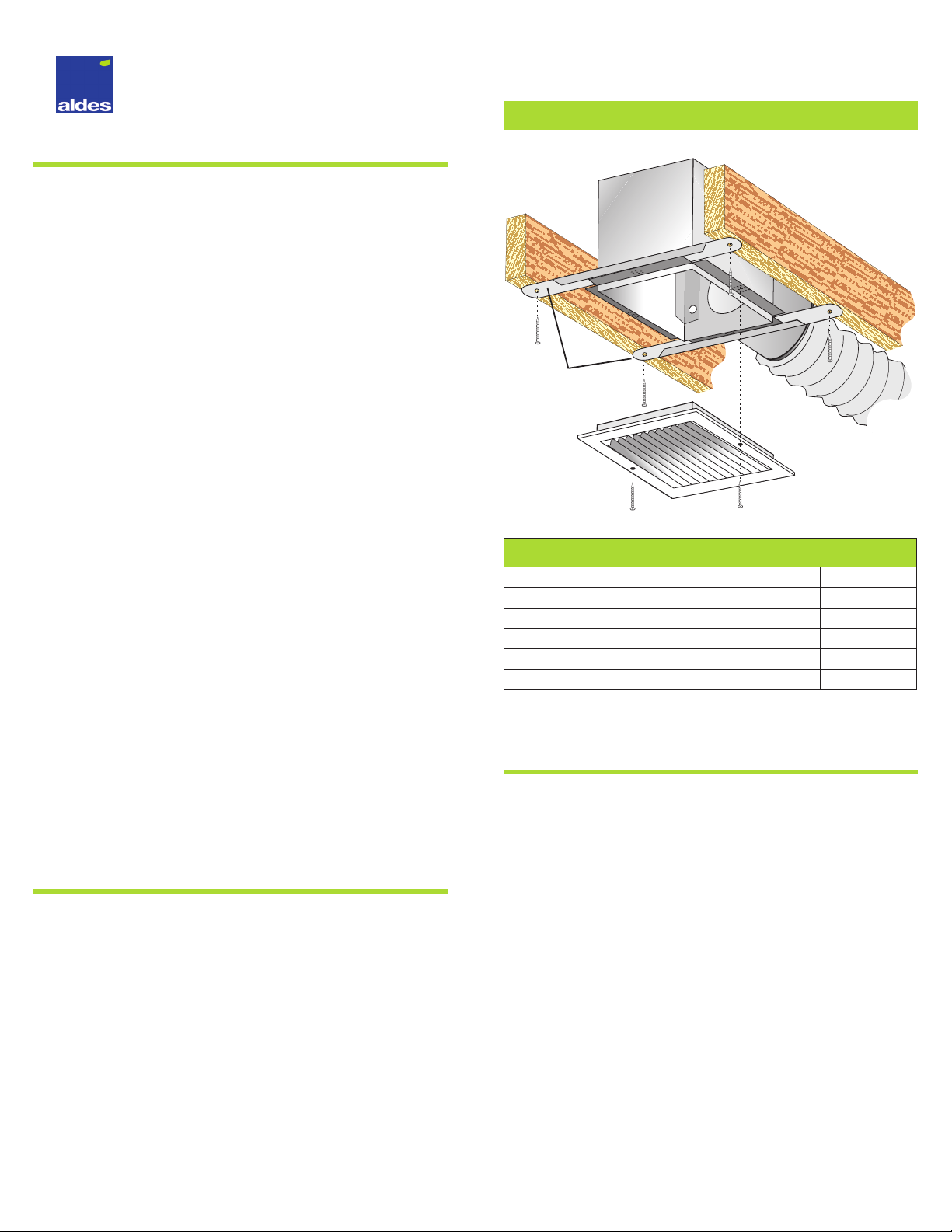

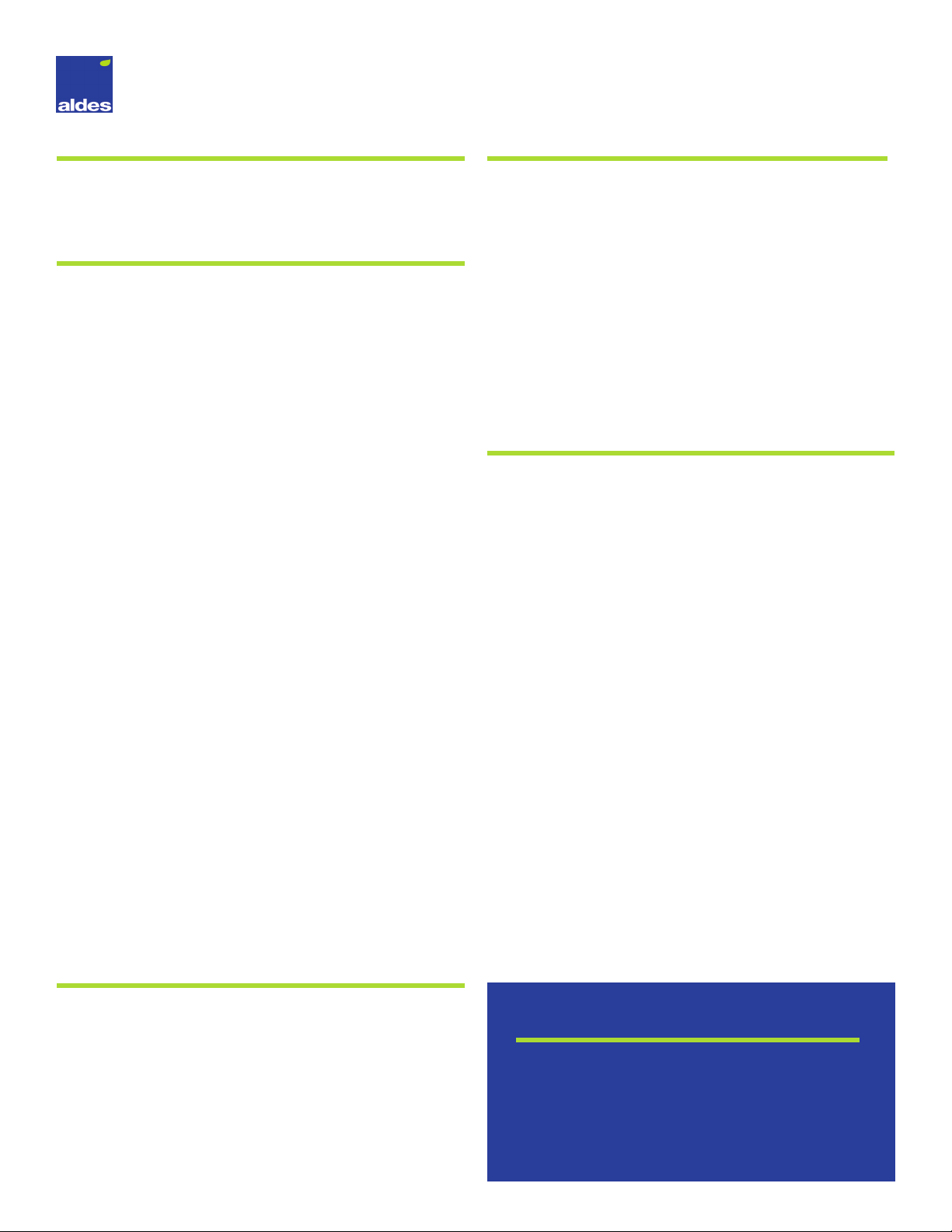

Duct Connections

Ducting may be exible or rigid, depending on local codes. If

permitted by code, insulated exible ducting is recommended.

To limit fan noise, at least 8 feet of insulated exible duct shall

be installed between the fan and grille(s). All exible duct

connections shall be secured with clamps or wire ties and

sealed with mastic or code-approved duct tape. All rigid ducts

are to be sealed on both ends and along the longitudinal seams

with mastic or code-approved duct tape.

Ducting shouldconform toNFPA90A and meettherequirements

of UL as a Class 0 or Class 1 duct to specication UL 181, Standard

for Factory-Made Air Ducts and Duct Connectors.

Installation Warning

TO REDUCE THE RISK OF FIRE, ELECTRIC SHOCK, OR INJURY

TO PERSONS, OBSERVE THE FOLLOWING:

1. Installation work and electrical wiring must be done by

qualied person(s) in accordance with all applicable codes

and standards, including re-rated construction.

2. Sucient air is needed for proper combustion and

exhausting of gases through the ue (chimney) of fuel-

burning equipment to prevent backdrafting. Follow the

heating equipment manufacturer’s guidelines and safety

standards such as those published by the National Fire

Protection Association (NFPA), the American Society for

Heating, Refrigeration and Air Conditioning Engineers

(ASHRAE), and the local code authorities.

3. When cutting or drilling into wall or ceiling, do not damage

electrical wiring and other hidden utilities.

4. When used as exhaust fans, ducted fans must always be

vented to the outdoors.

5. If this unit is to be installed over a tub or shower, it must

be marked as appropriate for the application and be

connected to a GFCI- (Ground Fault Circuit Interrupter)

protected branch circuit.

6. NEVER place a switch where it can be reached from a tub

or shower.

MAINTENANCE

MONTHLY:Inspect and clean the exhaust grilles and

lters, if so equipped.

ANNUALLY: To ensure the maximum eciency of the

fan unit, it is recommended to clean the inside of the

fan box as well as the blower wheel.