Visit our website at www.alemlube.com.au or www.alemlube.co.nz

NSW/ACT

TEL: (02) 9677 1555

FAX: (02) 9675 1155

QLD/PNG

TEL: (07) 3204 9166

FAX: (07) 3204 1224

VIC/ TAS

TEL: (03) 8787 8288

FAX: (03) 8787 8266

WA

TEL: (08) 9302 4199

FAX: (08) 9303 2095

SA/NT

TEL: (08) 8241 7111

FAX: (08) 8241 7011

NZ

TEL: (09) 447 1007

FAX: (09) 447 1008

5

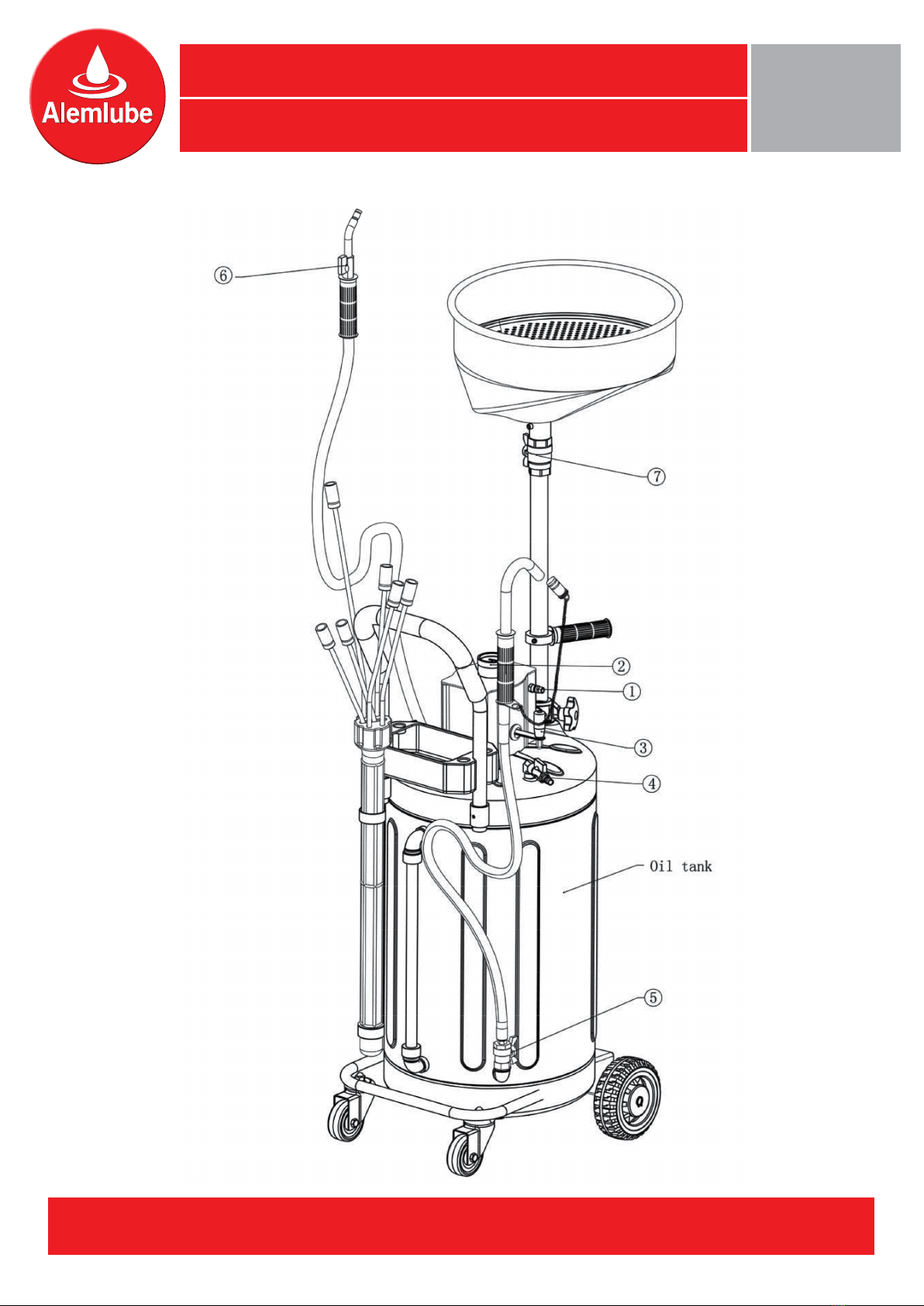

Mobile Waste Oil Drainer / Extractor

OWNER’S TECHNICAL MANUAL

30100

EJECTION

Tank Emptying (FIG 9 & FIG 10)

When the oil retained in tank is near full (FIG.10), you need to eject oil out

into a disposal tank and resolve the waste oil accordingly to the instruction

of local government.

1. Turn off all the valves.

2. Hold the ejection hook and insert it into the external disposal tank.

3. Connect the air compressor with the air inlet 4.

4. Turn on wing valve 5 for oil ejection.

5. Turn on the mini ball valve 4 gradually, adding tank pressure, turn off air

compressor when pressure reach to desired pressure. (The safety valve

will automatically release pressure when the tank pressure reach about

1.0 bar/14PSI, turn off the mini ball valve 4 immediately and quickly drop

the tank pressure below 1.0bar/14PSI).

6. Cut off air source after ejection, empty tank pressure and turn off all valves.

Note: Discharge Residual oil from Residual oil cup when it reaches

STOP sign. (FIG.10)

WARNING

1. Please hold the end of Ejection Hook to avoid waste oil spattering

out, cause an injury of eye, dirty of clothes.

2. Before disconnect extraction/ejection tube with fast couple (male),

making sure no any pressure existed in the tank.

Otherwise, oil will spray out.

TROUBLE SHOOTING

1. Vacuum gauge don’t work

• Check the air pressure: standard air pressure through air inlet valve should

between 87~116PSI /6~8bar; Air consumption is about 200L/Min.

• Make sure all the valves are on the correct place.

• Check vacuum operator-to-tank seal.

2. There is a gure showed on the vacuum gauge but the machine don’t

working and extracting

• Check extraction hose-to-probe seal.

• Temperature of waste oil is too low or not? (ordinary temperature of oil should between 40~60℃.)

• Extract grease oil or other oil with high density, which is, avoided.

• Make sure that extraction pipe open.

• Make sure that extraction pipe do not block off and probe don’t touch the bottom of tank.

• Make sure that the silencer haven’t been blocked.

INSPECTION, MAINTENANCE & CLEANING

1. Before each use, inspect the general condition of the machine Check for loose screws, air and oil leakage,

misalignment or binding of moving parts, cracked or broken parts, and any other condition that may affect

its safe operation. If abnormal noise or vibration occurs, have the problem corrected before further use.

Do not use damaged equipment.

2. Periodically recheck all hoses, valves, nuts, bolts, and screws for tightness.

3. For a long time to use, please check the adapter/ seal ring of the adaptors for leakage.

4. It’s necessary to drain the waste oil as soon as possible in case of the corroding of tank.

5. Store in a clean and dry location.

6. All maintenance and repairs must be completed by a qualied technician.

Fig 9

Fig 10