1. INTRODUCTION ............................................................................................................................................................... 1

1.1. PURPOSE................................................................................................................................................................. 1

1.2. PURPOSE AND CONTENT OF INSTRUCTIONS ........................................................................................................... 1

1.3. UPDATING THE INSTRUCTIONS................................................................................................................................ 1

1.4. GENERAL ................................................................................................................................................................. 1

1.5. LEGAL WARRANTY................................................................................................................................................... 1

1.6. RESPONSIBILITY OF THE MANUFACTURER .............................................................................................................. 1

1.7. CHARACTERISTICS OF THE USER............................................................................................................................. 2

1.8. TECHNICAL ASSISTANCE ......................................................................................................................................... 2

1.9. SPARE PARTS .......................................................................................................................................................... 2

1.10. RATING PLATE ..................................................................................................................................................... 2

1.11. DELIVERY OF THE COOKER .................................................................................................................................. 2

2. SAFETY WARNINGS ......................................................................................................................................................... 2

2.1. WARNINGS FOR INSTALLER..................................................................................................................................... 2

2.2. WARNINGS FOR USER.............................................................................................................................................. 2

2.3. WARNINGS FOR A MAINTENANCE WORKER ............................................................................................................. 3

3. FUEL CHARACTERISTICS AND DESCRIPTION OF THE COOKER ......................................................................................... 3

3.1 FUEL CHARACTERISTICS.......................................................................................................................................... 3

3.2. PELLETS STORAGE .................................................................................................................................................. 3

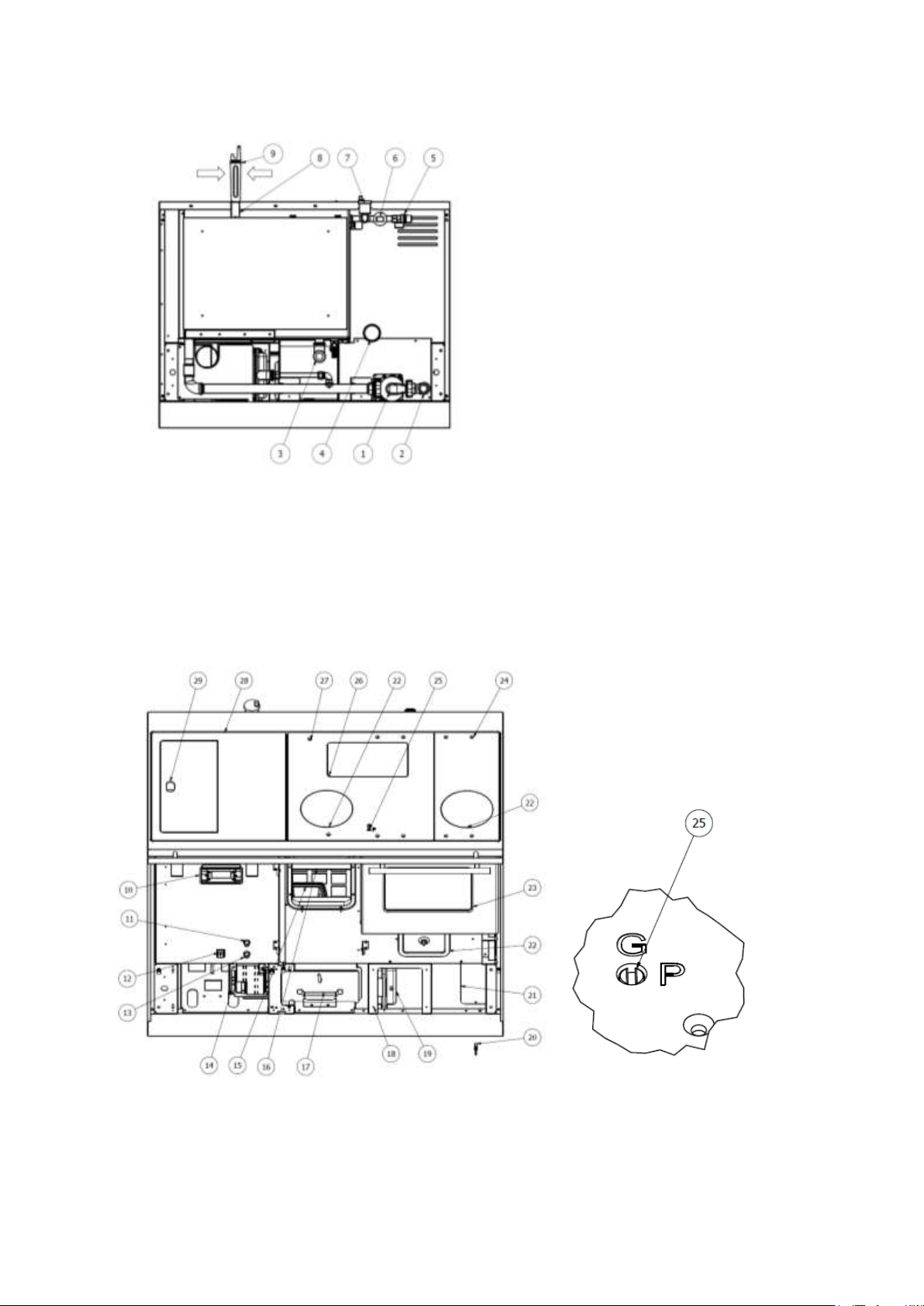

3.3. MAIN PARTS OF THE COOKER.................................................................................................................................. 4

3.4. DIMENSIONS OF THE COOKER ................................................................................................................................. 5

4. MOVING AND TRANSPORT .............................................................................................................................................. 5

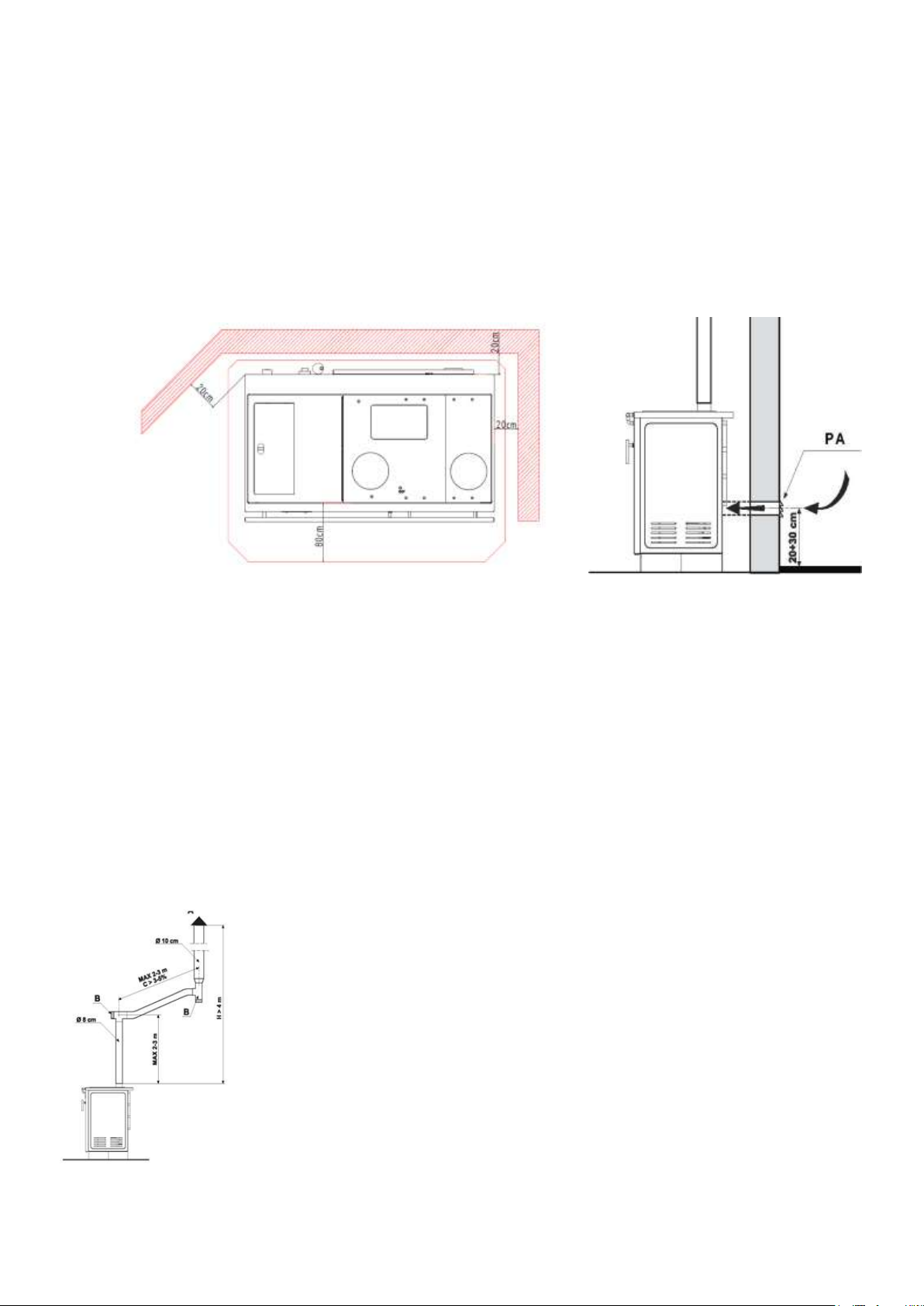

5. PREPARATION OF THE SPACE FOR INSTALLATION .......................................................................................................... 5

5.1. PRECAUTIONARY MEASURES .................................................................................................................................. 5

5.2. GENERAL MEASURES............................................................................................................................................... 5

5.3. LOCATION OF INSTALLATION OF THE COOKER ........................................................................................................ 6

5.4. AIR USED FOR COMBUSTION ................................................................................................................................... 6

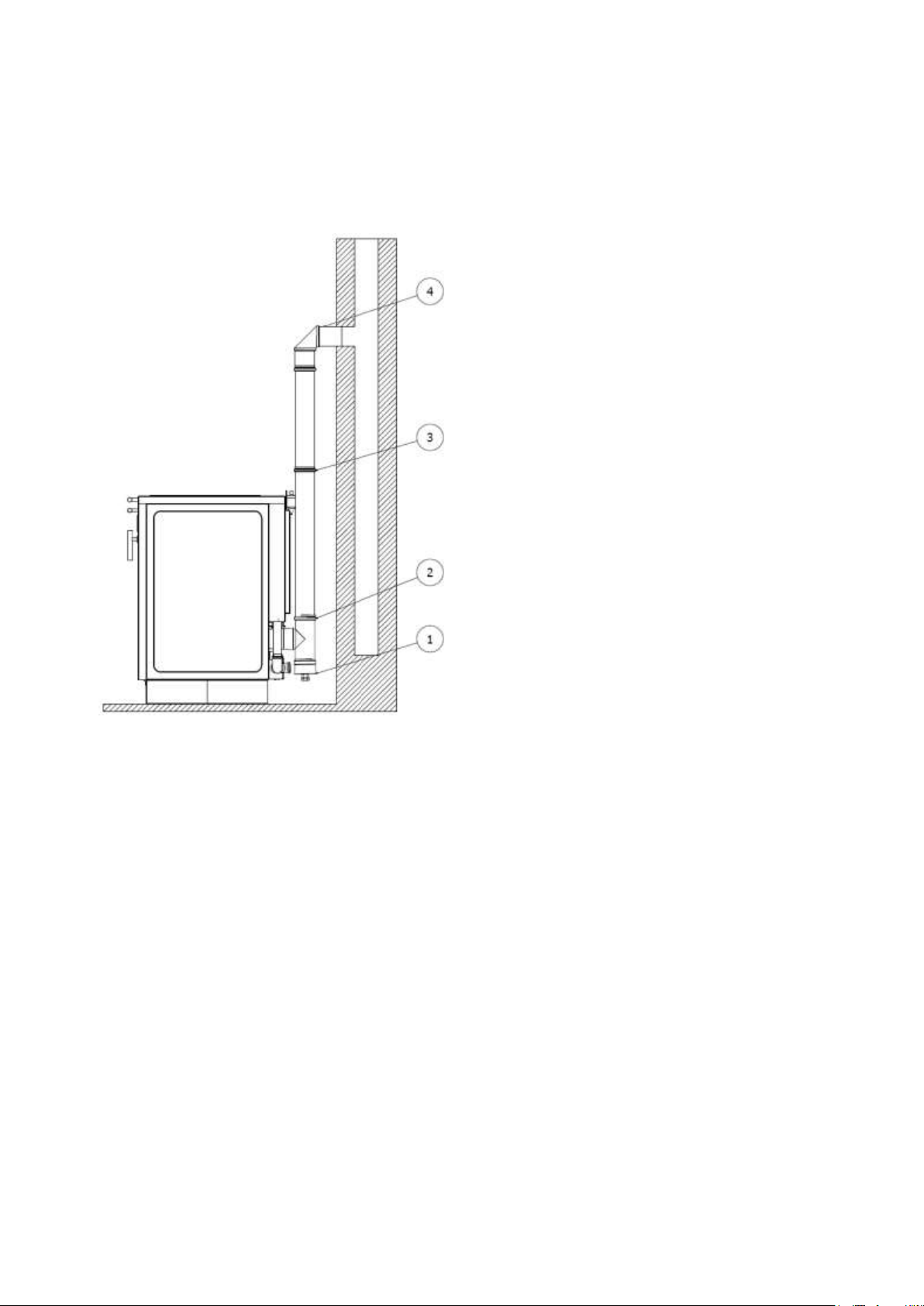

5.5. SMOKE EXTRACTION ............................................................................................................................................... 7

5.6. AIR USED FOR COMBUSTION ................................................................................................................................... 8

6. INSTALLING..................................................................................................................................................................... 2

6.1. SAFETY MEASURES FOR MAINTENANCE PERSONNEL.............................................................................................. 2

6.2. SAFETY MEASURES FOR USERS............................................................................................................................... 2

7. INSTRUCTIONS FOR SAFE TURNING ON AND CLEANING THE COOKER............................................................................. 3

7.1. REGULAR CLEANING AND MAINTENANCE PERFORMED BY THE USER OF THE COOKER............................................ 3

7.2. SPECIAL MAINTENANCE .......................................................................................................................................... 5

8. IMPORTANT SAFETY INFORMATION................................................................................................................................ 5

9. CHOOSING PELLETS........................................................................................................................................................ 6

9.1. PELLETS STORAGE .................................................................................................................................................. 6

10. CONNECTING HYDRAULIC INSTALLATION.................................................................................................................... 6

10.1. PRESSURE AND RETURN LINE.............................................................................................................................. 7

10.2. COOKER EMBEDDED COMPONENTS..................................................................................................................... 7

10.3. SAFETY VALVE (Figure 18, Position 6)................................................................................................................. 7

10.4. CIRCULATION PUMP (Figure 18, Position 1) ......................................................................................................... 7

10.5. AUTOMATIC AIR-BLEEDING VALVE (Figure 18, Position 8) ................................................................................... 7

10.6. EXPANSION VESSEL (Figure 18, Position 2) ......................................................................................................... 8

10.7. TAP FOR FILLING AND DISCHARGING (Figure 18, Position 9)................................................................................ 8

10.8. WATER PRESSURE SENSOR (Figure 18, Position 7) .............................................................................................. 8

11. FILLING THE INSTALLATIONS AND COMMISSIONING................................................................................................... 8

12. TIPS FOR THE USE OF THE HEATING SYSTEM .............................................................................................................. 8

12.1. COOKING, BAKING/ROASTING AND FRYING ......................................................................................................... 8

13.FEEDING THE PELLETS INTO THE FUEL STORAGE ........................................................................................................ 8

14. CONTROL SYSTEM OF THE COOKER............................................................................................................................. 9

14.1. ELECTRIC CONNECTIONS SCHEME ...................................................................................................................... 9

14.2. CONTROL PANEL (DISPLAY) - BUTTONS AND FUNCTIONS................................................................................... 9

14.3. MENU ................................................................................................................................................................ 11

14.3.1. COMBUSTION MANAGEMENT MENU ......................................................................................................... 12

14.3.2. HEATING MANAGEMENT MENU ................................................................................................................. 13

14.3.3. CHRONO MENU ......................................................................................................................................... 14

14.3.4. MANUAL PELLETS LOADING MENU ........................................................................................................... 15

14.3.5. MANUAL LOADING MENU .......................................................................................................................... 16

14.3.6. TIME AND DATE MENU .............................................................................................................................. 16

14.3.7. REMOTE CONTROL MENU.......................................................................................................................... 16

14.3.8. LANGUAGE SELECTION MENU ................................................................................................................... 16

14.3.9. DISPLAY MENU ......................................................................................................................................... 16

14.3.10. SYSTEM MENU.......................................................................................................................................... 16

14.4. COOKER IGNITION AND FUNCTIONAL CONDITIONS............................................................................................ 16

14.5. POSSIBLE PROBLEMS AND SOLUTIONS............................................................................................................. 18

15. SAFETY MEASURES.................................................................................................................................................... 19

16. FAULTS - CAUSES - SOLUTIONS ................................................................................................................................ 20

17. INFORMATION ON DISPOSAL AND DISASSEMBLING THE COOKER ............................................................................. 21