1

1. PURPOSE

The continually burning solid fuel for floor heating with solid fuel is used for:

-cooking,

-baking,

-heating apartments, individual houses and offices,

-production of hot sanitary water.

It is mostly installed as a solid fuel for floor heating, and it can also be installed for central heating.

2. THE RESPONSIBILITY OF THE MANUFACTURER

Upon publishing this Manual, ALFA PLAM will not accept any civil or legal responsibility, either direct on indirect, due to:

− Accidents occurred due to the non-observance of the standards and specifications stated in this

Manual,

− Accidents occurred due to the improper operation or use of the solid fuel by the user,

− Accidents occurred due to any modifications and repairs not approved by ALFA PLAM,

− Poor maintenance,

− Unpredictable events,

− Accidents occurred due to the use of spare parts that are not original spare parts or that are not

intended for these models of the solid fuel.

The installer of the solid fuel shall take the full responsibility for the installation.

2.1. THE BASIC CHARACTERISTICS OF THE USER

The solid fuel must be used by adult and responsible people.

Make sure that children do not approach the solid fuel, when it is in use, with the intention of playing.

Children must not approach the solid fuel, while in function, with the intention of playing. This appliance can be used by

children aged from 8 years and above and persons with reduced physical, sensory or mental capabilities or lack of experience

and knowledge. if they are supervised by an elderly person who is familiar with the instructions of use. Children cannot carry

out the cleaning and maintenance of the solid fuel, if they are not supervised by an elderly person.

2.2. THE TRANSPORTATION AND USE OF THE SOLID FUEL –HANDLING

During the use of the solid fuel care should be taken that the solid fuel is not leaned forward because the centre of gravity

of the solid fuel is oriented forward.

While moving the solid fuel, which must be carried out absolutely safely, ensure that the forklift truck has a carrying

capacity that is higher than the weight of the solid fuel it should lift. Avoid twitches and abrupt movements.

ALL THE PACKAGING MATERIAL SHOULD BE REMOVED AWAY FROM THE REACH OF CHILDREN AS THE MATERIALS

CONTAINED IN THE PACKAGING MAY CAUSE SUFFOCATION. THESE INCLUDE PLASTIC BAGS, FILMS, STYROFOAM, ETC.

2.3. THE RESPONSIBILITY OF THE INSTALLER

The responsibility of the installer is to perform all the checkups of the flue piping, air intake/supply, as well as all the

solutions required for the installation (incorporation) of your solid fuel.

The responsibility of the installer is to ensure that the solid fuel is in compliance with local regulations applicable in the

place where the solid fuel is installed (incorporated).

The use of the solid fuel must be in accordance with the instructions given in this Manual for use and maintenance, as well

as with all the safety standards prescribed by local legal regulations applicable in the place where the solid fuel is installed

(incorporated).

The installer must verify (confirm):

− The type of the solid fuel that is being installed,

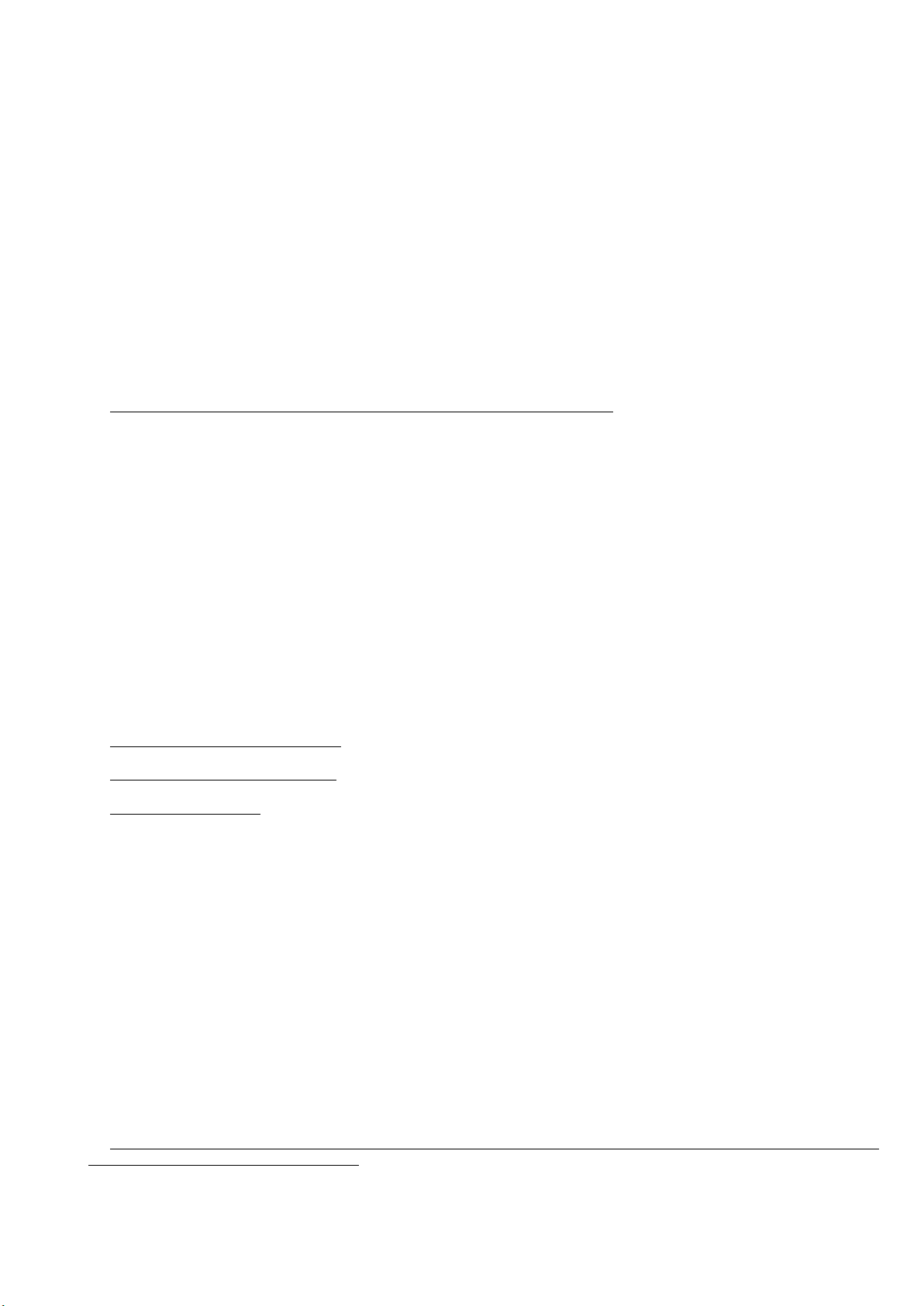

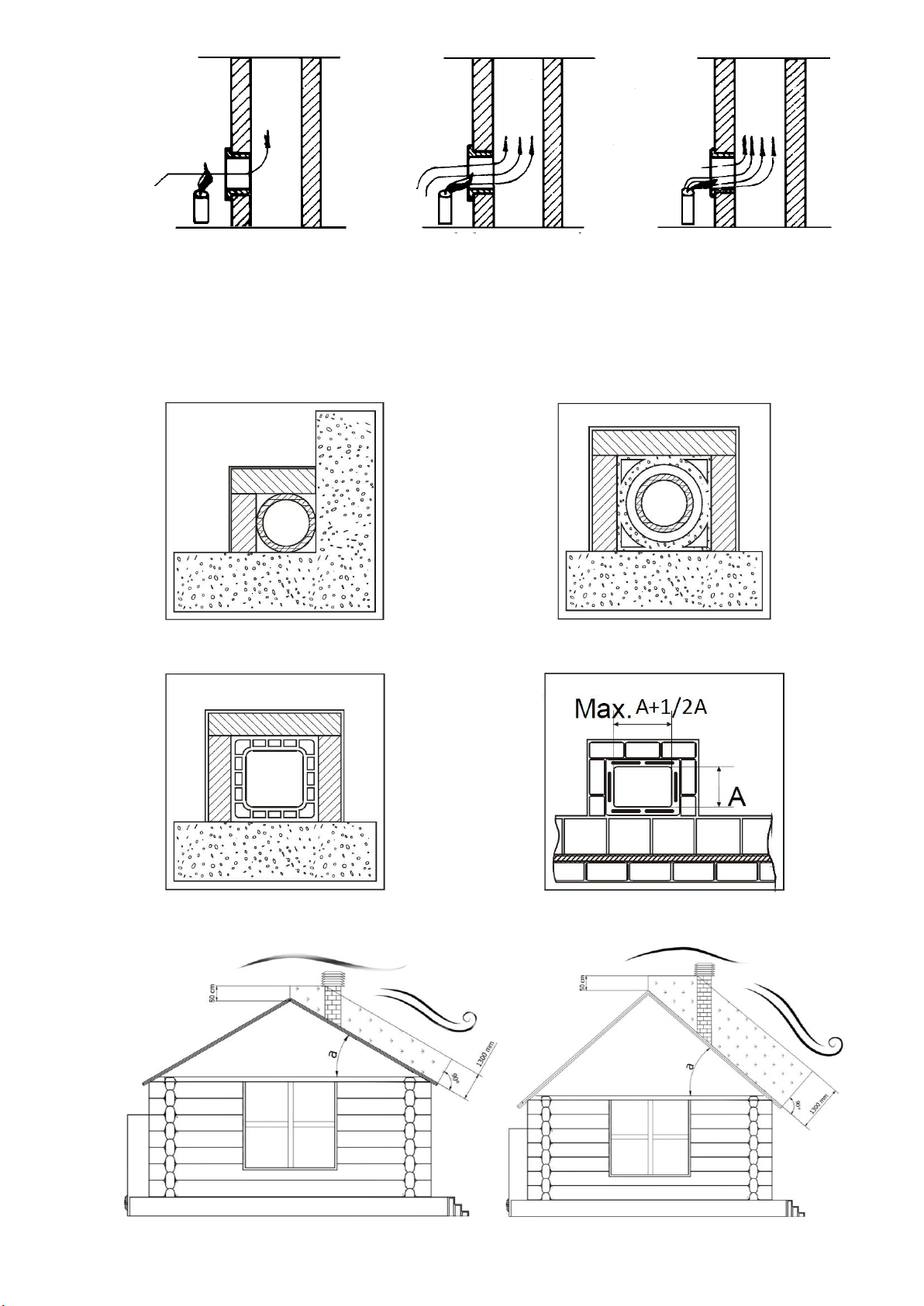

− Whether the room in which the solid fuel is being installed is appropriate, which is expressed as the minimum size of

the room required for the installation as prescribed by the solid fuel manufacturer,

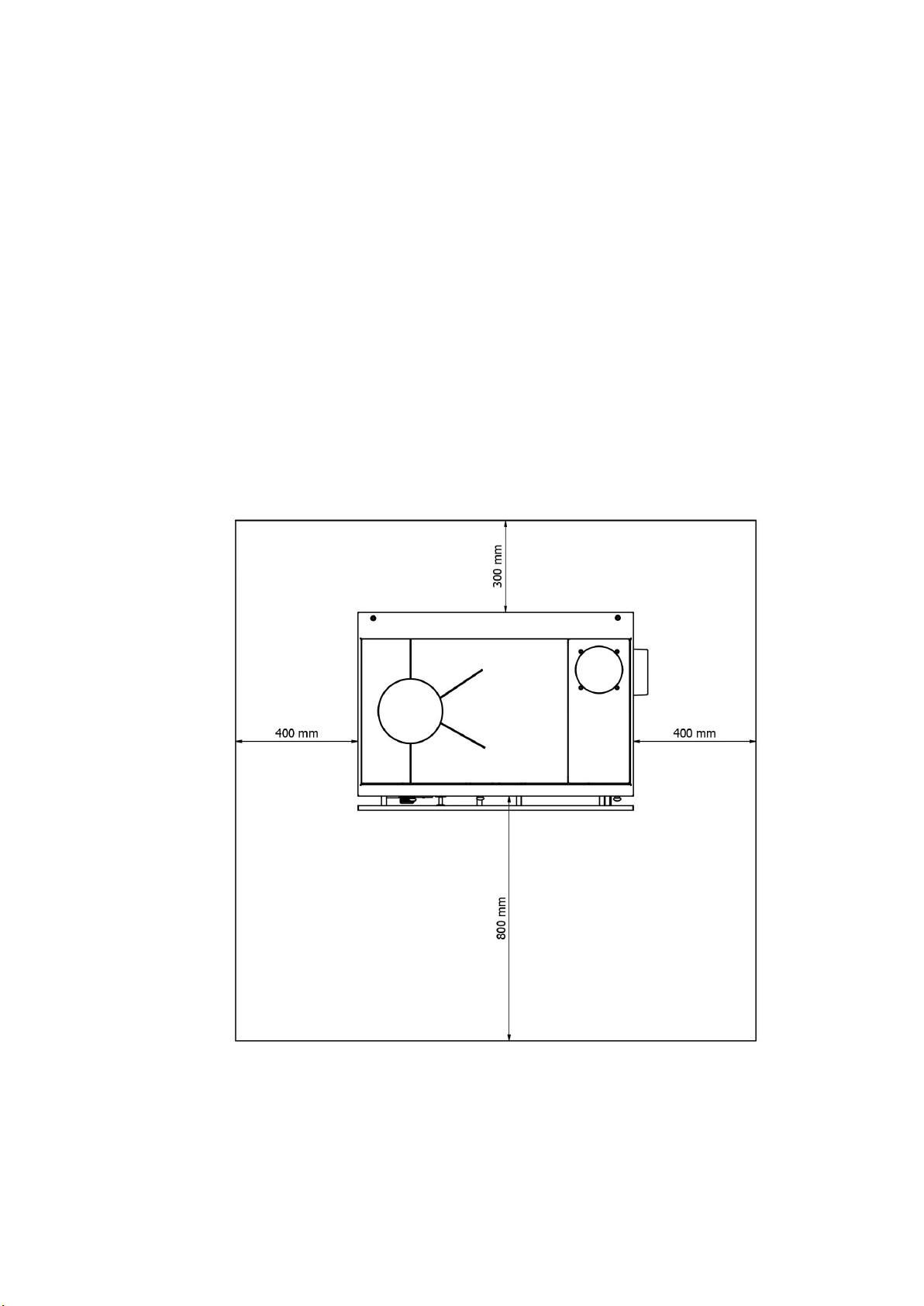

− Instructions of the heat generator manufacturer, related to the requirements of the smoke discharge system

(smoke discharge ducts and pipes),

− The internal cross section of the chimney, material the chimney is made of, cross-sectional uniformity, whether

there are any obstacles and barriers in the chimney,

− The height and vertical extension of the chimney,

− The height above the sea level at the place of installation/incorporation,

− The existence and suitability of a wind resistant protective cover of the chimney,

− The possibility of providing the external air intake and the size of required openings,

− The possibility of the simultaneous use of the solid fuel which is to be installed, together with the other equipment

already existing in that place.

If the results of all the checkups are positive, then the installer may proceed with the incorporation/installation of the solid

fuel. The instructions provided by the solid fuel manufacturer, as well as the fire prevention standards and safety standards

must also be observed.

When the installation is completed, the system must be put into a trial operation for at least 30 minutes in order to check

up all the packing and seals of the system.

When the incorporation and significant details are completed, the installer is obliged to provide the client with the

following:

− The Use and Maintenance Manual issued by the solid fuel manufacturer (if such a manual has not been delivered

with the solid fuel),

− The documents required for the compliance with existing standards.