Installation of furnace must strictly comply with applicable building codes and firefighting

requirements. Place where furnace is to be installed must be horizontal and with sufficient

bearing power, otherwise, appropriate measures on even load distribution should be taken. If

floor is made of flammable material (wood, plastic, textile, etc.) sheet metal plates, copper plates

or plates made of similar inflammable material must be inserted under furnace. This ground

surface must extend around furnace for minimum 50 cm. Clearance between furnace and

surrounding furniture and other objects made of wood, plastic or other flammable material must

be minimum 30 cm on sides and 25 cm on the back side of furnace. Clearance between

flammable materials and front fuel load opening must be minimum 80 cm.

Sufficient clearance must be maintained between furnace and surrounding flammable materials

(with wooden forms, furniture, curtains, etc.)

Nothing should be placed or mounted above the furnace if cast iron panel is used.

When installing outlet pipes for used air, minimum 40 cm of clearance must be maintained

between pipes and flammable materials.

Prior to connecting outlet pipe to chimney, consulting authorized organization dealing with

chimney safety is necessary. Connection of furnace to chimney is carried out with binding

sections in accordance with DIN 1298 or DIN EN 1856-2. Make sure that chimney connections do

not outstand in waste air and gas outlet cross section and that connections are firmly and

properly fastened. DIN-1 18160 must generally be complied with.

Chimney dimensioning is carried out in accordance with DIN EN 13384.

In order to achieve optimal furnace output, installation must be carried out properly and perfect

chimney function must be ensured. Existing chimney pressure should be tested prior to furnace

operation. Testing is done with a lighted candle placed in front of chimney opening. Chimney draft

is sufficient if candle flame twists towards the opening. Slight twisting of flame indicates

insufficient chimney draft.

If two hearths are installed on one floor (multiple use), distance between connections must be

minimum 50 cm.

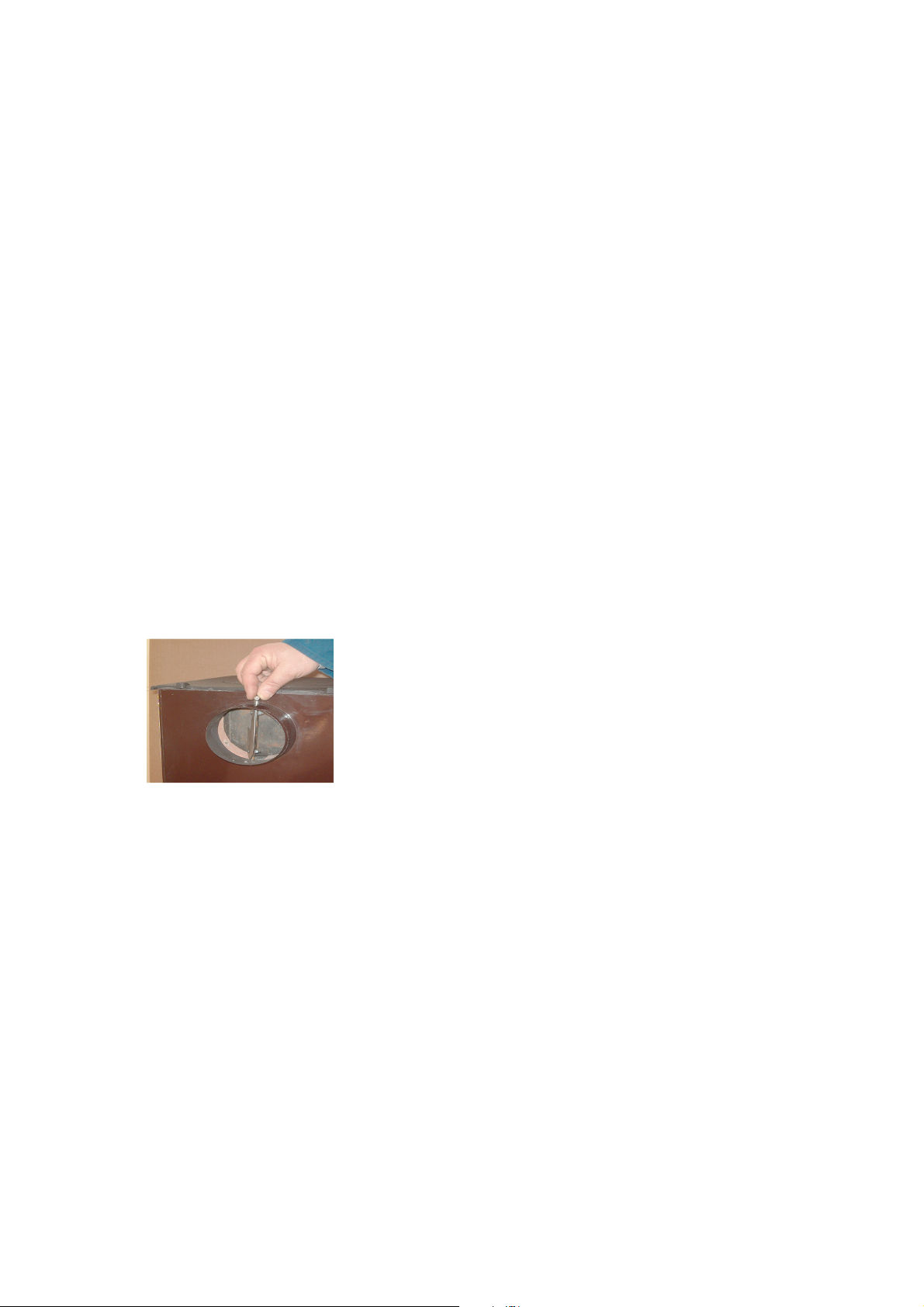

If chimney draft is to strong, it can be controlled (reduced) by

flue damper control kit, built in outlet pipe. Maximum reduction

of chimney draft is achieved when flue damper is positioned 90º

C versus outlet connection pipe axes (see figure 5).

Figure 5

5. Operating furnace

Prior to initial operation, wipe all enamel surfaces with damp cloth to avoid stains.

After reading Operation manual you may start operating furnace.

Open windows because anticorrosion protection releases odors and smoke during initial

operation. This is considered normal and will stop shortly. Ensure proper air circulation. If needed

turn on a fan for better air circulation. Maximum temperature load should be maintained for at

least one hour. If maximum temperature is not obtained during initial operation, odors and smoke

may occur again later.

Pregnant women and children should not be in the room during the initial operation.

Keep in mind that certain furnace parts (outlet pipe, fuel load door, hearth door, etc.) are hot

during furnace operation and may cause burns. Keep children away from furnace. During initial

operation add small quantities of fuel three times in order to prevent fireclay cracking.

5.1 Initial operation and operating furnace

- Open primary air control duct to maximum (figure 2, position 7)

- Open hearth door

- Insert wood wool, chippings or paper

- Put two logs above

- Light fire

- Close hearth door