AHE00053EN 1904

4

Alfa Laval is a trademark registered and owned by Alfa Laval Corporate AB.

Alfa Laval reserves the right to change specification without prior notification.

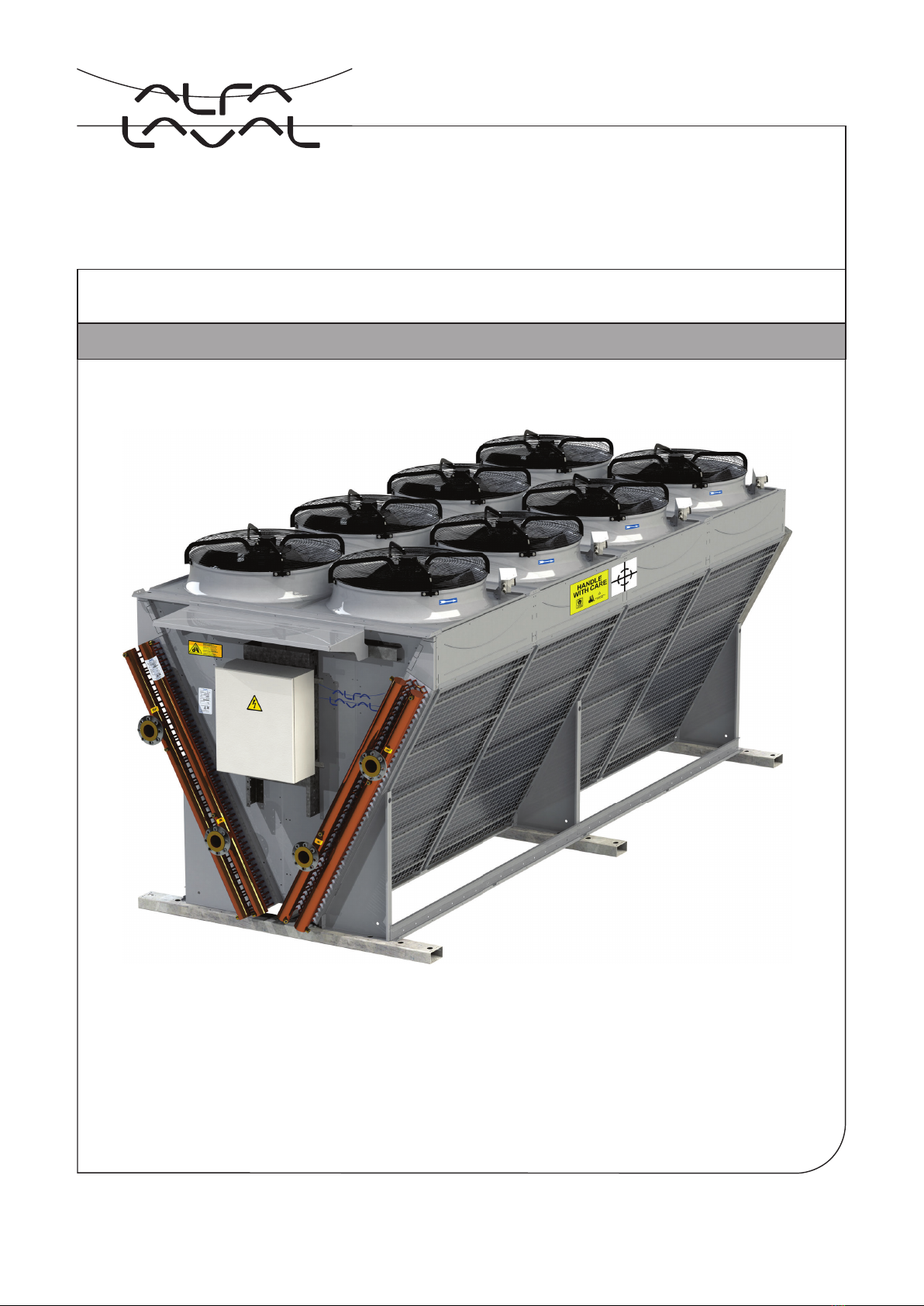

2 Product description

2.1 General information and application

The Alfa-V VDD series is a wide range of heavy duty dual fan row V-type dry coolers for HVAC,

refrigeration and various industrial applications such as water/glycol cooling.

For industrial applications, dry coolers are suitable for closed circuit cooling of various process liq-

uids in f.i. food, power, process and general industries. Alfa-V VDD dry coolers provide high capaci-

ties at reduced power consumption and a compact footprint.

• Capacity range (water, EN1048): 100 up to 1800 kW

• Design pressure: 10 bar. Each heat exchanger leak tested with dry air

2.2 Standard configuration

• Finned coil:

- Smooth copper tubing ø 12 and 16 mm (VDD and VDD6) or SS304 stainless steel tubing 16

mm (VDDY).

- Separate connections allow independent operation of both cooling coils.

• Fans:

-2 to 9 fan pairs, available in three fan diameters (ø 800 mm, ø 910 mm & ø 1000 mm) and dif-

ferent noise levels. ErP compliant motors with dynamically and statically balanced external rotor,

protection class IP 54 according to DIN 40050 and integrated thermo contacts to provide reli-

able protection against thermal overload. AC power supplies 400/50/3, 400/60/3 and 460/60/3.

EC power supply 380-480/50-60/3. AC/EC Fan motors manufactured in accordance with VDE

530/12.84

• Casing, supports and frame made of corrosion resistant galvanized steel (class C4-H).

Separated fan sections and removable fan rings.

• Frame construction provides high rigidity for protection against vibration and thermal expansion.

• Stickers indicate fan direction and refrigerant in/out.

2.3 Options

• Non-standard fin spacing (up to 3.2 mm)

• SS316L stainless steel tubing 16 mm

• SS header box (on special request)

• Coil corrosion protection

- Epoxy coated aluminium fins (EP)

- F-coat treatment (FC)

- Seawater resistant aluminium AlMg (SWR)

- R-Ind Fin

- R-Alprv

- R-AlMg

• Coil protection grid (GR)

• Spray water device kit (KW)

• Spray water system including pumping station (SWS)

• Casing coated RAL 9002 (other colors on special request)

• Container skid (SK)

• Ladder and railings

• Vibration dampers (VD)

• Expansion tank (ET)

• Special fan motors:

- Protection class IP55

- High-temperature motors

- IEC standard motors (on special request)

• Electrical options:

- Switch on/off (SW)

- EC Motors wired to a common terminal box (CBP=connection box, CBM=connection box and

master controller+temperature signal)

- Switchboard IP55 (B)

- AC Fan step control cabinet (BS/BST)