Table of contents

The information herein is correct at the time of issue but may be subject to change without prior notice

1. EC/EU Declaration of Conformity .................................................................. 4

2. Safety .................................................................................................... 5

2.1. Important information ............................................................................. 5

2.2. Warning signs ..................................................................................... 5

3. Introduction ............................................................................................ 6

3.1. Introduction ........................................................................................ 6

3.2. Intended use ...................................................................................... 6

3.3. Patents and trademarks ......................................................................... 7

3.4. Marking ............................................................................................ 7

3.5. ATEX/IECEx marking ............................................................................. 8

3.6. ATEX/IECEx temperature class and code ...................................................... 9

3.7. Quality system .................................................................................... 10

4. Installation .............................................................................................. 11

4.1. General description ............................................................................... 11

4.2. Functioning ........................................................................................ 11

4.3. General safety and installation instructions ..................................................... 12

4.4. Specific conditions for safe use in accordance with ATEX/IECEx certification .............. 13

4.5. Recycling information ............................................................................. 16

5. Operation ............................................................................................... 17

5.1. Normal operation ................................................................................. 17

5.2. Safety precautions ................................................................................ 18

6. Maintenance ........................................................................................... 19

6.1. Service and repair of ATEX/IECEx certified machines ......................................... 19

6.2. Service and repair of machines ordered with Alfa Laval Q-doc .............................. 19

6.3. Service and repair of machines ordered with Alfa Laval Q-doc + FAT-SAT ................. 19

6.4. Recommended service intervals ................................................................ 19

7. Technical data ......................................................................................... 20

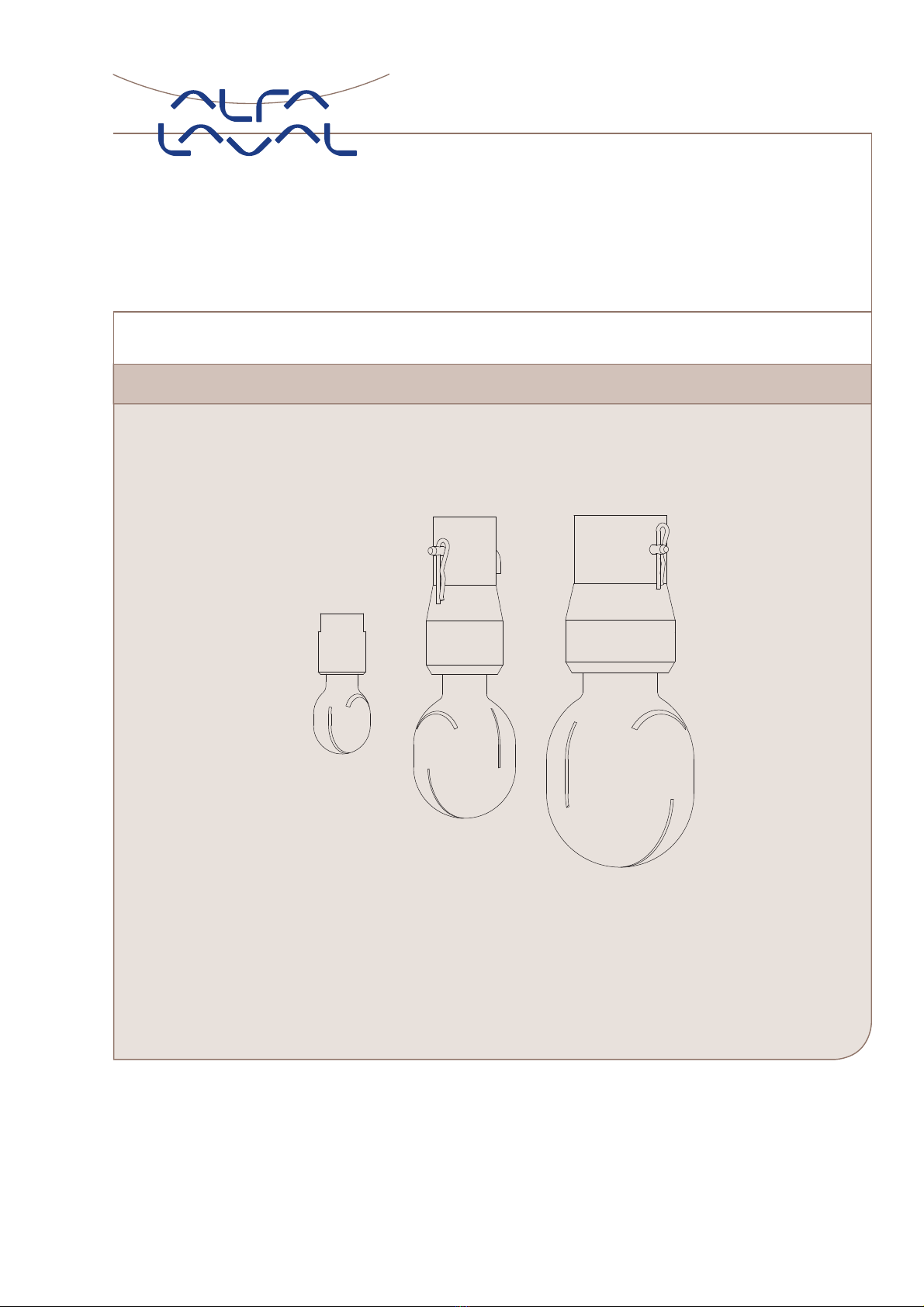

7.1. Alfa Laval Toftejorg SaniMicro ................................................................... 20

7.2. Alfa Laval Toftejorg SaniMidget .................................................................. 22

7.3. Alfa Laval Toftejorg SaniMagnum ............................................................... 24

8. Product programme .................................................................................. 26

8.1. Alfa Laval Toftejorg SaniMicro ................................................................... 26

8.2. Alfa Laval Toftejorg SaniMidget .................................................................. 27

8.3. Alfa Laval Toftejorg SaniMagnum ............................................................... 28

8.4. Available add-ons ................................................................................. 30

9. General information ................................................................................... 31

9.1. Service and repair ................................................................................ 31

9.2. How to contact Alfa Laval Kolding A/S ......................................................... 31

3