43

Before use, read this instruction manual carefully. If you have any questions, please

for accidents or damage caused by improper operation.

Application

Zogics Disinfectant Atomizing Sprayer is a high-efficiency sanitizing and disinfecting

tool that is designed to be used in a variety of commercial locations and industries

—ideal for large-scale applications of disinfecting solution in public facilities, such

as airports, hospitals, hotels, offices, restaurants, fitness clubs, and more.

Warning

1. DO NOT direct spray highly-toxic pesticides, undiluted pesticides or banned

pesticides/chemicals. Comply with safety instructions provided by the

manufacturer when using chemical solutions.

2. For safety, the tank CANNOT be filled with flammable, explosive, or highly-

volatile chemicals, such as gasoline, alcohol, phenylacetone, etc. DO NOT add

highly-corrosive liquid, such as caustic soda, hydrochloric acid, etc. (Keep the

machine dry. In order to avoid an electric shock, DO NOT operate the power

switch with wet hands.)

3. Operator should wear personal protective equipment such as protective clothing,

gloves, safety glasses, and masks.

4. This machine can only be operated by a person trained in the performance,

operation, and safety of the machine. Keep away from children.

Operation

1. Preparation: Plug into power outlet. Turn on the power switch to check that the

motor is running correctly, and then turn the power off. Add the desired solution

with the filter funnel (included). Tighten the tank lid.

2. Power on: Turn the power switch to (ON). Adjust the spray volume to the

appropriate requirements, then start to spray.

3. Power off: Raise the spray nozzle higher than the tank and turn the power switch

to (OFF). Keep the spray nozzle raised for about 2–3 seconds after you turn the

power off. This lets the remaining liquid in the pipe reflux into the tank and avoids

solution backing up in the pipe which may cause moisture damage to the motor.

Lastly, turn off the adjusting nut to prevent outflow when adding solution next time

the unit is used.

4. When the sprayer is in use, the high-speed gas flow will cause the sprayer and the

pipe to heat up. This is normal.

Usage Direction

1. The supply voltage should match the machine’s requirements. (110V/50Hz)

2. DO NOT fold or damage the pipe, and avoid metal and other sharp objects that

may puncture the pipe.

3. DO NOT turn the power switch on and off frequently, as this may damage the

switch and the motor. If you hear any abnormal sounds during usage, shut down

the unit immediately, cut off power, and contact professional personnel for repair. If

you cannot resolve the problem, please contact us directly (non-professionals are

strictly prohibited from disassembling & working on unit).

4. DO NOT use for an extended time under high humidity or in extreme heat or rain.

Excess humidity may cause internal corrosive damage.

5. When storing, keep the unit in a dry and cool place. DO NOT let children have

access to the machine.

6. Keep the machine dry. Operating the power switch when hands are wet may cause

electric shock.

7. When the machine tank is full with solution, be careful not to spill or dump any

solution out of the tank. Pay particular attention when transporting the unit.

8. After spraying, we recommend that you clean the machine with water. When

finished spraying, the sprayer should be cleaned and kept in a cool, dry place.

Avoid direct sunlight that may cause accelerated plastic aging.

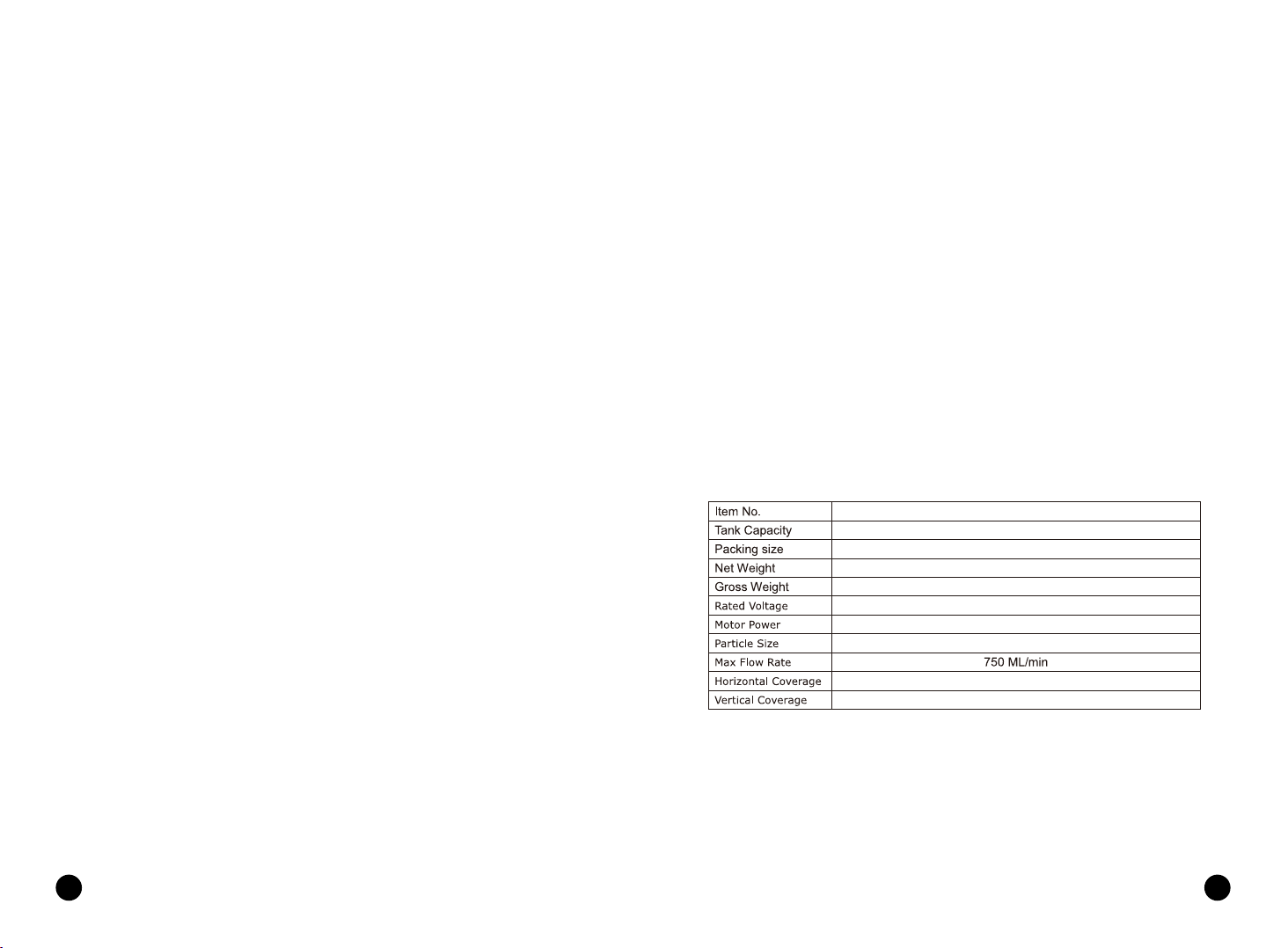

Technical Specifications

2.6 Gal (10L)

Z-DAS

18.5" x 7.5" x 18.9" (47 x 19 x 48 cm)

9 lbs (4.1 kgs)

10.8 lbs (4.9 kgs)

16.5 to 19.7 ft (5 to 6 meters)

5 to 6.5 ft (1.5 to 2 meters)

110V/50Hz

1400W

20–50 microns (variable)