Table of contents

The information herein is correct at the time of issue but may be subject to change without prior notice

1. EC/EU Declaration of Conformity .................................................................. 5

2. Safety .................................................................................................... 6

2.1. Important information ............................................................................. 6

2.2. Warning signs ..................................................................................... 6

3. Introduction ............................................................................................ 7

3.1. Introduction ........................................................................................ 7

3.2. Intended Use ...................................................................................... 7

3.3. Patents and Trademarks ......................................................................... 8

3.4. Reserved rights for design changes ............................................................ 8

3.5. Marking ............................................................................................ 8

3.6. ATEX/IECEx marking ............................................................................. 9

3.7. ATEX/IECEx temperature class and code ...................................................... 11

3.8. Quality system .................................................................................... 12

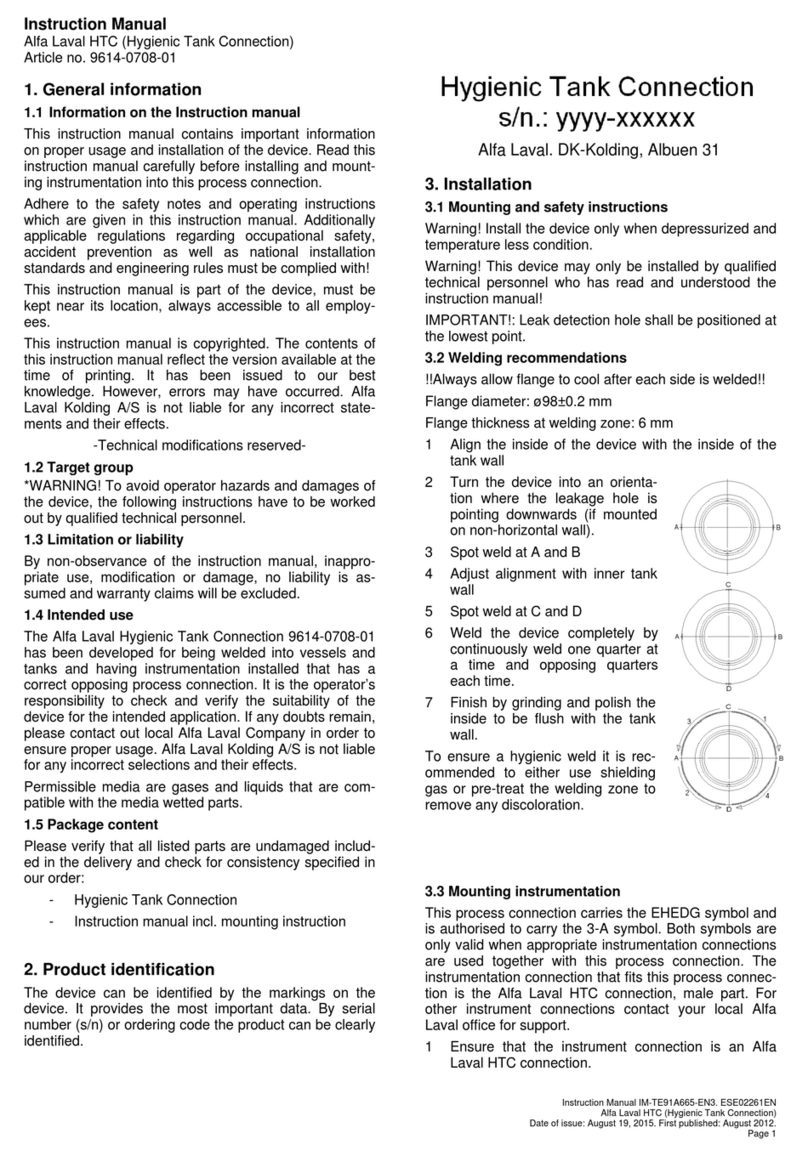

4. Installation .............................................................................................. 13

4.1. General description ............................................................................... 13

4.2. Functioning ........................................................................................ 14

4.3. Installation of Air Motor ........................................................................... 17

4.4. General safety and installation instructions ..................................................... 19

4.5. Specific conditions for safe use in accordance with ATEX/IECEx certification .............. 20

5. Operation ............................................................................................... 23

5.1. Normal operation ................................................................................. 23

5.2. Normal Operation of Air Motor .................................................................. 24

5.3. Safety Precautions ................................................................................ 25

6. Maintenance ........................................................................................... 26

6.1. Preventive Maintenance .......................................................................... 26

6.2. Reserved rights for design changes of Alfa Laval equipment used in validated processes 26

6.3. Preventive Maintenance of Air Motor ........................................................... 27

6.4. Service and repair of ATEX/IECEx certified machines ......................................... 28

6.5. Service and repair of machines ordered with Q-doc and with Q-doc + FAT-SAT .......... 29

6.6. Every 300 working hours ......................................................................... 30

6.7. Cleaner Head Unit - dismantling and reassembling ........................................... 31

6.8. Base Unit - Dismantling and Reassembling .................................................... 32

6.9. Air Motor Drive Unit - dismantling and reassemebling ........................................ 33

6.10.Rotacheck System ............................................................................... 34

7. Trouble shooting guide ............................................................................... 35

8. Technical data ......................................................................................... 36

9. Product programme .................................................................................. 40

9.1. Standard configurations .......................................................................... 40

9.2. Available add-ons ................................................................................. 42

9.3. Available add-ons for spare parts ............................................................... 43

9.4. Accessories ....................................................................................... 43

10. Parts drawings and lists, service kits and tools ................................................. 44

10.1.Toftejorg SaniJet 20, Air Driven (EPDM as standard) .......................................... 44

10.2.Toftejorg SaniJet 20 Air Driven improved surface finish (EPDM as standard) ............... 46

3