Table of Contents

1 Introduction . . . . . . . . . . . . . 5

1.1 Application . . . . . . . . . . . . . . . 6

1.2 Measuring system . . . . . . . . . . . . 7

1.3 Measuring principle . . . . . . . . . . . 8

1.4 Functional description . . . . . . . . . . 9

2 Installation . . . . . . . . . . . . . . 10

2.1 Probes . . . . . . . . . . . . . . . . 10

2.2 Silometer installation . . . . . . . . . . . 11

2.3 Transmitter wiring . . . . . . . . . . . . 13

2.4 Probe connection . . . . . . . . . . . . 15

2.5 Hardware configuration . . . . . . . . . . 17

2.6 Technical data: Silometer FMC 671 Z/676 Z

transmitter . . . . . . . . . . . . . . . 18

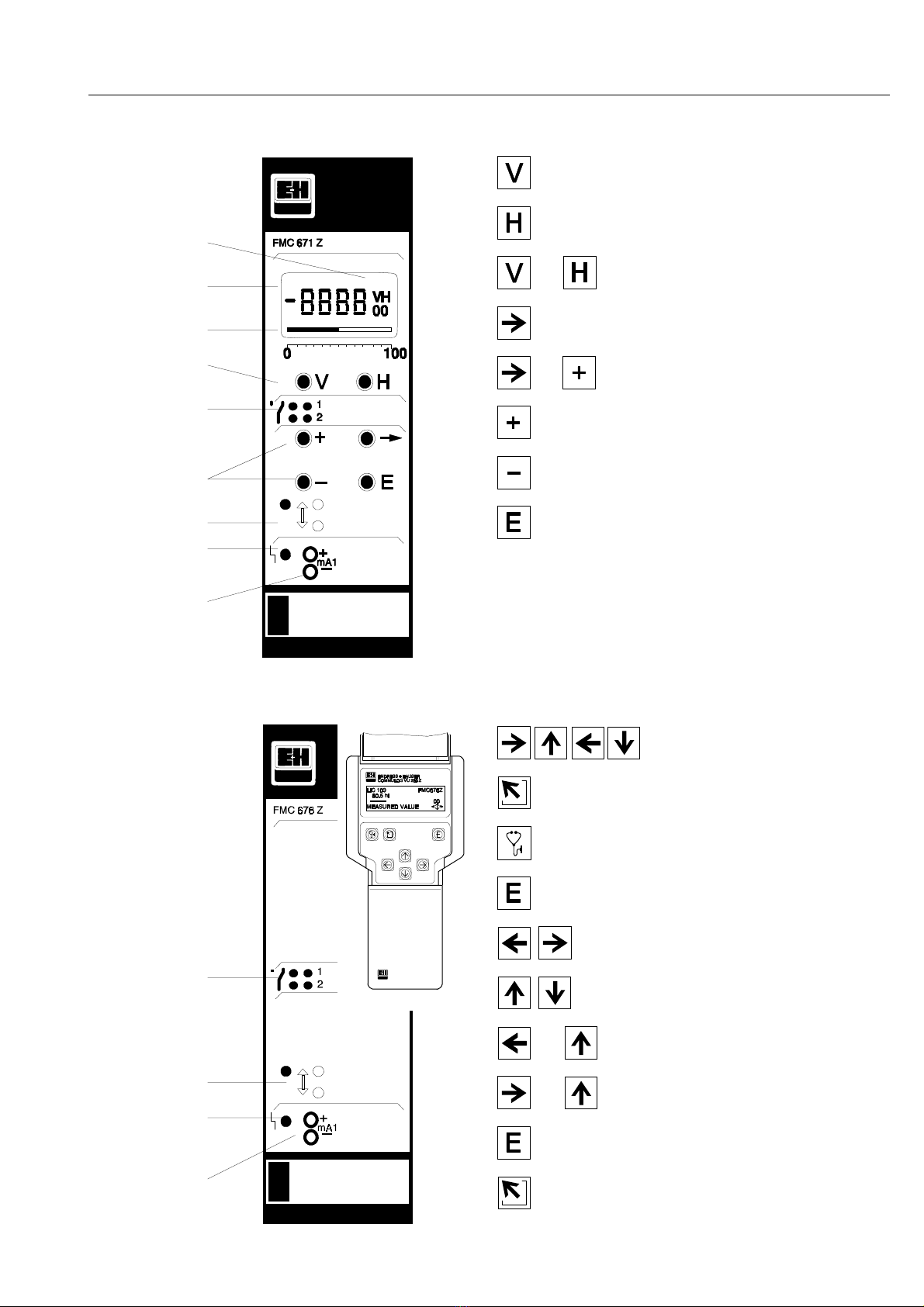

3 Operating elements . . . . . . . . . . 19

3.1 Commutec operating matrix . . . . . . . . 19

3.2 Operating elements: Silometer FMC 671 Z . . 20

3.3 Operating elements: Silometer FMC 676 Z . . 21

4 Calibration and Operation . . . . . . . 22

4.1 Commissioning of the transmitter . . . . . . 22

4.2 Empty/full calibration for level measurement . 23

4.3 Empty/full calibration for volume measurement 24

4.4 Level offset value . . . . . . . . . . . . 25

4.5 Measured value display . . . . . . . . . 26

4.6 Locking the parameter matrix . . . . . . . 26

5 Linearization . . . . . . . . . . . . . 27

5.1 Linearization for a horizontal cylindrical tank . 28

5.2 Linearization for a tank with conical outlet . . 29

5.3 Other modes . . . . . . . . . . . . . . 32

6 Analogue Outputs . . . . . . . . . . . 33

6.1 Configuration . . . . . . . . . . . . . . 34

7 Limit Switches . . . . . . . . . . . . 36

7.1 Relay settings . . . . . . . . . . . . . 37

7.2 Applications . . . . . . . . . . . . . . 38

8 Other Applications . . . . . . . . . . 41

8.1 »Dry calibration« for continuous level

measurement with Deltapilot probes . . . . 41

8.2 Level limit switching . . . . . . . . . . . 43

8.3 Continuous level measurement with separate

level limit detection . . . . . . . . . . . 46

8.4 Level measurement with automatic calibration

correction . . . . . . . . . . . . . . . 47

9 Trouble-Shooting . . . . . . . . . . . 50

9.1 Faults and warnings . . . . . . . . . . . 50

9.2 Simulation . . . . . . . . . . . . . . . 53

9.3 Exchanging transmitters or probes . . . . . 54

9.4 Repairs . . . . . . . . . . . . . . . . 55

10 Quick programming guide . . . . . . . 56

10.1 Level measurement with separate level switching,

capacitance probes . . . . . . . . . . . 56

10.2 Continuous volume measurement (linearization) 57

10.3 Level limit switching . . . . . . . . . . . 58

10.4 Level measurement with automatic calibration

correction: two capacitance probes . . . . 59

2

Silometer FMC 671 Z/676 Z Table of Contents