EN

8

vBefore operating the pressure tank unit, first make a visual check to ensure

there is no damage to the pressure tank unit (especially regarding power cable

and plug).

A damaged pressure tank unit must not be used.

vIn case of damage, please have the pressure tank unit checked by our

GARDENA Service Centre or by an authorised electrician.

Protect the pump from rain. Do not use the pressure tank unit in a wet or moist

area.

In order to avoid dry-running of the pressure tank unit, take care that the end of

the suction hose is always submerged into the liquid.

The pressure tank unit must not be run dry nor with the stopcock in the suction

pipework closed.

vBefore each operation, fill the pressure tank unit to overflowing with approx.

2to 3 l of the liquid to be pumped!

Sand and other abrasive substances in the liquid cause increased wear and

reduce the pump’s output.

When using the pump for domestic water supply, please adhere to the local

water and sewerage regulations. In addition observe the regulations of DIN 1988.

vIf necessary contact your local water authority.

DANGER! This product makes an electromagnetic field while it operates. This

field may under some conditions interfere with active or passive medical implants.

To decrease the risk of conditions that can possibly injure or kill, we recommend

persons with medical implants to speak with their physician and the medical

implant manufacturer before you operate the product.

DANGER! Small parts can be easily swallowed. There is also a risk that the poly-

bag can suffocate toddlers. Keep toddlers away when you assemble the product.

2. INITIAL OPERATION

Installing the Pressure Tank Unit:

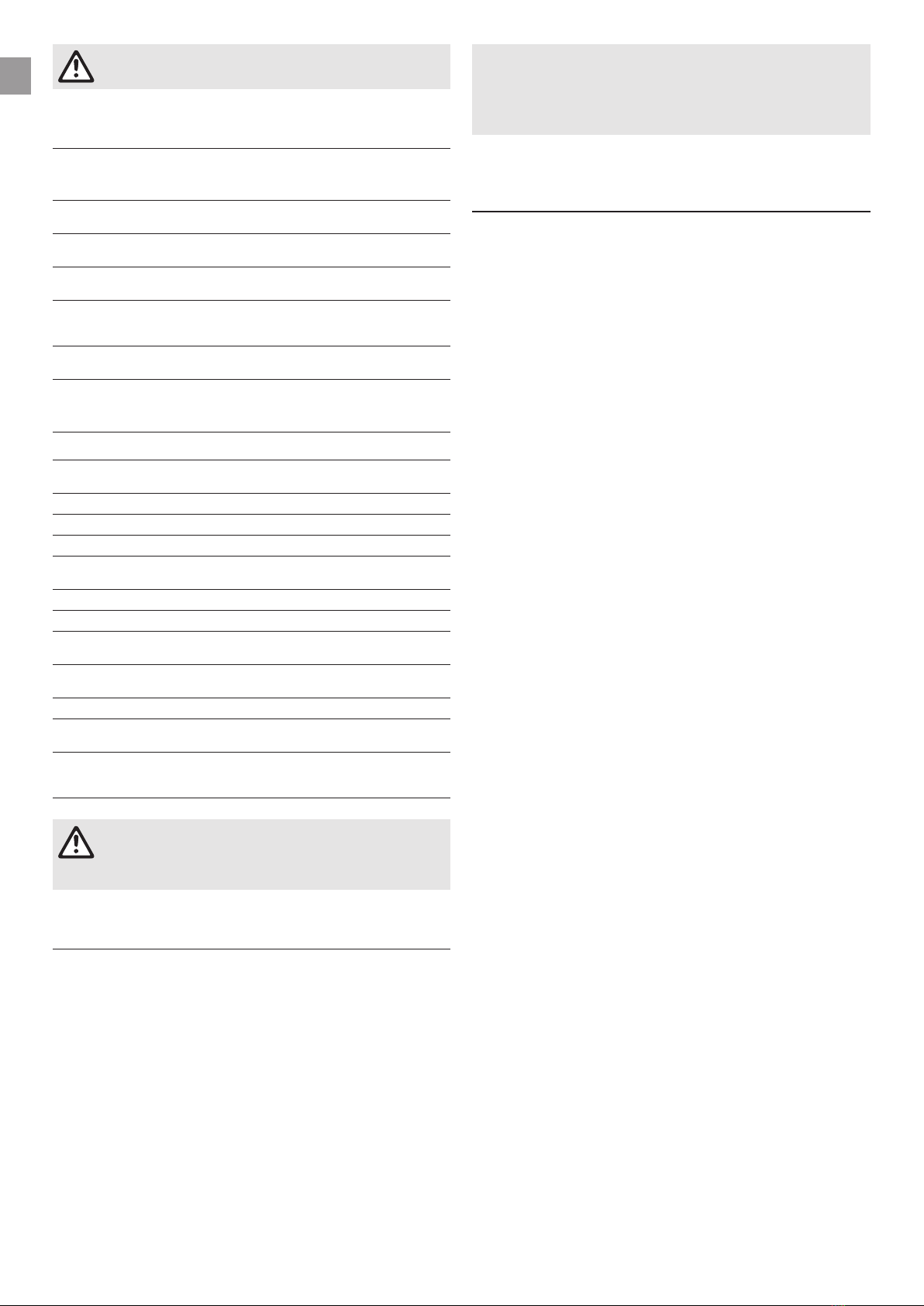

The installation position must be firm and dry, and permit a secure

mounting for the pressure tank unit.

vInstall the Pressure Tank Unit at a safe distance from the pumping

medium.

The pump must be installed in a location with low air humidity and suffi-

cient ventilation in the area of the ventilation slots. It must be at a distance

of at least 5 cm from the walls. No dirt contamination (e.g. sand or earth)

may be sucked in through the ventilation slots.

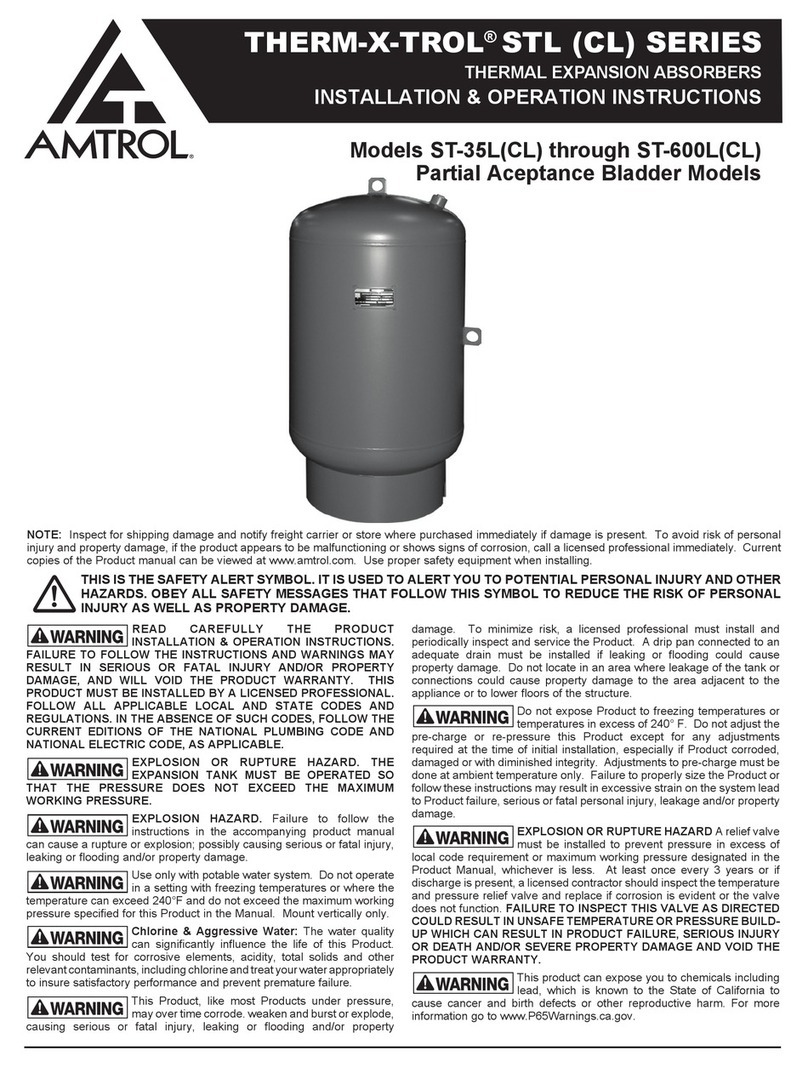

Fixed installation of the Pressure Tank Unit [Fig. I1]:

vThe Pressure Tank Unit can be screwed with all 4 feet 2onto asolid

surface 1.

Alternatively, spring mounted feet (Art. 1753-00.901.00) for low vibration

and quiet running are available as accessories via the GARDENA Service.

Install the pressure tank unit so that there is room to place asuitably sized

drainage tray under the drain screw 3to allow the unit or system to be

drained.

If possible, install the unit higher than the surface of the water to be

pumped. If this is not possible, install a vacuum-resistant valve between

the unit and the suction hose, for example for cleaning the integrated filter.

If the pump is permanently installed indoors for domestic water supply,

the Pressure Tank Unit should not be connected to the domestic water

pipework with rigid pipes but with flexible tubing, to reduce noise and to

avoid damage to the pump caused by pressure blows.

If the system is being installed permanently, please fit suitable valves on

both the intake and delivery sides. This is important e.g. for maintenance

and cleaning work or if the system is being shut down.

The connection pieces on the intake and delivery sides may only

be tightened by hand.

Connect the hose to the suction side [Fig. I2]:

A vacuum-tight suction hose must be used e.g.:

– GARDENA Suction Unit Art. no. 1411/1418/1412 or

– GARDENA Bore Hole Suction Hose Art. no. 1729.

Do not use any water hose snap connection system components on the

intake side!

v Connect the suction hose 5with the intake side

connection 6of the pump.

Connect the suction hoses 5without a threaded connector via a connec-

tion piece (e.g. Art. no. 1723/1724) 4with the intake side connection

and screw in place so that they are airtight.

To reduce the pump repriming time, we recommend using a suction hose

with backflow preventer, which prevents the suction hose emptying auto-

matically when the Pressure Tank Unit is switched off.

For suction heights exceeding 4 m also secure the suction hose 5

(e.g. by fastening it to a wooden post) to relieve the pump of the weight

of the suction hose.

If very fine dirt is present in the pumping medium, we recommend the

use of a GARDENA Pump Preliminary Filter Art. no. 1730/1731.

Connect hose to the output side [Fig. I3]:

Note:

Use pressure-tight GARDENA hoses, 19 mm (3/4") in diameter, in

connection with the GARDENA Quick-Release Threaded Connector with

33.3 mm (G1) internal thread, Art. no. 7109, and the GARDENA Suction

and High Pressure Connector, Art. no. 7120, for 19 mm (3/4") hoses

and a GARDENA Hose Clip, Art. no. 7192.

Under no circumstances use these hoses on the suction side.

1. Connect the delivery hose 7with one of the three connections 8

to the delivery side.

2. Unused pressure connections must be closed off with an end

cap 9.

Tip: With fixed piping, only assign max. 2 connections 8so that the air

can be bled off via the end cap 9of the third connection. Permanent

pipes must be laid at an ascending angle in order to allow the water to

flow back into the pump on the pressure side.

3. OPERATION

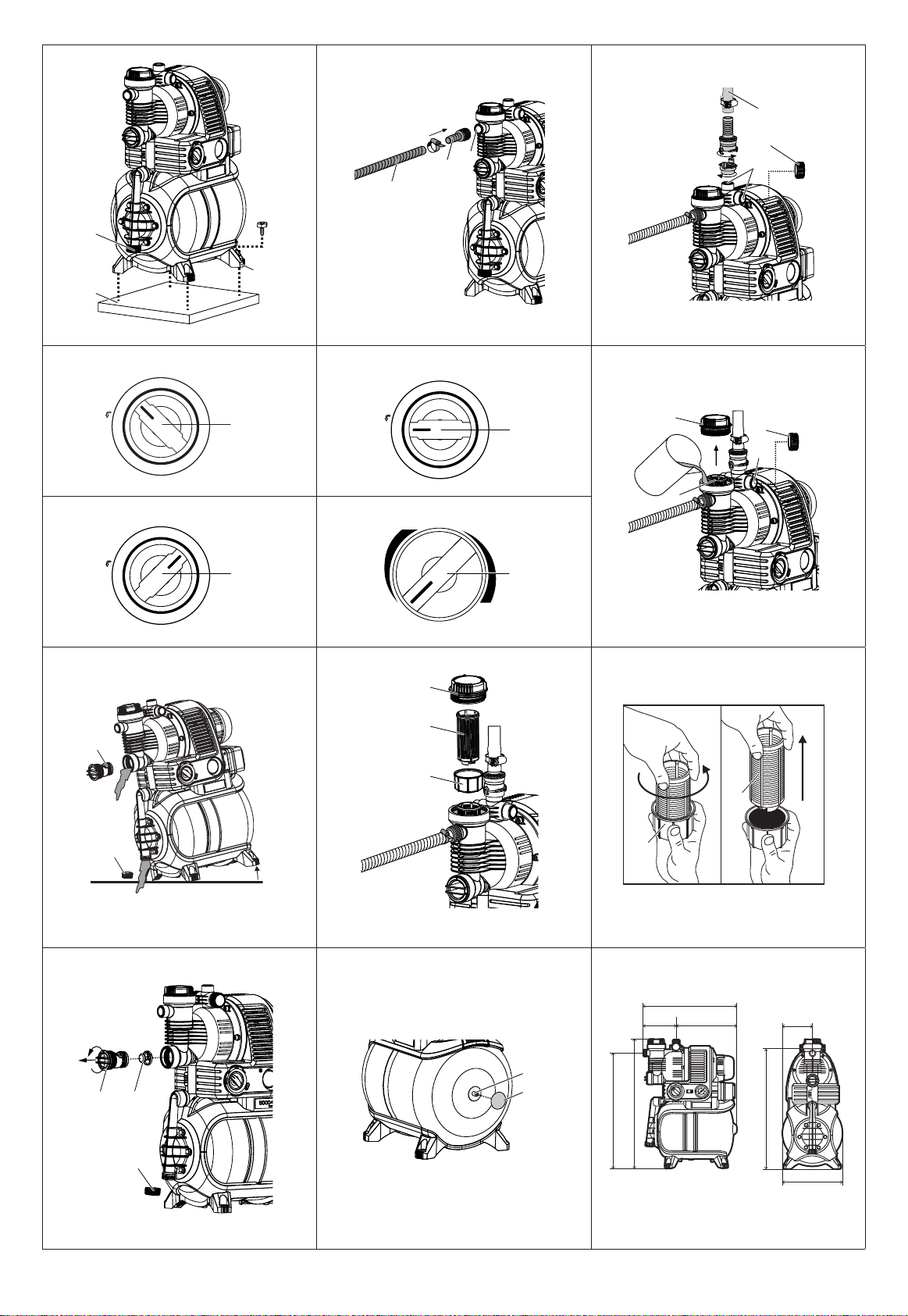

Starting the Pressure Tank Unit [Fig. O1/ O2/ O3]:

DANGER! Electric shock!

v Before filling the pump, unplug the equipment from the

mains.

CAUTION!

vFill the pump to the overflow (approx. 2 to 3 l) with water each

time before the pump is switched on.

1. Turn the rotary switch qto OFF.

2. Unscrew the cover 0of the filter chamber by hand.

3. Open an end cap 9on the delivery side to bleed off the air.

4. Open any valves in the delivery line (watering accessories, water stop,

etc.) and drain off any residual water in the delivery hose so that the air

can escape during filling and priming.

5. Slowly pour pumping medium (approx. 2 to 3 l) through the filler neck

euntil water emerges from the open delivery side connection 8.

6. Screw the filter chamber cover 0closed again, turning by hand until it

stops.

7. Close the end cap 9on the delivery side which had been ope-

ned to bleed off the air.

8. Insert the mains plug into a 230 V mains socket.

9. Turn the rotary switch qto START.The pump will start immedi-

ately!

Once priming has taken place, the rotary switch switches automatically to

AUTO and the dry-running safety is activated. Once the maximum pressu-

re is reached the pump will switch off automatically. When the pressure falls

below the minimum value due to water being drawn off, the pump will

switch on again automatically.

CAUTION!

If the pump has not started priming after 10 min.,

turn the rotary switch qto OFF.

vSee 6. TROUBLESHOOTING “The pump sucks nothing up”.

The maximum self-priming head of 8 m is only achieved if the pump is fil-

led until it overflows from the filler connection eand the delivery hose is

held high enough during self-priming so that no water can escape from

the pump via the delivery hose. It is not necessary to hold up the delivery

hose if filled suction hoses with backflow preventer are used.

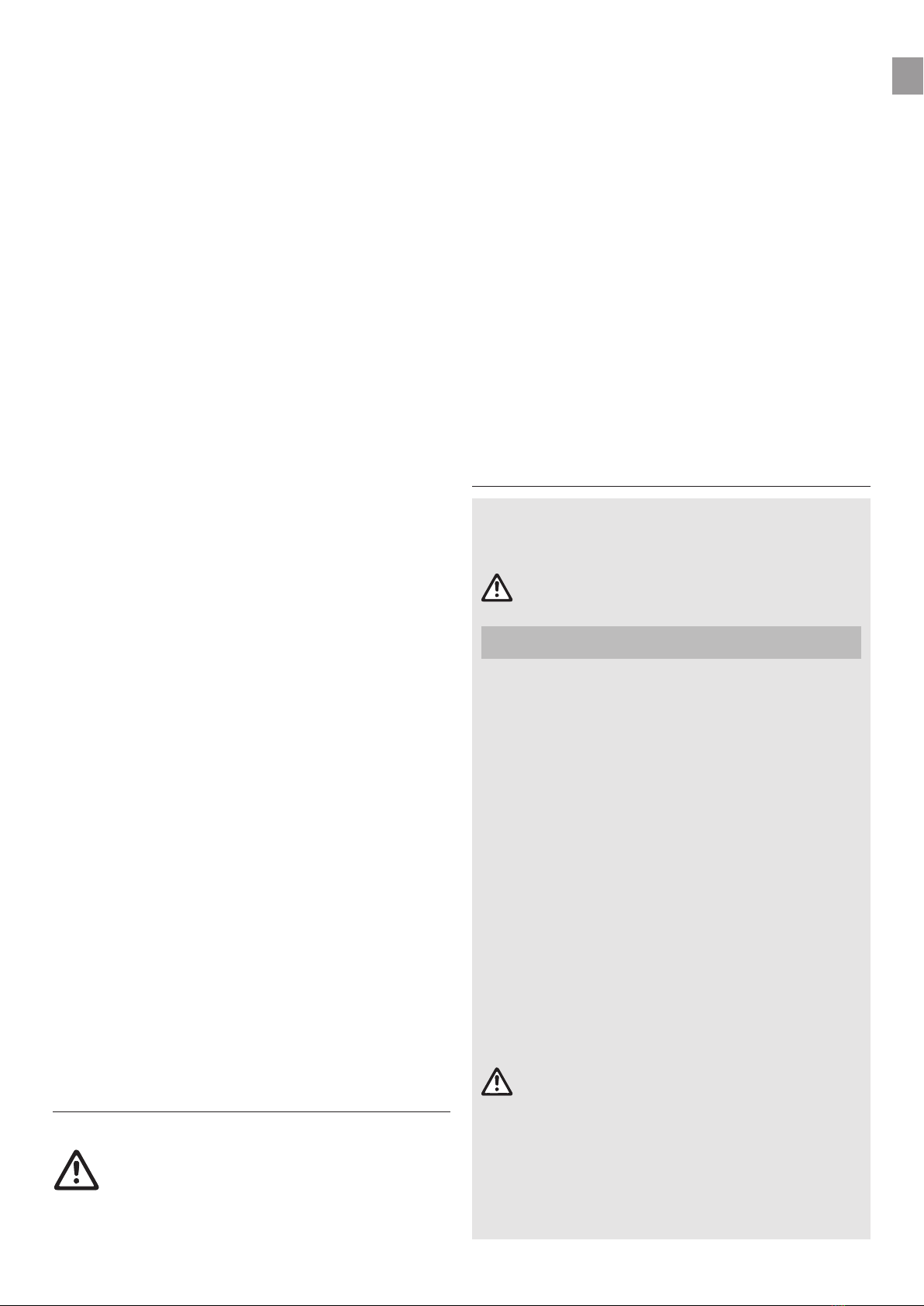

Manual mode (Man.) [Fig. O4]:

When conveying very large water quantities at very low pressure, the

pump switches off in Auto mode for safety reasons. However, should this

operation be required, the pump can be operated in manual mode

(Man.)

Warning: This deactivates the dry-running safety.

v Pull the rotary switch qand turn to Man.

The pump will start.