1 Introduction

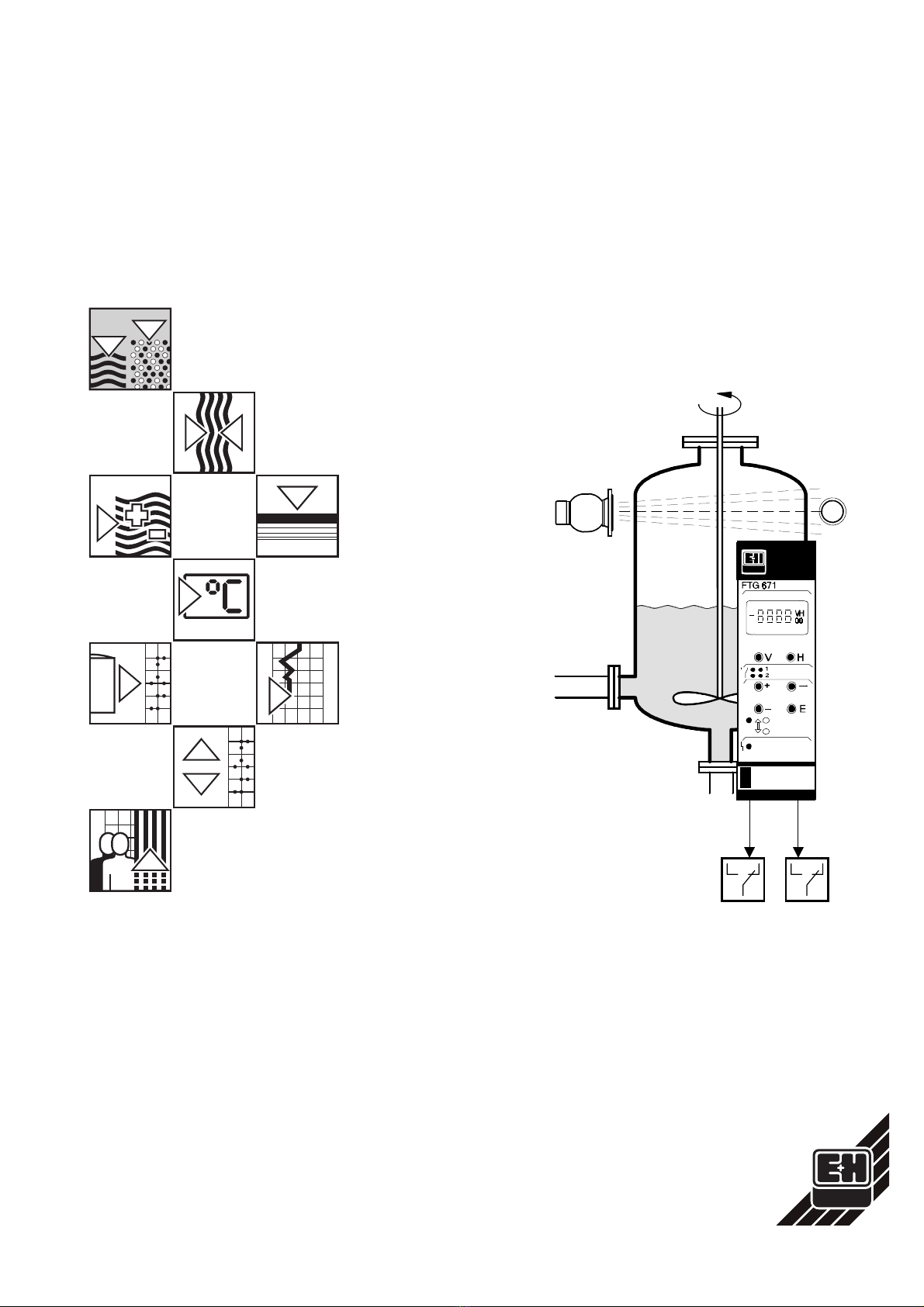

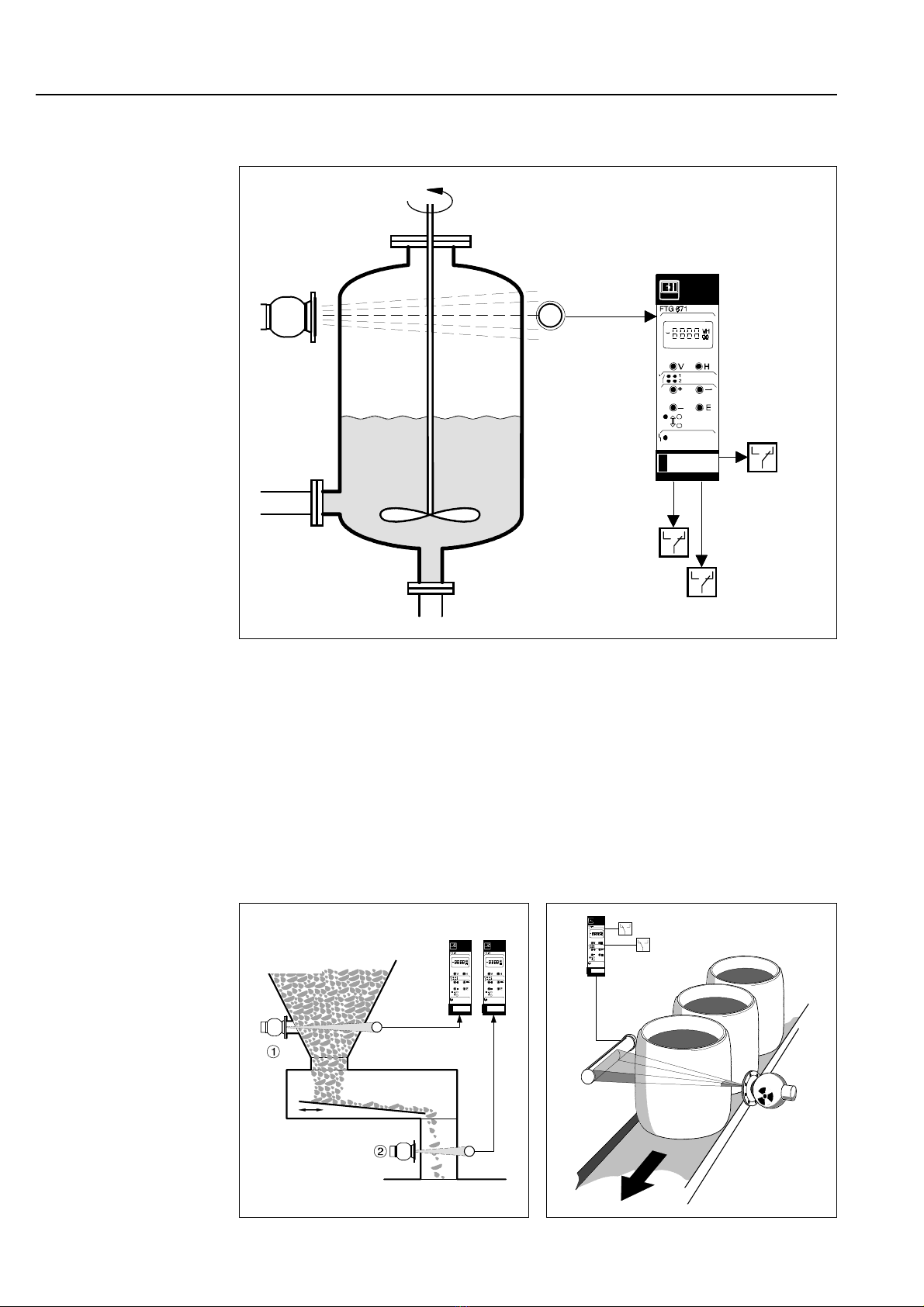

Short instructionsThe front cover contains short instructions for the standard set-up, level limit detection

with two limit relays, using the FTG 671, DG 57 and Cs 137 source.

In this manualUsers unfamiliar with the Gammapilot FTG 671 must read the operating instructions

which are structured as follows:

•Chapter 1: Introduction;

contains general information including application, measurement

principle and functional description.

•Chapter 2: Installation

contains instructions on the installation of the radioactive source,

Geiger-Müller and scintillation counters, Gammapilot FTG card,

hardware configuration, connection diagrams and technical data

for the plug-in card.

•Chapter 3: Controls;

describes operation with the front panel keys, Commulog VU 260 Z

and ZA 67…gateways.

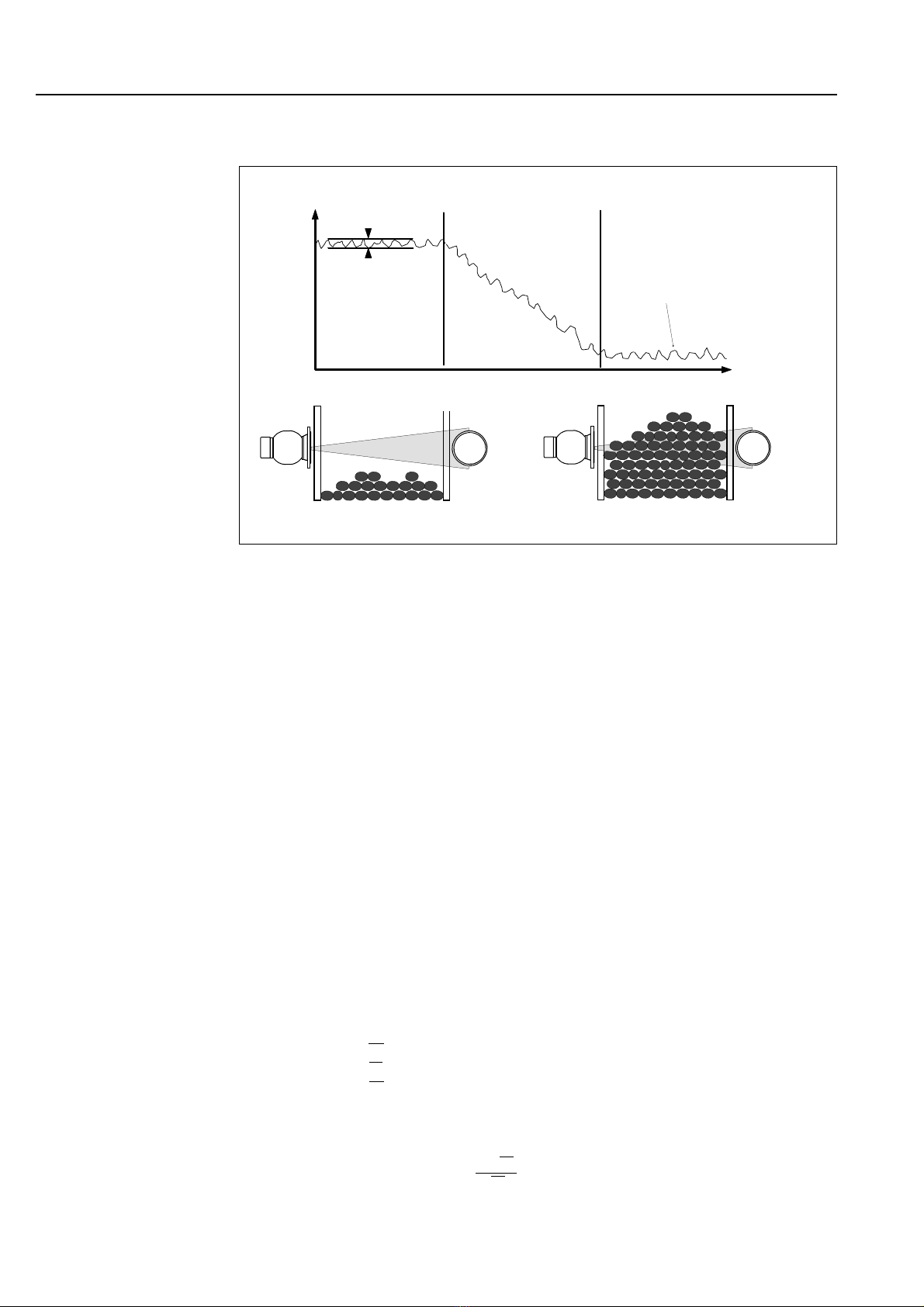

•Chapter 4: Calibration and Operation;

tells you how to commission and operate the Gammapilot for level

limit detection.

•Chapter 5: Limit Switches;

describes in detail the setting of the relays for fail-safe or

acknowleged operation.

•Chapter 6: Trouble-Shooting;

contains a description of the self-checking system with error

messages, the simulation feature as well as instructions for

configuration on replacement of the transmitter, source or detector.

•Index lists key words to help you find information quickly.

Further documentationIn addition to this manual, the following publications provide information on configuration

of the Gammapilot FTG 671.

•BA 028 Commulog VU 260 Z handheld terminal

•BA 054 ZA 672 Modbus Gateway

•BA 073 ZA 673 Profibus Gateway

•BA 085 ZA 674 FIP Gateway

The installation of the radioactive source and detector is described in the documentation

accompanying these articles as well as briefly in Chapter 2.

•TI 264F Source Container QG 020/100

•TI 346F Source Container QG 2000

•TI 180F Scintillation Detectors DG 57

•TI 197F Geiger-Müller counters DG 17 and DG 27

When installing detectors in explosion hazardous areas the instructions included in the

accompanying certification must also be observed.

Gammapilot FTG 671 Chapter 1: Introduction

5