Alfa Laval Mini ECO

Installation, service and operating instruction

4

7.5 OTC heating curve ................................................................................................................................. 29

7.6 Parallel adjustment of heating curve...................................................................................................... 29

7.7 Operating mode Auto ............................................................................................................................. 30

7.7.1 The Built-in Heating Program............................................................................................................ 30

7.7.2 Reviewing the Heating Program ....................................................................................................... 30

7.7.3 Temperature Override....................................................................................................................... 30

7.7.4 Disabling/enabling time periods ........................................................................................................ 30

7.7.5 Modifying the heating program.......................................................................................................... 31

8Activation of installer parameters CM737.........................................................................32

8.1 Entering the installer set-up mode ......................................................................................................... 32

8.2 Category 1 parameters: Control panel settings...................................................................................... 33

8.3 Category 2 parameters: ECO-functions................................................................................................. 33

8.4 Category 3 parameters: Setting and displaying sensor values.............................................................. 34

8.5 Category 4 parameters: Heating actuator settings................................................................................. 34

8.6 Category 5: Fault History........................................................................................................................ 34

9Troubleshooting the control panel CM737........................................................................35

9.1 Fault codes on the control panel CM737 ............................................................................................... 36

10 Pump settings and pump performance.............................................................................37

10.1 Performance view................................................................................................................................... 37

10.1.1 Operation status................................................................................................................................ 37

10.1.2 Alarm status ...................................................................................................................................... 37

10.2 Setting view............................................................................................................................................ 38

10.3 Toggling the settings of UPM3............................................................................................................... 38

10.4 Key lock function .................................................................................................................................... 38

10.5 Pump curve proportional pressure mode 2, PP2................................................................................... 39

10.6 Fault finding pump.................................................................................................................................. 40

11 Electrical connections........................................................................................................41

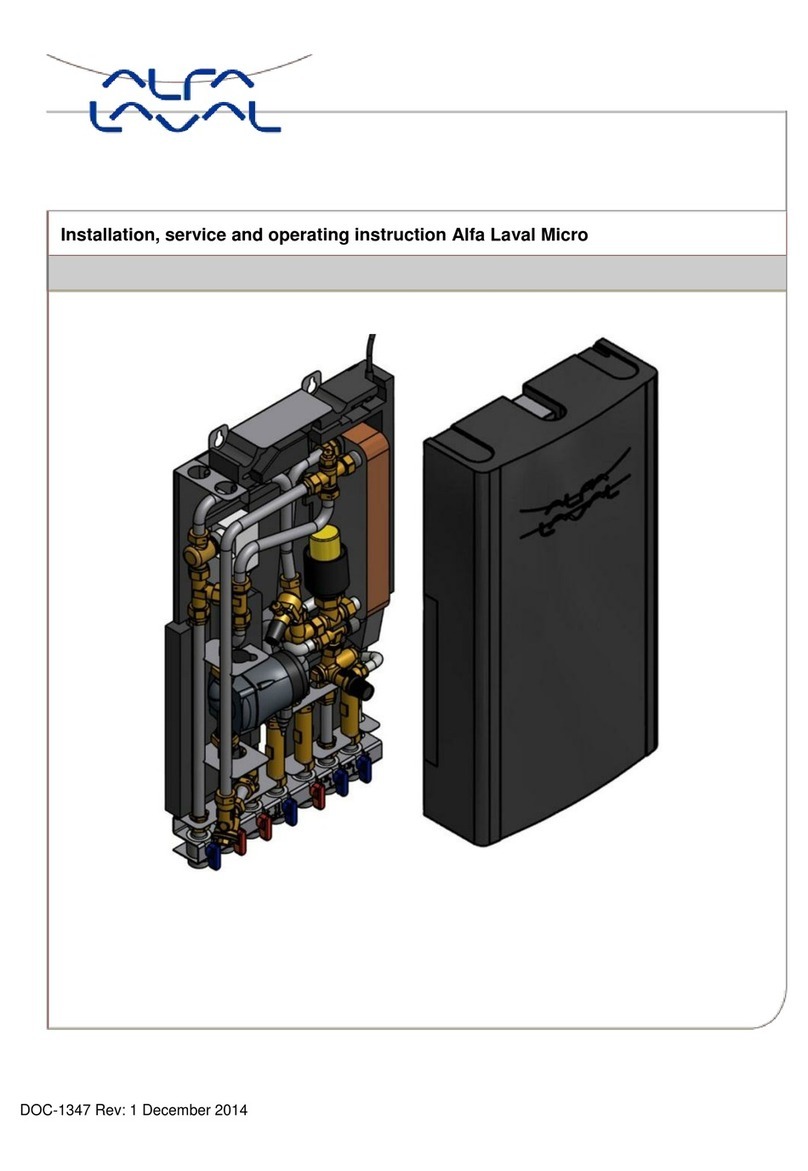

12 Schematic diagram, main components.............................................................................42

12.1 Mini ECO F1........................................................................................................................................... 42

12.2 Mini ECO F2........................................................................................................................................... 42

12.3 Mini ECO F3........................................................................................................................................... 43

12.4 Mini ECO F4........................................................................................................................................... 43

12.5 Mini ECO F5........................................................................................................................................... 44

13 Service instructions............................................................................................................45

13.1 Tap water service instructions................................................................................................................ 45

13.1.1 Tap water temperature too low ......................................................................................................... 45

13.1.2 Tap water temperature too high........................................................................................................ 46

13.1.3 Hot water temperature unstable or too low....................................................................................... 46

13.2 Heating system service instructions....................................................................................................... 46

13.2.1 Heating system temperature too high or too low .............................................................................. 46

13.2.2 No heating......................................................................................................................................... 48

13.2.3 Heating temperature unstable........................................................................................................... 49

13.2.4 Disturbing noise from the circulation pump or the radiator system................................................... 50

13.2.5 Heating system often needs topping up............................................................................................ 50

14 Service actions for the installer.........................................................................................51

14.1 Check the function of the valve for hot water......................................................................................... 51

14.2 Check the function of the heating actuator and valve............................................................................ 52

14.3 Check the volume take-up and pressure equalizing of the expansion vessel ....................................... 52

15 Maintenance and repairs....................................................................................................53

15.1 Cleaning the heating media filter............................................................................................................ 53

15.2 Cleaning the heating circuit filter............................................................................................................ 53

15.3 Change pump components or the complete pump................................................................................ 54

15.4 Change the hot water actuator and heat exchanger.............................................................................. 55

15.5 Change the hot water valve.................................................................................................................... 55

15.6 Change the heating actuator.................................................................................................................. 56

15.7 Change the heating valve....................................................................................................................... 56

15.8 Change the heating circuit supply temperature sensor.......................................................................... 57