3.1 Set upgun asfollows

•Connect Duo-hose (twinhose for atomising air and fluid) to material pressure tankor other

means of feeding fluid and to compressor.

Translucent part ofhose :for fluid(gun connection “M”)

Blue part ofhose :for atomising air (gun connection “AIR”)

•Setatomising air pressure to required spraydroplet sizes byreducing valve (notpartof the

spraygun).

•Setmaterial pressure to required material outletand spraydropletsizes bya2. reducing valve

(notpart of the spraygun).

IMPORTANT!

Fluid outputcan be regulated individually,applyneedle regulator (24.1) and counter nut

(23.1) for quantityoffluid flow.

Turning needle regulator right :lessfluid flow

Turning needle regulator left : more fluid flow

When you are sureoffluidflowopen trigger (19.1). Sprayoperation starts. You willnotice that you

receive so called “pre-air” prior to opening fluid flowwhen pulling the trigger.When releasing trigger you

still have “purging-air” after needle has closed nozzle and fluid flowwasstopped.This preventsthat

fluid formsdrop instead ofthe desired atomisation.

IMPORTANT!

After sprayoperation give a shortperiod of time “pre-air” respectively“purging-air”. This

preventsthat material blocked the nozzle.

3.2 OperatingInformation

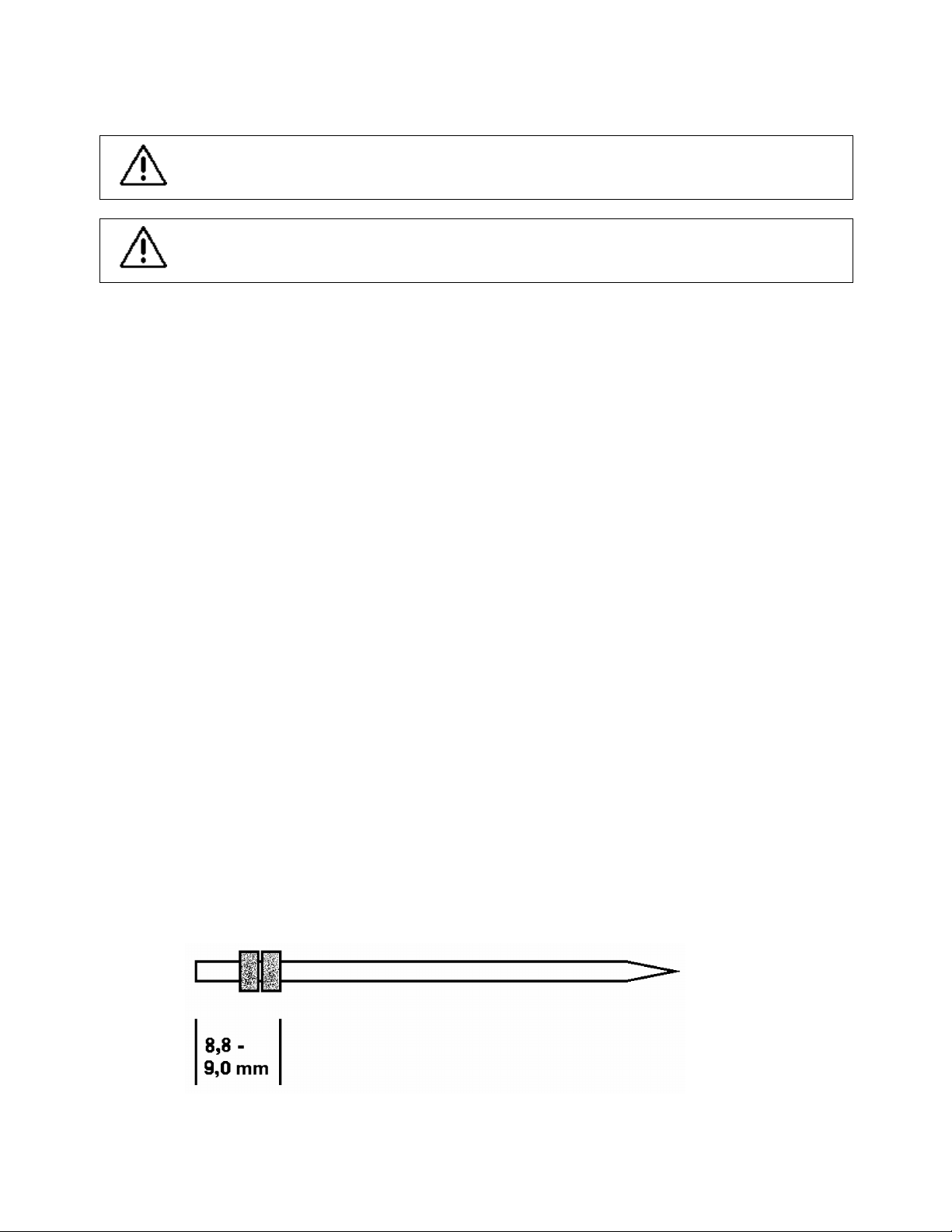

•Depending on viscosityoffluid nozzlebores are availablein 0,2 ;0,3;0,5;0,8and 1,0mm ∅

(onlyone size ofair cap isrequired).

•Standard version of gun has flatspraypattern aircap with approx. 60°sprayangle (3.1.1).If

round sprayis required, justreplace air cap bya round sprayair cap (3.1.2).

•Flatsprayaircap can be positioned for horizontal, vertical oranyin between position ofjet. For

special air capswith other sprayangels please contactthe manufacturer.

CAUTION!

Never pointthe spraygun againstpersons.Wearing eye protecting isstrongly

recommended.Sprayingprocedures cause noises depending on the used pressure. If

necessary,wearing of ear protection is recommended.

WARNING!

Danger caused bycombustible and noxious spraying material.Safetyinstructionson fluid

can and material data of fluid manufacturer mustdefinitelybe observed.

Don´tsmokewhen spraying paintsor solvents which have combustible properties.Allelectrical

installationswithin the spraying area mustbe explosion proof.Observe working safetyregulations in

respectof protective clothing (masks, clothing, ear protection,etc.).