Setting up your pedals

So you’ve just unboxed your new set of pedals, right? Let’s help you set them up, so you can

get racing as soon as possible.

Mounting your pedals to a rig

Notice: it’s better to adjust your pedals before you attach them to your rig. Some parts are

better accessible in that case.

If you’re using our base plate and heel rest combo, follow this part of the manual, where we’ll

show you how to put everything together. If you plan to attach our pedals to your rig without

our base plate, that’s fine, but you’ll have to figure it out on your own.

Fix your base plate to a rig

Notice: If you’re mounting the base plate against a flat surface, you’ll want to use some

washers to lift up the base plate, so there is room for bolts that hold the pedals themselves.

The first step is to fix the base plate to your rig. There are 10 countersunk holes on the base

plate, all of which can be used to screw the base plate down to your rig’s aluminum profiles

using the included countersunk M8 bolts.

Mount your pedals to the base plate

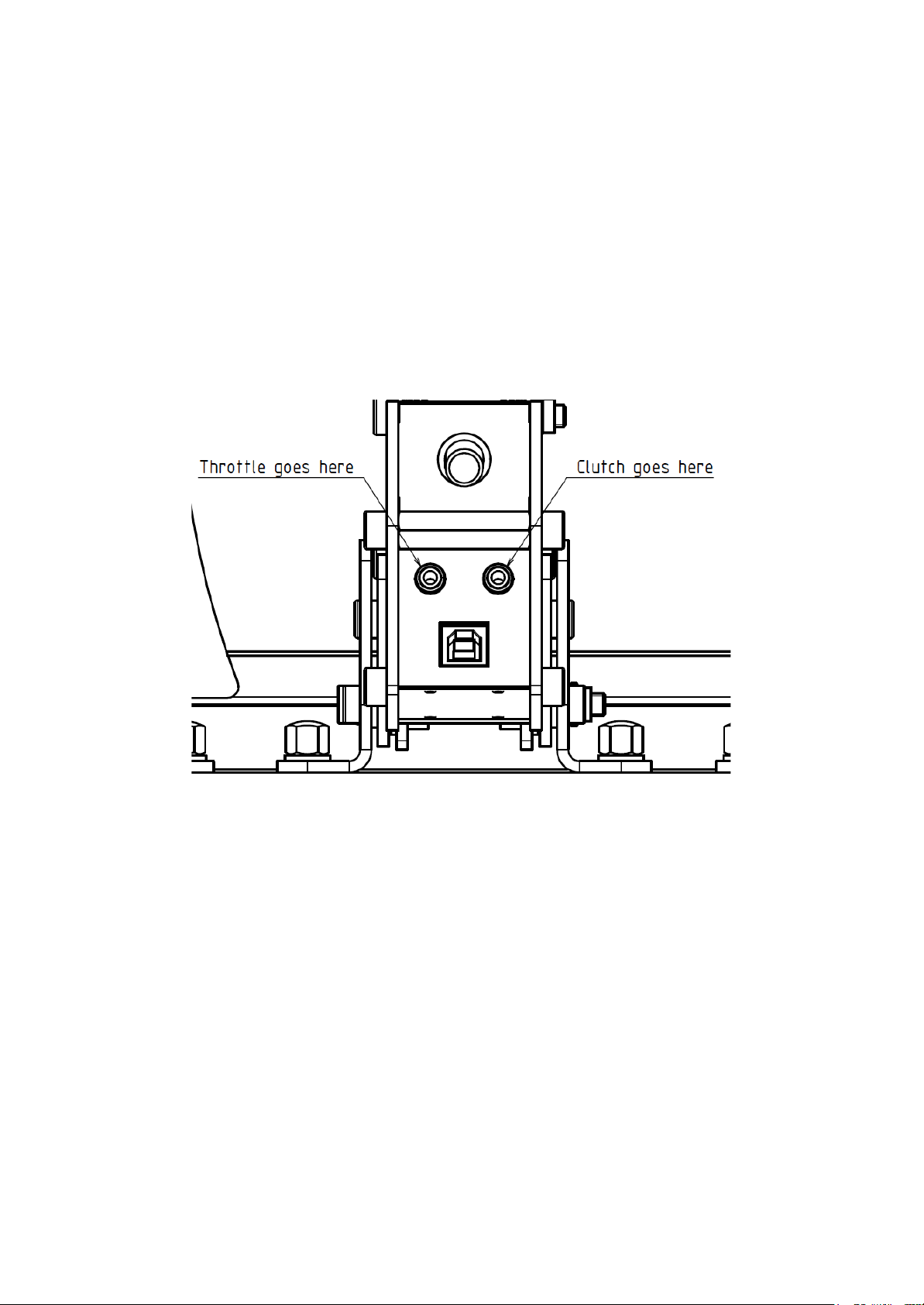

After fixing the base plate, you are ready to mount your pedals. Line up your pedals with the

grooves and attach the pedal with four pairs of a hex head M6 bolt and an acorn nut, as

seen in the figures below. Position the pedal to your liking before you tighten everything.