ALF-13131-E-02 All-Flo4

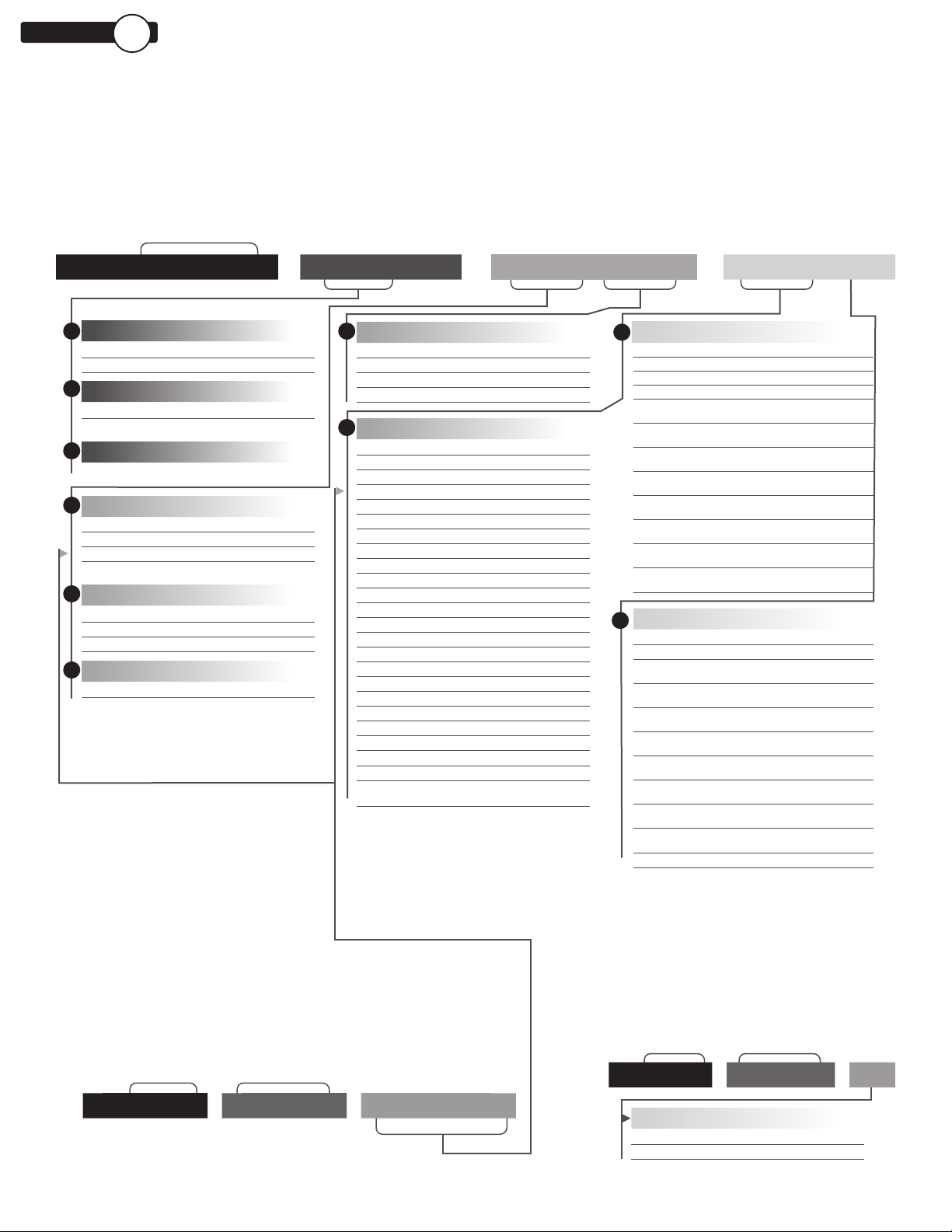

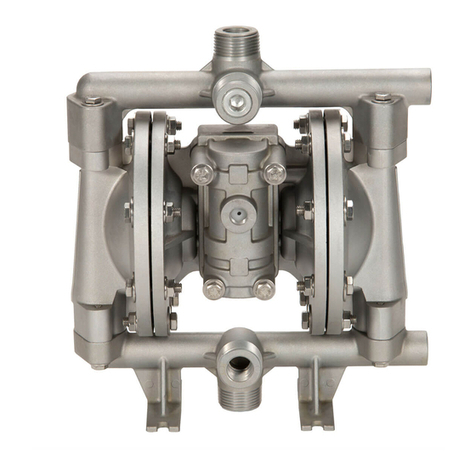

MODEL DESIGNATION MATRIX - ALUMINUM

SECTION 2

PRODUCT SERIES

FLUID CONNECTION TYPE

LIQUID SECTION

DIAPHRAGM

VALVE

VALVE SEAT/

BACKUP

O-RINGS

SPECIAL (OTHER)

PORTING

AIR SECTION

SPECIAL (HARDWARE,

MUFFLER, LUG)

S 0 5 0 -1 2 3- 4 5 6 7 - 8 9 10

FLUID CONNECTION TYPE

N = NPT

B = BSP

AIR SECTION

A = Aluminum

P = Polypropylene (Glass Filled)

LIQUID SECTION

A = Aluminum

DIAPHRAGMS

G = Geolast®

S = Santoprene®

T = PTFE with Santoprene® Backup

V = FKM

VALVE

N = Buna–N Max-Pass

TM

E = EPDM Max-Pass

TM

V = FKM Max-Pass

TM

VALVE SEAT/BACKUP

A = Aluminum

O-RINGS

N = Buna-N

E = EPFM

T = PTFE

V = FKM

PORTING

S = Standard (Suction Right / Discharge Right)

T = Suction Right / Discharge Left

X = Suction Left / Discharge Right

Y = Suction Left / Discharge Left

A = Suction Center Front / Discharge Center Front

B = Suction Center Front / Discharge Center Rear

D = Suction Center Front / Discharge Right

E = Suction Center Front / Discharge Left

F = Suction Center Rear / Discharge Center Front

G = Suction Center Rear / Discharge Center Rear

I = Suction Center Rear / Discharge Right

J = Suction Center Rear / Discharge Left

K = Suction Bottom / Discharge Center Front

L = Suction Bottom / Discharge Center Rear

N = Suction Bottom / Discharge Right

O = Suction Bottom / Discharge Left

P = Suction Right / Discharge Center Front

Q = Suction Right / Discharge Center Rear

U = Suction Left / Discharge Center Front

V = Suction Left / Discharge Center Rear

1 = Dual Suction / Single Discharge

2 = Dual Suction / Dual Discharge

3 = Single Suction / Dual Discharge

4 = All Ports Open (Standard ports will be left

un-plugged)

SPECIAL OPTION (HARDWARE, MUFFLER, LUG)

3 = Standard (Zinc Plated Steel Hardware, Plastic Muffler)

4 = Zinc Plated Steel Hardware, Metal Muffler

7= Stainless Steel Hardware, Plastic Muffler

8 = Stainless Steel Hardware, Metal Muffler

B = PTFE Coated Stainless Steel Hardware,

Plastic Muffler

C = PTFE Coated Stainless Steel Hardware,

Metal Muffler

D = Zinc Plated Steel Hardware, Plastic Muffler,

Grounding Lug Installed

E = Zinc Plated Steel Hardware, Metal Muffler,

Grounding Lug Installed

F = Stainless Steel Hardware, Plastic Muffler,

Grounding Lug Installed

G = Stainless Steel Hardware, Metal Muffler,

Grounding Lug Installed

H = PTFE Coated Stainless Steel Hardware,

Plastic Muffler, Grounding Lug Installed

I= PTFE Coated Stainless Steel Hardware, Metal Muf-

fler, Grounding Lug Installed

SPECIAL OPTION (OTHER)

0 = Standard (None)

1 = Cycle Counter Valve

2 = Solenoid Adaptor Valve 110/50 Volt AC,

120/60 Volt AC, DIN 43650B Connector

3 = Solenoid Adaptor Valve 110/50 Volt AC,

120/60 Volt AC Explosion Proof

4 = Solenoid Adaptor Valve 220/50 Volt AC,

240/60 Volt AC, 12 Volt DC, DIN 43650B Connector

5 = Solenoid Adaptor Valve 220/50 Volt AC,

240/60 Volt AC, 12 Volt DC Explosion Proof

6 = Solenoid Adaptor Valve 220/50 Volt AC,

240/60 Volt AC, 125 Volt DC, DIN 43650B Connector

7 = Solenoid Adaptor Valve 220/50 Volt AC,

240/60 Volt AC, 125 Volt DC Explosion Proof

8 = Solenoid Adaptor Valve 24 Volt DC, DIN 43650B

Connector

9 = Solenoid Adaptor Valve 24 Volt DC,

Explosion Proof

A = Grease Free (No Lubrication Assembly)

SIZE

WET END REPAIR KIT

Wet end kits are available and

consist of 2 diaphragms, (back-up

diaphragms if required), 4 Max-

Pass

TM

valves and 4 seat O-rings.

See matrix below.

1

2

7

8

9

10

AIR SECTION

A = Aluminum

P = Polypropylene (Glass Filled)

Bold indicates recommended options

AIR END REPAIR KIT

Air end repair kit contains pilot

sleeve assembly and main air valve.

DIAPHRAGM

O-RINGS

SWE-050-45X7

PRODUCT

SERIES

WET END

REPAIR KIT

PUMP SIZE

MATERIAL

SAK-050-2

PRODUCT

SERIES

PUMP SIZE

AIR END

REPAIR KIT

3

4

5

6

VALVE

* Solenoid Adaptor Valves only available on select pump models with polypropylene intermediate