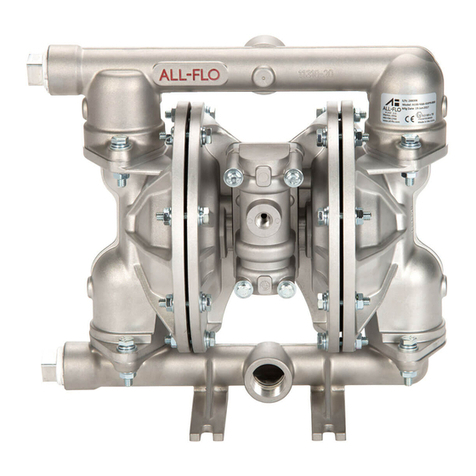

P300

1 2 Pump housing PE HP-2 80 01 20

PE conductive HP-2 80 01 21

2 1 Center housing PE HP-1 80 10 20

PE conductive HP-1 80 10 21

3

1 Suction port PE HP-2 80 25 20

PE conductive HP-2 80 25 21

1 Discharge port PE HP-2 80 025 20

PE conductive HP-2 80 025 21

4 2 Diaphragm TFM/PTFE HP-1 80 50 05

EPDM HP-1 80 50 08

NBR HP-1 80 50 10

5 4 Valve balls PTFE HP-1 80 60 23

EPDM HP-1 80 60 08

NBR HP-1 80 60 10

7 4 Sealing inlet/outlet -

SET

EPDM/EPDM HP-2 80 70 08

PTFE/FPM HP-2 80 73 14

PTFE/EPDM HP-2 80 73 15

PTFE-c./FPM HP-2 80 73 16

PTFE-c./EPDM HP-2 80 73 17

9 8 Housing bolt AISI 304 HP-2 80 042 50

11 4 Shock absorber NR/St37 HP-1 80 69 06

12 16 Nut with washer, cpl. AISI 304 HP-2 80 045 50

13 1 Air valve PET/NBR HP-1 80 020 31

PET/FPM HP-1 80 020 32

14 1 Shaft AISI 304 HP-1 80 40 50

15 6 O-ring NBR HP-1 40 87 10

FPM HP-1 40 87 09

16 2 Center housing seal PE HP-1 80 85 22

17 1 Muffler Diverse HP-1 80 99 00

18 1 Air adapter PP HP-1 80 46 28

22 4 Valve seat PE HP-2 80 54 20

PE-conductive HP-2 80 54 21

24 2 Plug lower PE HP-2 80 59 20

PE-conductive HP-2 80 59 21

25 2 Plug upper PE HP-2 80 55 20

PE conductive HP-2 80 55 21

26 2 Valve stopper PE HP-2 80 39 20

PE conductive HP-2 80 39 21

27 4 Bolt PE HP-2 80 38 20

PE conductive HP-2 80 38 21

28 2 Plug upper sealing FEP/FPM HP-2 80 78 04

EPDM HP-2 80 78 08

NBR HP-2 80 78 10

30 2 O-ring for center

housing seal NBR HP-1 80 85 10

35 1 Center housing

complete PE HP-1 80 11 20

PE conductive HP-1 80 11 21

70 16 Pump housing plug PE HP-2 80 058 20

82 2 Shaft allen pin screw AISI 304 HP-1 80 540 50

83 1 Muffler adapter PE HP-1 80 299 20

97 1 Valve seat key AISI 304 HP-1 80 254 50

98 1 Upper/lower plugs

key (SK5) diverse HP-1 80 158 00

99 1 Air valve (SK4) diverse HP-1 08 58 00

15 I All-Flo Pump Co.