All-Flo T025 Manual

!

13966-Txxx_Rev_D_21NOV2016!

2

TABLE!OF!!

CONTENTS!

!

!

1.!Warnings!and!Cautions!_________________________________________________________________________!3!

2.!Pump!Model!Matrix!____________________________________________________________________________!4!

3.!Pump!Dimensions!and!Specifications!_____________________________________________________________!5-6!

4.!Performance!Curves!and!Specifications!___________________________________________________________!7-8!

T025,!T038,!T050! ______________________________________________________________________________!7!

T100,!T150,!T200!______________________________________________________________________________!8!

5.!Installation,!Troubleshooting!and!Maintenance!__________________________________________________! 9-12!

Installation!________________________________________________________________________________! 9-10!

Troubleshooting!______________________________________________________________________________!11!

Operation!___________________________________________________________________________________!12!

Maintenance!_________________________________________________________________________________!13!

Shut!Down!___________________________________________________________________________________!14!

6.!Torque!Specifications!__________________________________________________________________________!15!

7.!Exploded!View!and!Parts!List!_________________________________________________________________! 15-26!

T025!_____________________________________________________________________________________!16-17!

T038!_____________________________________________________________________________________!18-19!

T050!_____________________________________________________________________________________!20-21!

T100!_____________________________________________________________________________________!22-23!

T150!_____________________________________________________________________________________!24-25!

T200!_____________________________________________________________________________________!26-27!

8.!Warranty!and!Registration!______________________________________________________________________!29!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

3

!

!

! !

13966-Txxx_Rev_D_21NOV2016!

4

!

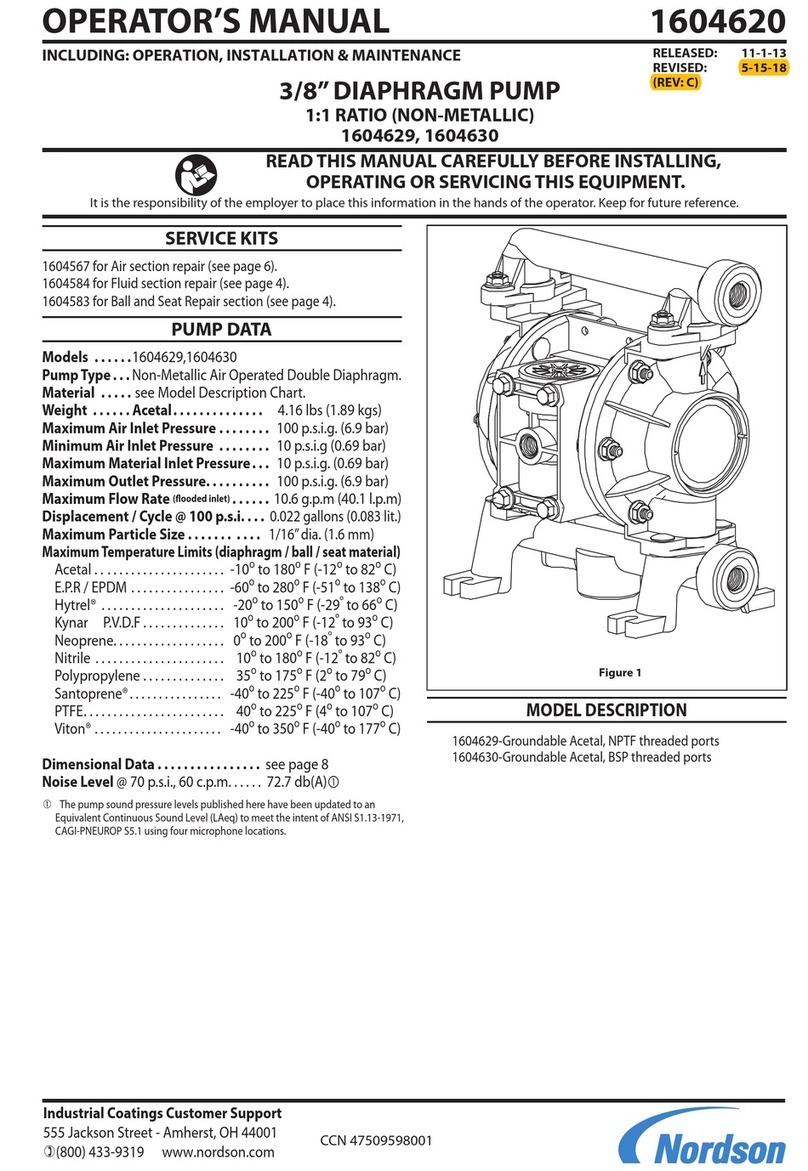

Model!Designation!Matrix!

!

5

Pump!Specifications!

!

!!

13966-Txxx_Rev_D_21NOV2016!

6

Pump!Dimensions!

!

!

! !

7

Performance Curves

Max. Flow: 2.6 gpm (10 lpm)

Max. Air Pressure: 116 PSI (8 bar)

Max. Solids: 1/16" (2 mm)

Max. Suction Lift Dry: 1.6 ft-H2O (0.5 m-H2O)

Max. Suction Lift Wet: 29.5 ft-H2O (9 m-H2O)

Wei ght : 3.3 lbs (1.5 kg)

Air Inl et : 1/8"

Liquid Inlet: 1/4"

Liquid Outlet: 1/4"

Height 5.12" (130 mm)

Wi dt h: 4.5" (114 mm)

Depth: 2.76" (70 mm)

T025 Performance Specifications

Max. Flow: 6.6 gpm (25 lpm)

Max. Air Pressure: 116 PSI (8 bar)

Max. Solids: 1/8" (3 mm)

Max. Suction Lift Dry: 6.6 ft-H2O (2 m-H2O)

Max. Suction Lift Wet: 29.5 ft-H2O (9 m-H2O)

Wei ght : 5.3 lbs (2.4 kg)

Air Inlet : 1/8"

Liquid Inlet: 3/8"

Liquid Outlet: 3/8"

Height 6.86" (174 mm)

Wi dt h: 5.04" (128 mm)

Depth: 4.13" (105 mm)

T038 Performance Specifications

Max. Flow: 14.5 gpm (55 lpm)

Max. Air Pressure: 116 PSI (8 bar)

Max. Solids: 5/32" (4 mm)

Max. Suction Lift Dry: 9.8 ft-H2O (3 m-H2O)

Max. Suction Lift Wet: 29.5 ft-H2O (9 m-H2O)

Wei ght : 15 lbs (6.8 kg)

Air Inl et: 1/4"

Liquid Inlet: 1/2"

Liquid Outlet: 1/2"

Height 9.96" (253 mm)

Wi dt h: 6.97" (177 mm)

Depth: 6.02" (153 mm)

T050 Performance Specifications

13966-Txxx_Rev_D_21NOV2016!

8

!

Max. Flow: 33 gpm (125 lpm)

Max. Air Pressure: 116 PSI (8 bar)

Max. Solids: 9/32" (7 mm)

Max. Suction Lift Dry: 13.1 ft-H2O (4 m-H2O)

Max. Suction Lift Wet: 29.5 ft-H2O (9 m-H2O)

Wei ght : 36.4 lbs (16.5 kg)

Air Inl et : 1/4"

Liquid Inlet: 1"

Liquid Outlet: 1"

Height 13.38" (340 mm)

Wi dt h: 19.13" (232 mm)

Depth: 7.78" (198 mm)

T100 Performance Specifications

Max. Flow: 83 gpm (315 lpm)

Max. Air Pressure: 116 PSI (8 bar)

Max. Solids: 3/8" (10 mm)

Max. Suction Lift Dry: 13.1 ft-H2O (4 m-H2O)

Max. Suction Lift Wet: 29.5 ft-H2O (9 m-H2O)

Wei ght : 98.1 lbs (44.5 kg)

Air Inl et: 1/2"

Liquid Inlet: 1 1/2"

Liquid Outlet: 1 1/2"

Height 17.95" (456 mm)

Wi dt h: 12.28" (312 mm)

Depth: 10.63" (270 mm)

T150 Performance Specifications

Max. Flow: 150 gpm (565 lpm)

Max. Air Pressure: 116 PSI (8 bar)

Max. Solids: 15/32" (12 mm)

Max. Suction Lift Dry: 16.4 ft-H2O (5 m-H2O)

Max. Suction Lift Wet: 29.5 ft-H2O (9 m-H2O)

Wei ght : 192 lbs (87 kg)

Air Inlet : 1/2"

Liquid Inlet: 2"

Liquid Outlet: 2"

Height 22.44" (570 mm)

Wi dt h: 15.16" (385 mm)

Depth: 13.78" (350 mm)

T200 Performance Specifications

9

Installation!

Piping!

Whenever!possible!ensure!the!pump!is!installed!using!the!shortest!possible!pipe!lengths!with!the!minimum!

amount!of!pipe!fittings.!Ensure!all!piping!is!supported!independent!of!the!pump.!!

!

Suction!and!discharge!piping!should!not!be!smaller!than!the!connection!size!of!the!pump.!When!pumping!liquids!of!high!

viscosity,!larger!piping!may!be!used,!in!order!to!reduce!frictional!pipe!loss.!!!

!

Employ!flexible!hoses!in!order!to!eliminate!the!vibration!caused!by!the!pump.!Mounting!feet!can!also!be!used!to!reduce!

vibration!effects.!

!

All!hoses!should!be!reinforced,!non-collapsible!and!be!capable!of!high!vacuum!service.!Ensure!that!all!piping!and!hoses!are!

chemically!compatible!with!the!process!and!cleaning!fluid.!!!

!

For!processes!where!pulsation!effects!should!be!reduced,!employ!a!pulsation!dampener!on!the!discharge!side!of!the!pump.!

!

For!self-priming!applications,!ensure!all!connections!are!airtight!and!the!application!is!within!the!pumps!

dry-lift!capability.!Refer!to!product!specifications!for!further!details.!!

!

For!flooded!suction!applications,!install!a!gate!valve!on!the!suction!piping!in!order!to!facilitate!service.!!For!unattended!

flooded!suction!operation,!it!is!recommended!to!pipe!the!exhaust!air!above!the!liquid!source.!In!the!event!of!a!diaphragm!

failure!this!will!reduce!or!eliminate!the!possibility!of!liquid!discharging!through!the!exhaust!onto!the!ground.!

!

Location!

Ensure!that!the!pump!is!installed!in!an!accessible!location,!in!order!to!facilitate!future!service!and!maintenance.!

!

Air!

Ensure!that!the!air!supply!is!sufficient!for!the!volume!of!air!required!by!the!pump.!Refer!to!product!specifications!for!further!

details.!For!reliable!operation,!install!a!5!micron!air!filter,!air-valve!and!

pressure!regulator.!Do!not!exceed!the!pumps!maximum!operating!pressure!of!120!psig.!

!

Remote!Operation!

Utilize!a!three!way!solenoid!valve!for!remote!operation.!This!ensures!that!air!between!the!solenoid!

and!the!pump!is!allowed!to!“bleed!off,”!ensuring!reliable!operation.!Liquid!transfer!volume!is!estimated!

by!multiplying!displacement!per!stroke!times!the!number!of!strokes!per!minute!

!

Noise!

Correct!installation!of!the!muffler!reduces!sound!levels.!Refer!to!product!specifications!for!further!details.!

!

Submerged!Operation!

For!submersible!operation,!pipe!the!air!exhaust!to!atmosphere!

13966-Txxx_Rev_D_21NOV2016!

10

Installation!

!

!

!

!

SELF!

PRIMING!APPLICATION

!

Suction!lift!capability!may!vary!depending!on!the!construction!materials!and!application!

parameters.!The!range!is!from!16.4!feet!dry!to!30!feet!in!a!primed!condition!(values!

calculated!for!pumping!water!at!68!degrees!Fahrenheit).!

!

!

SUBMERGED!OPERATION

!

All!pumps!may!operate!in!full!submersion.!Construction!materials!must!be!compatible!

with!surrounding!liquid!and!the!air!exhaust!must!be!placed!above!the!liquid!level.!

!

!

POSITIVE!SUCTION!HEAD

!

Common!as!a!method!of!drawing!off!the!bottoms!of!holding!tanks!and!clarifiers.!

Optimum!inlet!pressure!should!be!kept!at!14.5!PSI.!

!

! !

11

Troubleshooting!

PROBLEM!!!!!EFFECT/SOLUTION!

Pump!Will!Not!Cycle!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!

Discharge!line!closed!or!plugged!

Discharge!filter!blocked!

Check!valve!stuck!

Air!filter!blocked!

Air!supply!valve!closed!

Air!supply!hooked!up!to!muffler!side!of!pump!

Compressor!not!producing!air!or!turned!off!

Muffler!iced!or!blinded!

Diaphragm!ruptured!

Plant!air!supply!line!ruptured!

Air!valve!wear/debris!

Pilot!sleeve!wear/debris!

Diaphragm!rod!broken!

Diaphragm!plate!loose!

Pumped!Fluid!Coming!Out!of!Muffler!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!

Diaphragm!ruptured!

Diaphragm!plate!loose!

Inlet!liquid!pressure!excessive!(above!10!psig)!

Pump!Cycles!but!no!Flow!

Inlet!strainer!clogged!

Suction!valve!closed!

Suction!line!plugged!

No!liquid!in!the!suction!tank!

Suction!lift!excessive!

Debris!stuck!in!valves!

Excessive!wear!of!check!valves!

Air!leak!on!suction!side!with!suction!lift!

Pump!Cycles!with!Closed!Discharge!Valve!

Debris!stuck!in!check!valve!

Excessive!wear!of!check!valves!

Pump!Running!Slowly/Not!Steady!

Air!compressor!undersized!

Leak!in!air!supply!

Air-line,!filter!regulator!or!needle!valve!undersized!

Muffler!partially!iced!or!blinded!

Air!valve!gasket!leak!or!misalignment!

Air!valve!wear/debris!

Pilot!sleeve!wear/debris!

Liquid!fluid!filter!blocked!

Pump!may!be!cavitating,!reduce!speed!of!operation!

Suction!strainer!clogged!

Pump!Will!Not!Prime!

Air!leak!in!suction!pipe!

Air!leak!in!pump!manifold!connections!

Suction!strainer!and!lines!clogged!

Excessive!lift!conditions!

Check!valve!wear!

Debris!in!check!valve!

If!any!of!the!above!mentioned!causes!do!not!apply!to!your!problem,!contact!your!All-Flo!authorized!distributor.!

!

13966-Txxx_Rev_D_21NOV2016!

12

Operation!

!

!

!

!

1) Start!the!air!compressor.!

2) Open!the!air!valve.!Using!a!regulator!to!adjust!the!supply!air!pressure!within!the!permissible!range.!

3) Open!the!flow!valve!on!the!discharge!side.!

4) First,!check!that!fluid!is!flowing!inside!the!piping!and!is!being!pumped!to!the!discharge!side,!and!then!fully!open!the!air!valve.!

!

!

Flow!Adjustment!

!

!Adjust!the!flow!valve!on!the!discharge!side,!or!adjust!the!supply!air!pressure.!

!

!

!!

!

CAUTION

!

CAUTION

!

Before starting the pump, check that all piping is properly connected.

!

Before starting the pump, check that all the bolts are securely tightened.

!

Check that the regulator and the drain valve on the discharge side are closed and that the valve on the suction

side is opened if applicable.

!

The supply air pressure may initially rise during closing the flow valve. Make sure that the pressure is kept within

the normal operating range.

!

The permissible suction flow speed can vary depending upon the viscosity and specific gravity of the fluid, the

suction stroke and other factors. However in case of a rapid growth of the pump speed (flow speed of fluid),

cavitations will occur. This will reduce pump performance and may cause a malfunction. In order to prevent

cavitations, adjust the supply air pressure and the flow.

!

If fluid is not discharged after you start the pump, or if you hear an abnormal noise or notice any irregularity, shut

down the pump immediately.

13

Maintenance!

Cleaning!the!Pump!

!

!

!!!!

!

!

1) Remove!the!hose!from!the!suction!side!of!the!pump.!

2) Close!the!flow!valve!on!the!discharge!side!and!open!the!drain!valve.!Then!start!air!pressure!for!a!while!to!discharge!

possibly!much!fluid!remaining!inside!the!pump.!

3) Remove!the!hose!from!the!discharge!side,!and!attach!different!hoses!to!the!suction!side!and!the!discharge!side!for!

cleaning.!

4) Be!ready!with!a!vessel!with!cleaning!solution,!the!kind!appropriate!for!the!type!of!fluid!pumped.!Next!connect!the!

suction-side!and!the!discharge-side!hoses!of!the!pump.!

5) Start!the!pump!air!pressure!slowly,!and!let!the!cleaning!solution!circulate!for!sufficient!cleaning.!

6) Flush!with!clean!water.!

7) Remove!the!hose!from!the!suction!side!of!the!pump,!run!the!pump!for!a!while!to!purge!the!pump!of!remaining!fluid!as!

much!as!possible.!

!

!

!

!

!

!!

!

WARNING

!

CAUTION

!

Make sure that compressed air is not supplied to the pump BEFORE you start cleaning the pump.

!

Make sure that the pump is not pressurized BEFORE you start cleaning the pump.

!

Be extremely careful when removing piping - the fluid will run/flow out.

!

After cleaning with clean water, turn the pump upside-down to let the water flow out.

13966-Txxx_Rev_D_21NOV2016!

14

Shutdown!

Close!the!air!valve!of!the!pump!and!shut!off!the!supply!air.!

!

!

!

!

!

Daily!check!

!

Before!starting!pump!operation,!conduct!the!following!check!procedures!every!day.!In!case!there!appears!

any!irregularity,!do!NOT!start!running!the!pump!until!the!cause!of!the!irregularity!has!been!determined!and!

corrective!measures!have!been!taken.!

a)Make!sure!that!there!is!no!leakage!of!fluid!from!any!connection!part!or!the!pump.!

b) Make!sure!that!there!are!no!cracks!in!the!pump!casing!or!piping.!

c) Check!the!tightness!of!every!bolt!of!the!pump.!

d) Make!sure!that!the!connection!parts!of!the!piping!and!peripheral!equipment!are!not!loose.!

e)Make!sure!that!any!parts!of!the!pump!that!are!to!be!replaced!at!regular!intervals!have!been!changed.!

!

!

CAUTION

!

CAUTION

!

The pump can be shut down with the flow valve closed while air is being supplied. However DO NOT leave the pump

in this condition for many hours without supervision - there is a risk of a leak from the pump or piping, and fluid may

continue flowing out of the position of leakage.

!

When the pump is shut down while pumping slurry, particulate matter contained in the slurry will be deposited and get

stuck inside the out chamber. Therefore after finishing work the pump must be cleared of the remaining fluid. Otherwise

when starting the pump again, the diaphragm may get damaged and the center rod may bend.

!

Keep a vessel below the relief valve for any drain off.

!

Be careful! - Fluid under pressure will gush out the moment you open the valve.

!

If the pump is unused for a prolonged period, purge and clean it.

15

!

! !

Pump%Size

T025 18%in-lbs%(2%N-m)

T038 44%in-lbs%(5%N-m)

T050 62%in-lbs%(7%N-m)

T100 97%in-lbs%(11%N-m)

T150 133%in-lbs%(15%N-m)

T200 168%in-lbs%(19%N-m)

Maximum%Torque%Specifications

Torque%values%for%housing%bolts

13966-Txxx_Rev_D_21NOV2016!

16

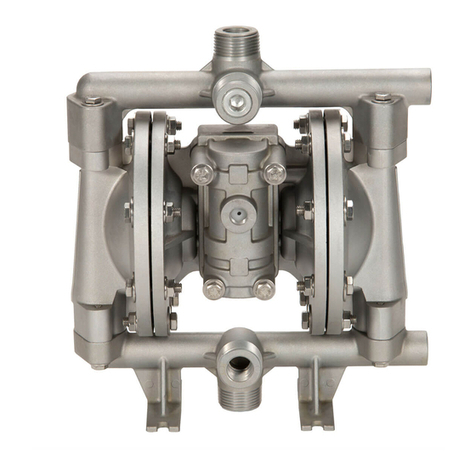

T025!-!EXPLODED!VIEW!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

17

T025!-!PARTS!LIST!

ITEM!

PART!NUMBER!

QTY!

DESCRIPTION!

MATERIAL!

1!

HP-2!08!01!23!

2!

Pump!housing!

PTFE!

HP-2!08!01!24!

Conductive!

PTFE!

2!

HP-1!08!10!20!

1!

Center!housing!

PE!

HP-1!08!10!21!

Conductive!PE!

3!

HP-2!08!30!23!

2!

Suction/Discharge!ports!BSP!

PTFE!

HP-2!08!30!23!

Suction/Discharge!ports!NPT!

PTFE!

n/a!

Suction/Discharge!ports-twin!(split!connection)!NPT!

PTFE!

n/a!

Suction/Discharge!ports-twin!(split!connection)!BSP!

PTFE!

HP-2!08!33!23!

1!

Suction!port-drum!

PTFE!

4!

HP-1!08!69!06!

4!

Shock!absorber!

NR/St37!

5!

HP-1!08!99!35!

1!

Muffler!

PE!porous!

6!

HP-2!08!54!23!

4!

Valve!seat!

PTFE!

7!

HP-2!08!59!23!

2!

Plug!lower!

PTFE!

8!

HP-2!08!055!23!

2!

Plug!upper!

PTFE!

9!

HP-2!08!39!23!

2!

Valve!stopper!

PTFE!

10!

HP-2!08!38!23!

2!

Bolt!

PTFE!

11!

HP-1!08!254!50!

1!

Valve!seat!key!

AISI!304!

12!

HP-1!08!158!00!

1!

Upper/lower!plug!key!(SK1,*-!SK2)!

diverse!

13!

HP-1!08!58!00!

1!

Air!valve!key!(SK4)!

diverse!

REPAIR!KITS!

A!

TAK-025!

KIT!

Air!valve!

PET/NBR!

W!

TWE-025-PTTT!

KIT!

PTFE!WET!KIT!

!

2!

Diaphragm!

TFM!/PTFE!

!

4!

Valve!balls!

PTFE!

!

4!

Sealing!inlet/outlet!

FEP/FPM!

!

2!

Plug!upper!sealing!

FEP/FPM!

!

1!

Muffler!

PE!porous!

!

! !

13966-Txxx_Rev_D_21NOV2016!

18

T038!-!EXPLODED!VIEW

!

! !

19

T038!-!PARTS!LIST!

ITEM!

PART!NUMBER!

QTY!

DESCRIPTION!

MATERIAL!

1!

HP-2!10!01!23!

2!

Pump!housing!

PTFE!

HP-2!10!01!24!

Conductive!

PTFE!

2!

HP-1!10!10!20!

1!

Center!housing!

PE!

HP-1!10!10!21!

Conductive!PE!

3!

HP-2!10!30!23!

2!

Suction/Discharge!ports!BSP!

PTFE!

HP-2!10!30!23!

Suction/Discharge!ports!NPT!

PTFE!

HP-2!10!31!23NPT!

Suction/Discharge!ports-twin!(split!connection)!NPT!

PTFE!

HP-2!10!31!23BSP!

Suction/Discharge!ports-twin!(split!connection)!BSP!

PTFE!

HP-2!10!33!23!

1!

Suction!port-drum!

PTFE!

4!

HP-1!08!69!06!

4!

Shock!absorber!

NR/St37!

5!

HP-1!08!99!35!

1!

Muffler!

PE!porous!

6!

HP-2!10!54!23!

4!

Valve!seat!

PTFE!

7!

HP-2!10!59!23!

2!

Plug!lower!

PTFE!

8!

HP-2!10!055!23!

2!

Plug!upper!

PTFE!

9!

HP-2!10!39!23!

2!

Valve!stopper!

PTFE!

10!

HP-2!10!38!23!

2!

Bolt!

PTFE!

11!

HP-1!10!254!50!

1!

Valve!seat!key!

AISI!304!

12!

HP-1!10!158!00*!

1!

Upper/lower!plug!key!(SK1,*-!SK2)!

diverse!

13!

HP-1!08!58!00!

1!

Air!valve!key!(SK4)!

diverse!

REPAIR!KITS!

A!

TAK-038!

KIT!

Air!valve!

PET/NBR!

W!

TWE-038-PTTT!

KIT!

PTFE!WET!KIT!

!

2!

Diaphragm!

TFM!/PTFE!

!

4!

Valve!balls!

PTFE!

!

4!

Sealing!inlet/outlet!

FEP/FPM!

!

2!

Plug!upper!sealing!

FEP/FPM!

!

1!

Muffler!

PE!porous!

!

!

! !

13966-Txxx_Rev_D_21NOV2016!

20

T050!–!EXPLODED!VIEW!

!

!

!

!!

This manual suits for next models

1

Table of contents

Other All-Flo Water Pump manuals

Popular Water Pump manuals by other brands

esotec

esotec 101018 operating manual

Aussie Pumps

Aussie Pumps Eco-Clean WHY1520 HYD Operator's instruction manual

Grundfos

Grundfos UPM3 manual

Einhell Royal

Einhell Royal SPU 80/1 operating instructions

Gardena

Gardena 9000/3 operating instructions

GORMAN-RUPP

GORMAN-RUPP V3A60-B Installation, operation and maintenance manual