All-Flo A100 Manual

all-o.com

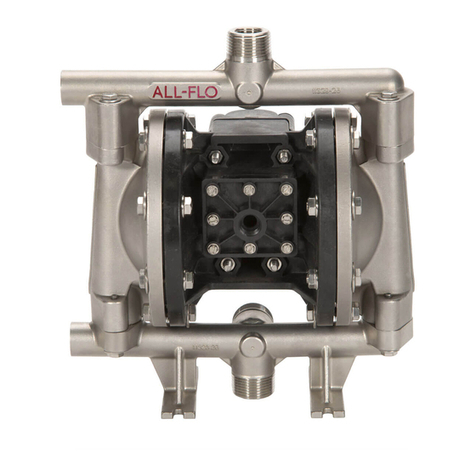

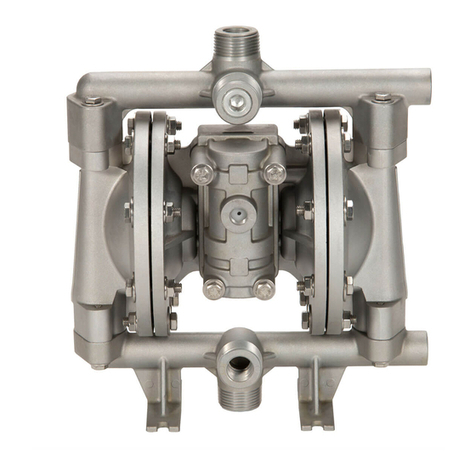

A100 - 1 INCH AIR OPERATED DOUBLE DIAPHRAGM PUMP

PUMP OPERATIONS & MAINTENANCE MANUAL

all-o.com

TABLE OF

CONTENTS

2

SECTION 1 WARNINGS, DANGERS AND CAUTIONS 3

SECTION 2 MODEL DESIGNATION MATRIX 4-5

SECTION 3 PRINCIPLES OF OPERATION 6

SECTION 4 DIMENSIONAL DRAWINGS 7

SECTION 5 PERFORMANCE CURVES

RUBBER, TPE AND PTFE DIAPHRAGMS...........................8

SECTION 6 INSTALLATION,

INSTALLATION .................................................................................... 9-10

TROUBLESHOOTING ...................................................................11

OPERATION.....................................................................................12

MAINTENANCE ............................................................................12

SECTION 7 REPAIR AND ASSEMBLY

PUMP WET END REMOVAL............................................ 13-14

AIR VALVE REMOVAL ........................................................ 15-16

PILOT VALVE REMOVAL...................................................17-18

TORQUE SPECIFICATIONS.......................................................18

SECTION 8 EXPLODED VIEWS AND PARTS LISTS 19-24

ALUMINUM AND STAINLESS ..................................................

STEEL (NON-PTFE DIAPHRAGMS) ............................ 19-21

ALUMINUM AND STAINLESS ..............................................

STEEL (PTFE DIAPHRAGMS)....................................... 22-24

SECTION 9 ELASTOMERS AND REPAIR KITS 25

SECTION 10 WARRANTY AND REGISTRATION 26

all-o.com 3

READ THESE WARNINGS AND SAFETY PRECAU-

TIONS PRIOR TO INSTALLATION OR OPERATION.

FAILURE TO COMPLY WITH THESE INSTRUCTIONS

COULD RESULT IN PERSONAL INJURY AND OR

PROPERTY DAMAGE. RETAIN THESE INSTRUCTIONS

FOR FUTURE REFERENCE.

WARNING Pump, valves and all containers

must be properly grounded prior to handling

flammable fluids and/or whenever static electricity

is a hazard.

WARNING Prior to servicing the pump,

ensure that the air and fluid lines are closed and

disconnected. While wearing personal protective

equipment, flush, drain and process liquid from the

pump in a safe manner.

CAUTION Do not connect a compressed air

source to the exhaust port of the pump.

CAUTION Ensure that the muffler is properly

installed prior to pump operation.

CAUTION Do not lubricate air supply.

CAUTION When selecting pump materials, be

aware of the following temperature limitations:

Buna-N (Nitrile): 10°F to 180°F (-12C to 82C)

Geolast®: 10°F to 180°F (-12C to 82C)

EPDM: -40°F to 280°F (-40C to 138C)

Santoprene®: -40°F to 225°F (-40C to 107C)

Viton®(FKM): -40°F to 350°F (-40C to 177C)

PTFE: 40°F to 220°F (4C to 104C)

Polyethylene: 32°F to 158°F (0C to 70C)

Polypropylene: 32°F to 180°F (0C to 82C)

PVDF: 0°F to 250°F (-18C to 181C)

Nylon: 0°F to 200°F (-18C to 93C)

Temperature limits are solely based upon

mechanical stress and certain chemicals will reduce

the maximum operating temperature. Consult a

chemical resistance guide for chemical compatibility

and a more precise safe temperature limit. Always

use minimum air pressure when pumping at elevated

temperatures.

CAUTIONS — READ FIRST!

WARNING

CAUTION

= Hazards or unsafe practices

which could result in severe

personal injury, death or

substantial property damage

= Hazards or unsafe practices

which could result in minor

personal injury, product or

property damage.

CAUTION Do not exceed 120 psig (8.3 bar)

air-inlet pressure.

CAUTION Ensure all wetted components are

chemically compatible with the process fluid and the

cleaning fluid.

CAUTION Ensure pump is thoroughly cleaned

and flushed prior to installation into a process line.

CAUTION Always wear Personal Protective

Equipment (PPE) when operating pump.

CAUTION Close and disconnect all

compressed air and bleed all air from the pump

prior to service. Remove all process fluid in a safe

manner prior to service.

CAUTION Blow out all compressed air

lines in order to remove any debris, prior to

pump installation.

CAUTION Ensure air exhaust is piped to

atmosphere prior to a submerged installation.

CAUTION Ensure all hardware is set to

correct torque values prior to operation.

SECTION 1

all-o.com

MODEL DESIGNATION MATRIX - ALUMINUM

SECTION 2

4

PRODUCT SERIES

FLUID CONNECTION TYPE

FLUID CHAMBERS/

MANIFOLDS

DIAPHRAGM

VALVE/BALL

VALVE SEAT

O-RINGS

SPECIAL (OTHER)

PORTING

INTERMEDIATE/

INNER CHAMBER

SPECIAL (HARDWARE,

MUFFLER, LUG)

A 1 0 0 -1 2 3- 4 5 6 7 - 8 9 10

FLUID CONNECTION TYPE

N = NPT

B = BSPT

INTERMEDIATE / INNER CHAMBER

A = Aluminum

FLUID CHAMBER / MANIFOLDS

A = Aluminum

DIAPHRAGMS

G = Geolast®

S = Santoprene®

T = PTFE with Santoprene® Backup

E = EPDM

N = Buna – N

V = Viton®/FKM

VALVE/BALL

G = Geolast®

S = Santoprene®

T = PTFE

E = EPDM

N = Buna – N

V = Viton®/FKM

3 = Stainless Steel

VALVE SEAT

P = Polypropylene

Y = Nylon

A = Aluminum

3 = Stainless Steel

O-RINGS

E = EPFM

N = Buna-N

T = PTFE

V = Viton®/FKM

PORTING

0 = Standard (Suction Center Front/Discharge

Center Rear)

A = Suction Center Front / Discharge Center Front

D = Suction Center Front / Discharge Right

E = Suction Center Front / Discharge Left

F = Suction Center Rear / Discharge Center Front

G = Suction Center Rear / Discharge Center Rear

I = Suction Center Rear / Discharge Right

J = Suction Center Rear / Discharge Left

P = Suction Right / Discharge Center Front

Q = Suction Right / Discharge Center Rear

S = Suction Right / Discharge Right

T = Suction Right / Discharge Left

U = Suction Left / Discharge Center Front

V = Suction Left / Discharge Center Rear

X = Suction Left / Discharge Right

Y = Suction Left / Discharge Left

1 = Dual Suction

2 = Dual Suction / Dual Discharge

3 = Dual Discharge

4 = All Ports Open (Standard ports will be left

un-plugged)

SPECIAL OPTION (HARDWARE, MUFFLER, LUG)

0 = Standard (Zinc Plated Steel Hardware, Plastic

Muffler)

4 = Zinc Plated Steel Hardware, Metal Muffler

7= Stainless Steel Hardware, Plastic Muffler

8 = Stainless Steel Hardware, Metal Muffler

B = PTFE Coated Stainless Steel Hardware,

Plastic Muffler

C = PTFE Coated Stainless Steel Hardware,

Metal Muffler

D = Zinc Plated Steel Hardware, Plastic Muffler,

Grounding Lug Installed

E = Zinc Plated Steel Hardware, Metal Muffler,

Grounding Lug Installed

F = Stainless Steel Hardware, Plastic Muffler,

Grounding Lug Installed

G = Stainless Steel Hardware, Metal Muffler,

Grounding Lug Installed

H = PTFE Coated Stainless Steel Hardware,

Plastic Muffler, Grounding Lug Installed

I = PTFE Coated Stainless Steel Hardware,

Metal Muffler, Grounding Lug Installed

SPECIAL OPTION (OTHER)

0 = Standard (None)

1 = Cycle Counter Valve

A = Grease Free (No Lubrication Assembly)

SIZE

WET END REPAIR KIT

Wet end kits are available and

consist of diaphragms, (back-up

diaphragms if required), balls,

seats and seat O-rings.

See matrix below.

1

2

6

7

8

9

10

INTERMEDIATE / INNER CHAMBER

A = Aluminum

Bold indicates recommended options

AIR END REPAIR KIT

Air end repair kit contains pilot

sleeve assembly and main air valve.

DIAPHRAGM

VALVE/BALL

VALVE SEAT

O-RINGS

AWE-100-4567

PRODUCT

SERIES

WET END

REPAIR KIT

PUMP SIZE

MATERIAL

AAK-100-2

PRODUCT

SERIES

PUMP SIZE

AIR END

REPAIR KIT

3

4

5

all-o.com 5

MODEL DESIGNATION MATRIX - STAINLESS STEEL

Bold indicates recommended options

PRODUCT SERIES

FLUID CONNECTION TYPE

FLUID CHAMBERS/

MANIFOLDS

DIAPHRAGM

VALVE/BALL

VALVE SEAT

O-RINGS

SPECIAL (OTHER)

PORTING

INTERMEDIATE/

INNER CHAMBER

SPECIAL (HARDWARE,

MUFFLER, LUG)

A 1 0 0 -1 2 3- 4 5 6 7 - 8 9 10

FLUID CONNECTION TYPE

N = NPT

B = BSPT

INTERMEDIATE / INNER CHAMBER

A = Aluminum

FLUID CHAMBER / MANIFOLDS

3 = Stainless Steel

DIAPHRAGMS

G = Geolast®

S = Santoprene®

T = PTFE with Santoprene® Backup

E = EPDM

N = Buna – N

V = Viton®/FKM

VALVE/BALL

G = Geolast®

S = Santoprene®

T = PTFE

E = EPDM

N = Buna – N

V = Viton®/FKM

3 = Stainless Steel

VALVE SEAT

3 = Stainless Steel

A = Aluminum

P = Polypropylene

Y = Nylon

O-RINGS

E = EPFM

N = Buna-N

T = PTFE

V = Viton®/FKM

PORTING

0 = Standard (Suction Center Front/Discharge

Center Rear)

A = Suction Center Front / Discharge Center Front

D = Suction Center Front / Discharge Right

E = Suction Center Front / Discharge Left

F = Suction Center Rear / Discharge Center Front

G = Suction Center Rear / Discharge Center Rear

I = Suction Center Rear / Discharge Right

J = Suction Center Rear / Discharge Left

P = Suction Right / Discharge Center Front

Q = Suction Right / Discharge Center Rear

S = Suction Right / Discharge Right

T = Suction Right / Discharge Left

U = Suction Left / Discharge Center Front

V = Suction Left / Discharge Center Rear

X = Suction Left / Discharge Right

Y = Suction Left / Discharge Left

1 = Dual Suction

2 = Dual Suction / Dual Discharge

3 = Dual Discharge

4 = All Ports Open (Standard ports will be left

un-plugged)

SPECIAL OPTION (HARDWARE, MUFFLER, LUG)

0 = Standard (Stainless Steel Hardware, Plastic

Muffler)

8 = Stainless Steel Hardware, Metal Muffler

B = PTFE Coated Stainless Steel Hardware,

Plastic Muffler

C = PTFE Coated Stainless Steel Hardware,

Metal Muffler

F = Stainless Steel Hardware, Plastic Muffler,

Grounding Lug Installed

G = Stainless Steel Hardware, Metal Muffler,

Grounding Lug Installed

H = PTFE Coated Stainless Steel Hardware,

Plastic Muffler, Grounding Lug Installed

I = PTFE Coated Stainless Steel Hardware,

Metal Muffler, Grounding Lug Installed

SPECIAL OPTION (OTHER)

0 = Standard (None)

1 = Cycle Counter Valve

A = Grease Free (No Lubrication Assembly)

SIZE

WET END REPAIR KIT

Wet end kits are available and

consist of diaphragms, (back-up

diaphragms if required), balls,

seats and seat O-rings.

See matrix below.

1

2

6

7

8

9

10

INTERMEDIATE / INNER CHAMBER

A = Aluminum

DIAPHRAGM

VALVE/BALL

VALVE SEAT

O-RINGS

AWE-100-4567

PRODUCT

SERIES

WET END

REPAIR KIT

PUMP SIZE

MATERIAL

AAK-100-2

PRODUCT

SERIES

PUMP SIZE

AIR END

REPAIR KIT

3

4

5

AIR END REPAIR KIT

Air end repair kit contains pilot

sleeve assembly and main air valve.

all-o.com

SECTION 3

PRINCIPLES OF OPERATION

6

The air-valve directs pressurized air behind the diaphragm on the right,

causing the diaphragm on the right to move outward (to the right).

Since both the right diaphragm and the left diaphragm are connected

via a diaphragm rod, when the right diaphragm moves to the right, the

left diaphragm (through the action of the diaphragm rod) moves to the

right also.

When the diaphragm on the left side is moving to the right, it is referred

to as suction stroke. When the left diaphragm is in its suction stroke,

the left suction ball moves upward (opens) and the left discharge ball

moves downward (closes). This action creates suction and draws liquid

into the left side chamber.

The air-valve directs pressurized air behind the left diaphragm, causing

the left diaphragm to move outward (to the left).

Since both the left diaphragm and the right diaphragm are connected

via a diaphragm rod, when the left diaphragm moves to the left, the

right diaphragm (through the action of the diaphragm rod) moves to

the left also.

When the diaphragm on the left side moves outward, the left discharge ball

moves upward (opens) and the left suction ball moves downward (closes).

This causes the liquid to leave the left side liquid outlet of the pump.

Simultaneously, the right diaphragm moves inward (to the left), which

causes the right suction ball to open and the right discharge to close,

which in turn causes suction, drawing liquid into the right chamber.

The process of alternating right suction / left discharge (and vice-versa)

continues as long as compressed air is supplied to the pump.

HOW AN AIR OPERATED DOUBLE

DIAPHRAGM PUMP WORKS

all-o.com

SECTION 4

7

1” PUMP DIMENSIONS

ALUMINUM & STAINLESS STEEL

13.0” (330mm)

1.3”

(33mm)

11.6”

(295mm)

8.4” (213mm)

12.4”

(315mm)

7.5”

(191mm)

1.5” (38mm)

6.9” (175mm)

9.1” (231mm)

*Note - Suction Center Front / Discharge Center Rear are default ports. See part number matrix option code

for additional porting options.

**Note - Standard Muffler Shown

0.4” (10mm)

7.3”

(185mm)

5.2” (132mm)

6.3”

(160mm)

4.0” (102mm)

3.3” (84mm)

1.3” (33mm)

3/4”-14 FNPT (Exhaust Port)

all-o.com

PERFORMANCE CURVES

8

PERFORMANCE CURVE (1” RUBBER)* Performance Specifications

Max. Flow: 48 gpm (182 lpm)

Max. Air Pressure: 120 psi (8.3 bar)

Max. Solids: 1/4” (6.4 mm)

Max. Suction Lift Dry: 17 ft-H2O (5.2 m-H2O)

Max. Suction Lift Wet: 30 ft-H2O (9.1 m-H2O)

Weight: AL-18 lbs (8 kg) / SS-38 lbs (17 kg)

Air Inlet: 1/2” FNPT

Liquid Inlet: 1” FNPT or 1” FBSPT

Liquid Outlet: 1” FNPT or 1” FBSPT

Height: 12.4” (315 mm)

Width: 13.0” (330 mm)

Depth: 8.4” (213 mm)

Performance Specifications

Max. Flow: 48 gpm (182 lpm)

Max. Air Pressure: 120 psi (8.3 bar)

Max. Solids: 1/4” (6.4 mm)

Max. Suction Lift Dry: 17 ft-H2O (5.2 m-H2O)

Max. Suction Lift Wet: 30 ft-H2O (9.1 m-H2O)

Weight: AL-18 lbs (8 kg) / SS-38 lbs (17 kg)

Air Inlet: 1/2” FNPT

Liquid Inlet: 1” FNPT or 1” FBSPT

Liquid Outlet: 1” FNPT or 1” FBSPT

Height: 12.4” (315 mm)

Width: 13.0” (330 mm)

Depth: 8.4” (213 mm)

Performance Specifications

Max. Flow: 45 gpm (170 lpm)

Max. Air Pressure: 120 psi (8.3 bar)

Max. Solids: 1/4” (6.4 mm)

Max. Suction Lift Dry: 17 ft-H2O (5.2 m-H2O)

Max. Suction Lift Wet: 30 ft-H2O (9.1 m-H2O)

Weight: AL-18 lbs (8 kg) / SS-38 lbs (17 kg)

Air Inlet: 1/2” FNPT

Liquid Inlet: 1” FNPT or 1” FBSPT

Liquid Outlet: 1” FNPT or 1” FBSPT

Height: 12.4” (315 mm)

Width: 13.0” (330 mm)

Depth: 8.4” (213 mm)

5

SECTION

*Flow rates indicated on all three charts shown were determined by pumping water at flooded suction. For optimum life and performance, pumps should

be specified so that daily operation parameters will fall in the center of the pump performance curve.

Primary A

x

XY

Max 120

Min 0 0

Major Uni

t

20 20

Minor Uni

t

55

Secondary X Y

Max 276

Min 0 0

Major Uni

t

76 46

Minor Uni

t

18.927 11.5

---

0 39 78 117 156 195

0 1020304

050

DISCHARGE FLOW-Liters/Min.

PRESSURE INLET/OUTLET PSIG (BARS)

TOTAL HEAD IN FEET (METERS)

DISCHARGE FLOW-U.S. Gals./Min.

276

(83,9)

230

(69,9)

184

(55,9)

138

(41,9)

92

(27,9)

46

(13,9)

120

(8,2)

100

(6,8)

80

(5,4)

60

(4,1)

40

(2,7)

20

(1,3)

P

ERFORMANCE CURVE (1" RUBBER)*

10

20

30

40

50

60

PERFORMANCE CURVE (1” TPE)*

m

ary A

x

XY

x

120

00

orUni

t

20 20

or Uni

t

55

o

ndary XY

x

276

00

or Uni

t

76 46

or Uni

t

18.927 11.5

03978117156195

0102

03

04

05

0

DISCHARGE FLOW-Liters/Min.

PRESSURE INLET/OUTLET PSIG (BARS)

TOTAL HEAD IN FEET (METERS)

DISCHARGE FLOW-U.S. Gals./Min.

276

(83,9)

230

(69,9)

184

(55,9)

138

(41,9)

92

(27,9)

46

(13,9)

120

(8,2)

100

(6,8)

80

(5,4)

60

(4,1)

40

(2,7)

20

(1,3)

E

RFORMANCE CURVE (1" TPE)*

40

50

60

10

20

30

PERFORMANCE CURVE (1” PTFE)*

m

ary A

x

XY

x

120

n

00

or Uni

t

20 20

n

or Uni

t

55

o

ndary X Y

x

276

n

00

or Uni

t

76 46

n

or Uni

t

18.927 11.5

0 39 78 117 156 195

0 1020304050

DISCHARGE FLOW-Liters/Min.

PRESSURE INLET/OUTLET PSIG (BARS)

TOTAL HEAD IN FEET (METERS)

DISCHARGE FLOW-U.S. Gals./Min.

276

(83,9)

230

(69,9)

184

(55,9)

138

(41,9)

92

(27,9)

46

(13,9)

120

(8,2)

100

(6,8)

80

(5,4)

60

(4,1)

40

(2,7)

20

(1,3)

P

ERFORMANCE CURVE (1" PTFE)*

40

50

60

10

20

30

all-o.com

SECTION 6

9

INSTALLATION, TROUBLE-

SHOOTING AND MAINTENANCE

INSTALLATION

PIPING

Whenever possible ensure the pump is installed using

the shortest possible pipe lengths with the minimum

amount of pipe fittings. Ensure all piping is supported

independent of the pump.

Suction and discharge piping should not be smaller

than the connection size of the pump. When pumping

liquids of high viscosity, larger piping may be used, in

order to reduce frictional pipe loss.

Employ flexible hoses in order to eliminate the vibration

caused by the pump. Mounting feet can also be used to

reduce vibration effects.

All hoses should be reinforced, non-collapsible and be

capable of high vacuum service. Ensure that all piping

and hoses are chemically compatible with the process

and cleaning fluid.

For processes where pulsation effects should be

reduced, employ a pulsation dampener on the discharge

side of the pump.

For self-priming applications, ensure all connections

are airtight and the application is within the pumps

dry-lift capability. Refer to product specifications for

further details.

For flooded suction applications, install a gate valve

on the suction piping in order to facilitate service.

For unattended flooded suction operation, it is

recommended to pipe the exhaust air above the liquid

source. In the event of a diaphragm failure this will

reduce or eliminate the possibility of liquid discharging

through the exhaust onto the ground.

LOCATION

Ensure that the pump is installed in an accessible

location, in order to facilitate future service and

maintenance.

AIR

Ensure that the air supply is sufficient for the

volume of air required by the pump. Refer to product

specifications for further details. For reliable

operation, install a 5 micron air filter, air-valve and

pressure regulator. Do not exceed the pumps

maximum operating pressure of 120 psig.

REMOTE OPERATION

Utilize a three way solenoid valve for remote

operation. This ensures that air between the solenoid

and the pump is allowed to “bleed off,” ensuring

reliable operation. Liquid transfer volume is estimated

by multiplying displacement per stroke times the

number of strokes per minute

NOISE

Correct installation of the muffler reduces sound

levels. Refer to product specifications for

further details.

SUBMERGED OPERATION

For submersible operation, pipe the air exhaust to

atmosphere

GROUNDING THE PUMP

Loosen grounding screw and install a grounding wire.

Tighten grounding screw. Wire size should be a 12

gauge wire or larger. Connect the other end of the wire

to a true earth ground.

all-o.com

SUGGESTED INSTALLATION

10

This illustration is a generic

representation of an air operated

double-diaphragm pump.

all-o.com 11

TROUBLESHOOTING

PROBLEM EFFECT/SOLUTION

Pump Will Not Cycle

Discharge line closed or plugged

Discharge filter blocked

Check valve stuck

Air filter blocked

Air supply valve closed

Air supply hooked up to muffler side of pump

Compressor not producing air or turned off

Muffler iced or blinded

Diaphragm ruptured

Plant air supply line ruptured

Air valve wear/debris

Pilot sleeve wear/debris

Diaphragm rod broken

Diaphragm plate loose

Pumped Fluid Coming Out of Muffler

Diaphragm ruptured

Diaphragm plate loose

Inlet liquid pressure excessive (above 10 psig)

Pump Cycles but no Flow

Inlet strainer clogged

Suction valve closed

Suction line plugged

No liquid in the suction tank

Suction lift excessive

Debris stuck in valves

Excessive wear of check valves

Air leak on suction side with suction lift

Pump Cycles with Closed Discharge Valve

Debris stuck in check valve

Excessive wear of check valves

Pump Running Slowly/Not Steady

Air compressor undersized

Leak in air supply

Air-line, filter regulator or needle valve undersized

Muffler partially iced or blinded

Air valve gasket leak or misalignment

Air valve wear/debris

Pilot sleeve wear/debris

Liquid fluid filter blocked

Pump may be cavitating, reduce speed of operation

Suction strainer clogged

Pump Will Not Prime

Air leak in suction pipe

Air leak in pump manifold connections

Suction strainer and lines clogged

Excessive lift conditions

Check valve wear

Debris in check valve

all-o.com

OPERATION

The Air-Operated Double Diaphragm Pump requires

a minimum of 20 psig of air to operate, with some

variation according to diaphragm material. Increasing

the air pressure results in a more rapid cycling of the

pump and thus a higher liquid flow rate. In order to not

exceed 120 psig of inlet air pressure, and for accurate

control of the pump, it is suggested to use a pressure

regulator on the air inlet.

An alternate means of controlling the flow-rate of the

pump is to use an inlet air valve and partially open or

close accordingly. When the air valve is completely in

the closed position, the pump will cease to operate.

A third method of controlling the flow rate of the

pump is to use a liquid discharge valve. Closing the

liquid discharge valve will cause a decrease in the

flow rate since the pump will operate against a higher

discharge pressure.

Solenoid control of the inlet air may also be used in

order to facilitate remote operation. A three way

solenoid valve is recommended, in order to allow the

air to “bleed off” between the solenoid and the pump.

Do not use valves for flow control on the suction side

of the pump. (Closing or partially closing a liquid

suction valve restrict the suction line and may cause

damage to the diaphragms.) Suction strainers may

be employed to reduce or eliminate larger solids, but

routine maintenance is necessary in order to prevent

a restriction on the suction.

MAINTENANCE

Due to the unique nature of each application, periodic

inspection of the pump is the best method to determine

a proper maintenance schedule. A record should be

kept of all repairs made to an installed pump. This will

serve as the best predictor of future maintenance.

Typical maintenance involves replacing of “wear-

parts” such as the diaphragms, balls, valve seats and

O-rings. Proper maintenance can ensure trouble-free

operation of the pump. Refer to repair and assembly

instructions for further details.

MAINTENANCE SCHEDULE

WEEKLY (OR DAILY)

Make a visual check of the pump. If pumped fluid is

leaking out of the pump, pipe fittings or muffler turn

off pump and schedule maintenance.

EVERY THREE MONTHS

Inspect fasteners and tighten any loose fasteners to

recommended torque settings.

Schedule pump service based on pump’s service

history.

12

all-o.com

SECTION 7

13

REPAIR AND ASSEMBLY

PUMP WET END REMOVAL

STEP 1

Using the 1/2 inch wrenches

remove four “Hex-Head Cap

Screws (5/16”-18 x 1-3/8”)”

and four “Compression Wash-

ers (5/16”)” from the “Discharge

Manifold”.

STEP 2

Remove the “Discharge Manifold”.

STEP 3

Remove the “O-Ring”, “Valve Seat”

and “Ball” from the “Discharge

Manifold”.

TOOLS NEEDED

1) One Wrench, 7/16 Inch

2) Two Wrenches, ½ Inch

3) Two Wrenches, ¾ Inch

WARNING Prior to servicing the pump, ensure that the air

and fluid lines are closed and disconnected. While wearing personal

protective equipment, flush, drain and process liquid from the

pump in a safe manner.

STEP 4

Using the 1/2 inch wrenches re-

move four “Hex-Head Cap Screws

(5/16”-18 x 1-3/8”)” and four

“Compression Washers (5/16”)”

from the “Suction Manifold”.

STEP 5

Remove the “Suction Manifold”.

STEP 6

Remove the “O-Ring”, “Valve Seat”

and “Ball”.

all-o.com

STEP 7

In order to remove both “Outer

Chambers”, using two ½ inch

wrenches, remove eight “Hex Head

Cap Screws (5/16”–18 x 1-3/8”)”,

eight Compression Washers (5/16”)

and eight “Hex Flange Nuts (5/16”-

18)”.

STEP 8

Remove both “Outer Chambers”

from the “Intermediate”.

STEP 9

Using two ¾ Inch wrenches,

remove “Outer Diaphragm Plate”,

“Diaphragm”, “Inner Diaphragm

Plate” and “Bumper” from one

side of the pump.

STEP 10

Placing the ¾ inch wrench on the remaining “Outer Diaphragm Plate”,

and the 7/16 inch wrench on the “Diaphragm Rod Assembly”, remove the

remaining “Outer Diaphragm Plate”, “Diaphragm”, “Inner Diaphragm

Plate” and “Bumper” from the other side of the pump.

14

PUMP WET END ASSEMBLY

To assemble the wet end of the pump, reverse the order of disassembly.

Ensure all hardware is fastened in accordance with torque specifications

(see page 18). Inverting one of the diaphragms during reassembly will

facilitate ease of assembly.

all-o.com 15

AIR VALVE REMOVAL

STEP 1

Using the 7/16 inch wrench, remove

four “Hex Head Cap Screws

(1/4”–20 x 3”)”, four “Lock Wash-

ers” (1/4”) and four flat

washers (1/4”)”.

STEP 2

Remove the main “Air-Valve

Assembly” from the pump.

STEP 3

Remove the “Air-Valve Gasket”

from the main “Air-Valve

Assembly”.

TOOLS NEEDED

1) One Wrench, 7/16 Inch

2) One Pick, General Purpose

3) One Pair of Pliers

WARNING Prior to servicing the pump, ensure that the air

and fluid lines are closed and disconnected. While wearing personal

protective equipment, flush, drain and process liquid from the

pump in a safe manner.

STEP 4

Remove the “Shuttle Plate” from

the main “Air-Valve Assembly”.

Note: The smooth shinny side of

the shuttle plate should be toward

the shuttle car.

STEP 5

Remove the “Shuttle” from the

main “Air-Valve Assembly”.

STEP 6

Using the pair of pliers, remove

the “Air Valve End Plug” from the

main “Air-Valve Assembly”.

Ensure the “O-Ring” is installed

when reassembling.

REPAIR AND ASSEMBLY

all-o.com

STEP 7

Remove the “Air Valve Spool” from

the main “Air-Valve Assembly”.

Note: The shorter piston is to be

on the plug side.

STEP 8

Using the pick, remove the “Lip

Seal (Air Valve)” from the main

“Air-Valve Assembly”.

STEP 9

Using the pick, remove the

second “Lip Seal (Air Valve)” from

the main “Air-Valve Assembly”.

AIR VALVE ASSEMBLY

To assemble the air valve, reverse the order of disassembly. During

assembly, ensure that the open side of the lip-seals are both facing

each other inward. Install the shuttle plate with the smooth/shinny side

toward the shuttle car. Lubrication of the air valve assembly, with a non-

synthetic lubricant, is recommended. Magna-Lube or Magna-Plate are

recommended for assembly lubrication (see detailed parts list for order-

ing information).

Note that if the lip-seals are installed incorrectly, they will be unable to

rotate. Insert the spool, the spool’s shorter piston is to be on the plug

side, ensure O-ring is enstalled, and then the air-valve end plug into

position.

16

all-o.com 17

PILOT VALVE REMOVAL

STEP 1

Using the screwdriver, remove

three “Phillips Flat-Head Mach

Screws” (#6-32 x 7/16) in order to

remove the “Retaining Plate”.

Repeat for other side of the pump.

STEP 2

Remove the diaphragm rod and

the pilot sleeve assembly from the

“Intermediate”.

STEP 3

Remove both “Lip Seals

(Diaphragm Rod)” and both “End

Spacers (Pilot Sleeve)” from the

pilot sleeve assembly. Remove

both “O-Rings (End Spacer)” from

both “End Spacers (Pilot Sleeve)”.

TOOLS NEEDED

1) One Screwdriver, Phillips #2

2) Two Wrenches, 7/16 Inch

WARNING Prior to servicing the pump, ensure that the air

and fluid lines are closed and disconnected. While wearing personal

protective equipment, flush, drain and process liquid from the

pump in a safe manner.

STEP 4

Remove three “Inner Spacers

(Pilot Sleeve)” and four “O-Rings

(Pilot Sleeve)” from the pilot

sleeve assembly.

STEP 6

Remove the “Pilot Sleeve” from

the disassembled “Diaphragm

Rod Assembly”.

REPAIR AND ASSEMBLY

STEP 5

Using two 7/16 inch wrenches,

disassemble the “Diaphragm Rod

Assembly” into its two parts.

Note they are installed with thread

locker.

all-o.com

PILOT VALVE ASSEMBLY

To assemble the pilot valve, reverse the order of disassembly. Should

process fluid have contact with the pilot valve O-rings, they should be

replaced as swelling may occur and cause irregular operation. During

assembly, ensure that the open side of the lip-seals are facing outward.

Lubrication of the pilot sleeve assembly, with a non-synthetic lubricant,

is

recommended in order to facilitate re-assembly into the intermediate.

Magna-Lube or Magna-Plate are recommended for assembly lubrication

(see detailed parts list for ordering information).

TORQUE SPECIFICATION CHART

RECOMMENDED TORQUE SPECIFICATIONS

1” Pumps Wrench Size

Manifold Bolts 115 in-lbs (13 N-m) 1/2”

Chamber Bolts 85 in-lbs (9.6 N-m) 1/2”

Air Valve Bolts 40 in-lbs (4.5 N-m) 7/16”

Diaphragm plate 70 in-lbs (7.9 N-m) 3/4”

Diaphragm plate (PTFE) 70 in-lbs (7.9 N-m) 3/4”

IN/FTLBS N•m

18

all-o.com 19

EXPLODED VIEW & PARTS LIST

ALUMINUM & STAINLESS STEEL

A100-*A*-****-*** (NON-PTFE DIAPHRAGM)

SECTION 8

2

3

6

7

8

9

14

15

16

17

18

19

20

21

22

24

25

26

27

29

32

13

36

3

21

2

21

2

21

22

24

11

12

25

34

30

23

1

4

5

10

28

33

31

35

28

33

37

all-o.com

PARTS LIST - ALUMINUM & STAINLESS STEEL

A100-*A*-****-*** (NON-PTFE DIAPHRAGM)

ITEM DESCRIPTION QTY PUMP MODEL PART NO. MATERIAL

1 PILOT SLEEVE 1 All Models 10105-31 Acetel

2 INNER SPACER PILOT SLEEVE 3 All Models 10203-40 Polyproplyene

3 END SPACER PILOT SLEEVE 2 All Models 10209-40 Polyproplyene

4 & 5 DIAPHRAGM ROD ASSEMBLY 1 All Models 35005-00 Stainless Steel

6 SHUTTLE 1 All Models 10431-32 Special

7 SHUTTLE PLATE 1 All Models 10451-77 Ceramic

8 AIR VALVE SPOOL 1 All Models 10482-31 Acetel

9 DIAPHRAGM 2 A100-*A*-N***-*** 10612-11 Buna-N

A100-*A*-V***-*** 10612-13 Viton®/FKM

A100-*A*-E***-*** 10612-15 EPDM

A100-*A*-G***-*** 10612-19 Geolast®

A100-*A*-S***-*** 10612-23 Santoprene®

10 OUTER CHAMBER 2 A100-*AA-****-*** 10726-20 Aluminum

A100-*A3-****-*** 10726-26 Stainless Steel

11 VALVE SEAT 4 A100-*A*-**A*-*** 10927-20 Aluminum

A100-*A*-**3*-*** 10927-26 Stainless Steel

A100-*A*-**P*-*** 10927-39 Polyproplyene

A100-*A*-**Y*-*** 10927-42 Nylon

12 BALL 4 A100-*A*-*G**-*** 11008-19 Geolast®

A100-*A*-*V**-*** 11008-13 Viton®/FKM

A100-*A*-*E**-*** 11008-15 EPDM

A100-*A*-*N**-*** 11008-21 Buna-N

A100-*A*-*S**-*** 11008-23 Santoprene®

A100-*A*-*3**-*** 11008-26 Stainless Steel

A100-*A*-*T**-*** 11008-45 PTFE

13 INNER DIAPHRAGM PLATE 2 All Models 11104-25 Plated Steel

14&32 OUTER DIAPHRAGM PLATE WITH STUD 2 A100-*AA-****-*** 11220-20 Aluminum

A100-*A3-****-*** 11220-26 Stainless Steel

15 DISCHARGE MANIFOLD 1 A100-NAA-****-0** 11310-20-NPT Aluminum

A100-BAA-****-0** 11310-20-BSPT Aluminum

A100-NA3-****-0** 11310-26-NPT Stainless Steel

A100-BA3-****-0** 11310-26-BSPT Stainless Steel

16 SUCTION MANIFOLD 1 A100-NAA-****-0** 11311-20-NPT Aluminum

A100-BAA-****-0** 11311-20-BSPT Aluminum

A100-NA3-****-0** 11311-26-NPT Stainless Steel

A100-BA3-****-0** 11311-26-BSPT Stainless Steel

17 INTERMEDIATE 1 A100-*A*-****-*** 11526-20 Aluminum

18 AIR VALVE BODY 1 All Models 11619-20 Aluminum

19 AIR VALVE END PLUG 1 All Models 11706-20 Aluminum

20 ORING AIR VALVE END PLUG 1 All Models 11913-11 Nitrile

21 ORING PILOT SLEEVE 4 All Models 11920-16 Urethane

22 ORING END SPACER 2 All Models 11923-11 Nitrile

23 ORING VALVE SEAT 4 A100-*A*-***N-*** 11947-11 Nitrile

A100-*A*-***V-*** 11947-13 Viton®/FKM

A100-*A*-***E-*** 11947-15 EPDM

A100-*A*-***T-*** 11947-17 PTFE

24 LIP SEAL DIAPHRAGM ROD 2 All Models 12000-76 Nitrile

20

Other manuals for A100

1

Table of contents

Other All-Flo Water Pump manuals

Popular Water Pump manuals by other brands

EBARA

EBARA ETM Operating and maintenance manual

MULTIQUIP

MULTIQUIP MAYCO LS300P Operation manual

Dover

Dover PSG WILDEN PS810 Engineering, operation & maintenance

Bosch

Bosch 0 986 580 943 installation instructions

DLS

DLS DLS-Pump 2071 user manual

Wilo

Wilo RP Series Installation and maintenance instructions

Zehnder Pumpen

Zehnder Pumpen MICROBOY operating instructions

Grundfos

Grundfos DMX 221 Installation and operating instructions

Grundfos

Grundfos Hydro Multi-B instructions

Grundfos

Grundfos MP 1 / Redi-Flo2 user manual

Hozelock Cyprio

Hozelock Cyprio EasyClear 9000 Installation and operating instructions

Costway

Costway ET1217 user manual