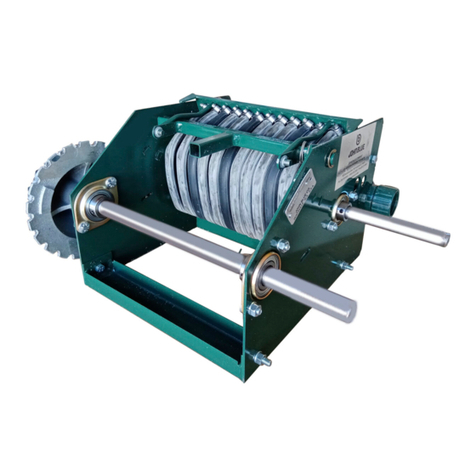

3.3 Racking/ Transferring Wine into glass

with the All in One Wine Pump

The All in One Wine Pump makes it very

simple for you transfer your wine. With this unit,

you now have the ability to transfer wine side by

side from a glass carboy or an open-top

fermenter to receiving glass carboy. You can

even transfer wine from the floor to an elevated

surface. This avoids the need to lift a heavy filled

carboy! The All in One can transfer from

virtually any container, as long as it is

transferring into a glass carboy that can

withstand the vacuum pressure.

Before using your new pump for the first

time, make sure to review all instructions

outlined in this manual. If you are having

trouble getting set up, videos are available on

allinonewinepump.com. Or you can contact us

directly at Allinonewinepump.com

We recommend you practice with

water first to gain experience and an

understanding of how the pump works.

1. Sanitize the unit (Section 2.3) (When

testing the unit with water, forgo the

sanitization process until you learn how

to set-up the All in One Wine Pump.

Otherwise, when using the pump with

wine, as always, the first step is to

sanitize the tubing, racking canes and

your glass carboy.

2. Connect your vacuum tubing by

matching BLUE to BLUE on the over-

flow container and matching RED to

RED to the #6.5 bung.

3. Connect your wine transfer tubing to the

racking cane and the other end to the

racking cane that is inserted in the #6.5

bung.

4. Insert the #6.5 bung into the receiving

glass carboy. Push downward on the

bung to ensure you have a good

seal.

5. Insert the racking cane into your carboy

of wine.

6. Turn the unit on.

7. Wine will start to flow from the full

vessel to the empty one.

8. With the installation of the vacuum

control valve (sold separately,) you can

slow the flow down as it reaches the

top. This will give you your desired fill-

level and will prevent wine from

entering the vacuum tubing.

9. Once the receiving vessel is full, press

the vacuum release valve to stop flow

and stop the vacuum.

10. Turn off the unit. Remove the #6.5 bung

assembly, top up the vessel and replace

your bung with air-lock or a solid bung.

If you are unable to top up your vessel

at this time, a headspace eliminator is

available at allinonewinepump.com

11. Rinse the wine transfer tubing with

warm water and hang dry. The vacuum

tubing will not need rinsing unless wine

has been sucked through into the over-

flow container.

Racking/ transferring from a large

vessel to a smaller vessel. When the wine

transfer is complete and the bung racking

assembly is left in the receiving carboy, wine

could be sucked back through the wine transfer

tubing and into the donor carboy in an attempt

at equilibrium between the two vessels. This may

happen even when the pump is shut off.

To prevent this:

Lift the racking cane out of the wine in

the donor vessel to get a small amount

of air in the wine transfer line.

Or remove the #6.5 bung racking

assembly and set it aside or in the next

receiving carboy.

Note: The All in One Wine Pump can also

be used to transfer wine into plastic (PET)

carboys. Please visit allinonewinepump.com for

the the Plastic (PET) Carboy Transfer Kit.