allfi 921300 User manual

Operating and maintenance instruction

Swivel Joint 90° and Parallel 1/4" 2.0 s ort

(4150 & 6200 bar / 60,000 & 90,000 psi)

Operating and maintenance instruction

ALLFI AG - Riedenmatt 1 – CH-6370 Stans

Tel.: +41 41 618 05 05 - Fax: +41 41 618 05 10

E-Mail: info@allfi.com - ttp://www.allfi.com

July 2022

General

2 / 24

Swivel Joint 90° & parallel 2.0 short (4150 & 6200 bar / 60,000 & 90,000 psi) ugust 8, 2022

Scope of application

T e present operating and maintenance instruction is valid for Swivel Joints 2.0.

921300 Swivel Joint 90° 1/4" 2.0 s ort 4150bar

921300-P Swivel Joint 90° 1/4" 2.0 s ort 6200bar

921400-P Swivel Joint parallel 1/4" 2.0 s ort 6200bar

General

3 / 24

Swivel Joint 90° & parallel 2.0 short (4150 & 6200 bar / 60,000 & 90,000 psi) ugust 8, 2022

Table of contents

1 General .......................................................................................................................................4

1.1 Information on use of the operation and maintenance instruction ......................................4

1.2 Scope of delivery .................................................................................................................4

1.3 Warranty claim ....................................................................................................................4

1.4 Disclaimer............................................................................................................................4

2 Security .......................................................................................................................................5

2.1 Declaration of symbols ........................................................................................................5

2.2 General warning notes ........................................................................................................5

2.3 Intended use .......................................................................................................................6

2.4 Inadmissible usage ..............................................................................................................7

2.5 Residual risks .......................................................................................................................7

2.6 Safety installations ..............................................................................................................8

2.7 Personal protection equipment ...........................................................................................8

2.8 Qualification of the staff ......................................................................................................8

3 Structure and function ................................................................................................................9

3.1 Structure .............................................................................................................................9

3.2 Function ............................................................................................................................ 11

3.3 ccessories ........................................................................................................................ 11

4 General technical data .............................................................................................................. 12

5 Installation and commissioning ................................................................................................. 13

5.1 Fixing the swivel joint to the machine ................................................................................ 14

5.2 Flush the swivel joint ......................................................................................................... 15

6 Deinstallation ............................................................................................................................ 15

7 Maintenance, Service and Repair .............................................................................................. 16

7.1 Regular maintenance ......................................................................................................... 16

7.2 Preventive maintenance .................................................................................................... 16

7.3 Replace HP-Seal ................................................................................................................. 17

7.4 Replace cover and pressure plate ...................................................................................... 18

7.5 Replace shaft and pressure plate ....................................................................................... 19

7.6 Replace needle bearing and o-rings ................................................................................... 21

8 Faults and Troubleshooting ....................................................................................................... 23

8.1 Leakage of the Swivel Joint ................................................................................................ 24

8.2 Further troubleshooting .................................................................................................... 24

9 Recycling ................................................................................................................................... 24

Appendix A – Tec nical drawing and parts list (s ipped wit t e product)

General

4 / 24

Swivel Joint 90° & parallel 2.0 short (4150 & 6200 bar / 60,000 & 90,000 psi) ugust 8, 2022

1 General

1.1 Information on use of the operation and maintenance instruction

T is operation and maintenance instruction is a key part of t e product. T e information in t is manual

is mandatory and must be read and understood by all t e persons before operating wit t e Swivel

Joint. T e manual must be stored in distance as well as always accessible to t e persons, working

wit t e Swivel Joint

If you ave any questions regarding t e contents of t is manual, please contact t e manufacturer di-

rectly.

ALLFI AG - Riedenmatt 1 – CH-6370 Stans

Tel.: +41 41 618 05 05 - Fax: +41 41 618 05 10

E-Mail: info@allfi.com - ttp://www.allfi.com

1.2 Scope of delivery

T e individual parts contained in t e s ipment can be gat ered from t e set list in t e appendix A

(tec nical drawing and part list). Upon receipt, t e s ipment as to be c ecked of integrity. Possible

detected defectives must be reported immediately to t e manufacturer.

1.3 Warranty claim

T e ALLFI AG grants warranty for t e s ipped parts as followed:

Material and manufacturer faults of 12 mont s from date of delivery or

Defects wit in t e first 2000 ours of operation

Following spare parts are excluded from t e warranty:

Pressure Plate

HP-Seal

S aft

Bearing

1.4 Disclaimer

ALLFI AG refuses any claims of liability (material damages, p ysical injury, as well as disruption of op-

eration), t at are a result of disregarding t is operating and maintenance instruction.

For example, t e damage because of:

Inadmissible application of t e Swivel Joint

Defective maintenance

T e disregard of operation instructions

C emical and electrolytical influences

Use of parts, spare parts or accessory from a t ird-party manufacturer

Arbitrary modifications

Not or insufficiently trained staff

T e disregard of all t ese instructions appens on exclusive risk and exclusive responsibility of t e cli-

ent. T e ALLFI AG is not liable for any production downtimes.

Security

5 / 24

Swivel Joint 90° & parallel 2.0 short (4150 & 6200 bar / 60,000 & 90,000 psi) ugust 8, 2022

2 Security

2.1 Declaration of symbols

T is operating and maintenance instruction manual contains important notes and symbols, w ic are

to be considered and followed. T ese include:

DA GER

Danger emphasizes operating and service procedures that if not avoided,

may lead to death or serious personal injuries.

WAR I G

Warnings emphasize operating or service procedures, or conditions that

can result in serious personal injury or death.

CAUTIO

Cautions emphasize operating or service procedures, or conditions that

can result in equipment damage or impairment of system operation. If not

avoided, light or medium body injuries could be the consequence.

NOTE

otes provide additional information that can expedite or improve operat-

ing or service procedures.

Danger symbol wit out key word: Additional notes

2.2 General warning notes

Using of t e Swivel Joint, t e following warnings are to be considered.

T e specified warnings are not only restricted to t e operation wit t e maximal

permissible operating pressure of 4150 bar / 60,000 psi or 6200 bar / 90,000

psi. T ey are also valid on work wit reduced operation pressures!

Security

6 / 24

Swivel Joint 90° & parallel 2.0 short (4150 & 6200 bar / 60,000 & 90,000 psi) ugust 8, 2022

DA GER

Danger of cutting of extremities on contact with waterjet

T e contact wit t e ig kinetic energy performing waterjet can ave t e conse-

quence of cutting of extremities or lead to ot er injuries.

Therefore:

Operate t e mac ine only, w en nobody stands in t e danger zone of t e

waterjet.

Never touc t e waterjet, not even wit personal protective equipment.

Always maintain a sufficient safety distance from t e swivel joint w en it is

pressurized.

Any injuries in connection wit t e waterjet, alarm t e emergency doctor imme-

diately.

CAUTIO

Danger of breathing difficulties and irritation of the skin and eyes by re-

leased solid particles or dust.

During mac ining of certain material, solid particles and dust may float in t e air,

w ic could cause breat ing difficulties and irritations to t e skin and eyes.

Therefore:

Ensure t e proper ventilation of t e room surrounding t e mac inery.

Ensure to wear t e personal protective equipment (protection glasses,

breat ing mask, gloves, …)

Additionally, t e rules and regulations of t e working place are to be followed to

prevent injuries!

2.3 Intended use

T e Swivel Joint is designed for t e transmission of rotary movements. T e swivel joint must be firmly

attac ed to t e mac ine. Only pure water may be used as working fluid. T e tec nical limit values

must always be observed.

Security

7 / 24

Swivel Joint 90° & parallel 2.0 short (4150 & 6200 bar / 60,000 & 90,000 psi) ugust 8, 2022

2.4 Inadmissible usage

Inadmissible usage of t e Swivel Joint includes:

T e usage of all ot er fluids ot er t an water

T e addition of ot er substances to t e water

Closure of t e pressure relief oles

Excessive application of t e Swivel Joint

Exceeding permitted limits

Operating t e Swivel Joint wit demounted or disabled tec nical protection

Transmission of axial and/or radial forces

T e use in t e food or p armaceutical sector

Likewise, all ot er uses of t e Swivel Joint deviating from t e intended use are not permitted. All ques-

tions s ould be adressed directly to t e manufacturer.

ALLFI AG - Riedenmatt 1 – CH-6370 Stans

Tel.: +41 41 618 05 05 - Fax: +41 41 618 05 10

E-Mail: info@allfi.com - ttp://www.allfi.com

2.5 Residual risks

T e manufacturer and/or operator of t e mac ine w ere t e Swivel Joint is built in, as taken every

precautionary measure possible to reduce residual risks, as far as possible reasonably practicably.

Operation

phase

Damage Danger Reason (possible)

measures

Operation P ysical in-

juries

Liquids leaking under

ig pressure (e.g. at

pressure relief oles)

Ignoring t e torque Follow t e torque

Damaged sealing

surfaces Regular supervi-

sion

Busted/Cracked con-

nections and ig -

pressure compo-

nents as a result of

defects

Protective wall as

a tec nical pro-

tective measure

Flying fragments

Ignoring t e torque Follow t e torque

Damaged sealing

surfaces Regular supervi-

sion

Busted/Cracked con-

nections and ig -

pressure compo-

nents as a result of

defects

Protective wall as

a tec nical pro-

tective measure

Security

8 / 24

Swivel Joint 90° & parallel 2.0 short (4150 & 6200 bar / 60,000 & 90,000 psi) ugust 8, 2022

2.6 Safety installations

T e manufacturer or t e operator of t e full mac ine, w ic t e Swivel Joint is built in, as ensured t e

following safety arrangements:

Safety devices to prevent flying fragments or liquids leaking under ig pressure

Emergency stoppage to immediately s ut down t e operating mac ine. T is emergency stop-

page is an integral part of t e system t at automatically activates in case of t e failure of ig -

pressure components or massive operating errors, alternatively it may be manually activated

by t e operator.

Danger for t e operator will arise if safety protections are not functionally, not

followed or evaded anytime. T e operator as to ensure t e functionality of t e

safety protections anytime.

2.7 Personal protection equipment

T e operator must offer is staff following protection equipment w ile e’s working:

Ear protector against:

Noise emissions

Wear protection glasses against:

Fluids and dust particles

Flying fragments

Hand guards against:

S arp edges of components

Intrusion of micro particles into t e skin

In alation protection against:

Dust particles, micro particles and spray mist

2.8 Qualification of the staff

T e Swivel Joint may only be operated and maintained by certified, trained staff.

Structure and function

9 / 24

Swivel Joint 90° & parallel 2.0 short (4150 & 6200 bar / 60,000 & 90,000 psi) ugust 8, 2022

3 Structure and function

3.1 Structure

Legend for:

921300, Swivel Joint Angle ¼” 2.0 s ort 4150bar

Item.

Qty.

Description Part-Number

1 1 Cover 90° Angle 2.0 921315-P

2 1 HP-Seal 2.0 912052

3 1 Pressure Plate 2.0 921002-P

4 1 S aft for Swivel joint 921313

5 1 Needle bearing 022016

6 1 Casing for Swivel Joint 921314

7 1 O-Ring D=9.53 x 1.78 010050

8 2 Gland Nut 1/4" 4150 bar 701403

9 2 Collar 1/4" 711403

10 1 O-Ring D=20.63 x 2.62 010145

Structure and function

10 / 24

Swivel Joint 90° & parallel 2.0 short (4150 & 6200 bar / 60,000 & 90,000 psi) ugust 8, 2022

Legend for:

921300-P, Swivel Joint Angle ¼” 2.0 s ort 6200bar

Item.

Qty.

Description Part-Number

1 1 Cover 90° Angle 2.0 921315-P

2 1 HP-Seal 2.0 912052

3 1 Pressure Plate 2.0 921002-P

4 1 S aft for Swivel joint 921313-P

5 1 Needle bearing 022016

6 1 Casing for Swivel Joint 921314

7 1 O-Ring D=9.53 x 1.78 010050

8 2 Gland Nut 1/4" 6200 bar 701403-P

9 2 Collar 1/4" 711403

10 1 O-Ring D=20.63 x 2.62 010145

Additionally for:

921400-P Swivel Joint Angle ¼” 2.0 s ort parallel 6200bar

Item.

Qty.

Description Part-Number

8 1 Gland Nut 1/4" 6200 bar 701403-P

9 1 Collar 1/4" 711403

11 1 Elbow 1/4" 201414A-P

Structure and function

11 / 24

Swivel Joint 90° & parallel 2.0 short (4150 & 6200 bar / 60,000 & 90,000 psi) ugust 8, 2022

3.2 Function

T e Swivel Joint can be rotated wit very low resistance even at a maximum allowed pressure. It is

not designed for t e transmission of axial and radial forces.

3.3 Accessories

Article: Wear parts set for 921300 Wear parts set for 921300-P

and 921400-P

Article no: 890051 890051-P

Consisting of: HP-Seal, Pressure Plate,S aft,

Needle bearing, O-Ringe

HP-Seal, Pressure Plate,S aft,

Needle bearing, O-Ringe

Article: Torque wrenc Spanner

Article no: 883000 AF 17 – 000339

AF 22 – 000272

Function: Tig tens screws wit a spe-

cific torque

Spanner for torque wrenc

Article: Disassembly Tool

Molykote DX Paste

Article no: 910078 051055

Function: Disassembly HP Seal from

Swivel Joint

Greasing screw connections

and metallic contact areas

General technical data

12 / 24

Swivel Joint 90° & parallel 2.0 short (4150 & 6200 bar / 60,000 & 90,000 psi) ugust 8, 2022

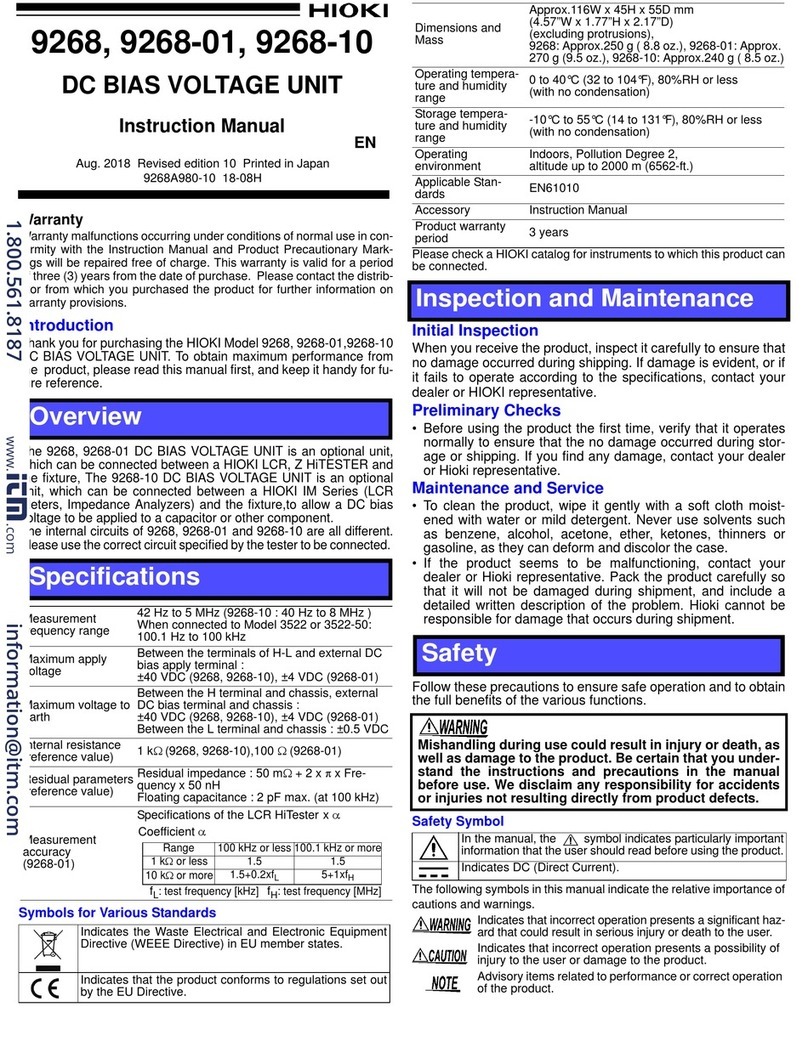

4 General technical data

Article no: 921300 921300-P 921400-P

Maximal working pressure: 4150 bar /

60,000 psi

6200 bar /

60,000 psi

6200 bar /

60,000 psi

Maximum recommended flow rate: 5 L/min /

1.3 gal/min

3 L/min /

0.8 gal/min

3 L/min /

0.8 gal/min

Connection tube diameter: HP-tube 1/4" HP-tube 1/4" HP-tube 1/4"

DN nominal size 1.6 mm 1.2 mm 1.2 mm

Flow factor Kv for water 1.2 l/min 0.8 l/min 0.7 l/min

Maximal working temperature: 50 °C 50 °C 50 °C

Maximal stocking temperature: 60 °C 60 °C 60 °C

Weig t: ca. 460 g ca. 460 g ca. 510 g

Requested water quality:

Water parameter Unit Value

Electrical Conductivity µS / cm 100 – 450

PH-value - 7.0 - 8.5

Total ardness °dH 2.0 - 10.0

Carbonate ardness

(acid capacity pH 4.3)

°dH 2.0 - 10.0

Degree of alkalinity pH 8.2 mmol / l 0 - 0.25

C loride mg / l ≤ 50

Iron mg / l ≤ 0.2

Manganese mg / l ≤ 0.05

Copper mg / l ≤ 2.0

Silicate mg / l ≤ 5.0

(Filtrate-) solid content mg / l ≤ 350

Tec nical data as dimensions can be found in t e tec nical drawing in appendix A.

Installation and commissioning

13 / 24

Swivel Joint 90° & parallel 2.0 short (4150 & 6200 bar / 60,000 & 90,000 psi) ugust 8, 2022

5 Installation and commissioning

WAR I G

Risk of injury: It is forbidden to close the pressure relief holes.

By closing t e pressure relief oles, t e Swivel Joint or parts of it may explode.

Therefore: Never close or cover any pressure relief oles.

Positions of the pressure relief holes (red arrows):

NOTE

Material damage as a result of pitting

Not or insufficient greased t reads or contact areas can pit.

Therefore:

Always grease t reads and metallic contact areas wit DX-Paste (Article no.

051055). C eck appendix A for additional information.

NOTE

Material damage or leakage as a result of fouling

Fouling components, especially at t reads, can lead to leakages and damage.

Therefore:

Pay attention to t e cleanliness of t e components w ile maintaining.

General installation tip:

Absolute cleanliness of t e pipes is important before connection.

Follow t e steps below for installation.

During startup and after inspection or maintenance, c eck t e water tig tness of

t e pneumatic valve.

Installation and commissioning

14 / 24

Swivel Joint 90° & parallel 2.0 short (4150 & 6200 bar / 60,000 & 90,000 psi) ugust 8, 2022

NOTE

Material damage as a result of leakages

Constant leakage may damage t e product.

Therefore:

Immediately eliminate leakages (see c apter 8 „Faults and Troubles ooting”).

5.1 Fixing the swivel joint to the machine

T e swivel joint is attac ed to t e mac ine wit t e four M5 t reads. Furt er fastening options must be

discussed wit t e manufacturer.

921300 921300-P

921400-P

During installation, ensure t at none of t e pressure relief oles are closed!

Make sure t at t e HP tubes are connected stress-free, i.e. do not exert any forces on

t e s aft.

Deinstallation

15 / 24

Swivel Joint 90° & parallel 2.0 short (4150 & 6200 bar / 60,000 & 90,000 psi) ugust 8, 2022

1. Slide t e gland nut over t e HP tube

2. Screw t e collar on t e HP tube (left-

anded t read). T ere must be 1 or 2

convolutions visible between t e conus

and t e pressure ring.

3. Connect t e ig -pressure lines to t e

Swivel Joint (Torque see appendix A)

5.2 Flush the swivel joint

Flus swivel joint wit water (p ≤ 500 bar) for 5 to 10 seconds.

6 Deinstallation

Before uninstalling t e Swivel Joint, release t e pressure of t e ig -pressure pipes

and protect t em against unexpected re-pressurization

Remove ig pressure line and its com-

ponents.

Remove Swivel Joint from mac ine.

Maintenance, Service and Repair

16 / 24

Swivel Joint 90° & parallel 2.0 short (4150 & 6200 bar / 60,000 & 90,000 psi) ugust 8, 2022

7 Maintenance, Service and Repair

Before uninstalling t e Swivel Joint, release t e pressure of t e ig -pressure pipes

and protect t em against unexpected re-pressurization

T e swivel joint must be removed from t e mac ine for maintenance, service and repair work in ac-

cordance wit C apter 6.

All maintenance, service and repair work not listed in t is c apter must be carried out by t e manufac-

turer.

NOTE

Material damage or leakage as a result of fouling

Dirty components, especially considering t e t reads, may lead to leakages and

damage of t e Swivel Joint.

Therefore:

Ensure a proper cleaning of t e components.

NOTE

Property damage as a result of pitting

T reads t at are not greased or insufficiently greased may pit.

Therefore:

Always grease t reads and metallic contact areas wit DX-Paste (Article no. 051055).

C eck appendix A for additional information.

7.1 Regular maintenance

W at By w om W en

C eck tig tness Operator Continuous

Rotary resistor Operator Periodically

7.2 Preventive maintenance

Every 25'000 revolutions or rotational movements: Replace seal and pressure plate, after 1 year at t e

latest.

Every 75'000 revolutions or rotational movements: Maintenance at ALLFI, replace bearing and s aft,

after 3 years at t e latest.

Replace swivel joint after 20'000 cycles: Pressure increase from 0 to > 3500 bar (pump start).

Maintenance, Service and Repair

17 / 24

Swivel Joint 90° & parallel 2.0 short (4150 & 6200 bar / 60,000 & 90,000 psi) ugust 8, 2022

7.3 Replace HP-Seal

Remove t e swivel joint from t e mac ine according to c apter 6.

1

1. Clamp t e swivel joint in a vice at t e

wrenc size 32mm.

Attention! Use protective jaws.

2

1. Loosen t e cover of t e swivel joint

wit an open-ended wrenc AF 22.

2. Screw t e cover out of t e casing.

3. C eck t e s aft for wear in t e area

of t e seal.

If t is is damaged, t e s aft must

also be replaced (see 7.5).

3

1. Remove t e seal wit Disassembly

Tool (910078).

2. Clean cover and casing.

4

1. Grease t read and sealing surface

according to appendix A.

2.

Pus t e new HP-seal onto t e

s aft.

3.

Screw on cover.

4.

Tig ten cover wit torque wrenc to

AF 22 (torque see Appendix A).

5.

Fix t e swivel joint in t e mac ine

according to c apter 5.1, flus ac-

cording to c apter 5.2 and c eck t e

water tig tness.

Maintenance, Service and Repair

18 / 24

Swivel Joint 90° & parallel 2.0 short (4150 & 6200 bar / 60,000 & 90,000 psi) ugust 8, 2022

7.4 Replace cover and pressure plate

Remove t e swivel joint from t e mac ine according to c apter 6. T e following pictures s ow t e

Swivel Joint 90° Angle. For t e Swivel Parallel proceed in t e same way.

1

1. Clamp t e swivel joint in a vice at

t e wrenc size 32mm.

Attention! Use protective jaws.

2

1. Loosen t e cover of t e swivel joint

wit an open-ended wrenc AF 22.

2. Screw t e cover out of t e casing.

3. C eck t e s aft for wear in t e area

of t e seal.

If t is is damaged, t e s aft must

also be replaced (see 7.5).

3

1. Pus t e s aft out of t e ousing

until t e gland nut is in contact. T is

also pus es out t e Pressure plate.

4

1. Remove t e pressure plate from t e

ousing and dispose of it.

2. Remove t e O-ring from t e ousing

and dispose of it. 3.

3. Clean s aft and ousing.

5

1. Pus t e s aft back into t e ousing

until it stops.

2. Grease t read, sealing surface and

new O-ring according to appendix A.

3. Press t e O-ring between t e s aft

and t e ousing until it is in contact

wit t e bearing all around.

Maintenance, Service and Repair

19 / 24

Swivel Joint 90° & parallel 2.0 short (4150 & 6200 bar / 60,000 & 90,000 psi) ugust 8, 2022

6

1. Insert new pressure plate

2.

Grease sealing surface according to

appendix A.

3.

Slide new HP-seal onto s aft.

7

1. Grease t read according to appendix

A.

2.

Screw on new cover.

3.

Tig ten cover wit torque wrenc to

AF 22 (torque see Appendix A).

4. Fix t e swivel joint in t e mac ine

according to c apter 5.1, flus ac-

cording to c apter 5.2 and c eck t e

water tig tness.

7.5 Replace shaft and pressure plate

Remove t e swivel joint from t e mac ine according to c apter 6. T e following pictures s ow t e

Swivel Joint 90° Angle. For t e Swivel Parallel proceed in t e same way.

1

1. Clamp t e swivel joint in a vice at

t e wrenc size 32mm.

Attention! Use protective jaws.

2

1. Loosen t e cover of t e swivel joint

wit an open-ended wrenc AF 22.

2. Screw t e cover out of t e casing.

Maintenance, Service and Repair

20 / 24

Swivel Joint 90° & parallel 2.0 short (4150 & 6200 bar / 60,000 & 90,000 psi) ugust 8, 2022

3

1. Remove t e seal wit Disassembly

Tool (910078).

2. Clean cover.

4

1. Remove collar and gland nut

5

1. T e s aft can now be pressed out of

t e ousing wit out muc effort. T is

also forces t e pressure plate out of

t e ousing.

2. Dispose s aft and pressure plate

6

1. Remove t e O-ring from t e ousing

if it as not already been ejected wit

t e s aft and discard it

2. clean ousing

7

1. Pus a new s aft into t e ousing

until it stops.

2. Grease t read, sealing surface and

new O-ring according to appendix A.

3. Press t e O-ring between t e s aft

and t e ousing until it is in contact

wit t e bearing all around.

8

1. Insert new pressure plate

2.

Grease sealing surface according to

appendix A.

3. Slide new HP-seal onto s aft.

This manual suits for next models

2

Table of contents

Other allfi Industrial Equipment manuals