allfi Abrasive Feeder 2.0 User manual

General

2 / 26

Abrasiv Feeder 2.0 27.07.2022

Scope of application

This installation and maintenance manual is valid for the following abrasive feeder

➢951400

➢FP-951400

➢TE-951400

➢WO-951400

The descriptions are shown with all options. Function and execution without mounted options are car-

ried out in the same way.

Adapter plates for most common motors are available on request. Please simply send a request with

details of the exact motor type to [email protected]m

General

3 / 26

Abrasiv Feeder 2.0 27.07.2022

Table of contens

1 General............................................................................................................................................ 5

Information on use of the operation and maintenance instruction....................................... 5

Scope of delivery ..................................................................................................................... 5

Warranty claim........................................................................................................................ 5

Disclaimer................................................................................................................................ 5

2 Security............................................................................................................................................ 6

Declaration of symbols............................................................................................................ 6

Intended use............................................................................................................................ 6

Inadmissible usage .................................................................................................................. 6

Residual risks........................................................................................................................... 7

Safety installations .................................................................................................................. 8

Personal protection equipment .............................................................................................. 8

Qualification of the staff.......................................................................................................... 8

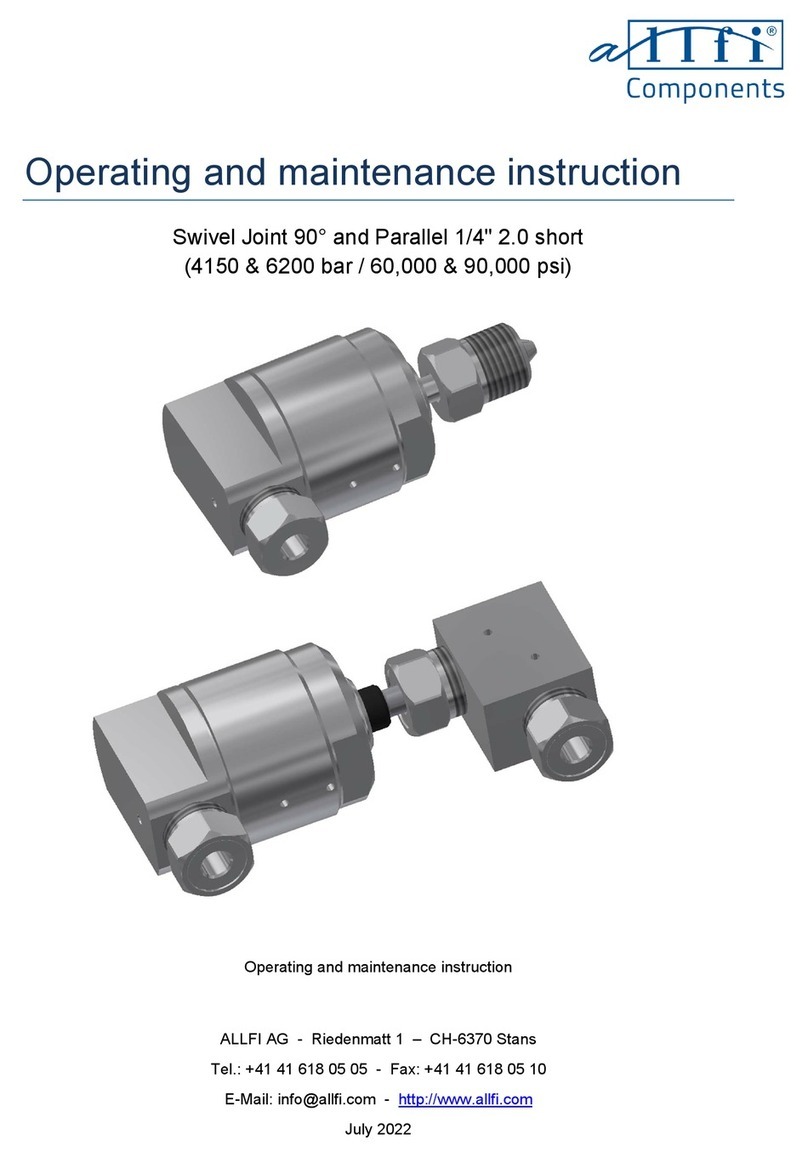

3 Structure and function of the abrasive feeder................................................................................ 9

Structure.................................................................................................................................. 9

Function................................................................................................................................. 10

Accessories ............................................................................................................................ 10

4 General technical data .................................................................................................................. 11

Delivery rate sand 80 mesh................................................................................................... 11

5 Installation and commissioning .................................................................................................... 12

Installing the abrasive dosing system.................................................................................... 12

Connecting hoses .................................................................................................................. 13

Electrical connection ............................................................................................................. 13

5.3.1 Mounting the connector housing.................................................................................. 14

6 Uninstalling.................................................................................................................................... 14

7 Maintenance.................................................................................................................................. 15

Belt replacement................................................................................................................... 15

Cleaning after backflow recoil or sand accumulation ........................................................... 16

8 Options .......................................................................................................................................... 17

Level Sensor........................................................................................................................... 17

Check Valve Sensor................................................................................................................ 18

9 Faults and Troubleshooting........................................................................................................... 20

10 Recycling.................................................................................................................................... 20

General

4 / 26

Abrasiv Feeder 2.0 27.07.2022

11 Data sheets................................................................................................................................ 21

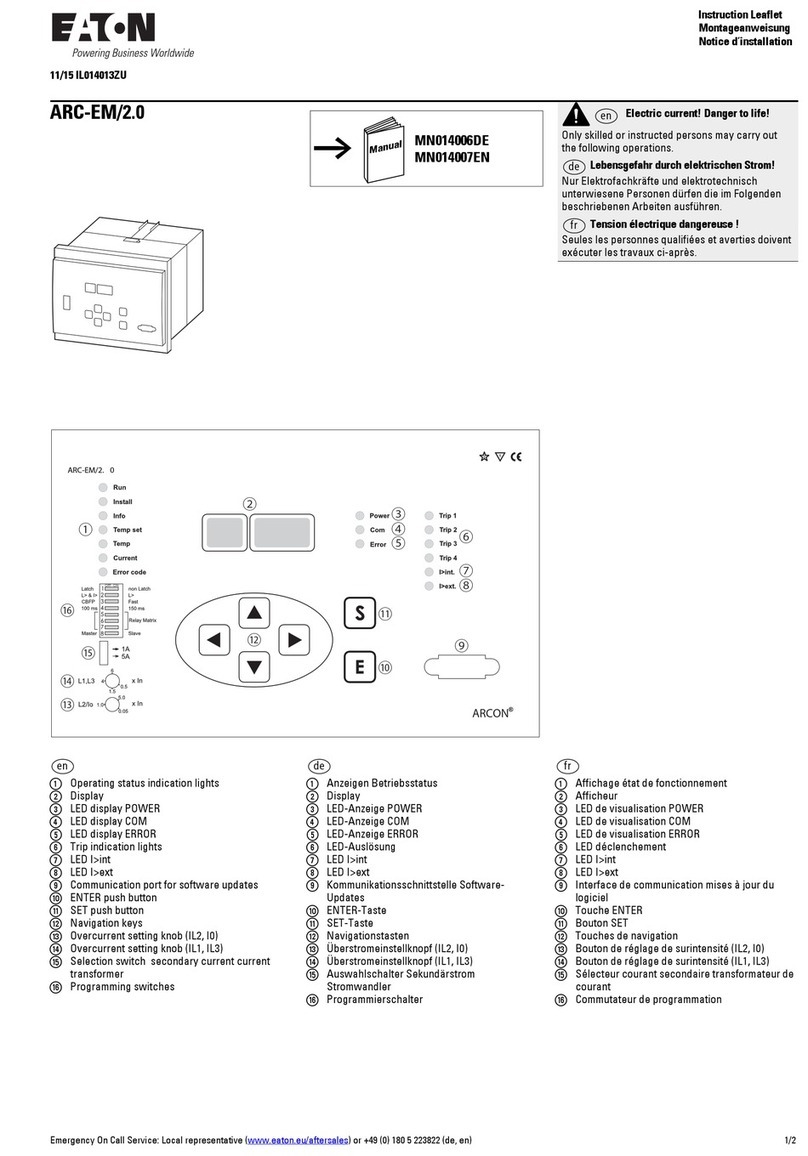

Linearer Servo Controller ...................................................................................................... 21

Linearer Servo Controller connection diagram ..................................................................... 22

11.2.1 Control with 0 - 10V voltage (standard)........................................................................ 22

11.2.2 Control with potentiometer (optional) ......................................................................... 22

Level Sensor........................................................................................................................... 23

Control Unit........................................................................................................................... 24

Back-flow Sensor ................................................................................................................... 25

Appendix A –Technical drawing and parts list (shipped with the product)

General

5 / 26

Abrasiv Feeder 2.0 27.07.2022

1 General

Information on use of the operation and maintenance instruction

This operation and maintenance instruction is a key part of the product. The information in this manual

is mandatory and must be read and understood by all the persons before operating with the pneumatic

valve 2.0. The manual must be stored in distance as well as always accessible to the persons, working

with the abrasive feeder 2.0.

Should you have any questions regarding the content of the manual, please contact the manufacturer

directly.

ALLFI AG - Riedenmatt 1 –CH-6370 Stans

Tel.: +41 41 618 05 05 - Fax: +41 41 618 05 10

Scope of delivery

The individual parts contained in the shipment can be gathered from the set list in the appendix A

(technical drawing and part list). Upon receipt, the shipment has to be checked of integrity. Possible

detected defectives must be reported immediately to the manufacturer.

Warranty claim

The ALLFI AG grants warranty for the shipped parts as followed:

➢Material and manufacturer faults of 12 months from date of delivery or

➢Defects within the first 2’000 hours of operation

Following spare parts are excluded from the warranty:

➢Belt

➢Geared Motor

➢Ball bearings

➢Sensors

➢Seals / O-Rings

Disclaimer

ALLFI AG refuses any claims of liability (material damages, physical injury, as well as disruption of op-

eration), that are a result of disregarding this operating and maintenance instruction.

For example the damage as a consequence of:

➢Inadmissible application of the abrasive feeder 2.0

➢Defective maintenance

➢The disregard of operation instructions

➢Chemical and electrolytical influences

➢Use of parts, spare parts or accessory from a third-party manufacturer

➢Arbitrary modifications

➢Not or insufficiently trained staff

The disregard of all these instructions happens on exclusive risk and exclusive responsibility of the cli-

ent. The ALLFI AG is not liable for any production downtimes.

Security

6 / 26

Abrasiv Feeder 2.0 27.07.2022

2 Security

Declaration of symbols

This operating and maintenance instruction manual contains important notes and symbols, which are

to be considered and followed. These include:

DANGER

Danger emphasizes operating and service procedures that if not avoided,

may lead to death or serious personal injuries.

WARNING

Warnings emphasize operating or service procedures, or conditions that

can result in serious personal injury or death.

CAUTION

Cautions emphasize operating or service procedures, or conditions that

can result in equipment damage or impairment of system operation. If not

avoided, light or medium body injuries could be the consequence.

NOTE

Notes provide additional information that can expedite or improve operat-

ing or service procedures.

Danger symbol without key word: Additional notes

Intended use

The abrasive dosing is used for dosing sand for abrasive water jet cutting. Sand quantity 50 to

1000g/min. Filling must be carried out with a abrasive hopper which conveys the sand into the inter-

mediate container without pressure. The dosing unit may only be used completely assembled and

must be permanently mounted on the machine. All hoses must be connected. Only dry sand mesh

from 60 to 250 may be used as abrasive.

Inadmissible usage

The inadmissible usege of the dosage includes, but is not limited to, the following:

➢Use of any abrasive other than sand

➢Any admixture of additives to the sand

Security

7 / 26

Abrasiv Feeder 2.0 27.07.2022

➢Excessive strain of the dosage

➢Exceeding the permissible limit values

➢Any modifications of the feeder

➢Operation of the dosing in dismantled or disabled technical protective devices (e.g. the plexi-

glass disc)

The uses listed below are also considered inadmissible if there are no suitable technical protective

measures to protect the operator, other groups of persons, the machine components themselves or

the environment:

➢Cutting materials whose processing releases harmful, aggressive or explosive substances in

the form of dust, microparticles or gas.

Likewise, all other uses of abrasive dosing that deviate from the intended use are considered inad-

missible. If you have any questions or concerns, please contact the manufacturer directly.

ALLFI AG - Riedenmatt 1 –CH-6370 Stans

Tel.: +41 41 618 05 05 - Fax: +41 41 618 05 10

Residual risks

The manufacturer and/or operator of the machine where the abrasive feeder 2.0 is built in, has taken

every precautionary measure possible to reduce residual risks, as far as possible reasonably practica-

bly.

Operation

phase

Damage

Danger

Reason

(possible) measures

Operation

Physical inju-

ries

Liquids or sand

leaking under

high pressure

Back-flow or sand

jam due to clogged

cutting head

Operate abrasive

feeder only completely

assembled

Keep a safe distance

Protective walls as a

technical protective

measure

Vent closed or

blocked

Never close the vent

Only use hose with in-

ner diameter adapted

to the connection

piece.

Do not bend the hose

Protective walls as a

technical protective

measure

Intrusion of

limbs into the ro-

tating belt

Missing protective

glass

Operate abrasive

feeder only completely

assembled

Security

8 / 26

Abrasiv Feeder 2.0 27.07.2022

Safety installations

The manufacturer or the operator of the full machine, which the arbrasive feeser 2.0 is built in, has en-

sured the following safety arrangements:

➢Protective devices against leaking liquid or sand

➢Emergency stoppage to immediately shut down the operating machine.

➔Active: Manually triggered by operator

➔Passive: Automatically triggered by:

oNon-return or sand accumulation (option 951401)

Danger for the operator will arise if safety protections are not functionally, not

followed or evaded anytime. The operator has to ensure the functionality of the

safety protections anytime.

Personal protection equipment

The operator must offer his staff following protection equipment while he’s working:

Ear protector against:

➢Noise emissions

Wear protection glasses against:

➢Fluids and dust particles

➢Flying fragments

Hand guards against:

➢Sharp edges of components

➢Intrusion of micro particles into the skin

Inhalation protection against:

➢Dust particles, micro particles and spray mist

Qualification of the staff

The abrasive feeder 2.0 may only be operated and maintained by certified, trained staff.

Structure and function of the abrasive feeder

9 / 26

Abrasiv Feeder 2.0 27.07.2022

3 Structure and function of the abrasive feeder

Structure

Structure and function of the abrasive feeder

10 / 26

Abrasiv Feeder 2.0 27.07.2022

Function

The abrasive feeder 2.0 is used for dosing sand for abrasive water jet cutting. Sand is transported

from the abrasive hopper into the container via a hose with the use of compressed air. The transported

air escapes via the vent. This must always be open, otherwise the container may burst. If required, a

hose can be connected to the venting nozzle. The dosage is performed by means a of special belt.

The quantity is controlled by the motor speed and is almost linear to the belt speed. The standard di-

rection of rotation is clockwise. This allows sand quantities of up to approx. 650 g/min to be achieved.

With the direction of rotation to the left, sand quantities of up to approx. 1000g/min are possible. In the

event of a sand backflow, the backflow preventer prevents the water-sand mixture from entering the

dosing housing. Without tools, the backflow preventer can be separated from the housing and cleaned

and dried with compressed air.

As an option, a sensor is available which detects a backflow as well as a sand jam. Another option is

the level sensor. This detects a too low sand level in the container. Both sensors can be used for a

warning message and or machine stop.

Accessories

Article:

Back-flow sensor

Level Sensor

Hose

Electrically conductive

Article no:

951401

951402

040141

Function:

Signals a water-sand

back-flow or a sand jam

Signals a level too low in

the sand container

For feeding sand from the

abrasive hopper

General technical data

11 / 26

Abrasiv Feeder 2.0 27.07.2022

4 General technical data

Height: 410mm

Width: 94mm

Depth: 144mm (depending on motor)

Empty weight: approx. 2 kg; without linear servo controller (LSC)

Usable sand volume: 400 ml

Dosing quantity: clockwise rotation: 50 - 650g/min

counterclockwise rotation: 80 - 1000g/min

Connection sand inlet: Hose connector Outer Ø 16mm

Connection Ventilation Hose: Hose connector Outer Ø 16.7mm

Hose Sand outlet Inner-Ø 6,4mm, Outer-Ø 9,6mm (2.5m included)

Max. motor speed 6300min-1

Gear ratio 60:1

Max. Pulley speed 105min-1

Further technical data such as connection dimensions can be found in the technical drawing in Appen-

dix A.

Data sheets for sensors & linear servo controller see chapter 11.

Delivery rate sand 80 mesh

General characteristic curve Only valid for Maxon motor

Installation and commissioning

12 / 26

Abrasiv Feeder 2.0 27.07.2022

5 Installation and commissioning

Installing the abrasive dosing system

The four M6 threads marked green at the bottom or on the back can be used to mount the dosage on

the cutting system.

For mounting the servo controller see chapter 11.1 and separate operating instructions.

General installation tip:

➢For an first installation, follow the corresponding subchapters step by step

➢Only operate the dosing unit completely assembled

➢Electrical components may only be connected by qualified personnel

Installation and commissioning

13 / 26

Abrasiv Feeder 2.0 27.07.2022

Connecting hoses

•Green dot:

Connection for the sand inlet from the Abrasive

Hopper.

Secure the hose with a clamp.

•Red dot:

Connection for venting.

In the event of a malfunction of the abrasive hop-

per, an air-sand mixture can escape.

Install a hose that is adapted to the size of the con-

nection, sloping down and kink-free so that no jam-

ming can occur.

The connection must not be closed, other-

wise the vessel may burst.

•Blue dot:

Connection to the abrasive cutting head for the

dosed sand. Install the supplied hose in a sloping

position and as short as possible in order to avoid a

jam. The direction of the connection can be se-

lected by turning the black non-return valve.

Electrical connection

The connection of the Maxon motor module is pre-installed, the counterpart is connected as explained

in chapter 5.3.1.

For the connection of the Linear Servo Controller and the connection with the motor see chapter 11.

The direction of rotation of the motor can be selected with the corresponding polarity.

Clockwise rotation: sand quantities from 50 - 650 g/min

Left turning: sand quantities from 80 - 1000g/min

Uninstalling

14 / 26

Abrasiv Feeder 2.0 27.07.2022

5.3.1 Mounting the connector housing

1

Strip 3 mm of insulation from both cable ends and

twist both copper ends.

Insert the socket contact including the yellow seal

with the " ERGOCRIMP" pliers

crimping,

with die for Ergo basic hand pliers

use.

Operate the pliers as far as they will go.

Use 1.0 mm crimping position!

Observe alignment of motor and connector hous-

ing during crimping!

2

Mount the socket housing,

red cable + at terminal 1

and

black cable - at terminal 2

Retract until it clicks.

3

Check that the cables are firmly seated by pulling

on them gently.

6 Uninstalling

•- Switching off the abrasive hopper

•- Remove hose from abrasive cutting head

•- Empty the container completely by switching on the dosing system

•- Remove remaining hoses and electrical connection.

•- Disconnect any existing sensors as well.

•- Unscrew the dosing unit, do not damage the sand container.

Maintenance

15 / 26

Abrasiv Feeder 2.0 27.07.2022

7 Maintenance

Belt replacement

A good belt condition is a prerequisite for correct operation of the feeder system. In case of slippage,

damage (cracks) or after 2000 operating hours, it is recommended to replace the belt.

•Remove the motor assembly (pos. 4) from the housing.

•Loosen nut (marked red) two turns while simultaneously holding the hexagon socket screw

(green).

•Sliding the unit in the direction of release

•The belt is now slackened and can be changed.

•Push the unit up to the stop and tighten in direction

•Tighten the lock nut (marked red) while holding the hexagon socket screw (green).

•Install the motor assembly (pos. 4) in the housing.

tighten

loosen

Maintenance

16 / 26

Abrasiv Feeder 2.0 27.07.2022

Cleaning after backflow recoil or sand accumulation

If a jam on the abrasive cutting head has caused a backflow or sand build-up, the backflow preventer

must be cleaned with compressed air and dried.

•Stop machine (high pressure pump &

abrasive hopper)

•If necessary, prepare a container to col-

lect the sand.

•Remove the hose from the abrasive cut-

ting head.

•Hold the black backflow-preventer valve

with your fingers at the green dot and

pull it out of the aluminium housing with

simultaneous turning and pulling move-

ments (red arrow).

•If necessary, collect sand with container

•Detach the drip tray using a screw-

driver.

•and extend upwards

•Blow out and dry Backflow-preventer

valve

•Also check if the aluminium housing is

dry and not clogged. If necessary, clean

and dry here as well.

•Assemble everything in reverse order

as follows

•Check whether the sheet is clicked in

correctly

Options

17 / 26

Abrasiv Feeder 2.0 27.07.2022

8 Options

Level Sensor

The level sensor signals a too low level in the sand container. The signal can be used for a warning

message and or machine stop.

The sensor is attached to the container with the supplied double-sided adhesive tape and is con-

nected to the Control Unit. After installation, the sensor sensitivity must be set on the Control unit of

the abrasive dosing system (Picture left).

HINT

Damage to property due to incorrect assembly

The power amplifier is IP40 certified. It is not protected against water in any form.

See also data sheets chapter 11.

Therefore:

Place this component in a place protected from water & steam. Alternatively, it

can be mounted in a waterproof box.

HINT

Install cables properly

Lead the sensor cable to the sensor in an arc without tension. Also make sure

that the cable to the control cabinet is long enough in all positions.

Options

18 / 26

Abrasiv Feeder 2.0 27.07.2022

1

1. Cut off the side tabs from the sensor.

2

2. Glue double-sided adhesive tape

onto the container at the point where

the sensor is to be fixed. Height see

picture left

3. Press the sensor onto the adhesive

tape The connection cable must

be on the left side and point-

ing downwards so that the

crosses, marked red in the top left

picture, are in contact with the adhe-

sive tape

4. Connect the sensor to the Control

unit (plug)

5. Connect the control unit to the cutting

system (see operating instructions

supplied)

6. Adjust the sensitivity on the Control

unit (see operating instructions sup-

plied)

Check Valve Sensor

The Check Valve sensor signals a water sand non-return or a sand jam. The signal can be used for a

warning message and or machine stop.

In addition to the sensor, the scope of delivery includes the screws for fixing to the drip tray as well as

the cable for potential equalization.

HINT

Do not set the sensor to teach mode

The sensor was already configured for the application before delivery. If the sen-

sor is incorrectly set to teach mode, smooth operation can no longer be guaran-

teed. If it is unintentionally taught, contact Allfi Service.

Options

19 / 26

Abrasiv Feeder 2.0 27.07.2022

HINT

Install cables properly

Lead the sensor cable in an arc to the sensor so that sufficient cable length is

available when removing the non-return unit. Also make sure that the cable to the

switch cabinet is long enough in all positions.

HINT

Mounting the sensor in the correct position

When mounting, the crosshairs on the sensor must point in the direction of the

black backflow preventer, otherwise the sensor will not function.

Correct assembly

Wrong assembly

The sensor cable can be guided to the left or

right.

The drip tray must be electrically connected to

the motor plate using the cable supplied.

For screw torque and electrical connection, re-

fer to the operating instructions supplied.

Faults and Troubleshooting

20 / 26

Abrasiv Feeder 2.0 27.07.2022

9 Faults and Troubleshooting

Depressurize high-pressure, water and compressed air lines before any trouble-

shooting.

Fault

Possible causes

Correction

Dosage tank does not fill with

abrasive sand

Sponsor does not support ade-

quately or not at all

Switching on or adjusting the

conveyor

Connection line between con-

veyor & dosing blocked or in-

terrupted

Clean or check the connecting

hose.

Air pressure in supply line for

dosing

too high (max. 3 bar)

Incorrect air pressure setting

on maintenance unit

Set the air pressure at the

maintenance unit to max. 3

bar.

Water/sand mixture repels or

accumulates in backflow pre-

venter

Focusing tube, nozzle, mixing

chamber, hose and / or back-

flow preventer blocked.

Clean the focusing tube, noz-

zle, mixing chamber, hose and

non-return valve.

The dosage container is over-

filled.

Sand outlet at venting from

Too high air pressure at the

abrasive conveyor

Adjusting the air pressure on

the abrasive conveyor cor-

rectly

Refill device on abrasive con-

veyor does not fill properly

Check abrasive conveyor

Container of abrasive conveyor

is almost empty

Filling sand

Overpressure in abrasive con-

tainer

Vent blocked at expansion

tank

Expose vent

Power supply for drive inter-

rupted

power supply

ensure

Drive motor defective

Replace drive motor

Servo controller defective

Linear Replace servo controller

Dosage does not promote

abrasive agent

Control loop failed

Control loop from potentiome-

ter or CNC

10 Recycling

The Abrasive feeder 2.0 is made of metal and plastic. All the metal parts can be recycled. The elec-

tronic- & plasticparts are to be professionally recycled as per local specifications.

Table of contents

Other allfi Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

Esko

Esko CDI CRYSTAL TOUCH 20.1 user manual

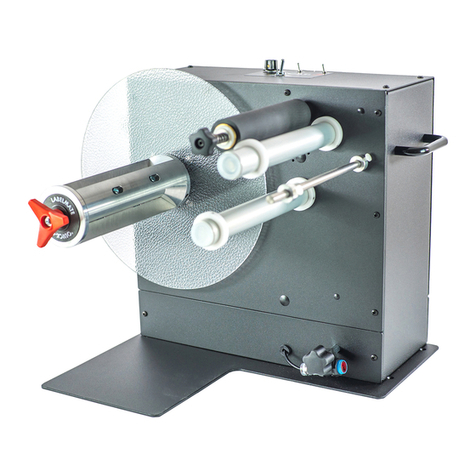

Labelmate

Labelmate ZCAT-6 user manual

Siemens

Siemens GAMMA UP 117/12 Operating and mounting instructions

Grundfos

Grundfos BACnet for MIXIT Functional profile and user manual

THORLABS

THORLABS KT120 user guide

Siemens

Siemens SIMATIC HMI IFP operating instructions

Titan

Titan 102 Installation, maintenance & parts manual

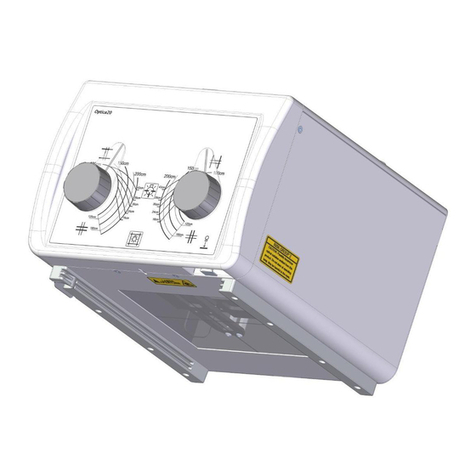

Varex Imaging

Varex Imaging Claymount Optica 20 Series user manual

Tyco Electronics

Tyco Electronics AMP 58246–1 instruction sheet

T&S

T&S B-0114-01 Installation and maintenance instructions

ABB

ABB TPL71-C34 Operation manual

PASCO

PASCO WA-9855 Product guide