allfi 906110 User manual

Operating and maintenance instruction

Cutting Head basic 1.1

(4150 bar / 60,000 psi)

Operating and maintenance instruction

ALL I AG - Riedenmatt 1 – CH-6370 Stans

Tel.: +41 41 618 05 05 - ax: +41 41 618 05 10

E-Mail: info@allfi.com - http://www.allfi.com

November 2022

General

Version 1.0 2 / 24

Cutting Head Type IV & V 2.0 (4150 bar / 60,000 psi) November 14, 2022

Scope of application

The present operating and maintenance instruction is valid for:

Basic 1.1 (4150 bar / 60,000 psi)

906110

General

Version 1.0 3 / 24

Cutting Head Type IV & V 2.0 (4150 bar / 60,000 psi) November 14, 2022

Table of contents

1 General .......................................................................................................................................4

1.1 Information on use of the operation and maintenance instruction ......................................4

1.2 Scope of delivery .................................................................................................................4

1.3 Warranty claim ....................................................................................................................4

1.4 Disclaimer............................................................................................................................4

2 Security .......................................................................................................................................5

2.1 Declaration of symbols ........................................................................................................5

2.2 General arning notes ........................................................................................................5

2.3 Intended use .......................................................................................................................6

2.4 Inadmissible usage ..............................................................................................................7

2.5 Residual risks .......................................................................................................................7

2.6 Safety installations ..............................................................................................................8

2.7 Personal protection equipment ...........................................................................................8

2.8 Qualification of the staff ......................................................................................................9

3 Structure and function ................................................................................................................9

3.1 Structure .............................................................................................................................9

3.2 Function ............................................................................................................................ 10

3.3 Accessories ........................................................................................................................ 10

4 General technical data .............................................................................................................. 11

5 Installation and commissioning ................................................................................................. 12

5.1 Fix cutting head to the machine ......................................................................................... 13

5.2 Flush cutting head ............................................................................................................. 14

5.3 Cutting head function check .............................................................................................. 15

6 Deinstallation ............................................................................................................................ 16

7 Maintenance, Service and Repair .............................................................................................. 16

7.1 Regular maintenance ......................................................................................................... 17

7.2 Replace Orifice .................................................................................................................. 17

7.3 Replace collimation tube ................................................................................................... 18

7.4 Reversing (turning) the valve seat ...................................................................................... 19

7.5 Replace seal kit and valve seat ........................................................................................... 20

7.6 Adjust the stroke of the pneumatic cylinder ...................................................................... 22

8 Faults and Troubleshooting ....................................................................................................... 23

8.1 Leakage of the cutting head: .............................................................................................. 23

8.2 Further troubleshooting .................................................................................................... 24

9 Recycling ................................................................................................................................... 24

Appendix A – Technical drawing and parts list (shipped with the product)

General

Version 1.0 4 / 24

Cutting Head Type IV & V 2.0 (4150 bar / 60,000 psi) November 14, 2022

1 General

1.1 Information on use of the operation and maintenance instruction

This operation and maintenance instruction is a key part of the product. The information in this manual

is mandatory and must be read and understood by all the persons before operating with the cutting

head type IV 2.0. The manual must be stored in distance as well as always accessible to the persons,

working with the cutting head type IV 2.0.

Should you have any questions regarding the content of the manual, please contact the manufacturer

directly.

ALL I AG - Riedenmatt 1 – CH-6370 Stans

Tel.: +41 41 618 05 05 - ax: +41 41 618 05 10

E-Mail: info@allfi.com - http://www.allfi.com

1.2 Scope of delivery

The individual parts contained in the shipment can be gathered from the set list in the appendix A

(technical drawing and part list). Upon receipt, the shipment has to be checked of integrity. Possible

detected defectives must be reported immediately to the manufacturer.

1.3 Warranty claim

The ALL I AG grants warranty for the shipped parts as followed:

Material and manufacturer faults of 12 months from date of delivery or

Defects within the first 2000 hours of operation

ollowing spare parts are excluded from the warranty:

Seal Kit (consist of Valve needle, HP-seal 2.0, spring & Pressure plate 2.0)

Valve Seat

Orifice

Collimation Tube

O-Ring

Valve Case

1.4 Disclaimer

ALL I AG refuses any claims of liability (material damages, physical injury, as well as disruption of

operation), that are a result of disregarding this operating and maintenance instruction.

or example, the damage as a consequence of:

Inadmissible application of the cutting head

Defective maintenance

The disregard of operation instructions

Chemical and electrolytical influences

Use of parts, spare parts or accessory from a third-party manufacturer

Arbitrary modifications

Not or insufficiently trained staff

The disregard of all these instructions happens on exclusive risk and exclusive responsibility of the

client. The ALL I AG is not liable for any production downtimes.

Security

Version 1.0 5 / 24

Cutting Head Type IV & V 2.0 (4150 bar / 60,000 psi) November 14, 2022

2 Security

2.1 Declaration of symbols

This operating and maintenance instruction manual contains important notes and symbols, which are

to be considered and followed. These include:

DA GER

Danger emphasizes operating and service procedures that if not avoided,

may lead to death or serious personal injuries.

WAR I G

Warnings emphasize operating or service procedures, or conditions that

can result in serious personal injury or death.

CAUTIO

Cautions emphasize operating or service procedures, or conditions that

can result in equipment damage or impairment of system operation. If not

avoided, light or medium body injuries could be the consequence.

NOTE

otes provide additional information that can expedite or improve operat-

ing or service procedures.

Danger symbol without key word: Additional notes

2.2 General warning notes

Using of the cutting head, the following warnings are to be considered.

The specified warnings are not only restricted to the operation with the maximal

permissible operating pressure of 4150 bar / 60,000 psi. They are also valid on

work with reduced operation pressures!

Security

Version 1.0 6 / 24

Cutting Head Type IV & V 2.0 (4150 bar / 60,000 psi) November 14, 2022

DA GER

Danger of cutting of extremities on contact with waterjet

The contact with the high kinetic energy performing waterjet can have the con-

sequence of cutting of extremities or lead to other injuries.

Therefore:

Operate the machine only, when nobody stands in the danger zone of the

waterjet.

Never touch the waterjet, not even with personal protective equipment.

Always sufficient safety distance during operation of the cutting head.

Never guide the cutting head by hand during operation.

Any injuries in connection with the waterjet, alarm the emergency doctor imme-

diately.

CAUTIO

Danger of breathing difficulties and irritation of the skin and eyes by re-

leased solid particles or dust.

During machining of certain material, solid particles and dust may float in the

air, which could cause breathing difficulties and irritations to the skin and eyes.

Therefore:

Ensure the proper ventilation of the room surrounding the machinery.

Ensure to wear the personal protective equipment (protection glasses,

breathing mask, gloves, …)

Additionally, the rules and regulations of the working place are to be followed to

prevent injuries!

2.3 Intended use

The intended use consists in:

operate the cutting head with air pressure

switch the cutting head on and off to cut different material

the fixed installation (no hand guidance) of the cutting head on the machine

if provisions against flying fragments or a leaking liquid with high pressure are made

if water is used exclusively as working fluid

if the technical limit values are respected

Security

Version 1.0 7 / 24

Cutting Head Type IV & V 2.0 (4150 bar / 60,000 psi) November 14, 2022

2.4 Inadmissible usage

Inadmissible usage of the cutting head includes:

The usage of all other fluids other than water

The addition of other substances to the water

Closure of the pressure relief holes

Manually guide the cutting head by hand

Excessive application of the cutting head e.g. large fluctuations in pressure

Exceeding permitted limits

Operating the valve with demounted or disabled technical protection

Use the cutting head as a security valve

The following uses are also considered inadmissible if suitable technical protective measures are not

taken to protect the operator, other groups of persons, the machine components themselves or the

environment:

The cutting of materials that release harmful, aggressive or explosive substances in the form

of dust, microparticles or gas.

Likewise, all other uses of the cutting head deviating from the intended use are not permitted. All ques-

tions should be addressed directly to the manufacturer.

ALL I AG - Riedenmatt 1 – CH-6370 Stans

Tel.: +41 41 618 05 05 - ax: +41 41 618 05 10

E-Mail: info@allfi.com - http://www.allfi.com

2.5 Residual risks

The manufacturer and/or operator of the machine where the cutting head is built in, has taken every

precautionary measure possible to reduce residual risks, as far as possible reasonably practicably.

Operation

phase

Damage Danger Reason (possible)

measures

Operation Physical

injuries

Liquids leaking under

high pressure (e.g. at

pressure relief holes)

Ignoring the torque ollow the torque

Damaged sealing

surfaces Regular supervi-

sion

Busted/Cracked

connections and

high-pressure com-

ponents as a result

of defects

Protective wall as a

technical protective

measure

lying fragments

Ignoring the torque ollow the torque

Damaged sealing

surfaces Regular supervi-

sion

Busted/Cracked

connections and

high-pressure com-

ponents as a result

of defects

Protective wall as a

technical protective

measure

Uncontrolled water jet Spring fracture Scheduled service

(chapter 7)

Security

Version 1.0 8 / 24

Cutting Head Type IV & V 2.0 (4150 bar / 60,000 psi) November 14, 2022

Operation

Physical

injuries

High kinetic energy of

water jet

Intrusion of extremi-

ties in working area

of water jet

Technical protec-

tive measures or

inherently reliable

construction of the

machine

High kinetic energy of

residual water jet

Cutting of material

Use correctly di-

mensioned water

jet absorber

Particles of raw material

and splash water

Wear protection

glasses and per-

sonal protection

equipment

Splash-water pro-

tection for technical

protective measure

Hearing

damage

Rapidly discharging of

fluid

Wear ear protector

Use correctly di-

mensioned water

jet absorber

2.6 Safety installations

The manufacturer or the operator of the full machine, which the cutting head is built in, has ensured

the following safety arrangements:

Protection against intrusion of extremities in working area of water jet

Safety devices to prevent flying fragments or liquids leaking under high pressure

Emergency stoppage to immediately shut down the operating machine

Active: Manually triggered by operator

Passive: Automatically triggered by:

o o Penetration of limbs into the working area of the water jet

o o ailure of high pressure components or gross operating faults

o o Collision of the cutting head with fixed parts

Danger for the operator will arise if safety protections are not functionally, not

followed or evaded anytime. The operator has to ensure the functionality of the

safety protections anytime.

2.7 Personal protection equipment

The operator must offer his staff following protection equipment while he’s working:

Ear protector against:

Noise emissions

Wear protection glasses against:

luids and dust particles

lying fragments

Structure and function

Version 1.0 9 / 24

Cutting Head Type IV & V 2.0 (4150 bar / 60,000 psi) November 14, 2022

Hand guards against:

Sharp edges of components

Intrusion of micro particles into the skin

Inhalation protection against:

Dust particles, micro particles and spray mist

2.8 Qualification of the staff

The cutting head may only be operated and maintained by certified, trained staff.

3 Structure and function

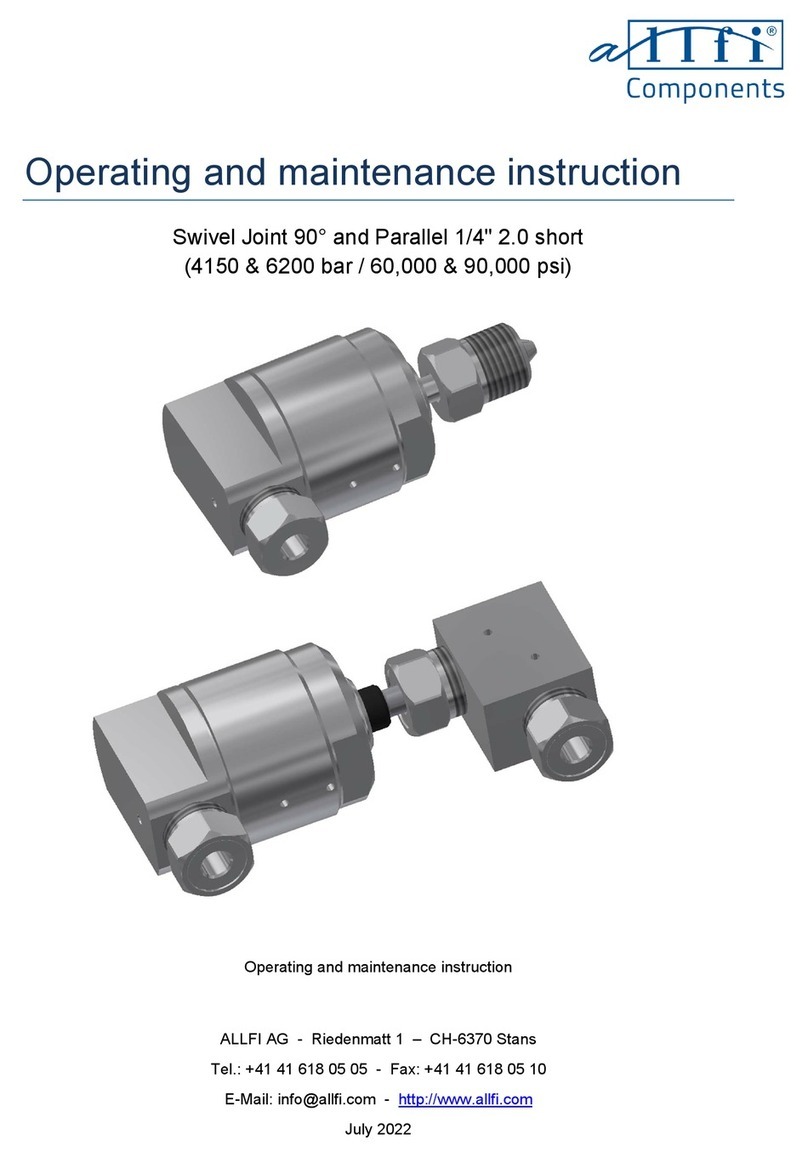

3.1 Structure

Legend

1 Pneumatic Cylinder Type V 2.0

2 Seal Kit

2.1. Valve needle

2.2. Supporting ring

2.3. HP-Seal

3 Supporting Disc basic 1.1

4 Valve Case

5 Valve Seat

6 O-Ring

7 Coupling Ring

8 Orifice Cap

9 Collimation Tube

10 Collar 1/4"

11 Gland Nut 1/4"

12 Orifice

Structure and function

Version 1.0 10 / 24

Cutting Head Type IV & V 2.0 (4150 bar / 60,000 psi) November 14, 2022

3.2 Function

The cutting head opens and closes with a pneumatic piston actuator. The pneumatic pressure in the

cylinder lifts the piston against the cylinder springs. The valve needle lifts simultaneous with the piston

from the valve seat and opens the water channel. After the compressed air has been released the

springs in the cylinder closes the water channel of the cutting head. The compressed air is controlled

on and off by a compressed air valve (not included in delivery). The maximal permissible operating

water pressure see chapter 4.

3.3 Accessories

Article: ace Spanner DX Paste P-Paste

Article no: 040006 051055 051065

unction: Adjust of the stroke Greasing screw connections

and metallic contact areas for

standard applications

Greasing screw connec-

tions and metallic contact

areas for food safe

All accessories for metric cutting heads are included in case set 882101

All accessories for imperial cutting heads are included in case set 882101-I

Article: Torque wrench Open end fitting Mounting tool for

O-ring

Ejector mandrel

Article no: 000468 A 15 – 000493

A 17 – 000339

A 5/8" – 000521

A 22 – 000272

A 24 – 000280

040011 900070

unction: Tightens screws

with a specific

torque

O-ring assembly and

disassembly

Replace Seal Kit

and Valve Seat

General technical data

Version 1.0 11 / 24

Cutting Head Type IV & V 2.0 (4150 bar / 60,000 psi) November 14, 2022

4 General technical data

Pneumatic pressure: 6 - 7 bar / 87 psi – 102 psi

Minimum working pressure: 800 bar (11,500 psi) @ 7 bar (102 psi) air pressure

1500 bar (21,500 psi) @ 6 bar (87 psi) air pressure

Maximal working pressure: 4150 bar / 60,000 psi

Maximal working temperature: 50 °C

Maximum transport and storage temperature: 60 °C

Reaction time: up to 4 switching cycles per seconds

Weight: ca. 1.2 kg

Noise emission: 70 – 120dB (a), depends on size of orifice and con-

struction of water jet absorber

Requested water quality:

Water parameter Unit Value

Electrical Conductivity µS / cm 100 – 450

PH-value - 7.0 - 8.5

Total hardness °dH 2.0 - 10.0

Carbonate hardness

(acid capacity pH 4.3)

°dH 2.0 - 10.0

Degree of alkalinity pH 8.2 mmol / l 0 - 0.25

Chloride mg / l ≤ 50

Iron mg / l ≤ 0.2

Manganese mg / l ≤ 0.05

Copper mg / l ≤ 2.0

Silicate mg / l ≤ 5.0

( iltrate-) solid content mg / l ≤ 350

Technical data as dimensions can be found in the technical drawing in appendix A.

Installation and commissioning

Version 1.0 12 / 24

Cutting Head Type IV & V 2.0 (4150 bar / 60,000 psi) November 14, 2022

General installation tip:

Use of a pneumatic oiler is forbidden.

Compressed air filter with water separator must be installed.

Compressed air filter and pneumatic valve must have a minimum nominal flow

rate of 5 m

3

/h.

Absolute cleanliness of the pipes is important before connection.

A high-pressure filter in front of the cutting head is recommended to extend the

service life. (e.g. ALL I HP- ilter 931335)

ollow the steps below for installation.

Before startup and after inspection or maintenance, check the water tightness of

the cutting head.

5 Installation and commissioning

WAR I G

Risk of injury: It is forbidden to close the pressure relief holes.

By closing the pressure relief holes, the cutting head or parts of it may explode.

Therefore: Never close or cover any pressure relief hole.

Positions of the pressure relief holes:

Installation and commissioning

Version 1.0 13 / 24

Cutting Head Type IV & V 2.0 (4150 bar / 60,000 psi) November 14, 2022

NOTE

Material damage as a result of pitting

Not or insufficient greased threads or contact areas can pit.

Therefore:

Always grease threads and metallic contact areas. Check appendix A for addi-

tional information.

NOTE

Material damage or leakage as a result of fouling

ouling components, especially at threads, can lead to leakages and damage.

Therefore:

Pay attention to the cleanliness of the components while maintaining.

NOTE

Material damage as a result of leakages

Constant leakage may damage the product.

Therefore:

Immediately eliminate leakages (see chapter 8 „ aults and Troubleshooting”).

5.1 Fix cutting head to the machine

The cutting head can be installed in the machine in two different ways. urther fastening options must

be discussed with the manufacturer.

During installation, ensure that none of the pressure relief holes are closed!

1. Unscrew gland nut from

coupling ring.

2. Remove collar from gland

nut.

Installation and commissioning

Version 1.0 14 / 24

Cutting Head Type IV & V 2.0 (4150 bar / 60,000 psi) November 14, 2022

3. Slide the gland nut over the

HP tube.

4. Screw the collar on the HP

tube (left-handed thread).

There must be 1 or 2 convo-

lutions visible between the

conus and the pressure ring.

ix coupling ring on mounting

plate

(Exemplary drawing)

Mount cutting head with

three M5 screws on machine.

ix on collimation tube

(Exemplary drawing)

Clamp cutting head on colli-

mation tube to the machine.

5. Mount cutting head on the

machine.

1. Connect the HP tube with

the cutting head

torque see appendix A.

2. Plug in compressed air

connection by snapping in.

5.2 Flush cutting head

To prevent particles carried with the water from clogging the nozzle or damaging the cutting head,

flush the cutting head:

When newly installed.

When servicing or replacing high pressure components upstream of the cutting head.

Procedure:

1. Remove orifice cap (see chapter 7.2)

2. Pressurize pneumatic cylinder with compressed air (6-7 bar), to open cutting head.

6

7

Installation and commissioning

Version 1.0 15 / 24

Cutting Head Type IV & V 2.0 (4150 bar / 60,000 psi) November 14, 2022

3. lush cutting head (p ≤ 500 bar / 7,250 psi) for 5 to 10 seconds with clean water.

4. Screw on orifice cap with inserted orifice on the collimation tube (see chapter 7.2)

NOTE

Possible damage as a result of direct transfer of the torque to the HP seal-

ing

The HP sealing will be damaged (pitting on sealing surface) if tight or loosen the

orifice cap without holding the collimation tube.

Therefore:

C

ounterhold collimation tube if tight or loosen orifice cap.

5.3 Cutting head function check

DA GER

Danger of cutting of extremities on contact with waterjet

The contact with the high kinetic energy performing waterjet can have the con-

sequence of cutting of extremities or lead to other injuries.

Therefore:

Operate the machine only, when nobody stands in the danger zone of the

waterjet.

Never touch the waterjet, even with personal protective equipment.

Always sufficient safety distance during operation of the cutting head.

Never guide the cutting head by hand during operation.

ix cutting head on the machine and operate the cutting head with operating pressure (water pressure

= operating pressure) 5-10 times. Check following points:

The cutting head opens and closes faultless

The cutting head operates promptly (no time lag)

Quality of the waterjet

Cutting head tightness

If all checked points above are ok, the cutting head will be ready for operation. Please see chapter 8

( aults and Troubleshooting) for fault diagnostics.

Deinstallation

Version 1.0 16 / 24

Cutting Head Type IV & V 2.0 (4150 bar / 60,000 psi) November 14, 2022

6 Deinstallation

Before uninstalling the cutting head, release pressure from the HP tubes and protect

against unexpected re-pressurizing.

7 Maintenance, Service and Repair

Before uninstalling the cutting head, release pressure from

the HP tube and protect against unexpected re-pressurizing.

It’s not necessarily to unmount the cutting head from the machine. Usually the maintenance is easier if

the HP tube is removed and the cutting head is unmounted from the machine.

All maintenance, service and repair work not written in this document has to be executed by the manu-

facturer. Especially service at the cylinder.

NOTE

Material damage or leakage as a result of fouling

Dirty components, especially considering the threads, may lead to leakages and

damage of the cutting head.

Therefore:

Ensure a proper cleaning of the components.

1. Remove pneumatic hose.

2. Remove HP tube.

3. Remove cutting head from the machine

2

1

Maintenance, Service and Repair

Version 1.0 17 / 24

Cutting Head Type IV & V 2.0 (4150 bar / 60,000 psi) November 14, 2022

NOTE

Possible damage as a result of direct transfer of the torque to the HP-tube

Loosening or tightening the cap (pos. 11 on page 11) without holding the colli-

mation tube can lead to damages on the HP tube connections

Loosening or tightening the collimation tube (pos. 9 on page 11) without holding

the valve case can lead to damages on the HP tube connections

Therefore:

Hold collimation tube when loosening or tightening the cap (pos. 11 on page 11)

with an open-end wrench.

Hold valve case when loosing or tightening the collimation tube (pos. 9 on page

11) with an open-end wrench.

NOTE

Property damage as a result of pitting

Threads that are not greased or insufficiently greased may pit.

Therefore:

Always grease threads and metallic contact areas. Check appendix A for additional

information.

7.1 Regular maintenance

What

By whom

When

Replace disc springs and O-rings in

pneumatic cylinder

Service ALL I AG All 2,000 operation hours / 1

million. Cycles of operation

Check stroke Operator All 500 operation hours /

100,000 Cycles of operation

Check tightness Operator Continuous

Check water jet quality Operator Continuous

Check rubber cap for any damage Operator Continuous

7.2 Replace Orifice

1

1. Make sure the cutting head is closed

2. Remove cap from collimation tube

Attention! Counterhold collimation tube.

3. Remove orifice from cap.

4. Clean cap and sealing surface of colli-

mation tube.

Maintenance, Service and Repair

Version 1.0 18 / 24

Cutting Head Type IV & V 2.0 (4150 bar / 60,000 psi) November 14, 2022

2

1. Insert orifice according illustration.

Type of orifice check appendix A

3

1. Screw cap on the collimation tube and

tighten the cap with a torque wrench

(moment of force according appendix A)

Attention! Counterhold collimation tube

2. Mount cutting head on the machine.

3. Cutting head function check (chapter

5.3).

7.3 Replace collimation tube

1

1. Make sure the cutting head is

closed

2. Remove cap with orifice from colli-

mation tube.

Attention! Counterhold collimation

tube.

2

1. Pressurize pneumatic cylinder with

compressed air (6-7 bar). The cut-

ting head is now open and the

valve seat will not be damaged.

2. Unscrew collimation tube from

valve case. Attention! Counterhold

on valve case A 24.

3. Grease thread of new collimation

tube (see appendix A)

4. Screw and tighten the new collima-

tion tube with a torque wrench

(torque see appendix A).

Attention! Counterhold on valve

case A 24.

5. Depressurize pneumatic cylinder

3

1. Screw cap with inserted orifice on

the collimation tube (chapter 7.2).

2. Cutting head function check (chap-

ter 5.3).

2

4

Maintenance, Service and Repair

Version 1.0 19 / 24

Cutting Head Type IV & V 2.0 (4150 bar / 60,000 psi) November 14, 2022

7.4 Reversing (turning) the valve seat

1

1. Removing the cutting head from

the machine is recommended, es-

pecially if the cutting head is at-

tached to the collimation tube

(Chapter 6)

2. Connect pneumatic line to pneu-

matic cylinder and pressurize with

compressed air (6-7 bar) The cut-

ting head is now open and the

valve seat will not be damaged.

3. Screw the collimation tube out of

the valve case. Attention! Coun-

terhold the valve case SW 24

2

1. Remove the O-ring from valve

case with help of tool 040011

2. Remove the valve seat from the

valve case. Note the orientation of

groove of the valve seat (top or

bottom).

3

When groove was on top:

Valve seat can be reinstalled with

groove at the bottom.

When groove was on bottom:

Now that both seats are worn out,

valve seat must be replaced with new

one and installed with groove on top.

It is recommended to change the seal

kit as well. (See chapter 7.5)

4

1. Insert O-ring into valve case using

assembly tool 040011

2. Screw collimation tube into valve

case and tighten (torque see ap-

pendix A). Attention! Counterhold

on valve case A 24.

3. Depressurize pneumatic cylinder

and

r

emove pneumatic line

4. ix cutting head to the machine.

(Chapter 5.1)

5. Cutting head function check (chap-

ter 5.3).

Groove

on top

Groove on

bottom

Maintenance, Service and Repair

Version 1.0 20 / 24

Cutting Head Type IV & V 2.0 (4150 bar / 60,000 psi) November 14, 2022

7.5 Replace seal kit and valve seat

1

1. To

Replace seal kit and valve seat

it is mandatory to remove the cut-

ting head from the machine.

(Chapter 6)

2. Connect pneumatic line to pneu-

matic cylinder and pressurize with

compressed air (6-7bar) The cut-

ting head is now open and the

valve seat will not be damaged

3. Unscrew the collimation tube from

the valve case. Counterhold on

valve case A 24.

4. Depressurize pneumatic cylinder

and

r

emove pneumatic line.

2

1. Remove the O-ring from valve

case with help of tool 040011.

2. Remove the valve seat from the

valve case. Note the orientation of

the valve seat for step 7.

3

1. Clamp pneumatic cylinder at the

width across flats in a bench vise.

Attention! Do not over tighten,

this would deform the cylinder.

Use protective jaws.

2. Unscrew valve case at the A 24.

4

1. Sit valve case on a solid surface

according illustration (needle point

face up).

2. Press the seal kit with the ejector

mandrel 900070 out of the valve

case.

3. Dispose/recycle the old seal kit.

3

Groove on

bottom

Groove on

top

Table of contents

Other allfi Industrial Equipment manuals