Allied Pumps Logikos Manual

Client / Project Name

Allied Pumps Packaged Water Solutions 1

Operation & Maintenance Manual

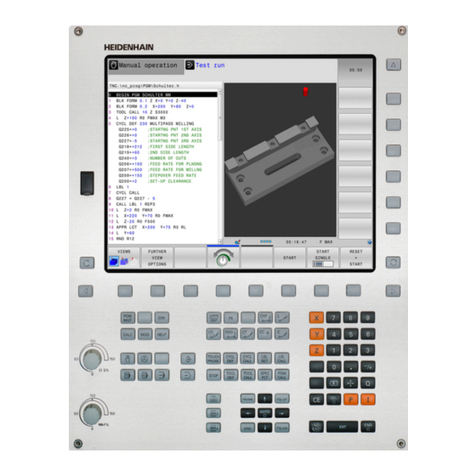

Logikos Pump Control System

Logikos Pump Control System Manual

Allied Pumps Packaged Water Solutions 2

Logikos Pump Control System Manual

Allied Pumps Packaged Water Solutions 3

CONTENTS

Logikos Pump Control System 4 - 30

1. Liquid Level 4

2. Digital input 9

3. Pump control 10 –14

4. Alarms 14 - 16

5. Running hours & servicing 17

6. PLC output 17

7. MODBUS interface 17 - 24

8. Programming menus 24 - 28

9. Status displays 29

10. Power up scape sequences 30

Appendix A: Warranty and Service Information

Logikos Pump Control System Manual

Allied Pumps Packaged Water Solutions 4

1 LIQUID LEVEL

1.1 LIQUID LEVEL SOURCE

This section applies only to the gathering of information regarding the liquid level and not the use or display of

the information.

The source of level information

comes from one of three sources

Multipoint

Nominally 10 conductivity sensors. Levels for alarms and

pump start etc can be changed by selecting different inputs

from the 10. Advanced setup allows the sensitivity of the

inputs to be selected. LEVEL1 is lower in the tank than

LEVEL10 whether tank empty or tank fill.

Individual

From 3 to 5 conductivity sensors or float switches connected

to level inputs 1 to 5. The functions are given in the table

below. Advanced setup allows the sensitivity of the inputs to

be selected.

Analogue

A continuously variable signal proportional to the depth.

Advanced Setup allows the Offset and Scale to be set. The

depth in mm is

Depth = Input x Scale + Offset

Where Depth is depth of liquid from bottom of tank. Input is

the input level scaled to 1 (ie 0 at 0V or 4mA and 1 at 10V or

20mA). Scale and Offset are Advanced Setup parameters.

Pressure

This setting is designed to be used in a constant pressure

system.

The input is a continuously variable signal from a pressure

transducer. Advanced Setup allows the Offset and Scale to be

set.

Separate on and off setpoints can be set for both duty and

standby pumps.

3 Level Probe

Designed for 3 conductivity sensors or float switches

connected to level inputs 2(Stop),3(Duty) & 5(Standby).

Advanced setup allows the sensitivity of the inputs to be

selected.

A high level alarm is generated after a programmable delay

Functions in Individual mode.

Tank Empty

Tank Fill

Input

Function

Function

Input

LEVEL5

High Level

High Level

LEVEL5

LEVEL4

Standby Pump Start

Pump Stop

LEVEL2

LEVEL3

Duty Pump Start

Duty Pump Start

LEVEL3

LEVEL2

Pump Stop

Standby Pump Start

LEVEL4

LEVEL1

Low Level

Low Level

LEVEL1

Logikos Pump Control System Manual

Allied Pumps Packaged Water Solutions 5

1.2 LIQUID LEVEL INTERPRETATION

1.2.1 Multipoint

In Multipoint mode the user selects a level input to correspond with each of the level functions. An

example, may be

Tank Empty

Tank Fill

Input

Function

Function

Input

LEVEL9

High Level

High Level

LEVEL9

LEVEL7

Standby Pump Start

Pump Stop

LEVEL7

LEVEL5

Duty Pump Start

Duty Pump Start

LEVEL3

LEVEL2

Pump Stop

Standby Pump Start

LEVEL2

LEVEL1

Low Level

Low Level

LEVEL1

1.2.2 Individual & 3 Level Probe

In Individual mode the function is fixed for each level input number. To change a level the user must

move the probe.

The sensor input position / functions are different for Individual Probes mode and 3 Level Probe mode:

Function

Individual Probes

3 Level Probe

High Level

L5

Timed

Standby Pump Start **

L4

L5

Duty Pump Start

L3

L3

Pump Stop

L2

L2

Low Level

L1

N/A

** Note –in a 2 pumps system with maximum pumps set as then Standby level will cause pumps to

changeover.

1.2.3 Analogue

In Analogue mode the user specifies depths for each function. An example is given in the table below. If

the current is less than approximately 4mA or above approximately 20mA or the calculation would

result in a tank less than empty or more than 110% full then a range error is generated. For reliable

analogue sensing the unit must be set up so that the conditions will not be reached unless there is a

problem. Great care is needed in deciding the calibration of the sensor and selection of the values. A

fully empty tank should report a couple of % of depth and be marginally above 4mA (or below

20mA). A full tank should report about 100% and be marginally below 20mA (Or above 4mA).

Logikos Pump Control System Manual

Allied Pumps Packaged Water Solutions 6

If High Level is enabled in Digital I/O then LEVEL5 input is monitored. If it is found to be

wet/conducting then the Level is taken to be the High Level setting. If the analogue reading was

less than High level when the LEVEL5 input is wet, then a range error is also generated.

1.2.4 Making the Best of Invalid Inputs

It is possible that one or more switches or conductivity probes may fail due to fat on electrodes or debris

etc. The unit has the option to generate an alarm when this occurs but will continue operation

according to the scheme described below.

In both Multipoint and Individual mode the tank level is mostly taken to be that of the highest sensor that

that it does not have a dry sensor immediately below. The exception is in the case of a high level

being present. If a Level sensor that corresponds to a High level is wet and there is a wet sensor

below it, then the level will be assumed to be no less than the High level. For this enhancement to be

active in Multipoint mode, High Level must be selected in digital I/O.

Multipoint Mode

LEVEL10

Dry

Dry

Dry

Dry

Dry

LEVEL9 (High)

Dry

Dry

Dry

Dry

Wet

LEVEL8

Dry

Dry

Dry

Dry

Dry

LEVEL7

Dry

Dry

Dry

Dry

Dry

LEVEL6

Dry

Dry

Dry

Dry

Dry

LEVEL5

Dry

Dry

Dry

Wet

Wet

LEVEL4

Dry

Dry

Dry

Dry

Dry

LEVEL3

Dry

Dry

Wet

Wet

Wet

LEVEL2

Dry

Wet

Wet

Wet

Wet

LEVEL1

Wet

Dry

Dry

Wet

Wet

Level used

1

0

3

3

9

Level Sense Alarm

No

Yes

Yes

Yes

Yes

Tank Empty

Tank Fill

Input

Function

Function

Input

2400mm

High Level

High Level

2400mm

2000mm

Standby Pump Start

Pump Stop

2000mm

1800mm

Duty Pump Start

Duty Pump Start

800mm

500mm

Pump Stop

Standby Pump Start

500mm

200mm

Low Level

Low Level

200mm

Logikos Pump Control System Manual

Allied Pumps Packaged Water Solutions 7

In Individual mode, above and below is according to the input position in the table below. Only those

inputs that are selected are considered used

Tank Empty

Tank Fill

Function

Function

High Level

High Level

Standby Pump Start

Pump Stop

Duty Pump Start

Duty Pump Start

Pump Stop

Standby Pump Start

Low Level

Low Level

1.3 LIQUID LEVEL DISPLAY

The unit has a bar graph consisting of 10 LEDs. These display the liquid level in the tank.

1.3.1 Multipoint

In multipoint mode, each LED corresponds to a probe input and the LED is on if the probe is wet.

Notionally each LED corresponds to 10% of the tank.

1.3.2 Individual

In individual mode, each input is assigned a notional percentage of tank height for the purposes of display.

Each LED on the bar graph represents 10%. The notional percentages are

Tank Empty

Tank Fill

Level

Function

Function

Input

80 to 100%

High Level

High Level

100%

60 to 70%

Standby Pump Start

Pump Stop

90%

40 to 50%

Duty Pump Start

Duty Pump Start

60 to 70%

30%

Pump Stop

Standby Pump Start

40 to 50%

10%

Low Level

Low Level

10 to 30%

Logikos Pump Control System Manual

Allied Pumps Packaged Water Solutions 8

In Tank Empty mode, when Standby pump start is not used, the High level input represents 60 to 100%.

When Low level is not used Pump Stop input represents 10 to 30%.

In Tank Fill mode, when High Level is not present, Pump stop represents 90 and 100%. When

Standby pump start is not present, Low level represents 10 to 50%

1.3.3 Analogue

In Analogue mode the LEDs come on at the points shown in the table.

Depth

Number of LEDs

up to 5%

none

5 to 15%

1

15 to 25%

2

25 to 35%

3

35 to 45%

4

45 to 55%

5

55 to 65%

6

65 to 75%

7

75 to 85%

8

85 to 95%

9

95% and above

10

The percentage is of the total tank depth not of the input signal range. For this reason the tank depth is

required as part of the level setup.

1.3.4 Constant Pressure

The level is set as proportion of pressure between the high and low alarm level set points.

Logikos Pump Control System Manual

Allied Pumps Packaged Water Solutions 9

2.3.5 Individual & 3 Level Probe

In individual mode, each input is assigned a notional percentage of tank height for the purposes of display.

Each LED on the bar graph represents 10%. The notional percentages are

Tank Empty

Tank Fill

Level

Function

Function

Input

100%

High Level (Timed)

High Level

N/A

75%

Standby Pump Start

Pump Stop

75%

50%

Duty Pump Start

Duty Pump Start

50%

30%

Pump Stop

Standby Pump Start

30%

N/A

Low Level

Low Level (Timed)

0%

2 DIGITAL INPUTS

The Advanced Programming mode allows the operator to determine how various inputs are

interpreted. For most digital inputs the operator can select if an input is active when the

connected contact is closed (active low), when the connected contact is open (active high) or not

used at all.

The inputs that may be configured for each pump are

Thermal

Motor Over temperature input

Overload

Overload on motor input

Pressure

Pressure input

No Flow

No Flow input

Seal

The seal leaking (Conductivity sensing. Always 3K and Active when wet).

The phase detects inputs may be configured as being used or not being used. In single phase systems

this must be selected to deactive.

High level and Low level inputs may be selected as being present or not. Low level is always active dry

and high level is always active wet.

Logikos Pump Control System Manual

Allied Pumps Packaged Water Solutions 10

3 PUMP CONTROL

3.1 NAMES AND PARAMETERS

The control algorithm for pump operation has the following controlling switch parameters which are

stored in EEROM and can be changed in Advanced Programming mode.

TankEmpty

If true the objective of the algorithm is to keep the tank level low

(empty)

TankFill

Not TankEmpty

OnePump

If true there is only one pump in the system

DualPump

If true two pumps may operate concurrently

The control algorithms described below uses the following terminology for inputs, output and

internal states.

The two physical pumps are Pump1 and Pump2. At power up Pump1 is the Duty Pump and

Pump2 is the Standby Pump.

Under Pump is true when the High Level is wet and Tank Empty. Under pump is true when

Low Level is dry and Tank Fill.

Level Stop is true if the stop level is dry and the mode is Tank Empty. Level stop is true if

the stop level is wet and the mode is Tank Fill.

Level Duty is true if the duty pump start level is wet and the mode is Tank Empty. Level

Duty is true if the duty pump start level is dry and the mode Tank Fill.

Level Standby is true if the Standby pump start level is wet and the mode is Tank Empty. Level

Standby is true if the Standby pump start level is dry and the mode Tank Fill.

3.2 THE HIGH LEVEL CONTROL ALGORITHM

This control algorithm determines which pumps should be on and off to perform the overall function of

the controller. Turning pumps off when there is a fault and manual pump control is discussed in The

Low Level Control Algorithm and Manual Control.

The following control algorithm is used in One Pump systems.

If LevelStop

If Pump1 is in Auto mode Pump1 is switched off

If Pump2 is in Auto mode Pump2 is switched off

Swapped is reset

Logikos Pump Control System Manual

Allied Pumps Packaged Water Solutions 11

Each time Level stop is newly reached the Duty Pump is toggled

If LevelDuty

If Pump1 is Duty Pump

If Pump1 is not bypassed and not faulted then Pump1 is turned on.

If Pump1 is faulted or bypassed Duty Pump is swapped.

If Pump2 is Duty Pump

If Pump2 is not bypassed and not faulted then Pump2 is turned on.

If Pump2 is faulted or bypassed Duty Pump is swapped.

IF NO PUMPS ARE UNFAULTED AND UNBYPASSED A NO PUMP ALARM IS

CREATED

If LevelStandby and DualPump

If Pump1 is not bypassed and not faulted then Pump1 is turned on.

If Pump2 is not bypassed and not faulted then Pump2 is turned on.

If UnderPump and not DualPump mode and not Swapped and both pumps are in auto then

Swapped is set

DutyPump is swapped

Both pumps are turned off (the new duty pump is turned on elsewhere)

3.3 THE LOW LEVEL CONTROL ALGORITHM

When manual control or the High Level Control Algorithm requires a pump to be on then the following

must be met before it is turned on.

There must be no pre-existing fault of the pump.

The pump must not be in manual override.

The current state of the fault inputs must all be OK –this includes the power supply being OK if

selected. The flow input is special in that it checked continuously after Flow Delay time since the

pump was last turned on. If the Fault inputs are not OK a fault is recorded for the pump.

The Pump Restart Delay must have elapsed since the last time this pump was started. This does

not generate a fault, only delay the starting of the pump. When a pump is started in this

section a start is recorded in the history.

Pump faults are cleared in the following way

Removing and Re applying power clears pump faults for both pumps Pressing the pump

button clears the pump for which the button is associated Pressing Alarm Reset clears pump

faults for both pumps.

3.4 MANUAL CONTROL

When the pump is in AUTO mode and the pump button is short pressed the pump switches to manual

OFF.

When in manual off mode and the button is short pressed the pump reverts back to AUTO mode.

Logikos Pump Control System Manual

Allied Pumps Packaged Water Solutions 12

A long press of the pump button will cause the pump to enter MANUAL on.

In Manual override the pump will stay on until the HIGH level is reached.

Auto is available if the pump is not currently faulted.

Manual OFF is always available, and the pump will remain in Manual OFF indefinitely, even if power is

removed and restored.

MANUAL On is available when all of the following are met

The pump has no current fault. (pressing the pump button clears any previous faults)

Not level stop

In systems that are not OnePump and not DualPump and the other pump is not on

If a fault occurs or HIGH level occurs during MANUAL on the pump is moved to Manual OFF.

A short press during MANUAL On reverts to manual OFF.

If the pump is in MANUAL on and pump is running then the MANUAL LED is slow pulsing otherwise if the

pump is not running then the LED is constant on.

If the power is removed and reapplied during any manual mode the pump will be in Bypass when

power is restored.

3.5 CONSTANT PRESSURE CONTROL

Constant pressure control is set by setting the level source to “PRESSURE” mode. (Mode=4), in the

ADVANCED MENUs.

The level input is sensed at the analog input to which is connected to a pressure transducer.

This may be as either (a) Constant Current input (4-20mA) or (b) Constant voltage 0-10VDc.

Note –the link on the D1237 module are used to select the input transducer type.

The analog input is sampled at a 32msec rate and then digital filtering is applied (Time Constant

256msec).

The LOAD DEFAULTS MENU allows selection for 1 or 2 pumps in constant pressure control mode.

The defaults are set for a 10BAR, 4-20mA pressure transducer.

The sensor span and offset parameters can be adjusted to suit the sensor.

One or two pump operation can be selected in the CONFIGURATION MENUS.

With two pump operation the selected duty pump alternates with each restart after BOTH pumps are

off.

The duty and standby on and off setpoints can be individually set for each pump.

This is accessed through the USER MENUs

Logikos Pump Control System Manual

Allied Pumps Packaged Water Solutions 13

This means that can have the duty pump on as pressure reduces down to low setpoint, or can have the

standby continue down to low setpoint, with duty pump stopping first.

Duty and Standby pump control work as in tank fill (low pressure==pumps on, high pressure==pumps

off) according to 5.2 and 5.3 above.

High and low alarm threshold can also be set.

These operate to generate alarms according to normal pump operation.

The maximum duty and pump restart period may be used as for normal pump operation.

Pump re-start period is timed from the last pump startup and can be used to prevent pump damage

due to constant short-cycling of the pump.

Each pump has a separate pump-restart timer.

The LED level indicator bar operation shows the pressure level as proportion of pressure between the

high and low alarm level set points.

ALARMS generally operate according to Section 6.

MANUAL override is not possible.

On power up a 200 second delay is applied for to the low pressure cutout to allow time for pressure

to build up. A 10 second delay is also applied to low pressure cutout during normal operation to allow

for short transient drops in pressure.

3.6 PUMP LEDs

The Auto pump LED

is on steady when the pump is in Auto mode and not running

is flashing when the pump is in Auto mode and is running

The Bypass, LED

Is on when the pump is in Bypass (manual off).

The Manual LED

Is on steady when the pump is on but subject to faults and Level Stop

Flashes when the pump is on because it is manual override and will not stop because of faults

or Level Stop.

3.7 MAXIMUM OFF TIME

In advanced setup a maximum off time can be set. The level is such that it is between stop and duty and

no pump is on for more that the maximum off time then the unit will function as if though a

momentary input on the duty level was received. Setting maximum off time to 0 disables this feature.

Logikos Pump Control System Manual

Allied Pumps Packaged Water Solutions 14

3.8 MAXIMUM DUTY

In advanced setups Maximum Duty time can be set. Maximum duty time is used to prevent the bearings

from burning out. Operation is explained from the perspective of tank empty - If start is dry and stop is

wet for more than the maximum duty time a pump stop is created. No alarm or warning is generated.

This effectively ends an Excess Run period because no pump is running. Setting this parameter to 0

disables the feature.

3.9 PUMPS TIMEOUT IN MANUAL MODE

This parameter sets the maximum time (0 to 3600 Second) that each of the pumps will remain in Manual

Mode. In any case the pumps are switched off when level reaches the Stop Level.

3.10 EXTERNAL INPUT

The external digital input function has a number of flexible options which can be set in the Digital I/O

menu.

The external input can be set to Pause or External Fault.

When set to operate as a Pause function, this will override the main pump controls and system will

continue to operate in same state at time it was paused.

There is an option to allow the high level alarm to override the pause.

When set to External fault, one of 7 external fault descriptions can be set. This will appear in the alarm

description on the LCD display.

An external fault condition can also be set cause 1 of 4 external functions to be activated, eg Alarm only,

Pumps OFF, Pump Start or Pump Off and Alarm.

3.11 AUX OUTPUT

The AUX relay output can be set to 1 of 5 functions.

(1) Well Wash –output to operate a separate well washing pump

(2) PLC –basic PLC output to interconnect with other PLC equipment

(3) High Level –operates when the high level is set

(4) Mixer –output to operate a mixer funciton

(5) Link to AUXIN –operates when AUX input is active.

4. ALARMS

4.1 ALARM SOURCES

The Alarm Sources are

Alarm Name

Cause

Level Sense

The unit has an invalid state on the level sensing inputs (such as a wet

point above a dry point and it has existed for over a minute)

No Pumps

Control algorithm needs a pump to be running but none is available

due to fault or manual bypass

Logikos Pump Control System Manual

Allied Pumps Packaged Water Solutions 15

Low Level

If the low level point is dry this alarm is generated (must be enabled

under Digital I/O section to become active)

High Level

If the high level point is wet this alarm is generated (must be enabled

under Digital I/O section to become active)

Power

Power had a phase fail or a under pumping condition was detected

soon after power up –which is most often caused when recovering from a

power failure. This feature must be enabled under Digital I/O section to

become active to enable phase fail detection.

Service

The run time on a pump exceeds the next service setting

External Fault

External (AUX) input is active.

This alarm has 3 programmable functions –Alarm Only, Pumps OFF & Pump Start

Excess Run

A pump run time has exceeded the set limit without reaching stop.

Strictly speaking, this alarm is exists only momentarily at the time when

either pump has been required for the Excess Run Time. So if the alarm

is reset while a pump is still running a new alarm will not be generated

again until neither pump is required and the Excess Run criteria has been

met again.

For Each Pump

Seal Probe

If the seal input is wet

Thermal

If the over temperature input is active

Overload

If the overload input is active.

Pressure

If the pressure input is active.

No Flow

If the No Flow input is active and the pump has been running for more

than Flow Delay time.

4.2 ALARM TYPES

An Alarm can be of three types. These are

Non Critical

Shows on display, fault LED and Non Critical Fault relay is

activated.

Local

Shows on display, fault LED, Non Critical Fault relay is

activated, Alarm relay and sounder are activated.

Critical & Local

Shows on display, fault LED, Critical Fault relay is activated,

Alarm relay and sounder are activated.

This means that an alarm is never off. At the least it will show on the display, the fault LED and the

non critical relay.

Logikos Pump Control System Manual

Allied Pumps Packaged Water Solutions 16

4.3 RESETTING AND MUTING ALARMS

Pressing the Mute button will cause the external sounder to be deactivated until a new alarm occurs.

Pressing the Alarm Reset button will do the same as pressing the Mute button plus also cause all new

alarms that are no longer present to be moved to previous alarms and then cleared. Only those

alarms that are no longer present will be cleared. For this reason it is best to use the Mute button to

silence the alarm response. Alarm Reset also clears any motor faults.

There is an option to auto mute alarms after a certain period of time. This time is in advanced setup. If

set to 0 there is not auto mute.

4.4 AUTO RESETTING ALARMS

4.4.1 The method of auto resetting alarms

Some alarms are cleared when a satisfactory recovery state has been identified. When cleared, they are

moved from “new” to “previous” and the sounder and alarm outputs are deactivated. Auto resetting

alarms will only auto reset if they will clear all of the currently active alarms. So for example, if a Level

sensing alarm occurred that led to a high level fault and the Level sensing alarm rectified itself the Level

Sensing alarm is not cleared until the high level alarm is also rectified (pumping down to stop).

4.4.2 The individual Auto Resetting alarms

In tank empty mode if the stop point is wet any low level alarm will be cleared automatically.

In tank fill mode if the stop point is dry any high level alarm will be cleared automatically.

In tank empty mode if the duty pump start point is dry any high level alarm will be cleared

automatically if the Level Alarm Auto Reset option is selected.

In tank fill mode if the duty pump start point is wet any low level alarm will be cleared automatically

if the Level Alarm Auto Reset option is selected.

If a level sense error disappears its alarm will be cleared automatically

If a no pump error disappears its alarm will be cleared automatically.

4.5 POWER UP WITH HIGH LEVEL ALARM PRESENT

Software versions prior to Version 4.0 would also set the Power Alarm when powered up with the High

Level alarm present.

This has been removed in Versions 4.0 and later.

Logikos Pump Control System Manual

Allied Pumps Packaged Water Solutions 17

4.6 HIGH LEVEL ALARM PAUSE OVERIDE

Version 4.1 includes and option in Digital I/O settings to allow a high level alarm to override the system

Pause function.

If the ‘Overides Pause’ option is enabled and if the high level alarm becomes active then the pumps are

started.

The pumps will run until the high level alarm condition is cleared (e.g. tank level drops below the high

level threshold)

5 RUNNING HOURS AND SERVICING

The unit accrues counts of certain events and operating times of the pumps. These counts may be

cleared in the Advanced Programming menu. The menu allows for each count to be cleared

separately.

The unit allows for a next service to be scheduled for each pump. The hours to next service are

displayed in the status display and an alarm may be set for pumps that have exceeded their service

interval.

5.1 PUMP RUNNING HOURS

The unit accrues the minutes for which each pump is running. At the end of each minute the value is

updated in nonvolatile memory.. Power failures cause the partly accrued minute to be lost. When pump

run time is displayed, it is displayed as hours and minutes. The maximum pump run time accrued of

32000 hours.

5.2 PUMP STARTS

Every time a pump is started the pumps start count in non volatile memory is updated. Manual Overide

starts are not counted.

6 PLC OUTPUT

The unit can be set to transmit a serial data stream giving the liquid level. See PLC_OUT.PDF.

The output is produced every 3 minutes if enabled in advanced programming.

Well wash, High Level output and PLC output are mutually exclusive as they share the same electrical

connections.

7 MODBUS INTERFACE

The unit provides a basic Modbus interface.

The following features are available.

Logikos Pump Control System Manual

Allied Pumps Packaged Water Solutions 18

DATA CONNECTION

Asynchronous

CMOS Logic Level (0 –5V) (See **Note below)

Speed - 9600 Bps Fixed

Data Bits - 8

Parity –Even

Stop Bits –1

MODBUS ADDRESS

Default Address = 5

Configured via front Panel Menus

Note –The Modbus feature is disabled by default and must be enabled via the front panel menus

MODBUS COMMANDS:

3 - Read Holding Registers

6 –Write Single Register

8 –Diagnostics Command

16 –Write Multiple Registers

7.1 NOTES ON SERIAL PORT INTERFACING

This interface is compatible with many RS232 Driver ICs but is operating with a reduced noise margin

and reduced output drive impedance.

As a general rule cable distance should be limited to <2metres and cables kept at least 100mm distance

from other high voltage or high current cables.

Shielding should be considered if these limits are compromised.

Connected devices should have an isolated signal reference otherwise grounding noise could cause

problems.

The interface has limited protection against high voltage or current surge.

This interface should be pre-tested and verified in the actual working environment

7.2 MODBUS REGISTER DESCRIPTIONS:

Notes for reading these tables:-

Generally the registers are 16bit integer number representation, with the following exceptions.

(1) Split as 2x 8 bit numbers –shown as Byte0 & Byte1

(2) Combined –where 2x 16 bit registers are combined to form a 32 bit number

These are shown as “Register Name- A” and “Register Name – B”

(3) Bitmapped –where the bit locations are shown as B0, B1, B2 , etc

The R/W field shows if the register is Read Only (R), or Read & Write (R/W)

Logikos Pump Control System Manual

Allied Pumps Packaged Water Solutions 19

7.2.1 Stored Parameters

REGISTER

NUMBER

DESCRIPTION

R/W

0

User Pin

R/W

1

Modbus Address

R/W

2

ID Low

R/W

3

ID High

R/W

4

Level Source

R/W

5

Level Sensitivity

R/W

6

Level Offset

R/W

7

Level Scale

R/W

8

Level Maximum Depth

R/W

9

Wellwash Period

R/W

10

Auto Mute Delay

R/W

11

Maximum Off Time

R/W

12

Wellwash Cycles

R/W

13

Main Control Flags

(Bitmapped)

B0 –Tank Empty

B1 –One Pump

B2 –Dual Pump

B3 - Flash Alarm

B4 –PLC Output

B5 –Model (0=Non Plus,

1=Plus)

B6 –Seal Lockout

B7 –Underpump Auto

Reset

B8-15 - Spare

R/W

14

Main Control Flags 2

(Bitmapped)

B0, B1, B2 –External

Function

B3 –High Level Out

B4–Pause Enabled

B5,6,7 - External Fault

Type

B8 –Mixer Out

B8 –15 - Spare

R/W

15

Digital Active Flags 1

(Bitmapped)

B0 –No Flow 1

B1 –No Flow 2

B2 –Pressure 1

B3 –Pressure 2

B4 –Overload 1

B5 –Overload 2

B6 –Thermal 1

B7 –Thermal 2

D8-15 - Spare

R/W

Logikos Pump Control System Manual

Allied Pumps Packaged Water Solutions 20

16

Digital Active Flags 2 (Bitmapped)

B0 –Seal 1

B1 –Seal 2 B2 - Phase

B3,4 –High Level

B5 –Low Level

B6-15 - Spare

R/W

17

Digital Polarity Flags (Bitmapped)

B0 –No Flow 1

B1 –No Flow 2

B2 –Pressure 1

B3 –Pressure 2

B4 –Overload 1

B5 –Overload 2

B6 –Thermal 1

B7 –Thermal 2

R/W

18

Main Control Flags 3 (Bitmapped)

B0–Main Control –Modbus

Enabled

B1 - High_overides_pause

B2-15 - Spare

R/W

19

Alarm Critical Flags A

B0 –Thermal 1

B1 –Thermal 2

B2 –Overload 1

B3 –Overload 2

B4 –Pressure 1

B5 –Pressure 2

B6 –No Flow 1

B7 –No Flow 2

B8 –Seal 1

B9 –Seal 2

B10 –Level Sense

B11 –Low Level

B12 –Hi Level

B13 - Power

B14 –No Pumps

B15 - Service

R/W

20

Alarm Critical Flags B

B0 –Excess Run

B1 –Aux

B2-15 - Spare

R/W

21

Alarm Enable Flags A

B0 –Thermal 1

B1 –Thermal 2

B2 –Overload 1

B3 –Overload 2

B4 –Pressure 1

B5 –Pressure 2

B6 –No Flow 1

B7 –No Flow 2

B8 –Seal 1

B9 –Seal 2

B10 –Level Sense

B11 –Low Level

B12 –Hi Level

R/W

Table of contents

Popular Control System manuals by other brands

Spraying Systems

Spraying Systems TeeJet TECHNOLOGIES BoomPilot installation manual

Spraying Systems

Spraying Systems TeeJet Technologies 744E user manual

Pro-tec

Pro-tec Algo-Tec 6400 Quick operating guide

Alfalaval

Alfalaval SB Carlsberg Flask instruction manual

Mill-right

Mill-right CARVE KING 2 Assembly instructions

DIS

DIS CCS 7800 user manual