ALLOMATIC APS1000-12 User manual

POWER INVERTER

APS1000-12 & APS2000-24

Table of Contents

Important Safety Information . . . . . . . . . . . . . . . . . . . . . . 1

General Safety Precautions. . . . . . . . . . . . . . . . . . . . . . 1

Precautions When Working With Batteries . . . . . . . . . . . . . . 1

General Informtion. . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Basis System Architecture . . . . . . . . . . . . . . . . . . . . . . . 4

Product Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Unpacking and Inspection . . . . . . . . . . . . . . . . . . . . . . 5

Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Mounting The Unit . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Battery Connection . . . . . . . . . . . . . . . . . . . . . . . . . . 7

AC Input/Output Connection . . . . . . . . . . . . . . . . . . . . . 9

Electrical Performance . . . . . . . . . . . . . . . . . . . . . . . . . 11

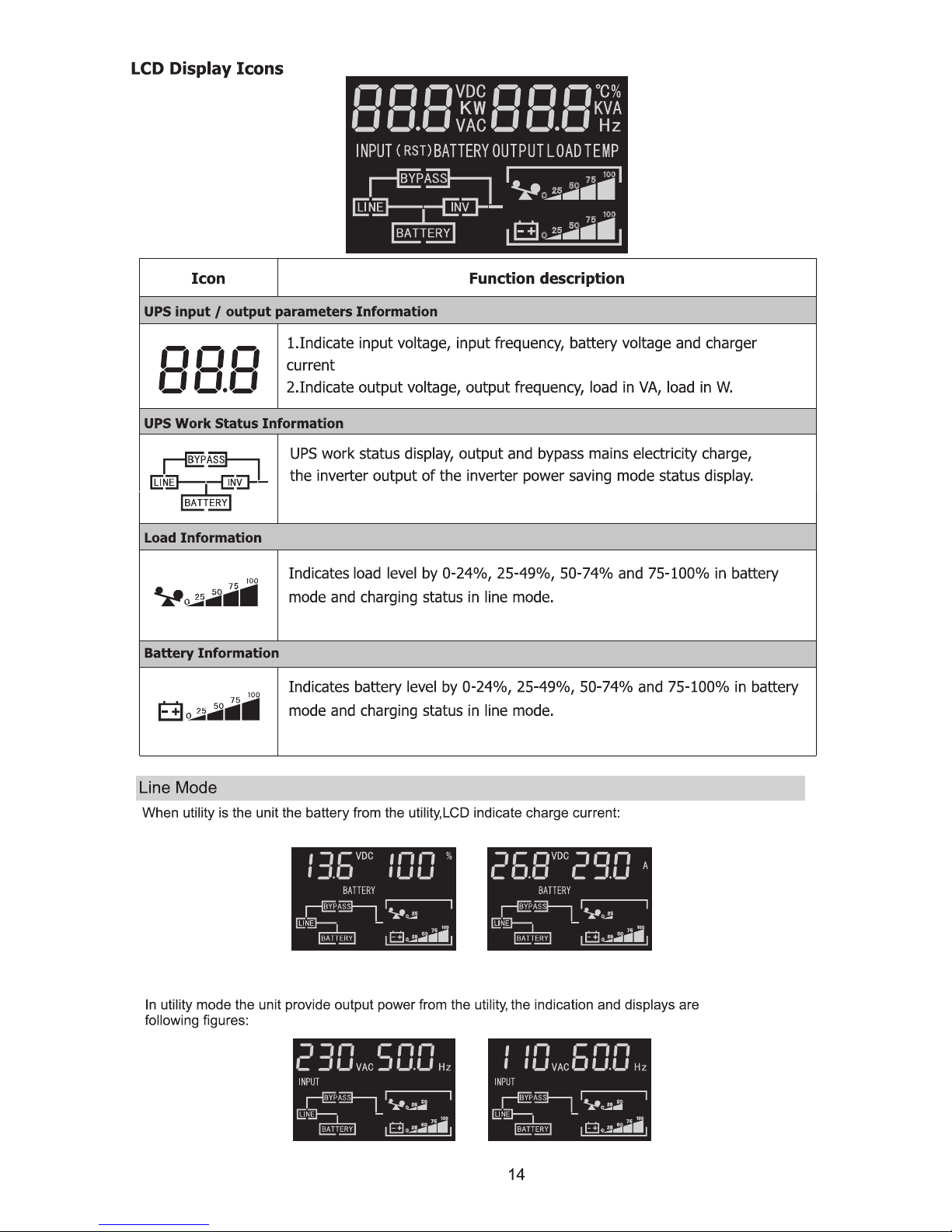

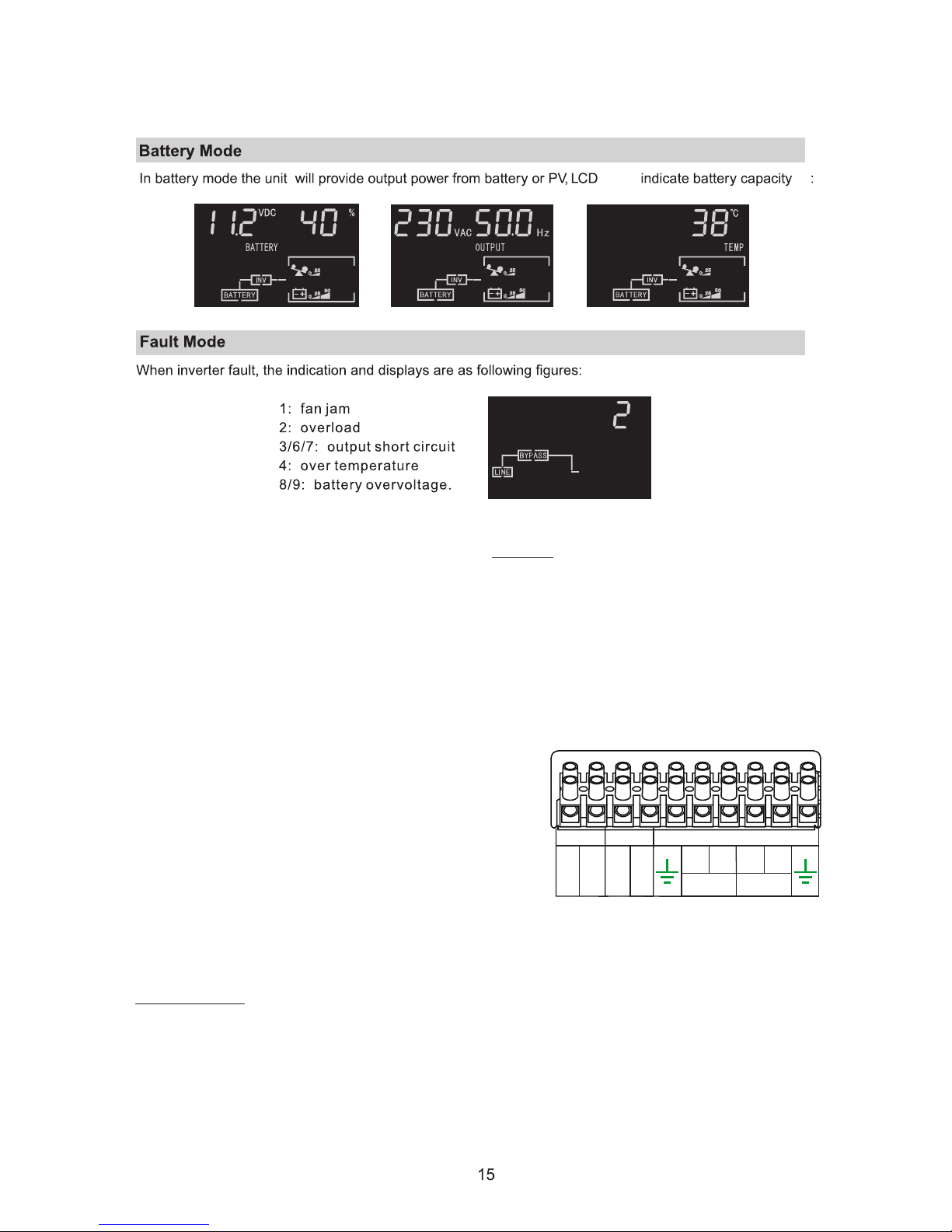

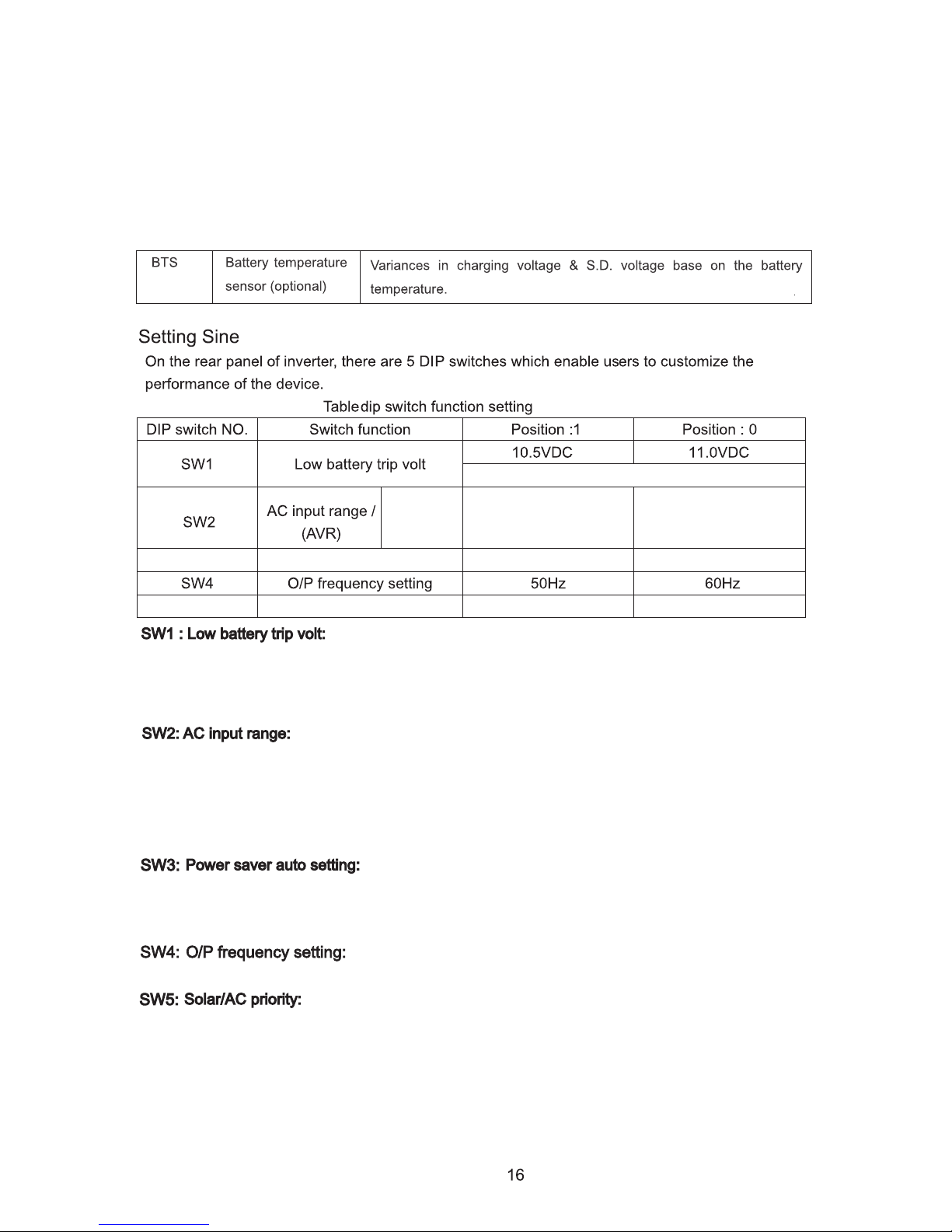

LCD Display Icons . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Relay connections for gate operator auto open/close functions. . . 15

Operating Mode Description . . . . . . . . . . . . . . . . . . . . . . 16

Warning Code/Audible Alarm . . . . . . . . . . . . . . . . . . . . . . 19

Troubleshooting Guide . . . . . . . . . . . . . . . . . . . . . . . . . 20

Important Safety Information

í ! wb Lb Dﱡ

This manual contains important instructions for APS1000-12 & APS2000-24 models that

shall be followed during installation and maintenance of the inverters.

General Safety Precautions

1. Before installing and using the inverter/charger, read all instructions and

cautionary markings on the inverter/charger and all appropriate sections of this

guide. Be sure to read all instructions and cautionary markings for any equipment

attached to this unit.

2. Install this unit away from direct sun light and where is not exposed to water

sprinklers.

3. To reduce risk of fire hazard, do not cover or obstruct the ventilation openings.

Do not install the inverter/charger in a zero-clearance compartment. Otherwise

overheating may occur.\

4. Use only attachments recommended or sold by the manufacturer. Doing

otherwise may result in a risk of fire, electric shock, or injury to persons.

5. To avoid a risk of fire and electric shock, make sure that existing wiring is in good

condition and that wire is not undersized. Do not connect the inverter/charger

with damaged or substandard wiring.

6. Do not operate the inverter/charger if it has received a sharp blow, been

dropped, or otherwise damaged in any way. If the inverter/charger is damaged,

read the warranty section.

7. Do not disassemble the inverter/charger. It contains no user-serviceable parts.

See warranty for instructions on obtaining service. Attempting to service the

inverter/charger yourself may result in a risk of electrical shock or fire. Internal

capacitors remain charged after all power is disconnected.

8. The inverter contains more than one live circuit (batteries and AC line). Power

may be present at more than one source. To reduce the risk of electric shock,

disconnect both AC and DC power from inverter/charger before attempting any

maintenance or cleaning or working on any circuits connected to the

inverter/charger. Turning off controls will not reduce this risk.

9. Use insulated tools to reduce the chance of short-circuits when installing or

working with the inverter or the batteries.

Precautions When Working with Batteries

1. Make sure the batteries are well ventilated. Avoid blocking enclosure vents.

2. Never smoke or allow a spark or flame near the inverter or batteries.

3. Use caution to reduce the risk of dropping a metal tool on the batteries. It could

spark or short circuit the battery or other electrical parts and could cause an

explosion.

4. Remove all metal items, like rings, bracelets, and watches when working with

lead-acid batteries. Lead-acid batteries produce a short circuit current high

enough to weld metal to skin.

5. Make sure someone is close enough to aid should anything dangerous occur

when you’re working near a lead-acid battery.

6. Prepare enough fresh water and soap in case battery acid contacts skin, clothing or

eyes.

7. Wear complete eye protection and clothing protection. Avoid touching your eyes

while working near batteries.

8. If battery acid contacts skin or clothing, wash immediately with soap and water. If

acid enters your eyes, immediately flood in cold water and get medical attention

immediately.

9. If you need to remove a battery, always remove the ground terminal from the

battery first. Make sure all accessories are off so you don’t cause a spark.

10. Always use identical types of batteries.

11. Never install old or untested batteries. Check each battery’s date code label to

ensure age and type.

12. Batteries are temperature sensitive. For optimal performance, they should be

installed in a stable temperature environment.

13. Always recycle old batteries. Contact your local recycling center for proper

disposal information.

General Information

Thank you for purchasing the APS inverter series.

The inverter is a combination of an inverter, charger.

It is packed with unique features and it is one of the most advanced inverter/charger

in the market today.

The inverter features an AC bypass circuit, powering your gate operators and access

controls or any appliance from the utility power or generator power while charging the

battery. When utility power fails, the battery backup system keeps your equipment

powered until utility power is restored. Internal protection circuits prevent over-

discharging the batteries by shutting down inverter when a low battery condition

occurs. When utility or generator power is restored, the inverter transfer to the AC

source and recharges the batteries.

The series inverter can also serve as a central hub of renewable energy system. Set

the series inverter to battery priority mode to designate it to inverter-preferred UPS

configuration. In this configuration, the load power is normally provided by the inverter,

However, if the inverter output is interrupted, an internal transfer switch automatically

transfers the load from the inverter to commercial utility power. The transfer time

between inverter and line is short(6ms typically), and such transfers are normally not

detected by even highly sensitive loads. Upon restoration of battery capacity, the

inverter will transfer back to inverter power (battery).

In the line priority mode, when utility power cuts off (or drops below acceptable range),

the transfer relay is de-energized and the load is automatically transferred to inverter

output.

Once the qualified utility power is restored, the relay is energized and the load is

automatically reconnected to utility power.

It features power factor, sophisticated multi-stage charging and pure sine wave output

with unprecedentedly high surge capability to meet demanding power needs of

inductive loads without endangering the equipment.

The inverter is equipped with a powerful charger of up to 70Amp (depending on

mode). The overload capacity is 125~150% of continuous output for up to 20 seconds

to reliably support tools and equipment longer.

Another important feature is that the inverter can be easily customized to solar priority

by DIP switch, this helps to extract maximum power from solar in renewable energy

systems.

To get the most out of the power inverter, it must be installed, used and maintain

properly.

Please read the instructions in the manual before installing.

Gate operators, access control devices and accessories.

Power tools-circular saws, drills, grinders, sanders, buffers, weed and hedge trimmers, air compressors.

Office equipment such as computers, printers, monitors, facsimile machines, scanners. Household items,

vacuum cleaners, fans, fluorescent and incandescent lights, shavers, sewing machines.

Kitchen appliances-coffe makers, blenders, ice makers, toasters.

Industrial equipment-metal halide lamp, high-pressure sodium lamp.

Home entertainment electronics-television, VCRs, video gate consoles, stereos, musical instruments,

satellite equipment.

ŸPure sine wave output

ŸAC/Battery priority Via function DIP switch

ŸAuto generator start. For gate operators Auto open

relay.

ŸMax. AC charge current 35A

ŸBuilt-in pure copper transformer

ŸLow battery trip voltage 10.5V/11.0V setting

ŸAuto sense 50HZ/60HZ

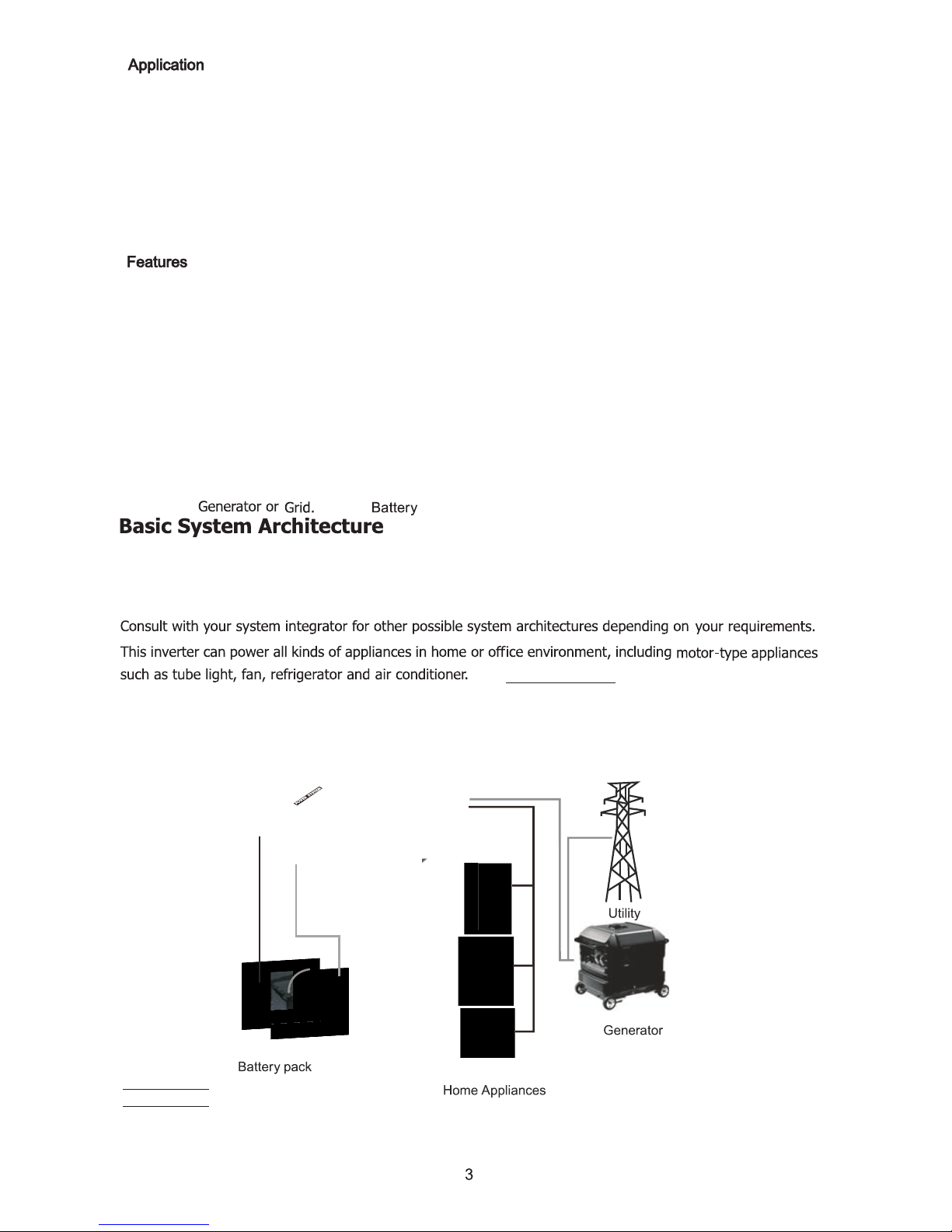

The following illustration shows basic application for this inverter. It also includes following devices to have

a complete running system:

Generator or Utility. Battery

Also Gate Operators and accessories.

APS1000-12 includes two 35Ahr batteries

APS2000-24 includes two 50Ahr batteries

Battery Type Selector

Charge Current Adjuster:25%,50%,75%,100%.

ON(Power Saver)

INVERTER OFF

ON

Connectors 8, 9 and

10 are extended to the

inverter front panel for

easy wiring.

IMPORTANT: When the inverter is

used to power Gate Operators,

switch must be in the ON position.

Not the ON (Power Saver) position.

Before installation, please inspect the unit. Be sure that nothing inside is damaged. You should see the

following items inside the main enclosure of the APS series inverters:

ŸMain inverter Unit

ŸTwo Batteries

35Ahr for APS1000-12

50Ahr for APS2000-24

ŸBattery breaker on the left side inside

enclosure

ŸAC Input/Output and relay connector on

inverter front panel

Mounting the unit

Consider the following before selecting where to install the unit:

ŸDo not install the inverter on flammable construction materials.

ŸMount on a solid surface.

ŸInstall the inverter at eye level in order to read the LCD display clearly.

ŸFor proper air circulation to dissipate heat, leave at least 3” gap above, below and

sides of the inverter enclosure.

ŸThe ambient temperature should be between 0ºF and 105ºF to ensure optimal

operation.

ŸThe recommended installation position is to be against the wall horizontally.

SUITABLE FOR MOUNTING ON CONCRETE OR OTHER NON-COMBUSTIBLE

SURFACE ONLY.

Mounting holes behind

packaging foam

Mounting holes

Install the unit using 4 screws on four mounting holes

Battery Connection

CAUTION: For safety and regulation compliance, it’s requested to install a separate DC

over-current protector between battery and inverter. DO NOT bypass the over-current

breaker that’s installed between inverter and batteries. Doing so, will increase the risk of

fire and possible harm to persons.

DC Wiring Recommendation

It is recommended the battery bank be kept as close as possible to the inverter. the

following is the recommended wiring options for 3 feet long cable.

APS series inverters use 4AWG cable that meet or exceed this requirement. If there is a

need to replace the battery cables, you must use the proper size to handle the power.

If Batteries need to be moved outside the inverter enclosure and need to extend the cable,

also increase the wire gauge thickness.

0-3 feet

1000W 2000W

0-3 feet

Two Batteries 4AWG BATTERY

CABLE

Over-Current

Breaker

One cable is always best, but cable is just copper and copper is what’s required, so it does

not matter if you use one cable or 10 cables as long as the square are adds up.

Performance of any product will be improved by thicker cable and shorter runs, so it is

recommended to keep the cables as short as possible.

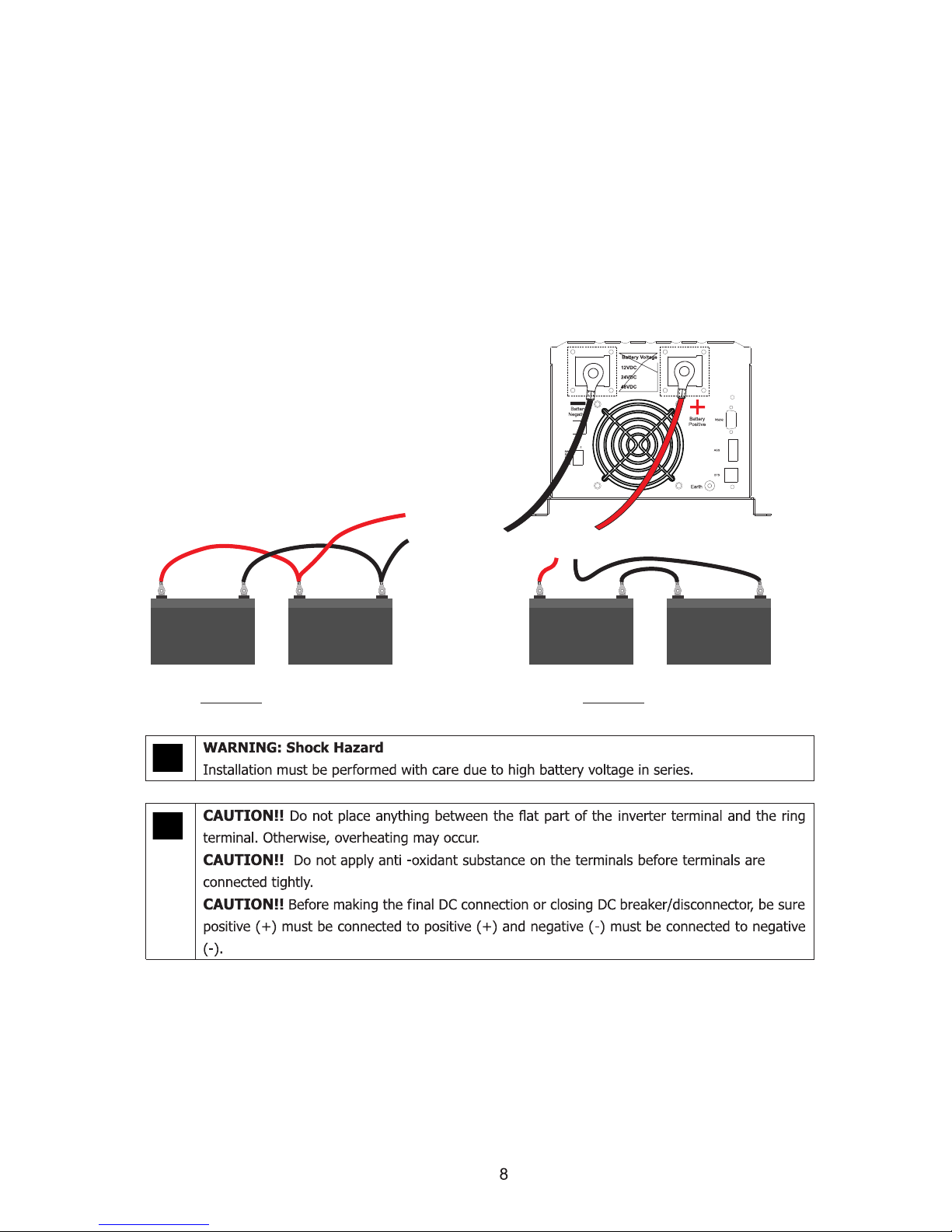

Please follow steps below in case battery cables need to be replaced:

1. Install battery ring terminals on recommended cable and terminal size.

2. Connect battery pack as unit requires. APS1000-12 must have batteries connected in

parallel, and the APS2000-24 in series.

NOTE: Please only use Sealed Lead Acid or Sealed GEL/AGM Lead-Acid Batteries.

3. Connect ring terminals of battery cable into inverter battery connector and make sure

bolts are tightened. Make sure polarity is correct at both ends of the cable (battery

terminals and inverter connectors) and that ring terminals are tightly screwed to battery

terminals.

+

+

+

+

+

- -

--

-

APS1000-12 Main battery bank, 12VDC.

(35Ahr included) wired in parallel. APS2000-24 Main battery bank, 24VDC.

(50Ahr included) wired in series.

PARALLEL

SERIES

++

- -

12V

24V

12V

35Ahr

12V

35Ahr 12V

50Ahr

12V

50Ahr

APS1000-12

APS2000-24

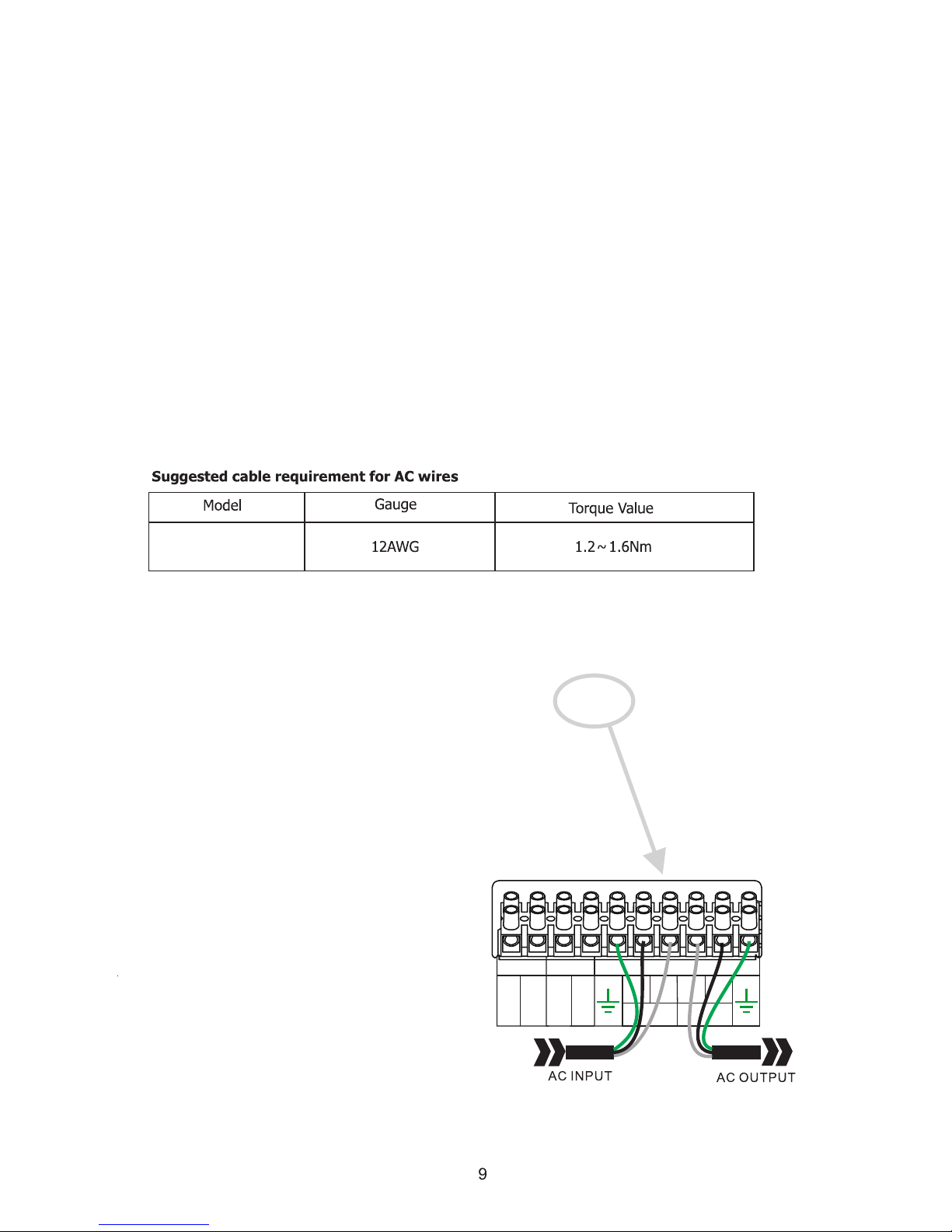

AC Input/Output Connection

Caution!! Before connecting AC input power source, please install a separate AC breaker

between inverter and AC input power source. This will ensure the inverter can be safely

disconnected during maintenance and fully protected from over current of AC input. The

recommended AC breaker is 30A for both APS1000-12 and APS2000-24 models.

Caution!! Please don’t connect the output AC to “Grid” terminals nor connect the grid to the

“Load” terminals. Doing so will permanently damage inverter.

WARNING! All wiring must be performed by a qualify person.

WARNING! It’s very important for system safety and efficiency operation to use appropriate

cable for Grid connection. To reduce risk of injury, please use the recommended proper

cable size as below.

AC Wiring

We recommend using 12AWG wire to the AC terminal block. If the inverter is installed

farther than 70 feet from main power source, wire gauge must be sized properly to avoid

big voltage drops. Be sure all wiring is UL compliant, call our tech support if you are not

sure how to wire any part of the inverter.

WARNING! It’s very important to do the wiring correctly on battery terminals and high

voltage AC side.

120V AC 60Hz 1000W

L LN N

INPUT OUTPUT

RLY 1

COMMON

N.O.

RLY 2

COMMON

N.O.

AC Wiring (120VAC, Single phase, 60Hz)

Input: Groung +Hot line +Neutral (Main Source)

Output: Neutral +Hot line +Ground (Load)

120V AC 60Hz 1000W

L LN N

INPUT OUTPUT

RLY 1

COMMON

N.O.

RLY 2

COMMON

N.O.

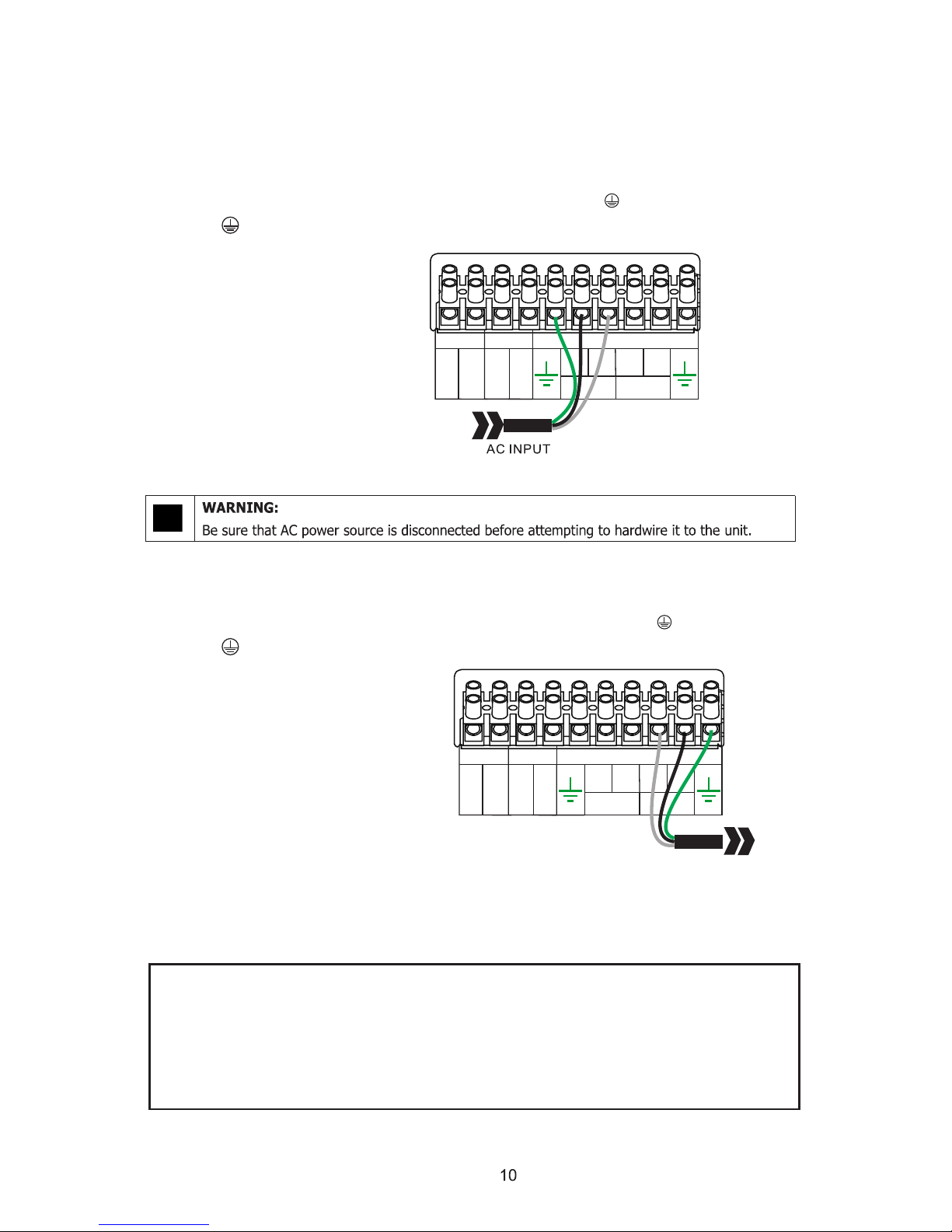

Please follow these steps to connect inverter to Load/Grid:

1. Before making Load/Grid connection, be sure to open DC protector/breaker first.

2. Strip each individual wire/conductor about 3/8”.

3. Connect grid wires according to polarity indicated on terminal block and tighten the

terminal screws. Be sure to connect protective earth conductor ( ) first.

-> Ground (green)

L-> LINE (black)

N-> Neutral (white)

4. Then, connect Load (output) wires according to polarity indicated on terminal block and

tighten terminal screws. Be sure to connect protective earth conductor ( ) first.

-> Ground (green)

L-> LINE (black)

N-> Neutral (white)

120V AC 60Hz 1000W

L LN N

INPUT OUTPUT

RLY 1

COMMON

N.O.

RLY 2

COMMON

N.O.

AC output

(load)

5. Make sure all wires are securely connected.

CAUTION: Appliances such as air conditioner require at least 2~3 minutes to restart

to have enough time to balance refrigerant gas inside of circuits. If a power outage

occurs and recovers in a short time, it will cause damage to your connected appliance.

To prevent this kind of damage, please check manufacturer of air conditioner if it’s

equipped with time-delay function before installation. Otherwise, this inverter will

trigger overload fault and cut off output to protect your appliance but it is still possible

it will cause internal damage to the air conditioner.

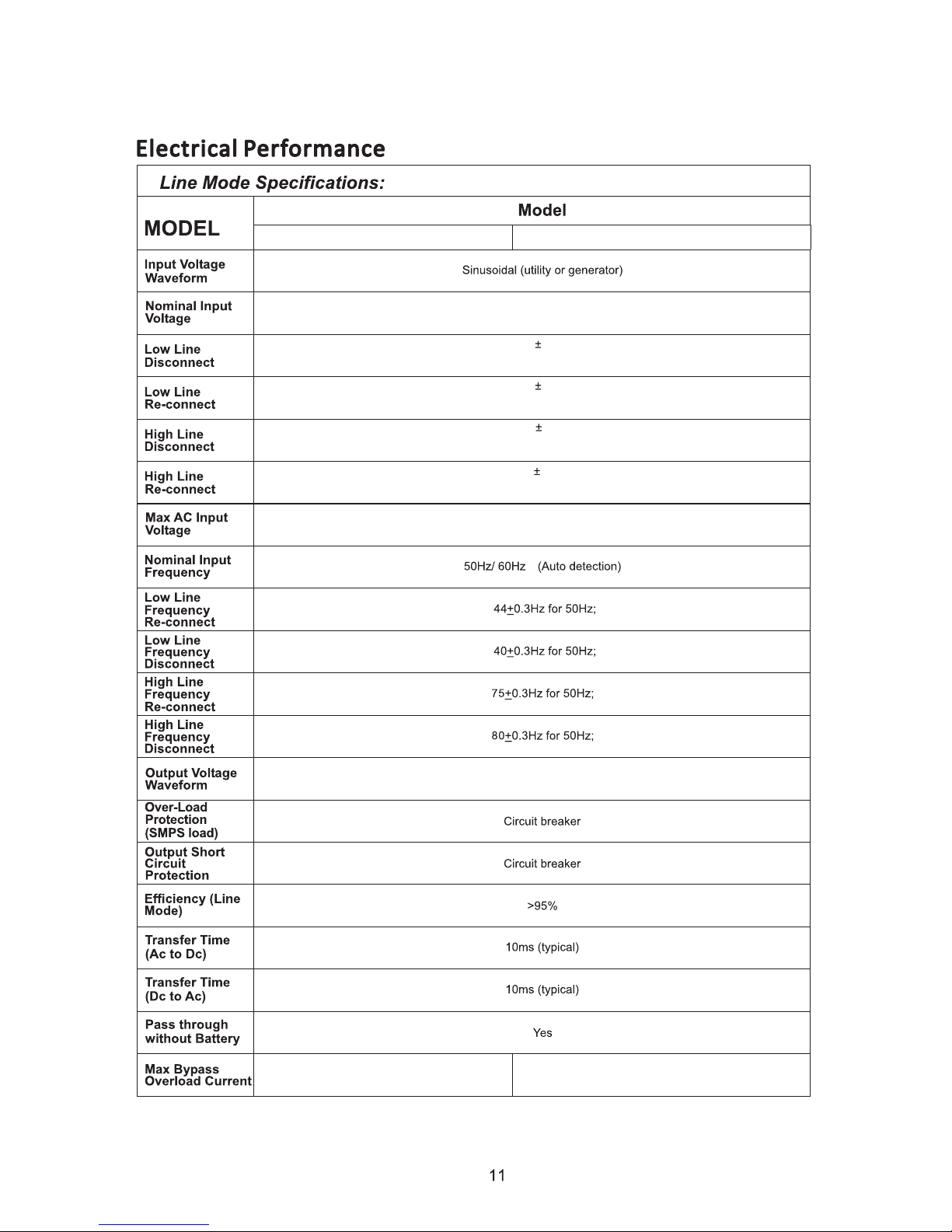

120Vac

75Vac 2%

80Vac 2%

140Vac

140Vrms

135Vac

2%

2%

30A 40A

APS1000-12 APS2000-24

Same as Input Waveform

120VAC

APS1000-12 APS2000-24

2,000VA 4,000VA

Instant Reverse Gate Motors

Two 1/2 HP or One 1HP Instant Reverse Gate Motors

Four 1/2 HP or Two 1HP

11Vdc ± 0.3Vdc

22V

11V

22Vdc ± 0.6Vdc

10.5Vdc ± 0.3Vdc 21Vdc ± 0.6Vdc

16Vdc ± 0.3Vdc 32Vdc ± 0.6Vdc

15.5Vdc ± 0.3Vdc 31Vdc ± 0.6Vdc

120Vac

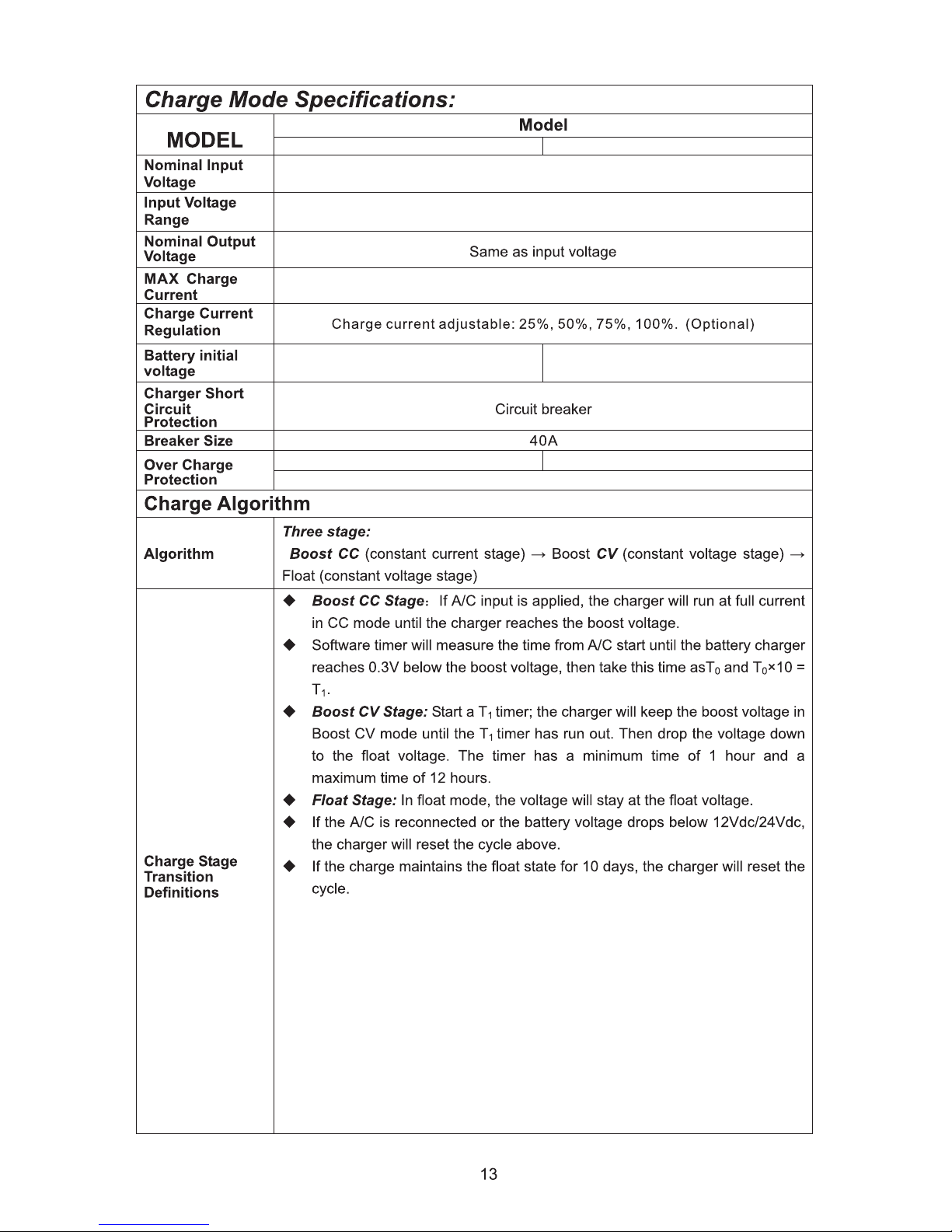

75-140Vac

10.5-15.7Vdc

35A

APS1000-12 APS2000-24

21V-31.4Vdc

≥15.7Vdc

≥31.4Vdc

Alarm beeps 0.5s second & Fault after 60s

Auto generator start (AGS)

There is an extra connector in front of the inverter (Relay 2) used to start a generator or to

trigger a gate operator to open the gate before battery runs out of power. If the utility power is

abnormal and single battery discharges below 11VDC, the inverter will send out a signal to

either a generator start circuit or to a gate operator to trigger the gate to open. Once the battery

is charged to 13.5VDC or higher, the signal will deactivate and switch to normal operation.

Auto AC power off signal

Includes a relay N.O. contact used to trigger a gate operator to open the gate on AC utility

power failure. Once AC utility power fails, the relay will trigger the signal.

120V AC 60Hz 1000W

L LN N

INPUT OUTPUT

RLY 1

COMMON

N.O.

RLY 2

COMMON

N.O.

Relay Function for gate operators:

RELAY 1: Activates immediately after a power outage. I

can be to trigger a gate operator to open the gate. One

time open. It will stay active until power is restored.

RELAY 2: Activates after a power failure and battery

voltage has reached the low level threshold. It could be

used to trigger a gate operator to open before battery is

fully depleted.

Using this relay to trigger a gate to open, will allow a

gate operator to run on battery backup but will ensure

gate opens before battery fails.

For Failsafe connect to gate operator OPEN CMD

For Failsecure connect to gate operator CLOSE_CMD

120VAC 75-140VAC 95-140VAC

*2 for APS2000-24

SW3 Power saver auto setting check load every 5s

check load every 30s

SW5 Battery/AC priority setting Utility priority Battery priority

For APS1000-12, the low battery trip volt is set at 11.0VDC for sealed lead acid battery. It

can be changed to 10.5VDC using Sw1 for deep cycle lead acid battery, this is to prevent

batteries from over-discharging while there is only a small load applied on the inverter. (*2

for APS2000-24)

There are different acceptable AC voltage input ranges for different kinds of loads. For

some relatively sensitive electronic devices, a narrow input range of 95-140 VAC is

required to protect them.

While for some resistive loads which work in a wide voltage range, the input AC range can

be customized to 75-140VAC, this helps to power loads with the most AC input power

without switching to battery bank. For gate operators we use the setting 75-140VAC

By default the inverter is set to detect the load for 250ms every 5 seconds. This cycle can

be customized to 30 seconds through the Sw3 DIP switch. Note: Power saver mode should

not be used when using inverter for a gate operator.

Set the inverter frequency while in battery mode.

The inverter is designed with AC priority by default. This means, when AC input is present,

the battery will be charged first, and the inverter will transfer the input AC to power the load.

Only when AC input is stable for a continuous period of 15 days, the inverter will start a

battery inverting cycle to protect the battery. After 1 cycle normal charging and AC will be

restored and go back to bypass mode.

Low trip to AC model

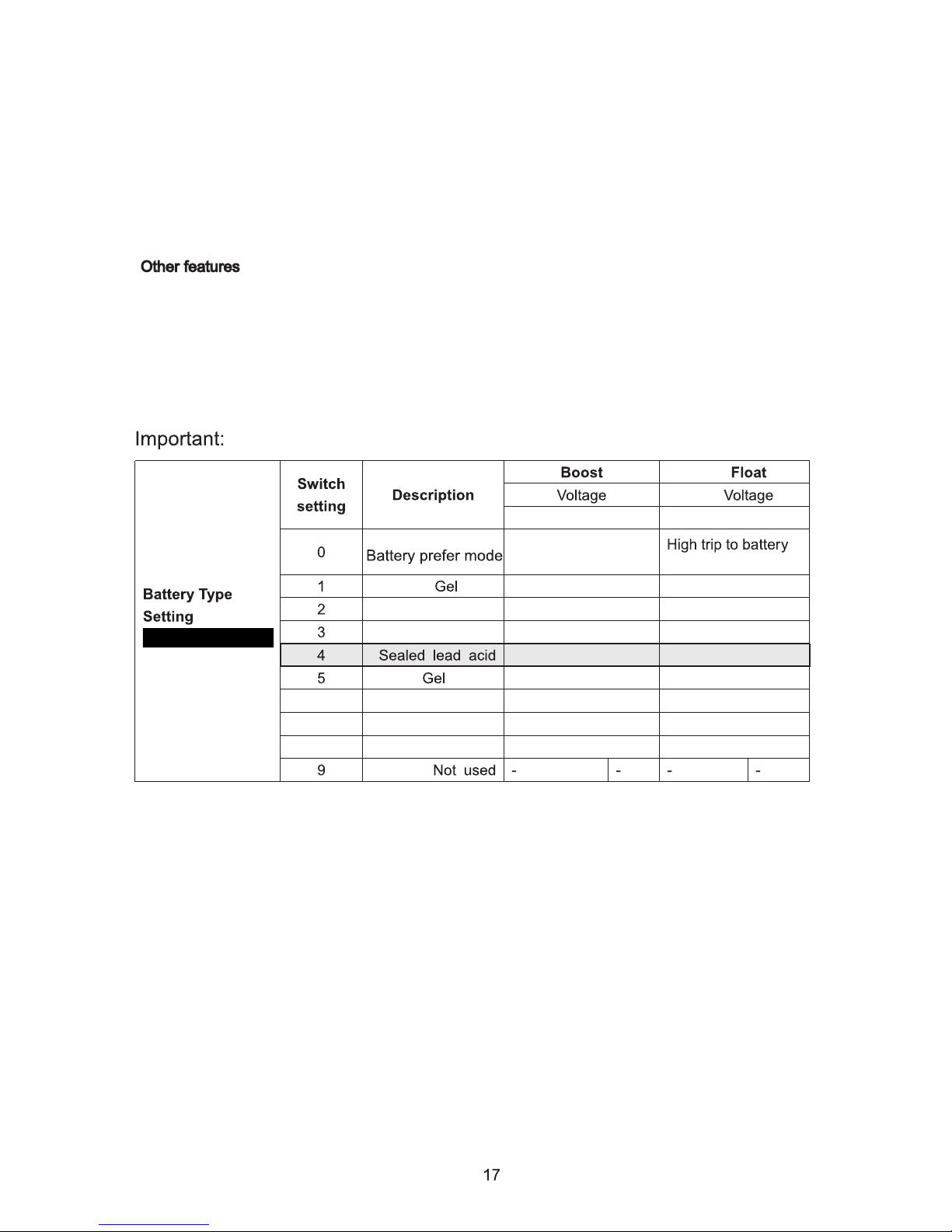

Note: APS series inverter include Sealed Lead Acid Batteries. If different chemistry batteries are used,

this setting must be adjusted to match the charging voltage appropriate for the type of battery.

The AC priority and battery priority switch is SW5. When switch is set to battery priority, the inverter

will run on battery power even if AC input is present. Only when the battery voltage reaches the low

voltage threshold (11.5V for 12V & 23V for 24V). The inverter transfers to AC input, charges battery,

and switches back to battery when it is fully charged. This function is mainly for wind/solar

applications and utility power is strictly backup. But it could also be useful in locations where a lot of

brow-outs happen.

Battery voltage restart

After low battery voltage shut off (10.5V for 12V model / 20V for 24V model), the inverter is able to

restore operation after the battery recovers to 13V for 12V model and 26V for 24V model (with power

switch still in the “ON” position). This function helps to save the users extra work reactivating the

inverter when the low battery voltage returns to an acceptable range in the renewable energy

systems. the built in battery charger will automatically reactivate as soon as utility/generator ac has

been stable for 15 seconds.

APS1000-12/APS2000-24 APS1000-12/APS2000-24

AGM 1

11.5V/23V

AGM 2

EURO

Open lead acid

De sulphation

7 Calcium

13.4V/27.4V

USA 14V/28V

14.1V/28.2V

14.6V/29.2V

14.4V/28.8V

14.4V/28.8V

14.8V/29.6V

15.1V/30.2V

15.5V/31V

13.4V/26.8V

13.7V/27.4V

13.6V/27.2V

13.3V/26.6V

13.8V/27.6V

13.6V/27.2V

4 hours then off

14V/28V

By restarting the inverter. Turn it OFF and back ON.

This manual suits for next models

1

Table of contents