FORM DOC 120 A

MU 7093 EN C

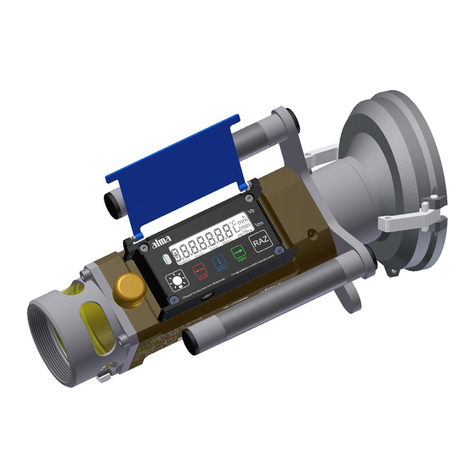

DUAL TRONIQUE

This document is available on www.alma-alma.fr

6SET THE DUAL TRONIQUE: SUPERVISOR MODE............................................................................. 33

6.1 Menu CALIBRATION/ GAUGE............................................................................................... 33

6.1.1 Pumped mode ..........................................................................................................................................33

6.1.1.1 Sub-menu ENTER STANDARD VALUE..............................................................................................33

6.1.1.2 Sub-menu LINEARISATION/FLOW...................................................................................................34

6.1.2 Gravity mode............................................................................................................................................35

6.2 Menu PRODUCT SETTINGS................................................................................................... 35

6.3 Menu CONFIGURATION....................................................................................................... 37

6.3.1 Sub-menu ID LINES...................................................................................................................................37

6.3.2 Sub-menu EM SETTINGS –Not applicable ...............................................................................................37

6.3.3 Sub-menu VEHICLE...................................................................................................................................37

6.3.4 Sub-menu CURRENCY...............................................................................................................................37

6.3.5 Sub-menu LOADING PLAN........................................................................................................................37

6.3.6 Sub-menu ADDITIVE TYPE ........................................................................................................................38

6.3.7 Sub-menu REMOTE CONTROL..................................................................................................................38

6.4 Menu SETTINGS .................................................................................................................. 39

6.4.1 Sub-menu VOLUME or MASS SETTINGS...................................................................................................39

6.4.2 Sub-menu FLOWRATE SETTINGS..............................................................................................................40

6.4.3 Sub-menu TIMING SETTINGS ...................................................................................................................40

6.4.4 Sub-menu BACKUP VALUES......................................................................................................................41

6.5 Menu TIME ADJUSTMENT.................................................................................................... 41

6.6 Menu PRINTER SETTINGS..................................................................................................... 41

6.7 Menu DSPGI........................................................................................................................ 42

6.8 Menu COMPUTING.............................................................................................................. 43

6.9 Menu LANGUAGE................................................................................................................ 43

6.10 Menu ICOM MENUS ............................................................................................................ 43

7CONFIGURE THE DUAL TRONIQUE: METROLOGICAL MODE........................................................... 45

7.1 Menu INDICATOR REFERENCE.............................................................................................. 45

7.2 Menu CONFIGURATION....................................................................................................... 45

7.2.1 Sub-menu DUAL OPTION..........................................................................................................................45

7.2.1.1 DUAL OPTION NOT ENABLED .........................................................................................................46

7.2.1.2 DUAL OPTION ENABLED .................................................................................................................46

7.2.2 Sub-menu INSTRUMENTATION................................................................................................................47

7.2.2.1 PTO .................................................................................................................................................47

7.2.2.2 OVERFILL PREVENTION ...................................................................................................................47

7.2.2.3 ADDITIVE INJECTOR ........................................................................................................................48

7.2.2.4 PUMPED NOT COUNTED.................................................................................................................48

7.2.3 Sub-menu COMPARTMENT OPTIONS ......................................................................................................48

7.2.4 Sub-menu OPTION CMA –Not applicable................................................................................................49

7.2.5 Sub-menu HYDRAULIC –Not applicable ..................................................................................................49