10 PSG-125 5” PNEUMATICANGLE GRINDER

AIR PRESSURE AND VOLUME

The recommended air pressure for this pneumatic angle grinder is 90 PSI.

The most important factor in running this angle grinder is the volume of

air being supplied to the angle grinder. The volume is the air consumption

needed to run this angle grinder at a constant speed under light downward

hand pressure. The volume is measured in CFM (cubic foot per minute (ft3/

min)). Alpha® recommends running the tool at the maximum ow volume

of 33 CFM to get the full 1.4 HP rating out of the angle grinder.

It is also very important to keep your air cool, dry, and clean, so look for

a compressor with a refrigerated dryer and high-eciency lter built-in or

purchase a separate air dryer and lter unit rated for your compressor’s

CFM. (See page 12 for Alpha®Filter/Regulator Manifold System)

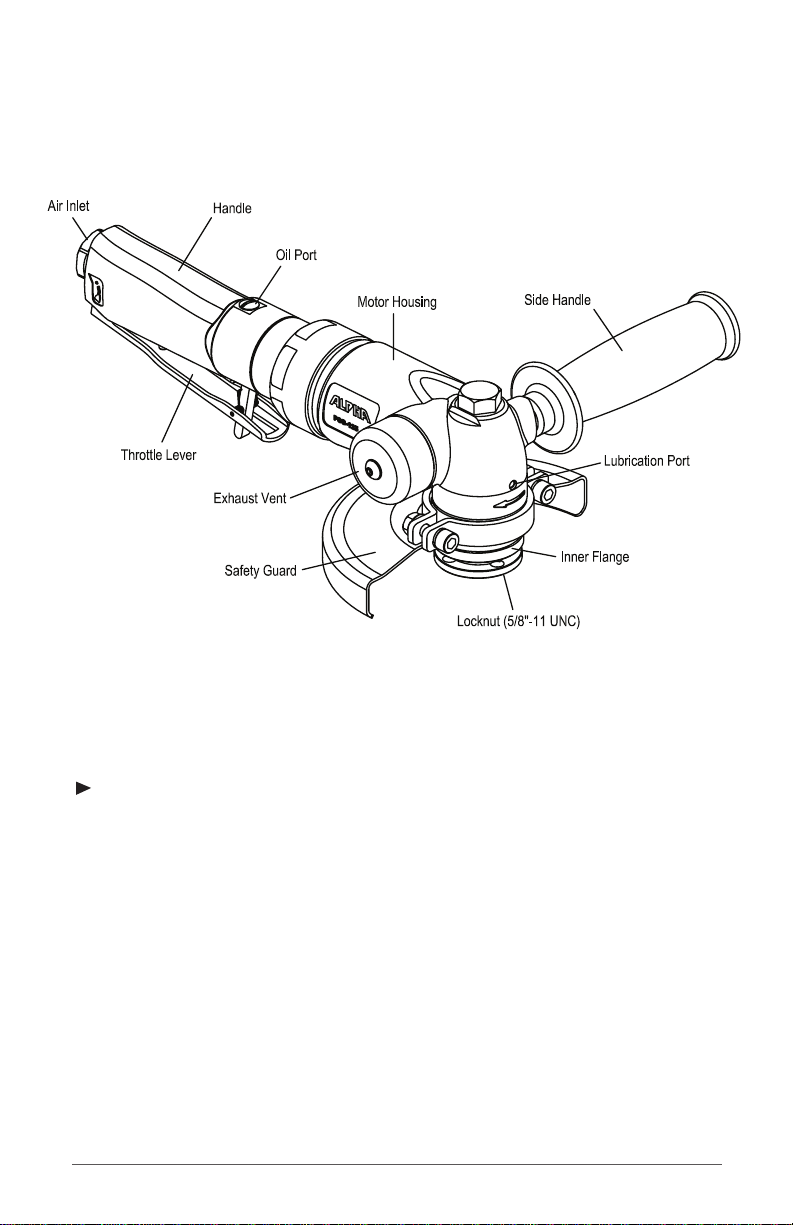

RUST PROTECTION (A rust inhibitor oil is used to protect the tool

from rusting when not in use)

PROPERCAREANDMAINTENANCEAREIMPORTANT FACTORSIN

PREVENTING THIS TOOL FROM RUSTING ON THE INSIDE WHEN

NOT IN USE.

At the end of each workday, place 4-5 drops of rust inhibitor oil (included

with each angle grinder) into the tool using the oil port. Depress the throttle

lever varying the speed from very low to half speed, for thirty seconds. This

will allow the oil to transition into the rotor assembly and coat the inside of

the tool.

CLEANING THE ROTOR ASSEMBLY

Over time, the rotor assembly can ll up with oil sludge, vane dust residue,

and contamination and will need to be cleaned. To accomplish this, remove

the muer assembly from the tool to allow the waste to exit. You can hold a

paper towel over the exit port to reduce the sound level and catch the exiting

waste. Add 10 to 20 drops of oil to the oil port and run the tool varying the

speed from very slow to half speed, for two to three minutes to allow the

oil to process through the machine. Check the paper towel for exit waste,

continue until there is little to no exit waste.

Run the tool at its slowest speed. If the tool sounds like it is running with

a variation in speed, this is an indication that one of the vanes is still stick-

ing in the rotor. Repeat the process to see if this will correct the variation

in sound. If the problem continues, contact an authorized Alpha®Repair

Center for routine repair and maintenance.