2

Dear Customer,

Thistool isthe resultofmorethan75yearsofexperiencein the design and

manufacturing ofpneumatictoolsforthe industrial market.

Wekindlyaskthatyou read theseoperating instructionscarefullysothatyou

toolsafelyandfor manyyears tocome.

If you need additional information,pleasecontact your DEPRAG

Representative,one ofour international supportofficesorusdirectat

DEPRAG.Wewill be happytoanswer anyquestions.

Pleasevisitour web site: www.deprag.com / www.depragindustrial.cz

Content

1SAFETYTIPS................................................................................................................3

1.1. GeneralSafetyTips....................................................................................................3

1.2. SafetyTipsforGrinders..............................................................................................4

1.3. OwnerObligation........................................................................................................7

1.4. OperatorObligation....................................................................................................8

1.5. WarrantyandLiability.................................................................................................8

1.6. SymbolDescription.....................................................................................................9

1.7. ObserveEnvironmentalRegulations........................................................................10

2DESIGNATEDEQUIPMENTUSE...............................................................................11

3INSTALLATION............................................................................................................11

4OPERATION................................................................................................................12

5HANDLING...................................................................................................................13

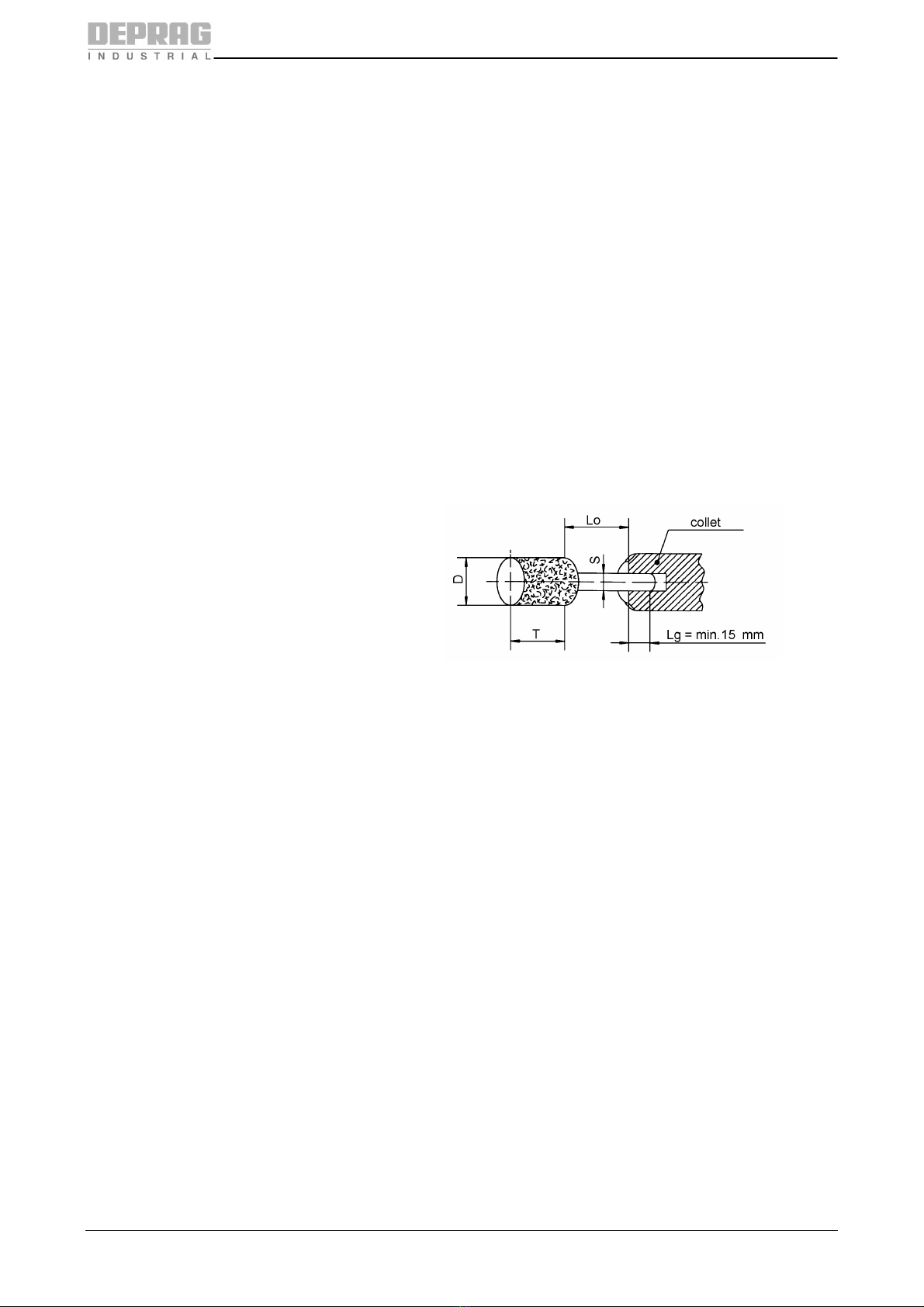

5.1. Partialair extraction atthe spindleend.....................................................................14

6DISASSEMBLY-ASSEMBLY......................................................................................15

6.1. ReplaceO-RinginValve...........................................................................................16

6.2. ReplaceVanes.........................................................................................................16

6.3. SparePartsDrawing.................................................................................................18

6.4. DimensionalDrawing................................................................................................22

7MAINTENANCEAND UPKEEP...................................................................................23

7.1. WearParts................................................................................................................23

8TROUBLE SHOOTING................................................................................................24

9DELIVERYCAPACITY.................................................................................................24

10 ACCESSORIES – OPTIONALEQUIPMENT.............................................................25

11 STORAGE..................................................................................................................25

12 TECHNICAL DATA.....................................................................................................26

13 DISPOSAL..................................................................................................................27

14 CONFORMITYDECLARATION.................................................................................28

15 SERVICELOCATIONS AND AUTHORIZEDPARTNERS.........................................29