2

TABLE OF CONTENTS

Introduction...................................................................................................... 3

About the Symbols .......................................................................................... 3

General Safety Instructions ............................................................................. 4

Safety Instructions for Electric Tools................................................................ 5

Grounding Instructions .................................................................................... 7

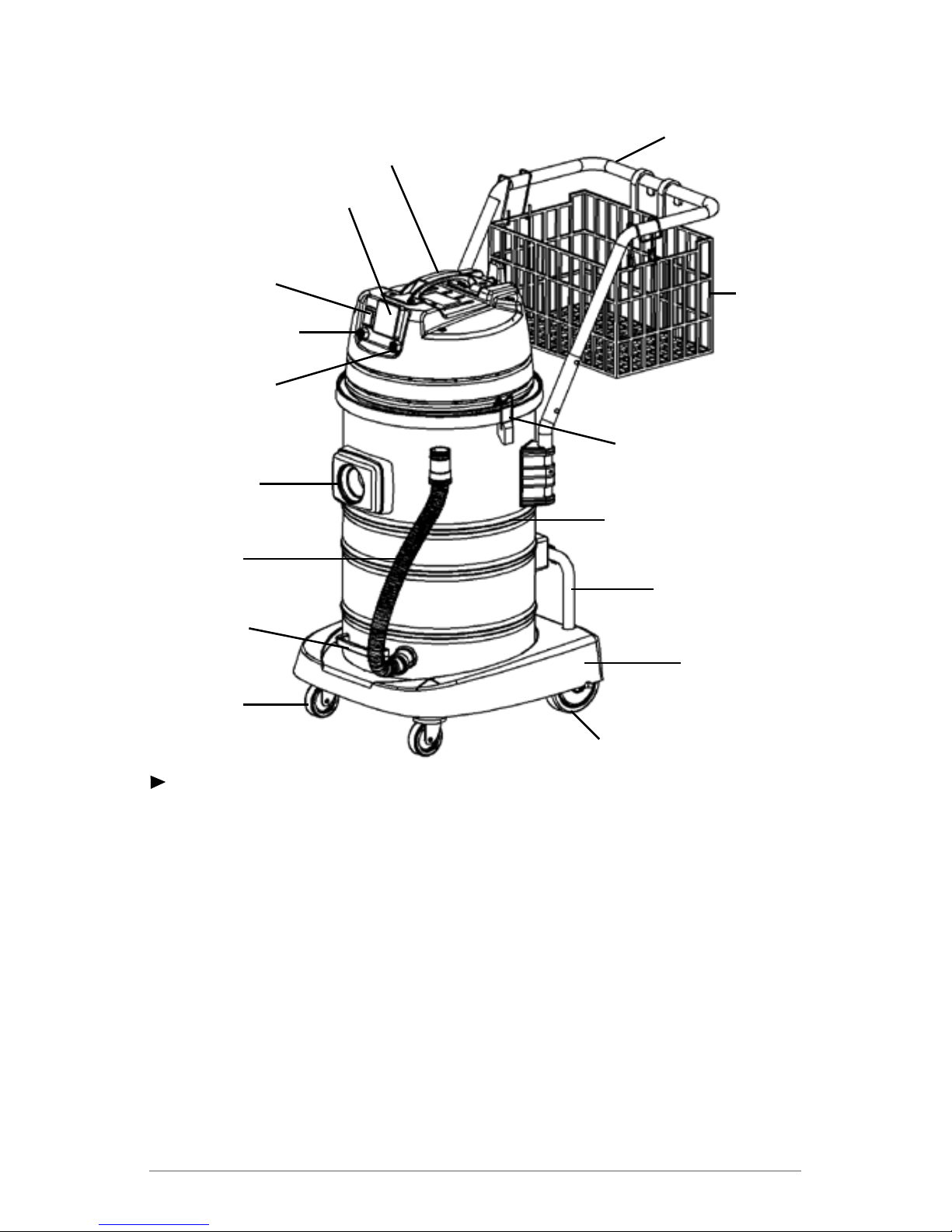

HEPA Wet/Dry Vacuum Overview ................................................................... 8

Specications............................................................................................ 8

HEPA Wet/Dry Vacuum Accessories ............................................................... 9

Components.............................................................................................. 9

Additional Safety Instructions ........................................................................ 10

Operating Method.......................................................................................... 12

Connection.............................................................................................. 12

Operation - Electric Tool.......................................................................... 13

Operation - Pneumatic Tools................................................................... 13

Adjusting Handrail Height........................................................................ 14

Connecting the Alpha®Ecoguards .......................................................... 14

Connecting to Palm Sanders, Gear Action Sanders

and Sanding Blocks ................................................................................ 15

Setting up the Vacuum for Wet Use ........................................................ 16

Automatic Suction Shut Off ........................................................................... 17

Emptying Liquid from the Tank ...................................................................... 17

Maintenance.................................................................................................. 18

Attaching the Storage Basket........................................................................ 19

Alpha®HEPA Wet/Dry Vacuum Schematic (Inside)....................................... 21

Alpha®HEPA Wet/Dry Vacuum Schematic (Outside).................................... 22

Alpha®HEPA Wet/Dry Vacuum Parts List...................................................... 23

Accessories and Factory Service .................................................................. 26

Warranty ........................................................................................................ 26

Product Registration...................................................................................... 27