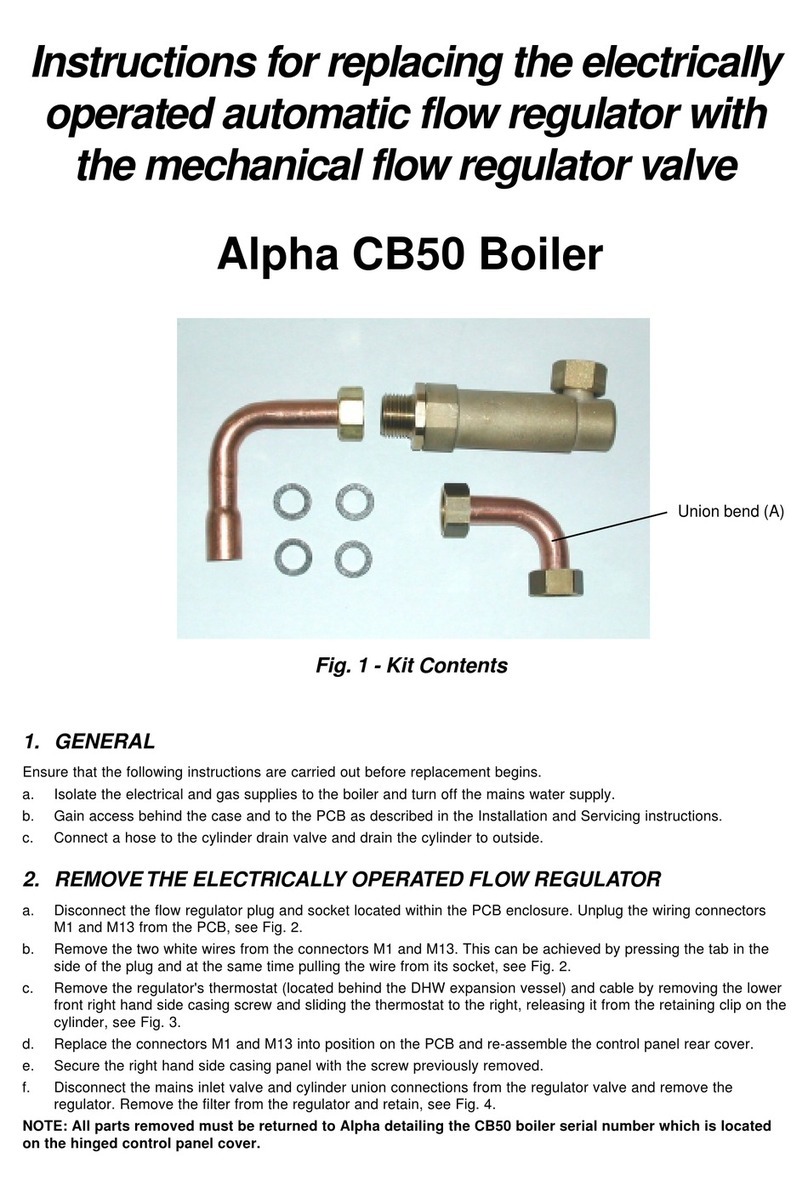

INSTALLATIONUSERMAINTENANCE

3 Alpha Intec 50CS

CONTENTS

1.1 INTRODUCTION.

e Alpha InTec 50CS is a oor standing, high eciency, condensing, room-sealed combination boiler. e burner is lit electronically and the heat

output is controlled by a modulating fan and gas valve.

is is a combination boiler (for domestic use only) providing both central heating and domestic hot water at mains pressure.

e boiler is supplied with a pump, pressure relief valve, expansion vessel and pressure gauge fully assembled and tested. It is designed for use with a

fully pumped, sealed and pressurised central heating system.

e boiler must be installed indoors in a frost free environment.

IMPORTANT

is boiler meets the requirements for Building Regulations for unvented hot water storage systems and the Local Authority must be notied of the

intention to install. erefore the installation must be carried out by a person competent to install unvented hot water systems.

It is the law that all gas appliances are installed by a competent person, i.e. Gas Safe registered personnel, in accordance with the following

recommendations:-

Current Gas Safety (Installation and Use) Regulations

All current Building Regulations issued by the Department of the Environment, i.e. Approved Document L1.

Building Standards (Scotland) (Consolidation) Regulations issued by the Scottish Development Department

UK Water Regulations/Byelaws (Scotland)

Health & Safety Document No. 635 (e Electricity At Work Regulations 1989)

e installation should also be in accordance with the following British Standard Codes of Practice:-

BS 5440:1 Flues

BS 5546: Installation of hot water supplies for domestic purposes

BS 6700: Design, installation, testing and maintenance of services supplying water

BS 6798: Installation of gas red hot water boilers

BS 6891: Gas installation

BS 7593: Code of Practice for treatment of water in heating systems

BS 7671: Requirements for electrical installations, IEE Wiring Regulations

BS EN 12828 Heating systems in Buildings. Design for water based heating systems

BS EN 12831 Heating systems in Buildings. Method of calculation for design heat load

BS EN 14336 Heating systems in Buildings. Installation and commissioning of water based heating systems

Reference should be made to DEFRA document 'Guide to condensing boiler installation assessment procedures for dwellings'.

If installation is in a timber framed building, refer to the Institute of Gas Engineers document IGE/UP/7.

is appliance meets the requirements of IPX4D, i.e. degree of protection against moisture.

is appliance contains no asbestos and no substances have been used in the construction process that contravene the COSHH Regulations (Control

of Substances Hazardous to Health).

Failure to install this appliance correctly could lead to prosecution. It is in your own interest and that of safety to ensure that the law is complied with.

Manufacturer's instructions must NOT be taken in anyway as over-riding statutory obligations.

Notes: 1. Ensure that the Benchmark Checklist has been completed aer the boiler has been installed and commissioned.

2. It is the law that all boiler installations are registered by the installer through the Gas Safe Gas Work Notication Scheme.

3. e boiler must only be used with Alpha CD condensing ue components.

NOTE: e boiler can be supplied ready for use with Propane (LPG).

e LPG boiler is also designed for use with a fully pumped, sealed and pressurised heating system.

In addition to the regulations and requirements stated in these installation and servicing instructions, LPG boilers must be installed in accordance

with BS 5482:1 - e Installation of Propane Burning Appliances in Permanent Dwellings.

Installation pipes, cylinders and pressure regulators for LPG boilers should be tted in accordance with BS5482:1. Bulk tank installations must comply

with the requirements of the Home Oce code of practice for the storage of liqueed petroleum gas at xed installations.

LPG boilers must not be installed in a room or internal space below ground level, e.g. in a basement or cellar, except where at least one side is open to

ground level.

LPG supply pipes must be capable of delivering the required quantity of gas in addition to the demand from any other appliances in the house. e

complete installation must be tested for gas soundness against leaks.

LPG boilers have been tested and factory set for use with Propane (LPG), it should only be necessary to ensure the correct gas supply pressure of 37 mbar is

available.

1 BOILER INSTALLATION

USER pageINSTALLATOR page MAINTENANCE page

1 Boiler installation.................................................3

1.1 Introduction. ........................................................3

1.2 Dimensions...........................................................4

1.3 Connections.........................................................................4

1.4 Remote controls and programmable room

thermostats (optional).........................................5

1.5 External temperature sensor (optional)............5

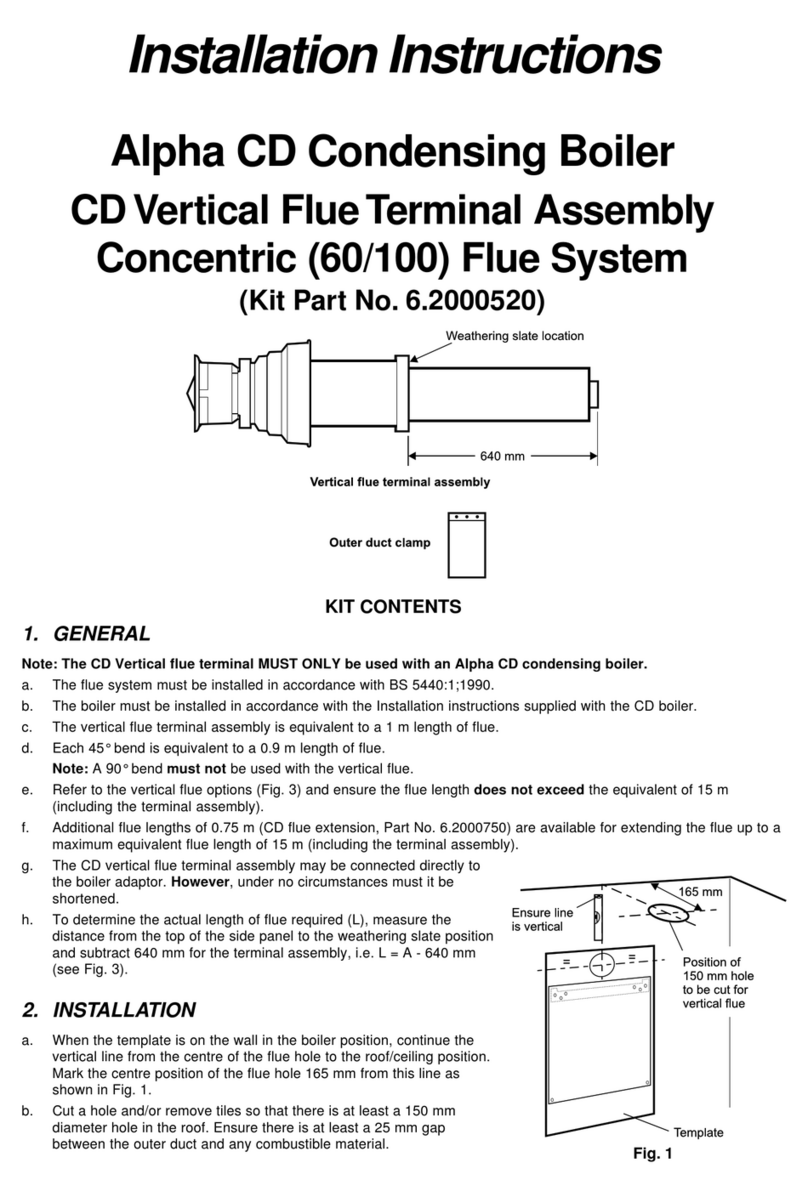

1.6 Fit the ue.............................................................6

1.7 Reduce the ue.....................................................7

1.8 Extend the ue .....................................................8

1.9 Plume management components (optional)....9

1.10 Vertical ue options...........................................11

1.11 Disposal of condensate......................................11

1.12 Flush the system. ...............................................12

1.13 Fill the system.....................................................12

1.14 Circulation pump...............................................13

1.15 Boiler components.............................................15

2 User and maintenance instructions.................16

2.1 Servicing. ............................................................16

2.2 General warnings...............................................16

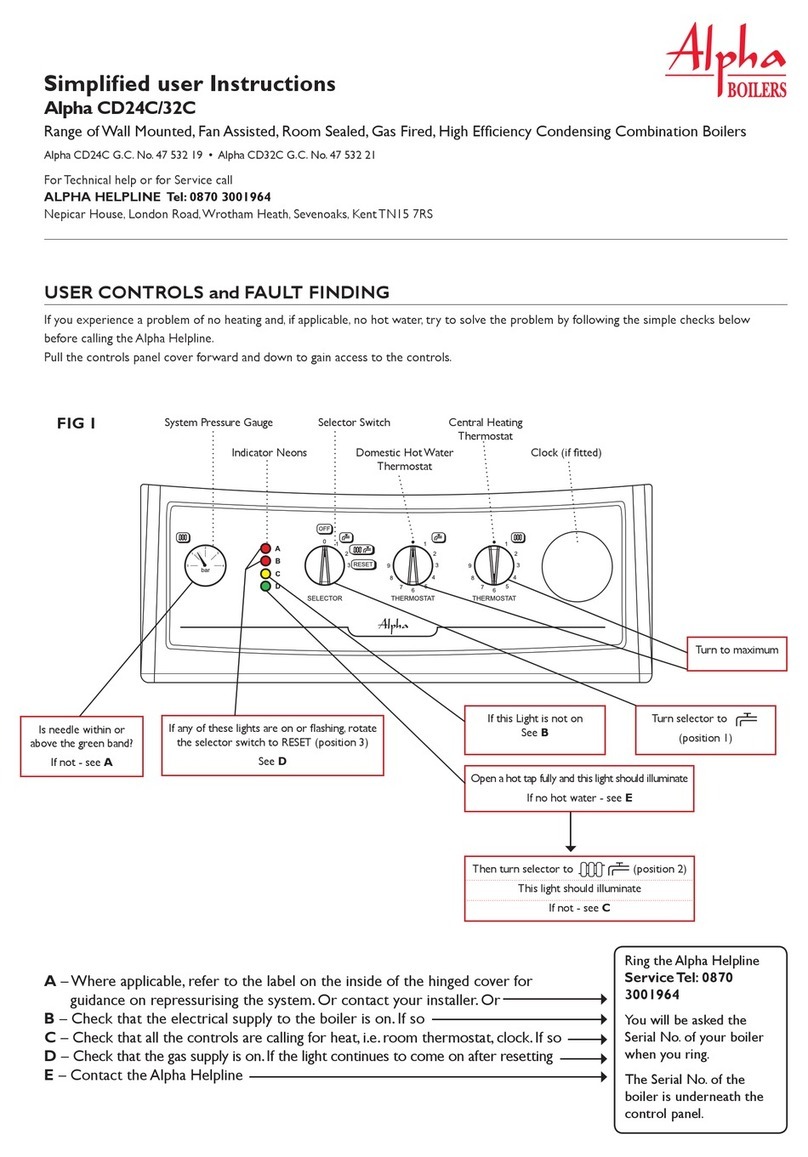

2.3 Control panel......................................................16

2.4 Operating modes. ..............................................17

2.5 Using the boiler. .................................................17

2.6 Fault signals. .......................................................18

2.7 Boiler shutdown.................................................19

2.8 Restore the system pressure..............................19

2.9 Drain the system................................................19

2.10 Drain the hot water system...............................19

2.11 Anti-freeze protection.......................................19

2.12 Case cleaning......................................................19

2.13 Decommissioning..............................................19

2.14 Parameters and information menu. ................20

3 Boiler start-up (initial check)...........................21

3.1 Hydraulic diagram.............................................21

3.2 Wiring diagram..................................................22

3.3 Troubleshooting.................................................22

3.4 “Chimney sweep function”................................22

3.5 Pump anti-seize function..................................23

3.6 ree-way anti-seize function..........................23

3.7 Radiator anti-freeze function...........................23

3.8 P.C.B. periodic self-check. ................................23

3.9 Automatic vent function...................................23

3.10 Yearly appliance check and maintenance. ......23

3.11 Casing removal...................................................24

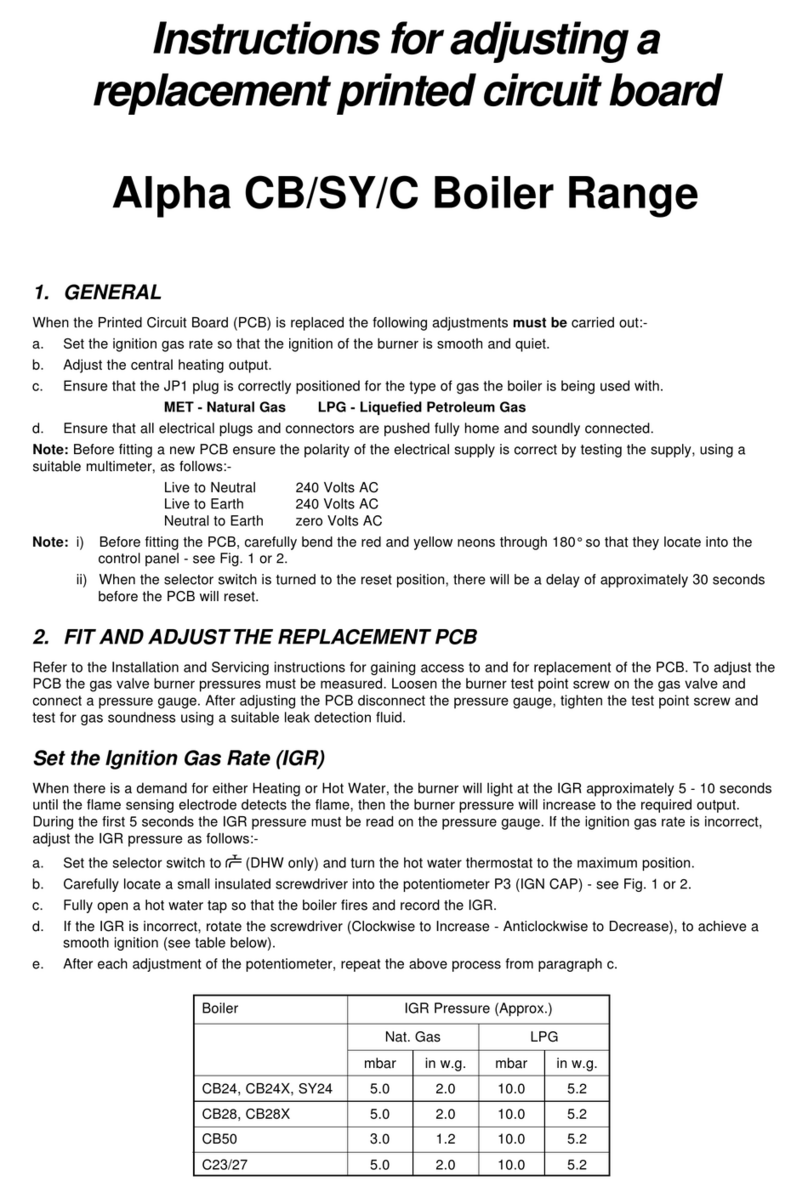

3.12 Combustion settings..........................................25

3.13 Technical data.....................................................26

3.14 Short parts list ....................................................27

Benchmark checklist .........................................28

Service record.....................................................29