Introduction:

A novel, manoeuvrable and marvelous Quad Flyer Spider 500X is now released from

ALWARE design ompany! Spider 500X was designed based on Sport Flying and with

Spider shape. Constru t with eight pie es(2 olors) of super bright LEDs, it is easier to

dis riminate different flying dire tions no matter in daylight or night time and makes the

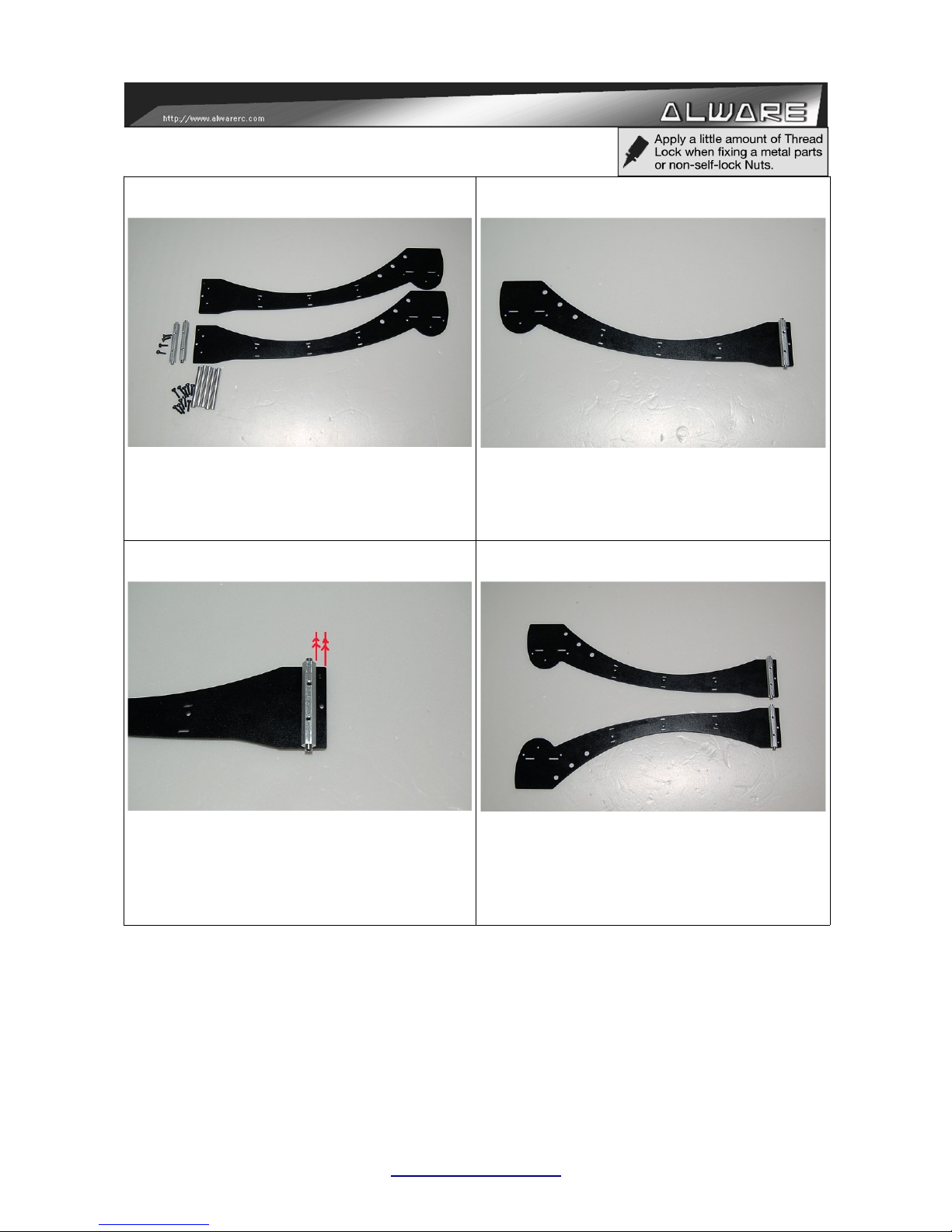

Spider 500X look supper brilliant! Furthermore, with a ollapsible body design, it is more

onvenient for storage and transportation. Unlike other lower level ollapsible design, ea h

arm of Spider 500X ould be folded onveniently without using any tools. Combined with a

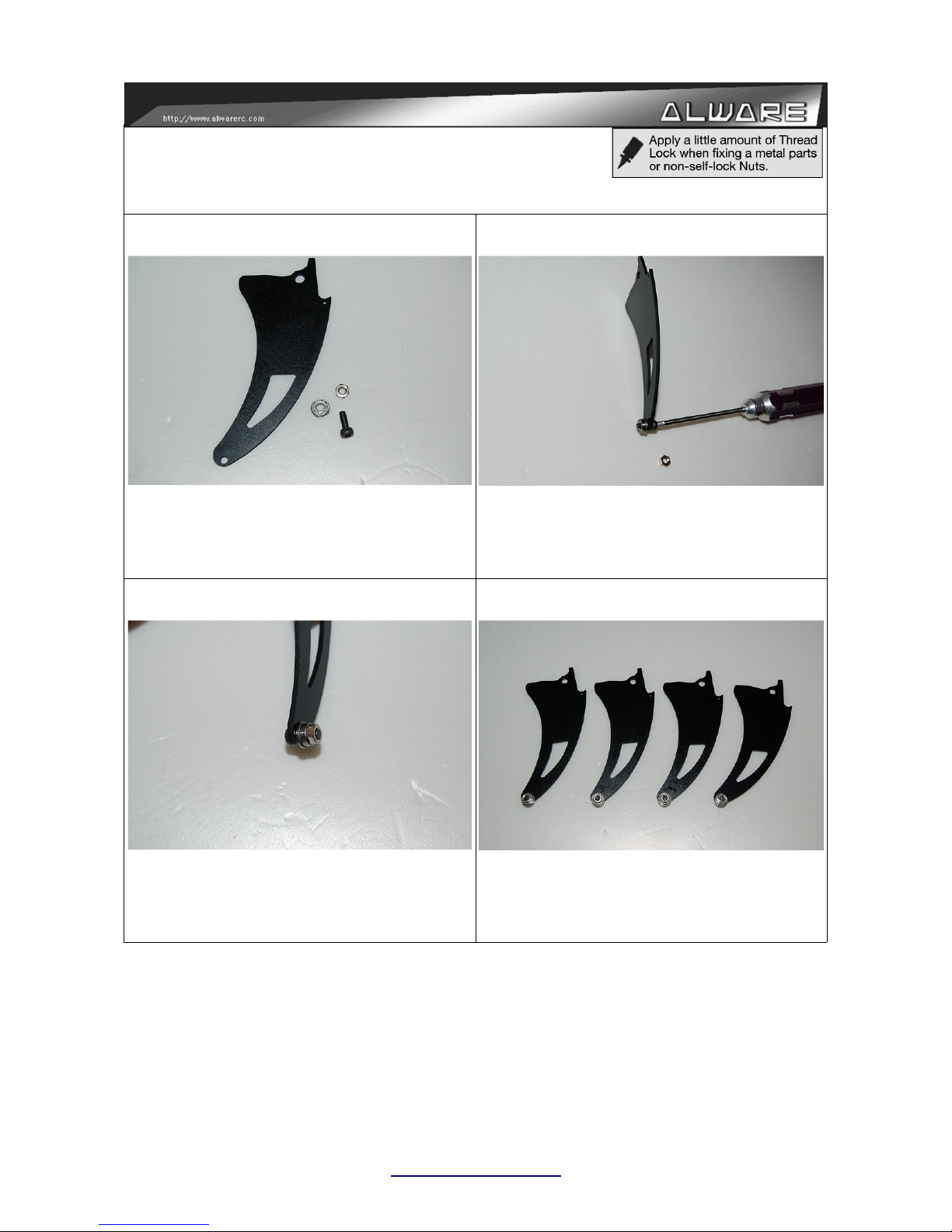

2-axises FPV amera mount and four individual spring damper landing gears, Spider 500X

obviously is an advan ed QuadFlyer in the market.

Features:

- Glass fiber sheets and Collapsible body design greatly redu e the damage rate on a

small rash, parts an be repaired easily.

- High manoeuvrability and stability modes an be set freely for Sport Flying or Aerial

Filming.

- Allow the usage with all original ele troni s from GAUI 330X su h as Gyro GU-344,

Motors and ESCs et . Upgraded motors an also be used as to in rease the flying power.

(10In h props are needed to use with original 330X motors.)

- High flight effi ien y with Standard Battery (3S 2000mAh) and 330X motors. 10min or

more flight time an be optained with 10in hes props.

- Ex ellent wind resistan e, the effi ien y and load of the propellers are perfe tly optimized

so a better wind resistan e will be a hieved.

- 2-axises FPV amera mount is in luded for aerial filming.

- Carry bag (is optional).

Specification:

Net Weight: 375g

Total Weight: 900g (with 2200mAh 3S Lipo battery)

Length: 500mm (between two Diagonal motors)

Flight time: 10mins (with GAUI S orpion 2208-1050kv motor, 10 In h Props & 2200mAh

3S Lipo)

www.alwarerc.com