Amadas RMH1000M User manual

Round Module Handler

Model RMH1000M

1st Edition, S/N 480000

January 2011

MAN119

©2011

Rev. 1

Round Module Handlers are manufactured

by AMADAS Industries.

You can find us on the web at:

www.amadas.com

or email us at:

Or contact us at:

P.O. Box 1833

Suffolk, VA 23439

(mailing)

1100 Holland Road

Suffolk, VA 23434

(shipping)

(757) 539-0231 (phone)

(757) 934-3264 (FAX)

P.O. Box 3687

Albany, GA 31701

(mailing)

1701 South Slappey Boulevard

Albany, GA 31706

(shipping)

(229) 439-2217 (phone)

(229) 439-9343 (FAX)

RMH1000M Introduction

MAN119 1/20/2011 i

Table of

Contents

Welcome...................................................iii

Specifications........................................ iv

Dimensions............................................v

1 Safety.....................................................1

Overview................................................2

Safety Symbols Used........................2

Protective Devices ............................2

Careful Lifting....................................2

Hydraulics .........................................2

Transporting the RMH............................3

Safety Symbols......................................4

Safety Alert Symbol...........................4

Safety Instructions.............................4

Notes.................................................4

Safety Guidelines...................................5

Safety Signs......................................5

Learn Your Machine..........................5

Machine Function..............................5

Safety Practices.....................................6

Operating the RMH...........................6

Servicing the RMH............................6

Safety Decals.........................................7

2 Preparation..........................................11

Post Delivery Inspection ......................12

Assembly.........................................12

Hydraulic System.................................13

Purge the Fork Cylinders ................14

Purge the Lift Cylinders...................15

Purge the Tilting Cylinders..............16

Install the Lift Mast (Optional)..............17

3 Operation.............................................19

Before Beginning .................................20

Tractor Hitch ........................................20

Attaching the Tractor.......................20

Lower Hitch Points..........................21

Top Hitch Point................................22

Introduction RMH1000M

ii 1/20/2011 MAN119

3 Operation (continued)

Support Feet....................................23

Transporting the RMH..........................24

Fork Operation .....................................25

Fork Balance ...................................25

Optional Shock Absorber.................25

Operating the Side Shift Cylinders ..26

Fork Positions ......................................28

4 Maintenance........................................29

Before Performing Maintenance..........30

Regular Maintenance......................30

Parts................................................31

Lubrication.......................................32

Beginning of Season............................34

End of Season .....................................34

Warranty..................................................35

RMH1000M Introduction

MAN119 1/20/2011 iii

Welcome

to

AMADAS

Industries

With origins dating back to 1963, AMADAS

Industries and its predecessors have a long

history of providing high-quality, reliable,

and innovative equipment for the farming

industry. AMADAS equipment is currently

at work throughout the United States and in

many other countries. This equipment

ranges from the Magnum Fource Peanut

Combine, Tree Bark Processing and

Packaging Machinery, Hi-Speed Cotton

Stalk Puller/Chopper, Reel Rain Traveler

Irrigation Systems, to the Round Module

Handler.

We are confident you will experience many

good years of service with your AMADAS

Round Module Handler. If any need should

arise, we pledge the best efforts of our

people and dealers to assist you.

One of the most important factors to both

safety and maximum performance is for

every machine operator to understand

thoroughly the safe operation of this

equipment. Please invest the time to read

this manual to ensure that injuries are

prevented and to receive the maximum

productivity from your AMADAS machine.

Thank you for choosing AMADAS

Industries. We are strongly committed to

your satisfaction and safety. Our goal is for

you to be satisfied with our machinery for

many years and it is our hope that you will

choose AMADAS again for your equipment

needs.

Introduction RMH1000M

iv 1/20/2011 MAN119

RMH1000M

Congratulations on your purchase of a

Round Material Handler! We’re proud of

our handlers and the design and

workmanship that go into every AMADAS

machine.

The AMADAS RMH1000M is the heavy-

duty solution to moving and loading round

cotton modules. The RMH1000M has been

built specifically to be compatible with the

John Deere 7760 Cotton Picker modules.

With its rugged yet simple construction, the

RMH1000M should provide years of trouble-

free service.

Benefits

The Round Module Handler offers the

following benefits:

Heavy Duty Tubular Construction

Our module mover is made of square

tubing, assuring ample strength to

handle the largest modules with ease

while keeping the weight of the RMH to

a minimum.

Unique Hydraulic Side-Shift

(Optional)

Our machine combines balanced close

of fork movement with side shift in one

unique valve assembly, eliminating the

need for a secondary hydraulic outlet

and insuring proper module alignment

during loading or truck staging.

66” Loading Height*

The AMADAS RMH1000M raises

modules up to 66” for easy loading on

flat beds and trailers.

*Lift height is also dependent on tractor

tire size and 3-point hitch link settings.

Loading Lights

As night work is normal during cotton

harvest, the RMH1000M comes

standard with adjustable work lights to

make night work safer and more

convenient.

Models

AMADAS Round Module Handling

equipment is available in the following

configurations:

RMH1000M – the Round Module Handler

plus the Lift Mast for the most complete

tractor-mounted round module moving

system available.

RMH1000 – the Basic Round Module

Handler for bale staging and infield moving

with 18” of ground clearance.

RMH1010 – the Module Mast, which can be

purchased and bolted onto the RMH1000 to

achieve full lift height and loading potential.

Note that all photos in this manual are of the

RMH1000M with the RM1010 attached.

RMH1000M Introduction

MAN119 1/20/2011 v

Specifications

Lifting capacity 6500 lbs

Height Base Only 69” (91” to lights)

Height with Mast 100”

Width Base Only (forks closed) 64”

Width with Mast (forks closed) 91”

Width Base Only (forks open) 114”

Width with Mast (forks open) 114”

Length Base Only 129”

Length with Mast 136”

Shipping Weight Base RMH1000 2750 lbs

Shipping Weight Mast RMH1010 2100 lbs

Shipping Weight RMH1000M 4850 lbs

Lift Height Base Only 24”

Lift Height with Mast 66”

Lift cylinders 3.5” x 48”

Fork cylinders 3.5” x 26”

Tilt cylinders 3” x 10”

Hitch CAT III, IVN or IV

Lights 2 adjustable work lights

Introduction RMH1000M

vi 1/20/2011 MAN119

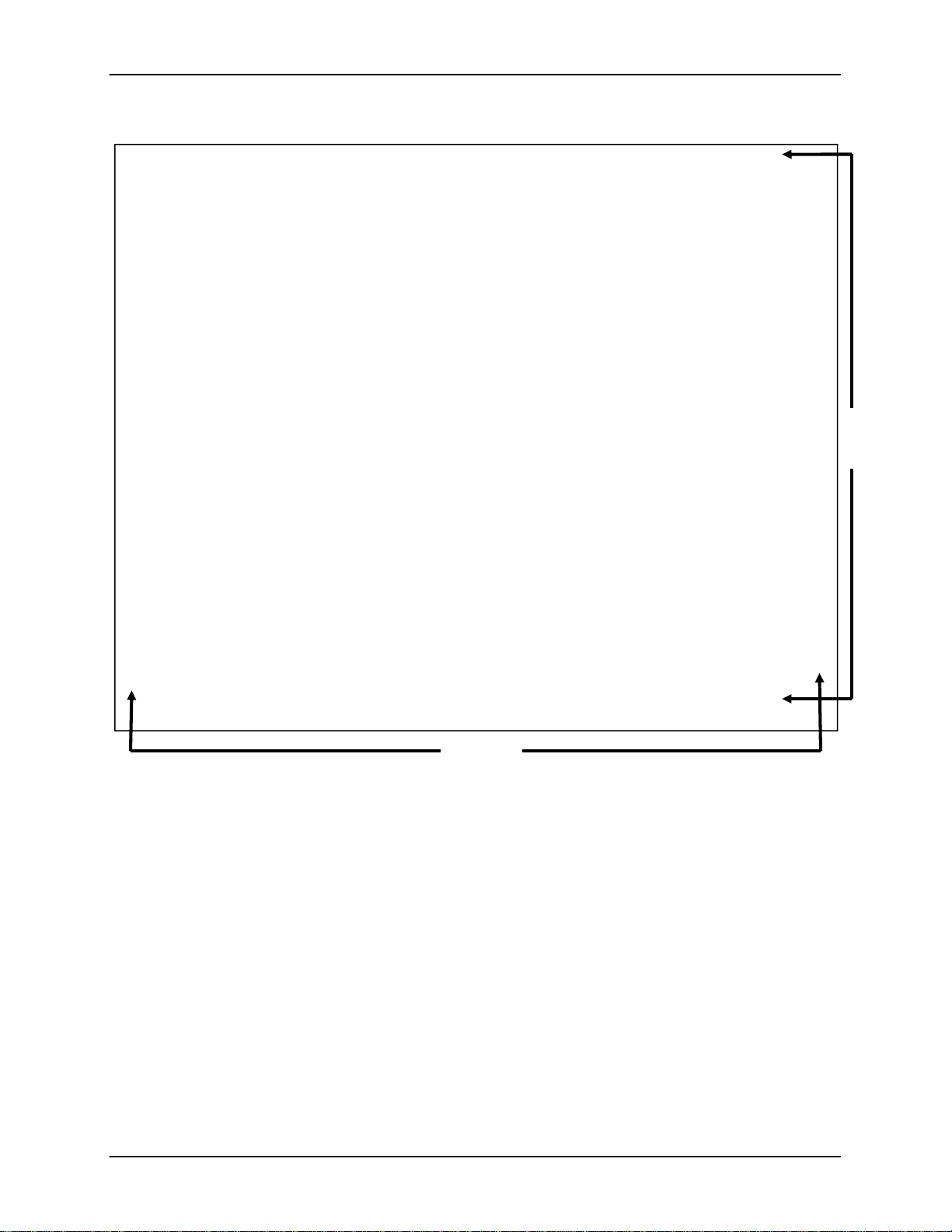

Dimensions

136”

100”

NOTE! Dimensions shown are of the RMH1000 with the RMH1010 module mast.

RMH1000M Introduction

MAN119 1/20/2011 vii

100”

90-114”

NOTE! Dimensions shown are of the RMH1000 with the RMH1010 module mast.

Introduction RMH1000M

viii 1/20/2011 MAN119

NOTES

Other manuals for RMH1000M

1

This manual suits for next models

1

Table of contents