1-1

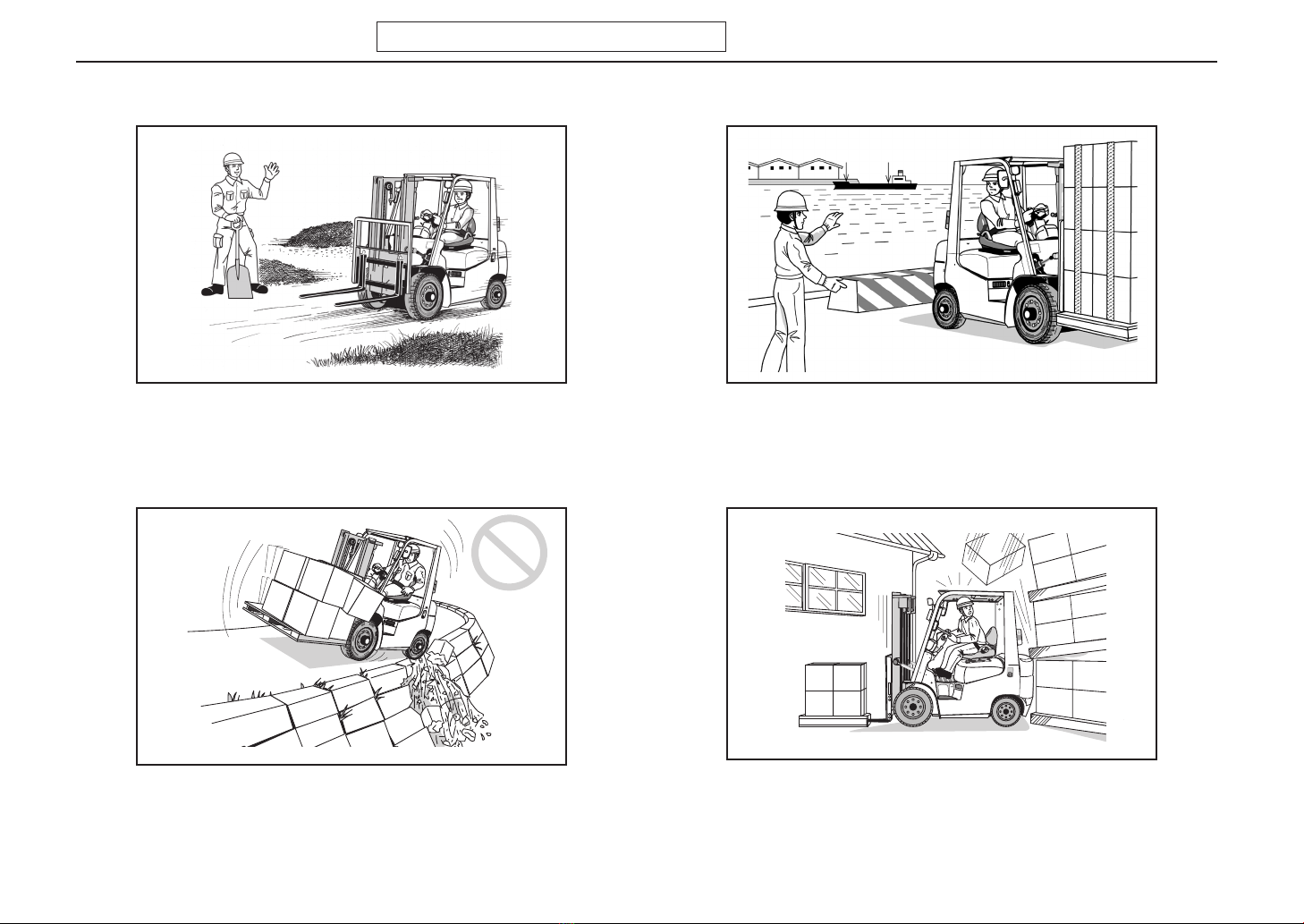

FOR SUPERVISORS

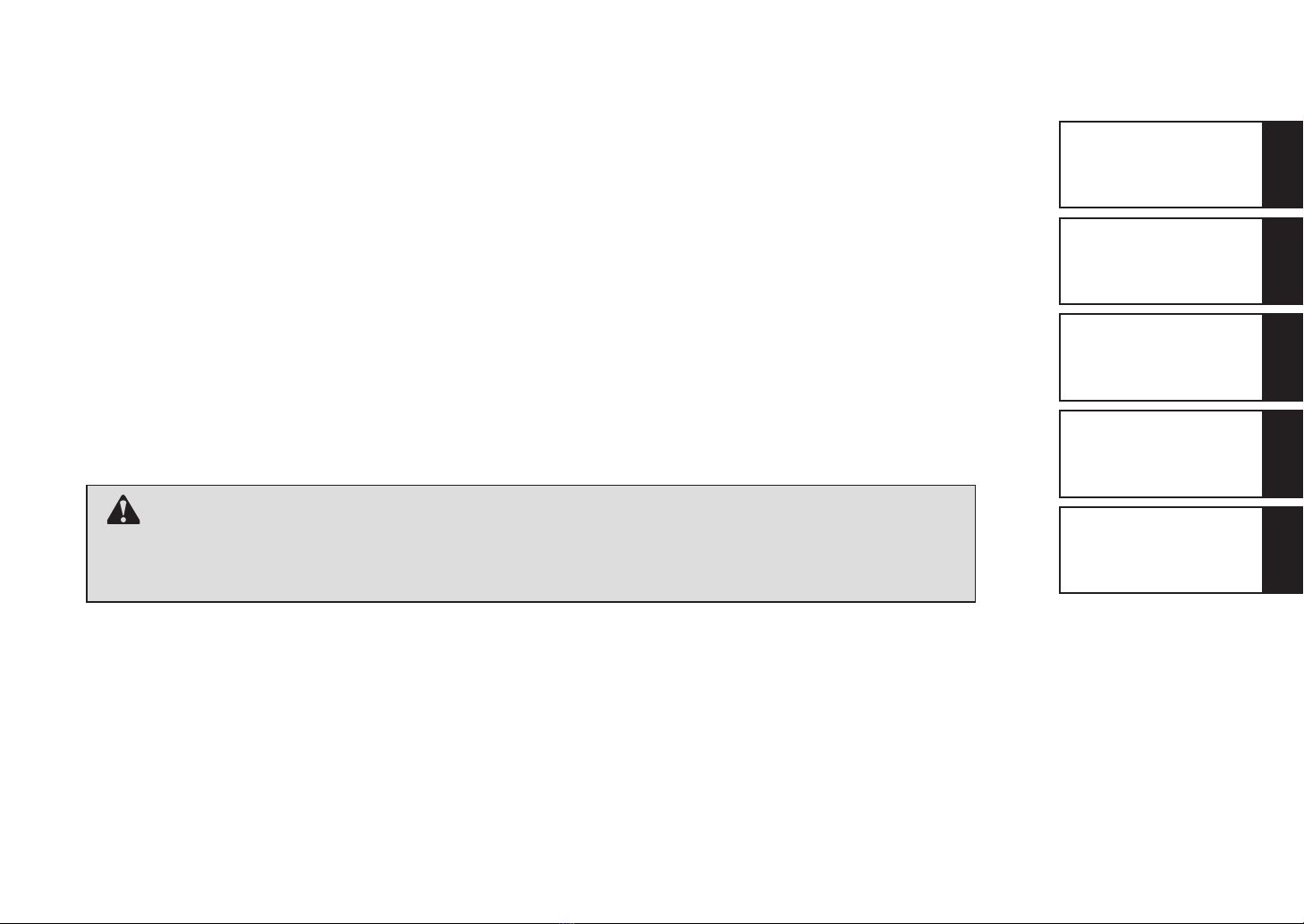

Lift truck accidents cause dozens or hundreds of deaths every

year, and even greater numbers of personal injuries.

UniCarriers has steadily improved the design and fabrication of

our lift trucks so they may be used more safely and efficiently,

but many accidents still occur due to improper use. Accidents

are often the result of more than just “bad driving”. The use of

inappropriate types of equipment, the selection of inappropriate

attachments or accessories, inappropriate operating environments,

careless designation of operators, and failure to properly train the

operator are other common causes of accidents.

It is not possible to describe all potentially hazardous situations

which may occur while operating, inspecting or servicing a

forklift truck. The warnings and cautions in this manual, including

the decals attached to the forklift, are not intended to cover all

possible working hazards.

If you operate, inspect or service the forklift in a manner not

described in this manual, please be careful because you do so at

your own risk.

This chapter covers the methods of accident prevention which are

primarily the responsibility of supervisory personnel.

•Pages 1-2 through 1-13 contain instructions which should be

enforced by the personnel supervising the operation of the lift

truck. Please make sure the operators also read these pages.

•Page 1-14 and the following pages contain specic precautions

directly related to the operation of the lift truck.

The following symbols, found throughout this manual, alert you to

potentially dangerous conditions to the owner and the operator.

Become completely familiar with the truck before proceeding with

operating, checking and servicing the truck.

This manual and the decals afxed to the truck use the following

safety alert indications.

SIGNAL WORD CLASSIFICATION

DANGER

Failure to follow the instructions in the

message will likely cause a serious accident or

death.

WARNING

Failure to follow the instructions in the

message might cause a serious accident or

death.

CAUTION

Failure to follow the instructions in the

message may cause personal injury or damage

to the truck or other property.

NOTE

The information will help to prolong the service

life of the truck. The message is not directly

related to accident prevention.

Right

Left

Forward Backward

The diagram above indicates the meanings of the terms “forward”,

“backward”, “right” and “left” used in this manual.