4

•Energy Management System Features

Temperature Setback - This option can save energy dol-

lars for unrented or unoccupied rooms by automatically

setting back the operational temperatures. This mode of

operation is selected through the configuration routine

(see Configuration Settings section). NOTE: Temperature

setback does not work with a wired remote thermostat.

Door Switch and Motion Sensor Low VoltageTerminals (DS1,

DS2, MS1, MS2) - The door switch and motion sensor oper-

ate as a unit, the door switch terminals allows for wired

connection of a door sensor to the control board. The

motion sensor interprets any door movement as a signal

of occupancy. If the switch between DS1 and DS2 is closed,

the door control will interpret the room door as closed. If

the switch between MS1 and MS2 terminals is opened (or

closed if unit is configured for normally open) the control

will interpret the action as a signal of occupancy. If thirty

minutes pass without any door activity, Energy Manage-

ment Temperature setback activates.

Serial Port Interfaces - Two serial ports located on the

control board provide easy access for two-way communi-

cations to the control board from an optional RF antennae

can be attached for wireless communications.

TRANSPORTATION DAMAGE

All units are securely packed in shipping containers tested

according to International Safe Transit Association specifica-

tions. The carton must be checked upon arrival for external

damage. If damage is found, a written request for inspection

by the carrier’s agent must be made immediately.

In the event of damage, the consignee must:

1. Make notation on delivery receipt of any visible damage to

shipment or container.

2. Notify carrier promptly and request an inspection.

3. In case of concealed damage, carrier should be notified as

soon as possible—preferably within 5 days.

4. File the claim with the following supporting documents

within the 6 month statute of limitations.

a. Original Bill of Lading, certified copy, or indemnity

bond.

b. Original paid freight bill or indemnity in lieu thereof.

c. Original invoice or certified copy thereof, showing

trade and other discounts or reductions.

d. Copy of the inspection report issued by carrier’s

representative at the time damage is reported to the

carrier.

The carrier is responsible for making prompt inspection of

damage and for a thorough investigation of each claim. The

distributor or manufacturer will not accept claims from dealers

for transportation damage.

UNIT ACCESSORIES

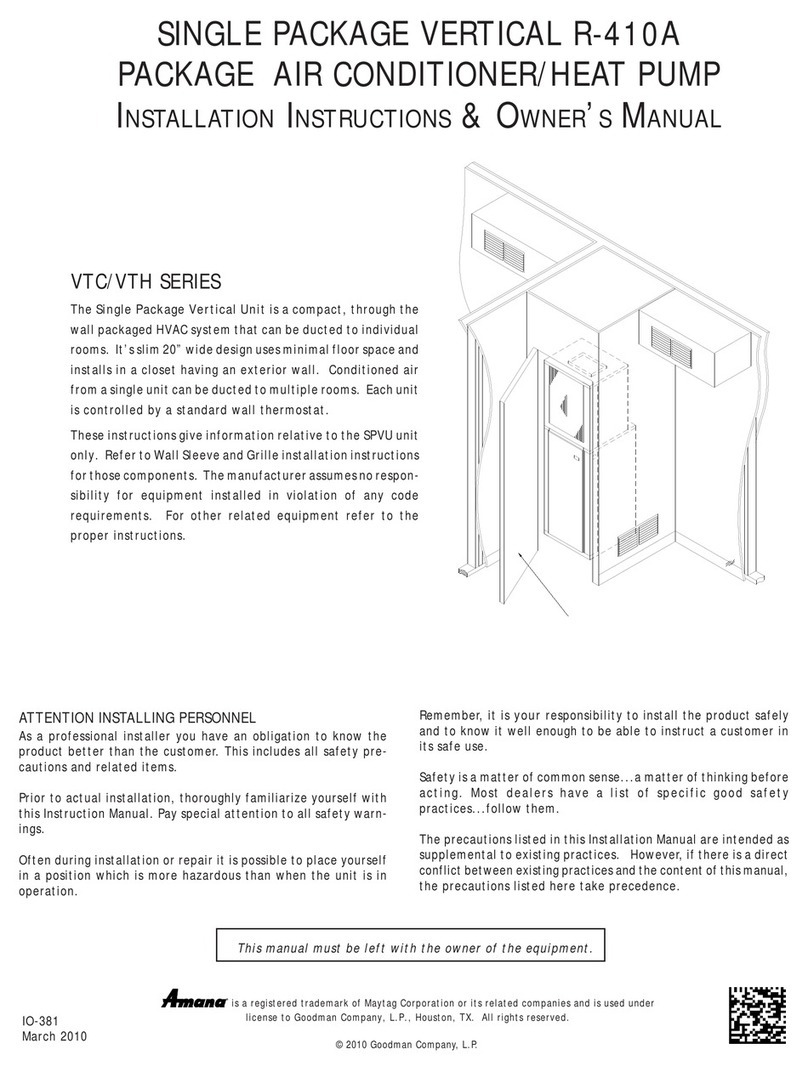

This unit is designed for through-the-wall installation in new or

existing buildings. To complete the installation of this PTAC, an

insulated wall sleeve and an outdoor grille (either the stamped

aluminum grille, the architectural grille or polymer grille) are

required.

The chassis and the cabinet front are shipped in one carton.

Optional accessories to complete a particular installation are

the following:

OPTIONAL ACCESSORIES

Power Switch Kit Wire Harness Kit

Wall Sleeve Kit Circuit Breaker Kit

Key Lock Kit Architectural Grille Kit

Drain Kit Remote Escutcheon Kit

Filter Kit External Transformer Kit

Subbase Kit Water or Steam Valve Kit

Hard Wire Kit Condensate Disposal Pump Kit

Main Duct Kit Remote Temperature Sensor Kit

Power Vent Kit Wireless RF Antenna

Leveling Legs Kit Wireless RF Thermostat

Hydronic Heat Kit Wireless Motion Sensor

Stamped Grille Kit Wireless Door Switch

Curtain Guard Kit Wired Motion Sensor

Polymer Grille Kit Wired Door Switch

Extension Duct Kit Extra Deep Sleeves

Wall Thermostat Kit

Fuse Holder Kit

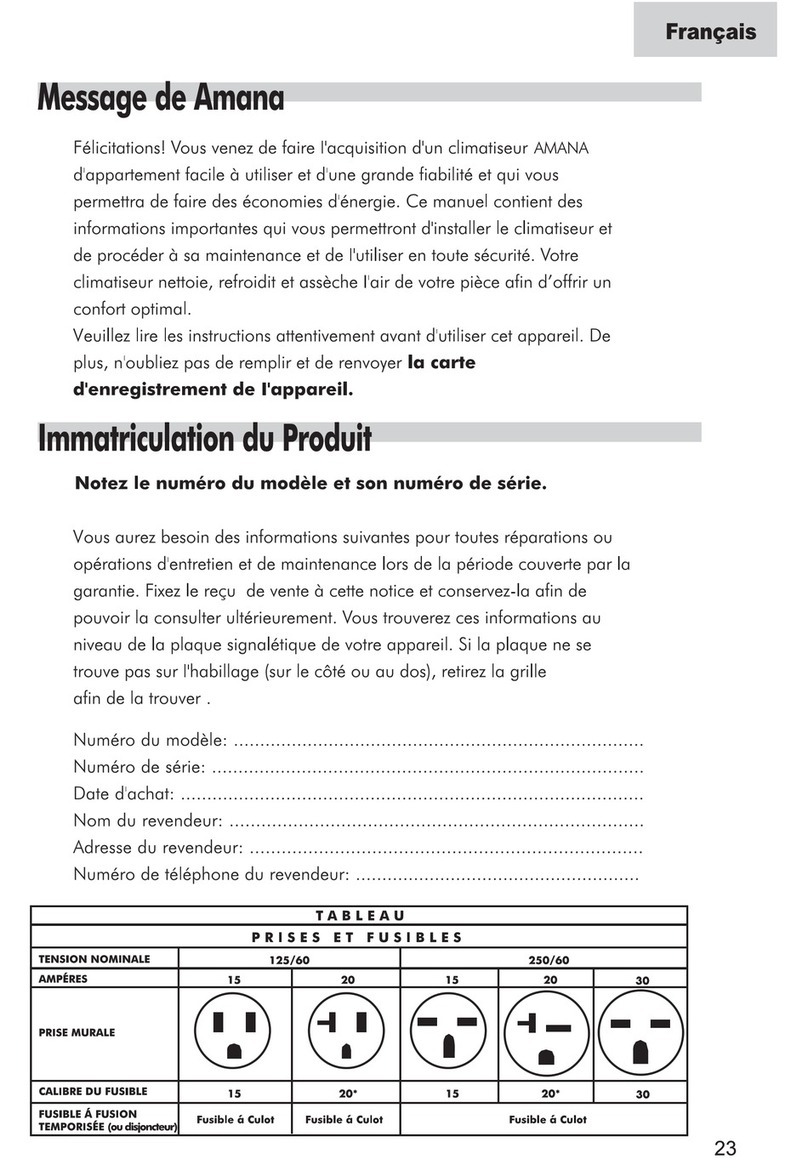

NOTE: Consult sales literature for the appropriate voltage and

amperage selections, if applicable. For additional details and

illustrations of the accessories, refer to the Architect’s and

Engineer’s Manual.