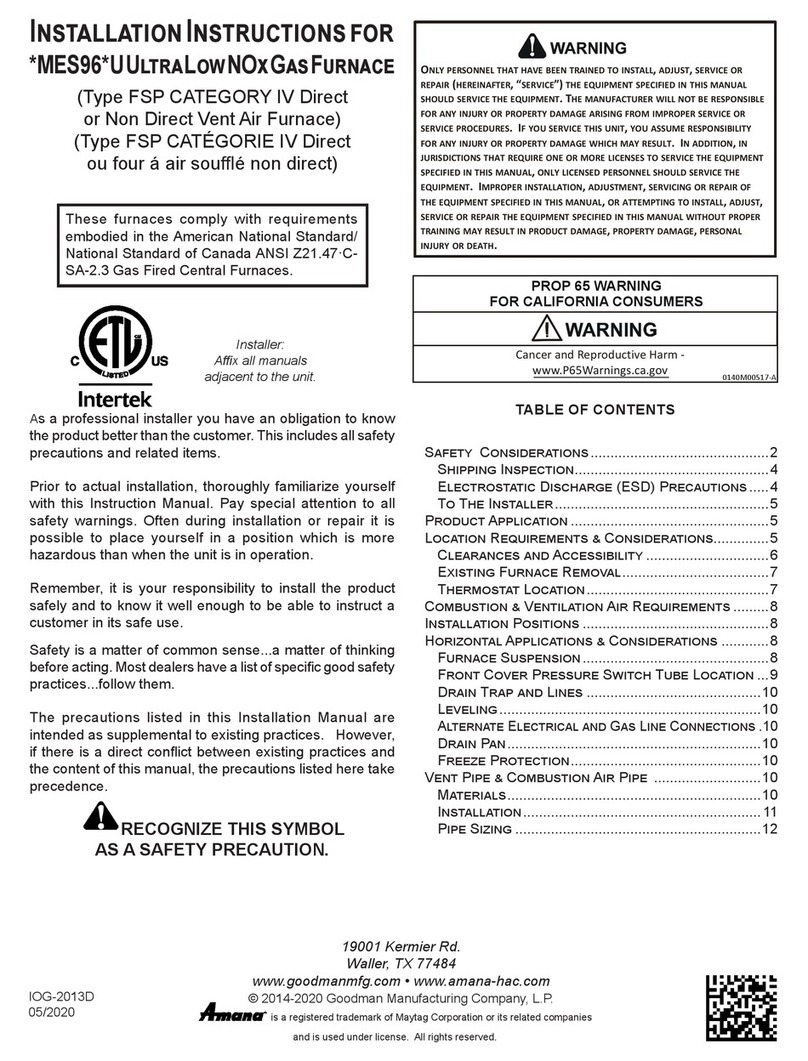

CHIMNEY

or

GAS

VENT

Note:

Each

air

duct

opening

shall

have

a

free

area

of

not

less

than

one

square

inch

per

2,000

Btu

per

hour

of

the

total

input

rating

of

all

equip-

ment

in

the

en-

closure.'

'If

the

appliance

room

is

located

against

an

outside

wall

and

the

air

openings

communicate

directly

with

the

outdoors,

each

opening

shall

have

a

free

area

of

not

less

than

one

square

inch

per

4,000

Btv

per

hour

of

the

total

input

rating

of

all

appliances

in

the

enclosure.

Fig.

4.

Equipment

Located

in

Confined

Spaces;

All

Air

from

Outdoors.

See

5.3.3-b.

5.3.4

Specially

engineered

Installations:

The

requirements

of

5.3.3

shall

not

necessarily

govern

when

special

engineering,

approved

by

the

authority

having

juris-

diction,

provides

an

adequate

supply

of

air

for

combustion,

ventilation,

and

dilution

of

flue

gases.

5.3.5

Louvers

and

Grilles:

In

calculating

free

area

in

5.3.3,

consideration

shall

be

given

to

the

blocking

effect

of

louvers,

grilles

or

screens

protecting

openings.

Screens

used

shall

not

be

smaller

than

1

/

4

inch

mesh.

If

the

area

through

a

design

of

louver

or

grille

is

known,

it

should

be

used

in

calculating

the

size

of

opening

required

to

provide

the

free

area

specified.

If

the

design

and

free

area

is

not

known,

it

may

be

assumed

that

wood

louvers

will

have

20-25

percent

free

area

and

metal

louvers

and

grilles

will

have

60-75

percent

free

area.

Louvers

and

grilles

shall

be

fixed

in

the

open

position

or

interlocked

with

the

equipment

so

that

they

are

opened

automatically

during

equipment

operation.

5.3.6

Special

Conditions

Created

by

Mechanical

Exhaust-

ing

or

Fireplaces:

Operation

of

exhaust

fans,

ventilation

systems,

clothes

dry-

ers,

or

fireplaces

may

create

conditions

requiring

special

attention

to

avoid

unsatisfactory

operation

of

installed

gas

uti-

lization

equipment.

VENTING

For

information

on

venting,

please

ual

shipped

with

the

furnace.

®

WARNING

consult

the

venting

man

-

This

furnace

is

not

recommended

for

common

venting

application

with

other

induced

draft

appliances.

Failure

to

fol-

low

these

instructions

can

result

in

bodily

injury

or

death

from

asphyxiation.

Therefore,

carefully

read

and

follow

all

instructions

given

in

this

section

and

the

venting

manual

instructions

shipped

with

the

furnace.

WHEN

AN

EXISTING

FURNACE

IS

REMOVED

FROM,A

VENTING

SYSTEM

SERVING

OTHER

APPLIANCES,

the

venting

system

may

be

too

large

to

properly

vent

the

remain-

ing

attached

appliances.

The

following

steps

shall

be

followed

with

each

appliance

remaining

connected

to

the

common venting

system

placed

in

operation,

while

the

other

appliances

remaining

connected

to

the

common

venting

system

are

not

in

operation.

(a)

Seal

any

unused

openings

in

the

common

venting

system.

(b)

Visually

inspect

the

venting

system

for

proper

size

and

horizontal

pitch

and

determine

there

is

no

blockage

or

restriction,

leakage,

corrosion

and

other

deficiencies

which

could

cause

an

unsafe

condition.

(c)

Insofar

as

is

practical,

close

all

building

doors

and

win-

dows

and

all

doors

between

the

space

in

which

the

appliances

remaining

connected

to

the

common

venting

system

are

located

and

other

spaces

of

the

building.

Turn

on

clothes

dryers

and

any

appliance

not

connected

to

the

common

venting

system.

Turn

on

any

exhaust

fans,

such

as

range

hoods

and

bathroom

exhausts,

so

they

will

oper-

ate

at

maximum

speed.

Do

not

operate

a

summer

exhaust

fan.

Close

fireplace

dampers.

(d)

Follow

the

lighting

instructions.

Place

the

appliance

being

inspected

in

operation.

Adjust thermostat

so

appliance

will

operate

continuously.

(e)

Test

for

spillage

at

the

draft

hood

relief

opening

after

5

minutes

of

main

burner

operation.

Use

the

flame

of

a

match

or

candle,

or

smoke

from

a

cigarette,

cigar,

or

pipe.

(f)

After

it

has

been

determined

that

each

appliance

remain-

ing

connected

to

the

common

venting

system

properly

vents

when

tested

as

outlined

above,

return

doors,

win-

dows,

exhaust

fans,

fireplace

dampers

and

any

other

gas

-

burning

appliance

to

their

previous

conditions

of

use.

(g)

If

improper

venting

is

observed

during

any

of

the

above

tests,

the

common

venting

system

must

be

corrected

in

accordance

with

the

latest

edition

of

the

National

Fuel

Gas

Code,

ANSI

Z223.1.

If

resizing

any

portion

of

the

common venting

system,

use

the

appropriate

table

in

Appendix

G

in

the

latest

edition

of

the

National

Fuel

Gas

Code,

ANSI

Z223.1.

Also

consult

the

vent-

ing

manual

shipped

with

the

furnace.

DUCTWORK

—AIR

FLOW

Duct

systems

and

register

sizes

must

be

properly

designed

for

the

C.F.M.

and

external

static

pressure

rating

of

the

furnace.

Ductwork

should

be

designed

in

accordance

with

the

recom-

mended

methods

of

"Air

Conditioning

Contractors

of

America"

manual.

A

duct

system

should

be

installed

in

accordance

with

Standards

of

the

National

Board

of

Fire

Underwriters

for

the

Installation

of

Air

Conditioning,

Warm

Air

Heating

and

Ventilating

Systems,

Pamphlets

No.

90A

and

90B.

Furnace

models

GU1045B25B,

GU1070B30B, GU1090B30B,

GU1115B35B

and

GUI140B35B

are

shipped

with

one

filter,

(refer

to

Pg.

2

for

size),

intended

for

the

return

air

duct

to

be

attached

to

either

side

of

the

furnace

cabinet.

If

the

return

air

duct

is

to

be

attached

to

the

bottom

of

the

furnace

cabinet,

the

filter

that

was

supplied

with

the

furnace, may

not

be

of

the

proper

size.

Refer

to

the

chart

below

for

filter

sizes

when

using

bottom

return.

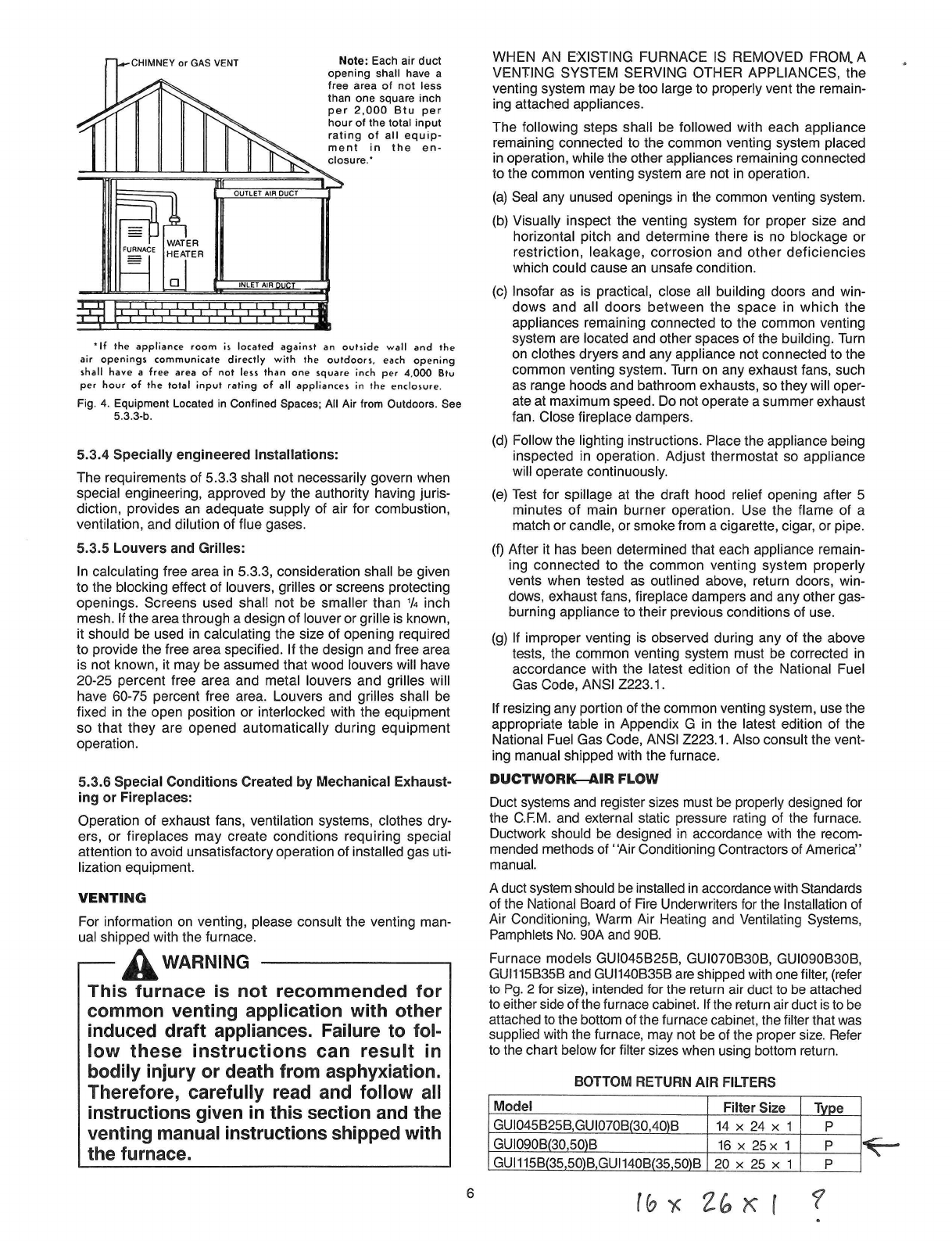

BOTTOM

RETURN

AIR

FILTERS

_Model

Filter

Size

Type

GU1045B25B,GU1070B(30,40)B

14

x

24

x

1

P

GU1090B(30,50)B

_

16

x

25x

1

P

GUI115B(35,50)B,GU1140B(35,50)B

20

x

25

x

1

P

6