3

!

WARNING

To reduce the risk of fire, electric shock, serious injury

ordeath to persons whenusing your washer,follow

these basic precautions:

1. Readall instructions before usingthe washer.

2. Referto the Grounding Instructionsin the Installa-

tionManualforthe proper grounding of thewasher.

3. Donotwash articles that havebeen previously

cleaned in, washed in, soaked in, or spotted with

gasoline,dry-cleaningsolvents,or other flammable

orexplosivesubstancesas they give off vapors

that could ignite or explode.

4. Donot add gasoline, dry-cleaningsolvents, or

otherflammable or explosive substancesto the

washwater. These substances give offvapors that

couldignite or explode.

5. Undercertain conditions, hydrogengas may be

produced in a hot water system that has not been

used for two weeks or more. Hydrogen gas is

explosive. If the hot water system has not been

usedfor such a period,before using awashing

machineorcombination washer-dryer, turnon all

hotwater faucets andlet the water flow fromeach

forseveral minutes. This willrelease any accumu-

lated hydrogen gas. The gas is flammable, do not

smoke or use an open flame during this time.

6. Do not allow children to play on or in the washer.

Closesupervisionof children is necessarywhen

the washer is used near children. This is a safety

rulefor all appliances.

7. Beforethewasherisremovedfromservice or

discarded,remove the door tothe washing com-

partment.

8. Do not reach into the washer if the wash tub is

moving.

9. Do not install or store the washer where it will be

exposedtowaterand/or weather.

10. Do not tamper with the controls.

11. Donot repair or replace anypart of the washer, or

attemptany servicing unless specifically recom-

mendedin the User-Maintenance instructionsor in

publisheduser-repairinstructions that you under-

stand and have the skills to carry out.

12. To reduce the risk of an electric shock or fire, do

not use an extension cord or an adapter to con-

nect the washer to the electrical power source.

13. Use yourwasher only forits intended purpose,

washingclothes.

14. Always disconnect the washer from electrical

supplybefore attempting any service.Disconnect

the power cord by grasping the plug, not the cord.

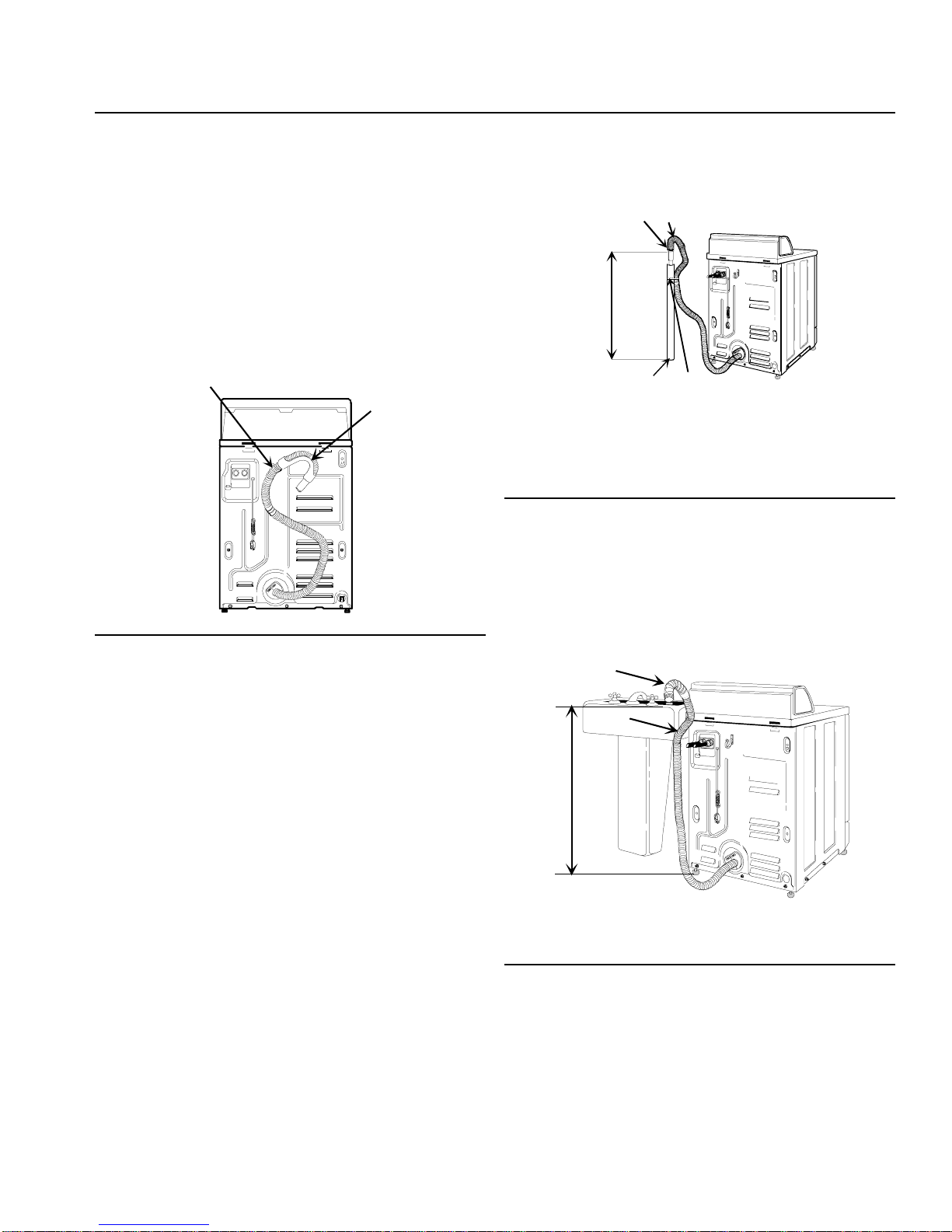

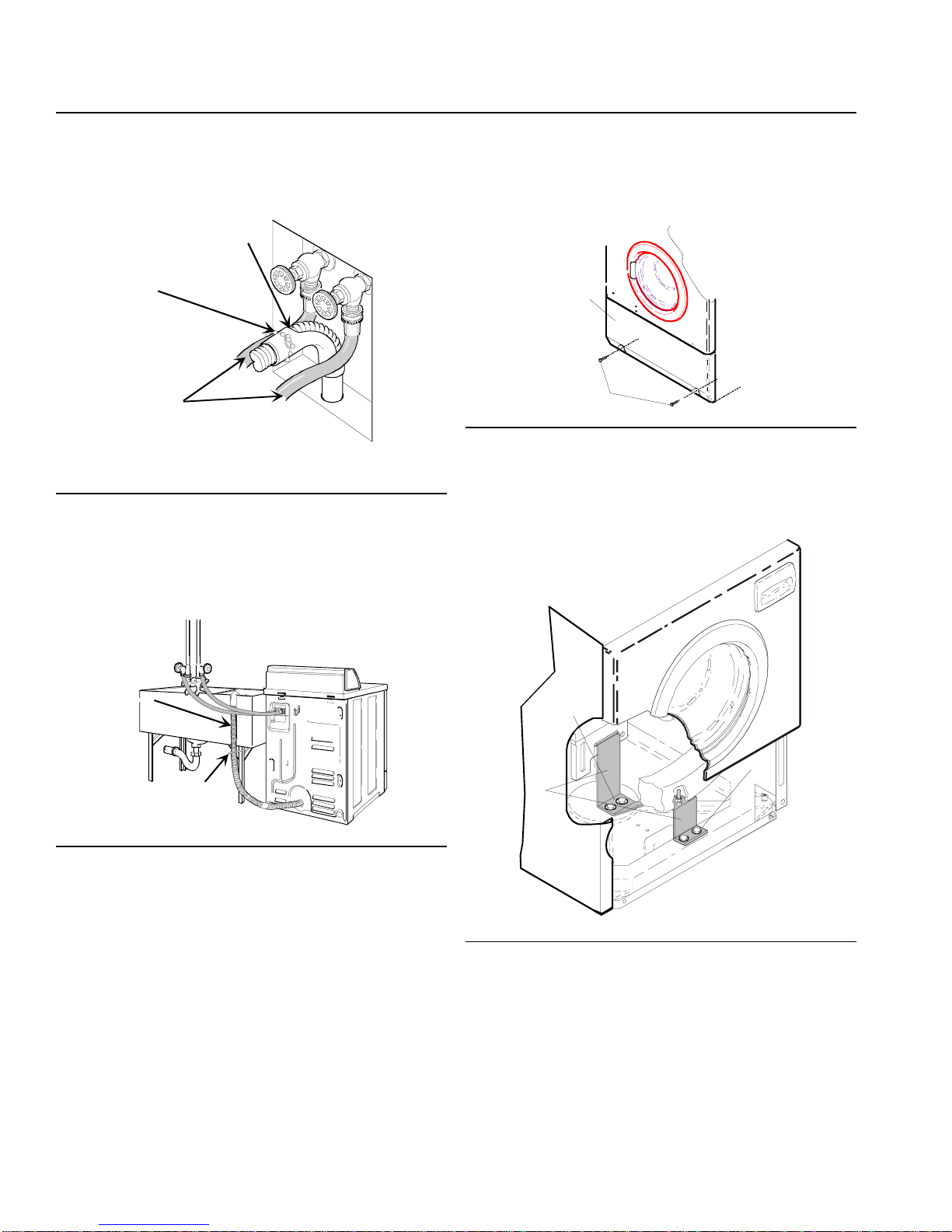

15. Install thewasher according tothe Installation

Instructions.All connections forwater, drain,

electricalpower and grounding mustcomply with

local codes and be made by licensed personnel

when required. Do not do it yourself unless you

knowhow!

16. Toreduce the riskof fire, clothes which have

traces of any flammable substances such as

vegetableoil, cooking oil, machineoil, flammable

chemicals, thinner, etc. or anything containing wax

or chemicals such as in mops and cleaning cloths,

must not be put into the washer. These flammable

substances may cause the fabric to catch on fire

by itself.

17. Do not use fabric softeners or products to elimi-

natestatic unlessrecommended bythe manufac-

turerof the fabric softeneror product.

18. Keep yourwasher in good condition.Bumping or

droppingthewasher can damage safetyfeatures.If

this occurs, have your washer checked by a

qualifiedserviceperson.

19. Replacewornpowercords and/or loose plugs.

20. Besurewaterconnectionshaveashut-offvalve

and that fill hose connections are tight. Close the

shut-offvalves atthe end of eachwash day.

21. Loading door must be closed any time the washer

is to fill, tumble or spin. Do not attempt to bypass

the loading door switch by permitting the washer to

operatewiththe loading door open.

22. Always readand follow manufacturer’s instructions

onpackages of laundryand cleaning aids. Heed all

warningsor precautions. To reduce therisk of

poisoning or chemical burns, keep them out of the

reach of children at all times (preferably in a locked

cabinet).

23. Always followthe fabric care instructions supplied

bythegarmentmanufacturer.

24. Neveroperatethewasher with any guards and/or

panelsremoved.

25. Do notoperate the washer with missingor broken

parts.

26. Do not bypass any safety devices.

27. Failure to install, maintain, and/or operate this

washeraccordingto the manufacturer’s instruc-

tions may result in conditions which can produce

bodilyinjuryand/or property damage.

Note:TheWarning and Important SafetyInstructions

appearingin this manualare not meant to coverall

possible conditions and situations that may occur.

Common sense, caution and care must be exercised

wheninstalling,maintaining, or operating thewasher.

Alwayscontact your dealer, distributor,service agent or

themanufacturer about any problemsor conditions you

donotunderstand.