GENERAL INFORMATION

Amana Compact Washer n

1-5

Using the Dispensers

Using the Dispensers

Add Laundry Products

If using liquid laundry detergent, single-dose laundry packets,

color-safe bleach, Oxi-type boosters, or fabric soener crystals,

add to the wash basket prior to adding laundry.

NOTE: Always follow manufacturer’s instrucons.

UsingYour Washer

4PSUBOEQSFQBSFZPVSMBVOESZ

■Empty pockets. Loose change, buttons, or any small

object can pass under the washplate and become

trapped, causing unexpected sounds.

■Sort items by recommended cycle, water temperature,

and colorfastness.

■Separate heavily soiled items from lightly soiled.

■Separate delicate items from sturdy fabrics.

■Do not dry items if stains remain after washing; heat

can set stains into fabric.

■Treat stains promptly.

■Close zippers, fasten hooks, tie strings and sashes.

Remove non-washable trim and ornaments.

■Mend rips and tears to avoid further damage to items

during washing.

Helpful Tips:

■For best performance, use HE liquid detergent when washing

bulky items.

■Use mesh bags to help avoid tangling when washing

delicate or small items.

■Turn knits inside out to avoid pilling. Separate lint-takers

from lint-givers. Synthetics, knits, and corduroy fabrics will

pick up lint from towels, rugs, and chenille fabrics.

/05& Always read and follow fabric care labels instructions

to avoid damage to your items.

"EEMBVOESZQSPEVDUT

IMPORTANT: If you are using the Compact Dryer Stack Stand

(Part Number 49971), pull the washer forward before lifting

the washer lid.

If you are using liquid laundry detergent, single-dose laundry

packets, color-safe bleach, Oxi-type boosters, or fabric softener

crystals, add to the wash basket prior to adding laundry.

NOTE: Always follow manufacturer’s instructions.

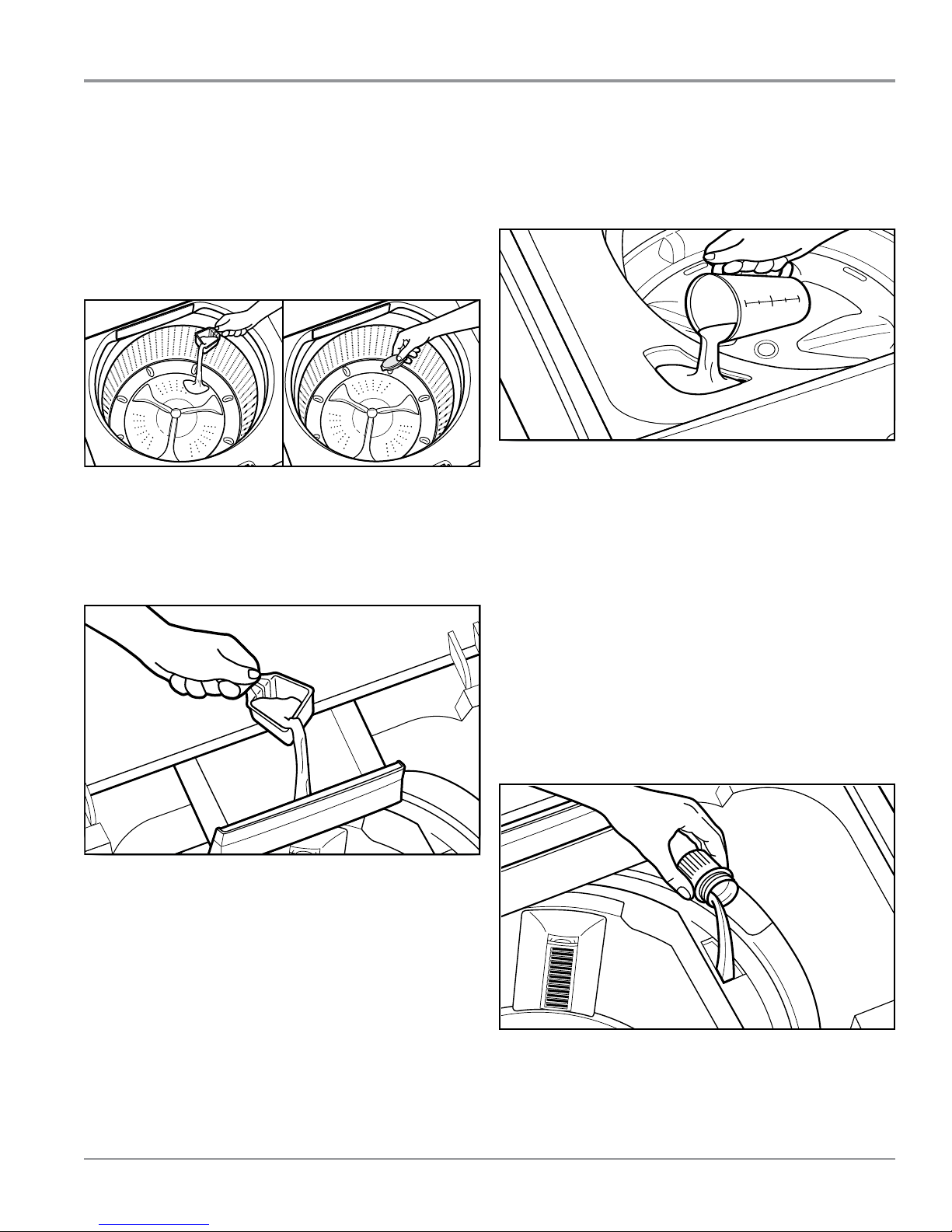

-PBEMBVOESZJOUPXBTIFS

Max

load

level

For best performance, load items

in loose heaps evenly around the

washplate. Try mixing different

sized items to reduce tangling.

*.1035"/5 Items need to move

freely for best cleaning and to reduce wrinkling and tangling.

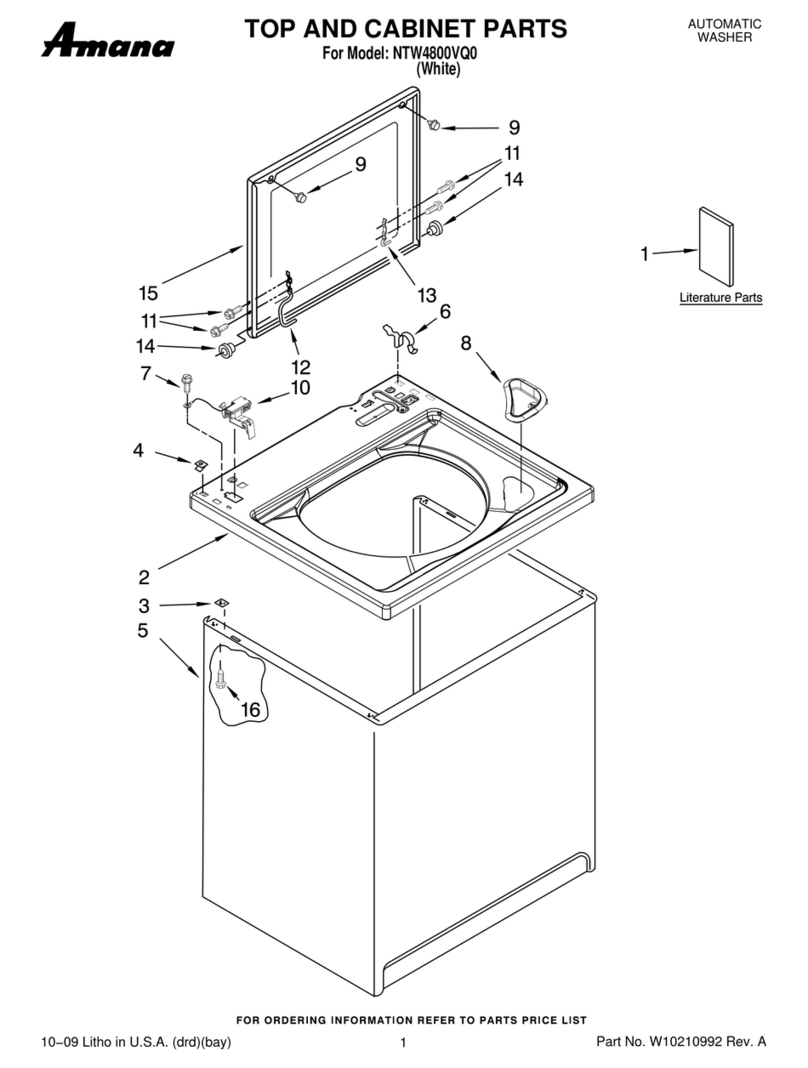

Figure 1

Add Powdered HE Detergent

NOTE: Do not add liquid laundry detergent, single-dose

laundry packets, color-safe bleach, Oxi-type boosters, or

fabric soener crystals to dispensers. They will not dispense

correctly. Add to the basket prior to adding laundry.

Using Laundry Product Dispensers

NOTE: Do not add liquid laundry detergent, single-dose

laundry packets, color-safe bleach, Oxi-type boosters, or

fabric softener crystals to dispensers. They will not dispense

correctly. Add to the basket prior to adding laundry.

"EEQPXEFSFE)&EFUFSHFOU

*.1035"/5 Use only High Efficiency detergents. The

package will be marked “HE” or “High Efficiency.” Low-water

washing creates excessive sudsing with a regular non-HE

detergent. Using regular detergent will likely result in longer

cycle times and reduced rinsing performance. It may also

result in component failures and noticeable mold or mildew.

HE detergents are made to produce the right amount of

suds for the best performance. Follow the manufacturer’s

instructions to determine the amount of detergent to use.

/05&4

■Use only powdered HE detergent in the detergent

dispenser. Add liquid HE detergent or single-dose packets

to the basket prior to adding laundry.

■See “Washer Maintenance” for information

on recommended method of cleaning washer dispensers.

"EEMJRVJEDIMPSJOFCMFBDI

UPEJTQFOTFS

Bleach will be dispensed automatically during the wash part

of the cycle. Do not overfill, dilute, or use more than 1 cup

(250 mL). Do not use color-safe bleach or Oxi products in

the same cycle with liquid chlorine bleach.

"EEMJRVJEGBCSJDTPGUFOFS

Pour a measured amount of liquid fabric softener into

dispenser; always follow manufacturer’s directions for correct

amount of fabric softener based on your load size. Fabric

Softener is added during rinse.

*.1035"/5 Do not overfill or dilute. Overfilling dispenser will

cause fabric softener to immediately dispense into washer.

It is normal for a small amount of water to remain in the

dispenser at the end of a cycle.

NOTE: The fabric softener dispenser rotates around the wash

basket and may not be in the same spot each time.

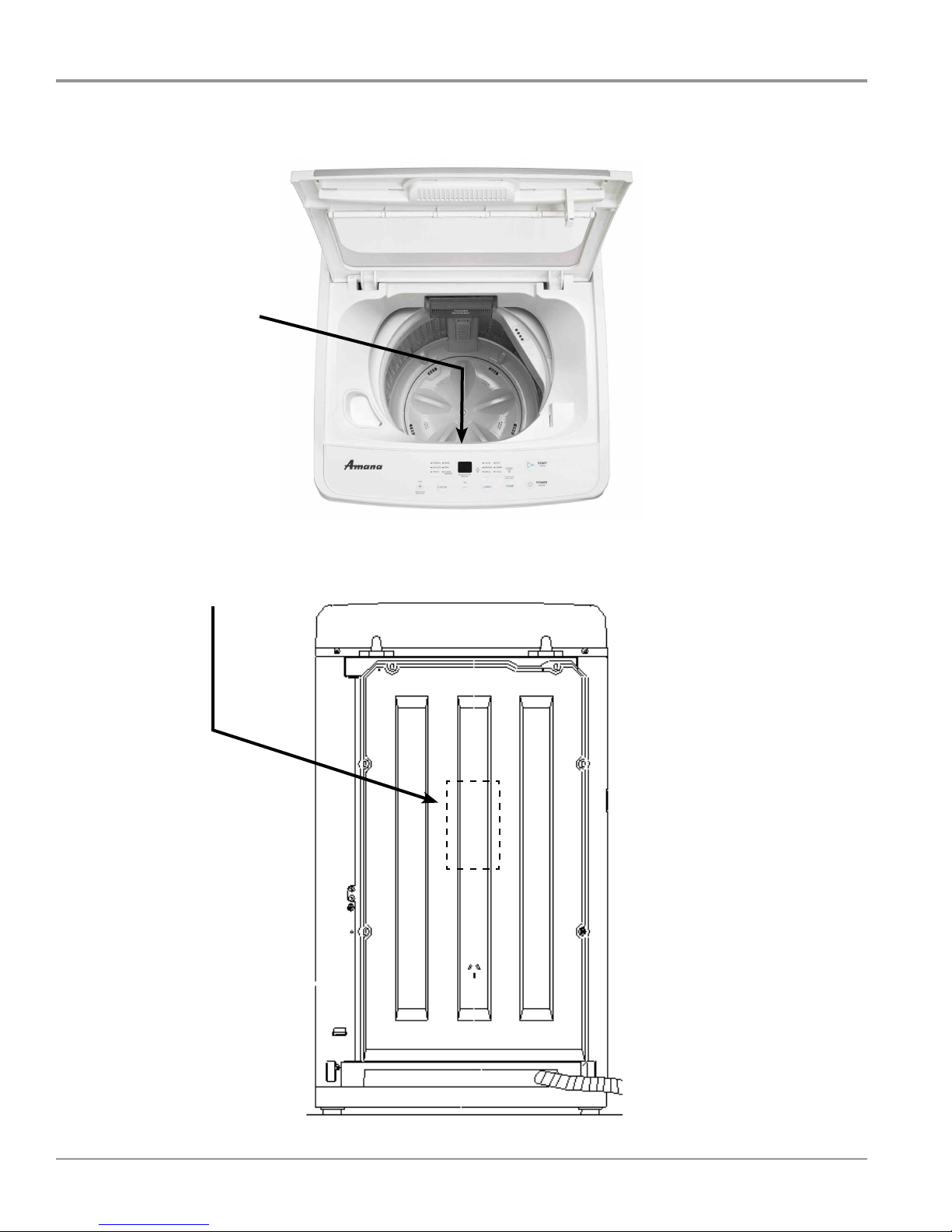

5PVDI108&3UPUVSOPOXBTIFS

Close the washer lid. Washer will not fill, agitate or spin

with the lid open. Make sure the dispenser drawer is closed

completely, then touch POWER to turn on the washer.

4FMFDU-0"%TJ[F

Press the LOAD button to select the correct setting for

your wash load and the type of fabric being washed.

Choose a water level that allows the load to move freely

for best fabric care.

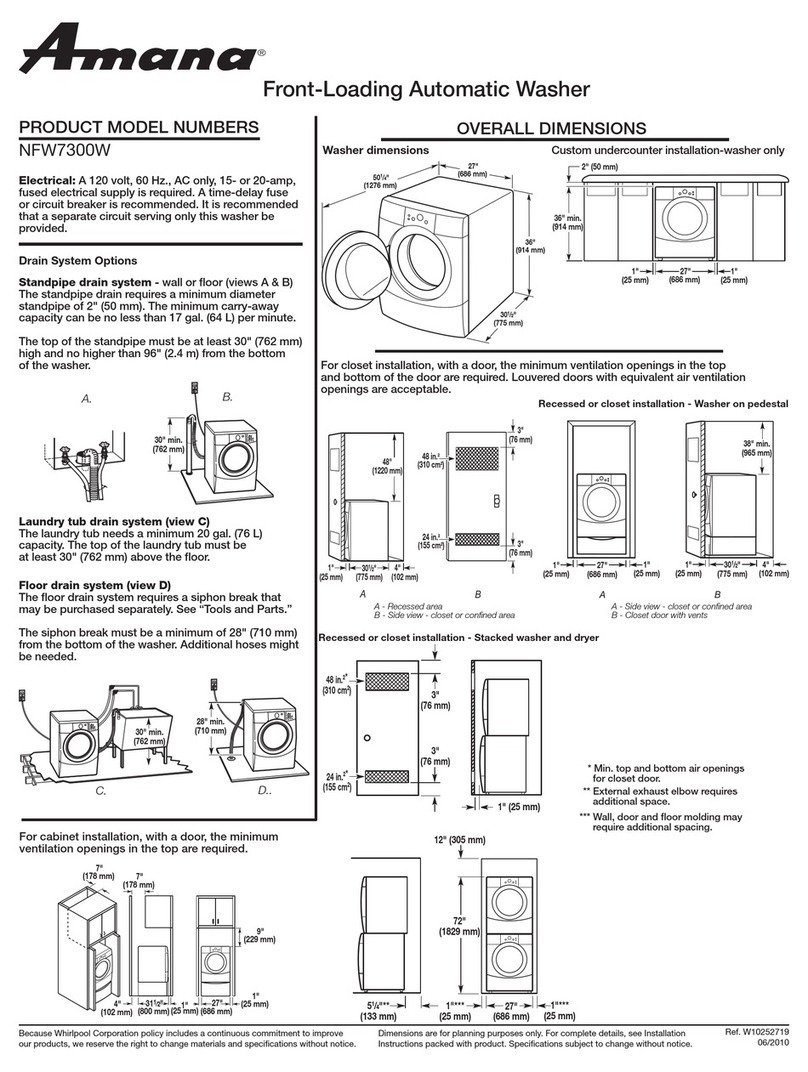

Figure 2

IMPORTANT: Use only High Eciency detergents. The package

will be marked “HE” or “High Eciency.” Low-water washing

creates excessive sudsing with a regular non-HE detergent.

Using regular detergent will likely result in longer cycle

mes and reduced rinsing performance. It may also result

in component failures and noceable mold or mildew. HE

detergents are made to produce the right amount of suds for

the best performance. Follow the manufacturer’s instrucons

to determine the amount of detergent to use.

NOTES:

nUse only powdered HE detergent in the detergent

dispenser. Add liquid HE detergent or single-dose packets

to the basket prior to adding laundry.

Add Liquid Chlorine Bleach to Dispenser

Using Laundry Product Dispensers

NOTE: Do not add liquid laundry detergent, single-dose

laundry packets, color-safe bleach, Oxi-type boosters, or

fabric softener crystals to dispensers. They will not dispense

correctly. Add to the basket prior to adding laundry.

"EEQPXEFSFE)&EFUFSHFOU

*.1035"/5 Use only High Efficiency detergents. The

package will be marked “HE” or “High Efficiency.” Low-water

washing creates excessive sudsing with a regular non-HE

detergent. Using regular detergent will likely result in longer

cycle times and reduced rinsing performance. It may also

result in component failures and noticeable mold or mildew.

HE detergents are made to produce the right amount of

suds for the best performance. Follow the manufacturer’s

instructions to determine the amount of detergent to use.

/05&4

■Use only powdered HE detergent in the detergent

dispenser. Add liquid HE detergent or single-dose packets

to the basket prior to adding laundry.

■See “Washer Maintenance” for information

on recommended method of cleaning washer dispensers.

"EEMJRVJEDIMPSJOFCMFBDI

UPEJTQFOTFS

Bleach will be dispensed automatically during the wash part

of the cycle. Do not overfill, dilute, or use more than 1 cup

(250 mL). Do not use color-safe bleach or Oxi products in

the same cycle with liquid chlorine bleach.

"EEMJRVJEGBCSJDTPGUFOFS

Pour a measured amount of liquid fabric softener into

dispenser; always follow manufacturer’s directions for correct

amount of fabric softener based on your load size. Fabric

Softener is added during rinse.

*.1035"/5 Do not overfill or dilute. Overfilling dispenser will

cause fabric softener to immediately dispense into washer.

It is normal for a small amount of water to remain in the

dispenser at the end of a cycle.

NOTE: The fabric softener dispenser rotates around the wash

basket and may not be in the same spot each time.

5PVDI108&3UPUVSOPOXBTIFS

Close the washer lid. Washer will not fill, agitate or spin

with the lid open. Make sure the dispenser drawer is closed

completely, then touch POWER to turn on the washer.

4FMFDU-0"%TJ[F

Press the LOAD button to select the correct setting for

your wash load and the type of fabric being washed.

Choose a water level that allows the load to move freely

for best fabric care.

Figure 3

Bleach will be dispensed automacally during the wash part of

the cycle. Do not overll, dilute, or use more than 1 cup (250

mL). Do not use color-safe bleach or Oxi products in the same

cycle with liquid chlorine bleach.

Add Liquid Fabric Softener

Pour a measured amount of liquid fabric soener into

dispenser; always follow manufacturer’s direcons for correct

mount of fabric soener based on your load size. Fabric

Soener is added during rinse.

IMPORTANT: Do not overll or dilute. Overlling dispenser will

cause fabric soener to immediately dispense into washer.

It is normal for a small amount of water to remain in the

dispenser at the end of a cycle.

NOTE: The fabric soener dispenser rotates around the wash

basket and may not be in the same spot each me.

Using Laundry Product Dispensers

NOTE: Do not add liquid laundry detergent, single-dose

laundry packets, color-safe bleach, Oxi-type boosters, or

fabric softener crystals to dispensers. They will not dispense

correctly. Add to the basket prior to adding laundry.

"EEQPXEFSFE)&EFUFSHFOU

*.1035"/5 Use only High Efficiency detergents. The

package will be marked “HE” or “High Efficiency.” Low-water

washing creates excessive sudsing with a regular non-HE

detergent. Using regular detergent will likely result in longer

cycle times and reduced rinsing performance. It may also

result in component failures and noticeable mold or mildew.

HE detergents are made to produce the right amount of

suds for the best performance. Follow the manufacturer’s

instructions to determine the amount of detergent to use.

/05&4

■Use only powdered HE detergent in the detergent

dispenser. Add liquid HE detergent or single-dose packets

to the basket prior to adding laundry.

■See “Washer Maintenance” for information

on recommended method of cleaning washer dispensers.

"EEMJRVJEDIMPSJOFCMFBDI

UPEJTQFOTFS

Bleach will be dispensed automatically during the wash part

of the cycle. Do not overfill, dilute, or use more than 1 cup

(250 mL). Do not use color-safe bleach or Oxi products in

the same cycle with liquid chlorine bleach.

"EEMJRVJEGBCSJDTPGUFOFS

Pour a measured amount of liquid fabric softener into

dispenser; always follow manufacturer’s directions for correct

amount of fabric softener based on your load size. Fabric

Softener is added during rinse.

*.1035"/5 Do not overfill or dilute. Overfilling dispenser will

cause fabric softener to immediately dispense into washer.

It is normal for a small amount of water to remain in the

dispenser at the end of a cycle.

NOTE: The fabric softener dispenser rotates around the wash

basket and may not be in the same spot each time.

5PVDI108&3UPUVSOPOXBTIFS

Close the washer lid. Washer will not fill, agitate or spin

with the lid open. Make sure the dispenser drawer is closed

completely, then touch POWER to turn on the washer.

4FMFDU-0"%TJ[F

Press the LOAD button to select the correct setting for

your wash load and the type of fabric being washed.

Choose a water level that allows the load to move freely

for best fabric care.

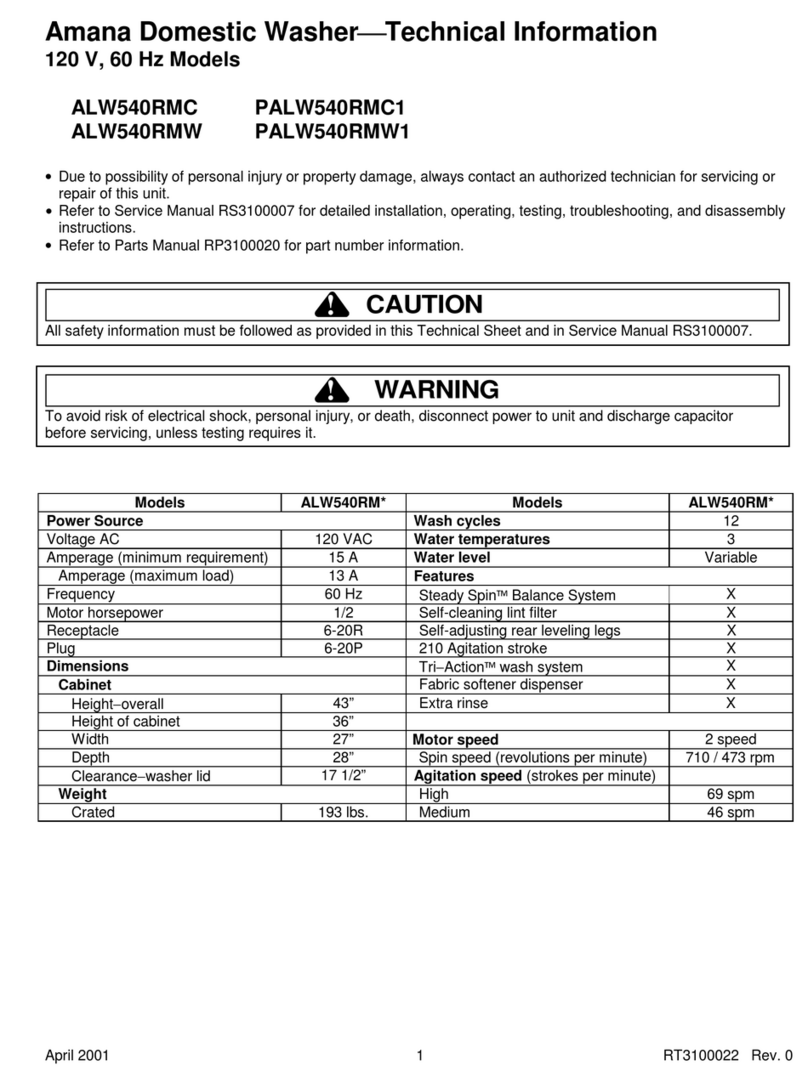

Figure 4