•

•

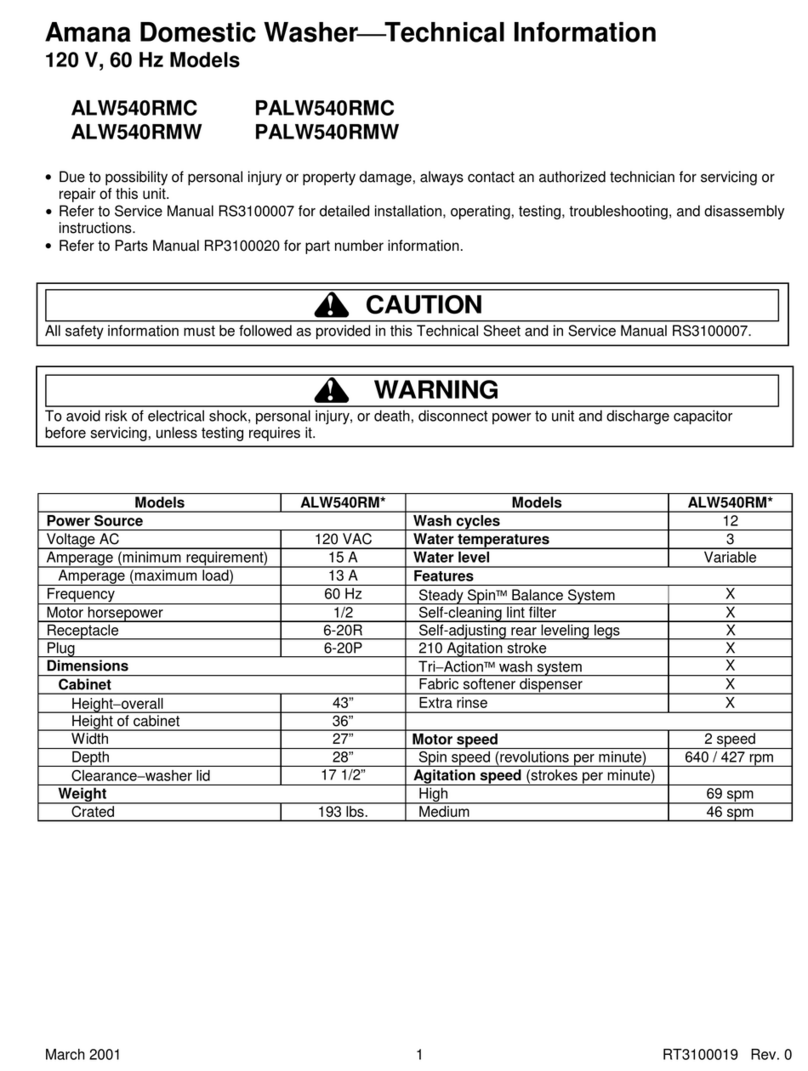

Table

of

Contents

Nameplate

Location

............................................... 2

Model

Identification

............................................... 2

SECTION

1-

Grounding

1.

Wall Receptacle Polarity Check.........................5

2.

Power Cord to Cabinet Top, Cabinet Top

to Control Hood Mounting Bracket,

Pressure Switch Mounting Bracket and

Ground Tab

on

Graphic Panel ...........................5

3. Control Hood Wire Harness to Top Left

Rear Corner Gusset of Cabinet .........................6

4. Wire Harness to Motor .......................................6

SECTION

II

-Service Procedures

Graphic Panel, Control Hood and Controls ........ 7

5. Control Hood Assembly ................................... 1O

6. Timer ................................................................

10

7. Temperature Switch .........................................

11

8. Pressure Switch ...............................................

12

9.

Graphic Panel ..................................................

12

10. Loading Door ...................................................

12

11.

Agitator ............................................................

13

12. Agitator, Drive Bell and Seal Assembly ............

14

13. Front Panel ......................................................

17

14. Motor and Mounting Bracket............................ 17

15. Idler Lever and Pulley ...................................... 19

16. Motor Drive Pulley............................................20

17. Motor Switch ....................................................23

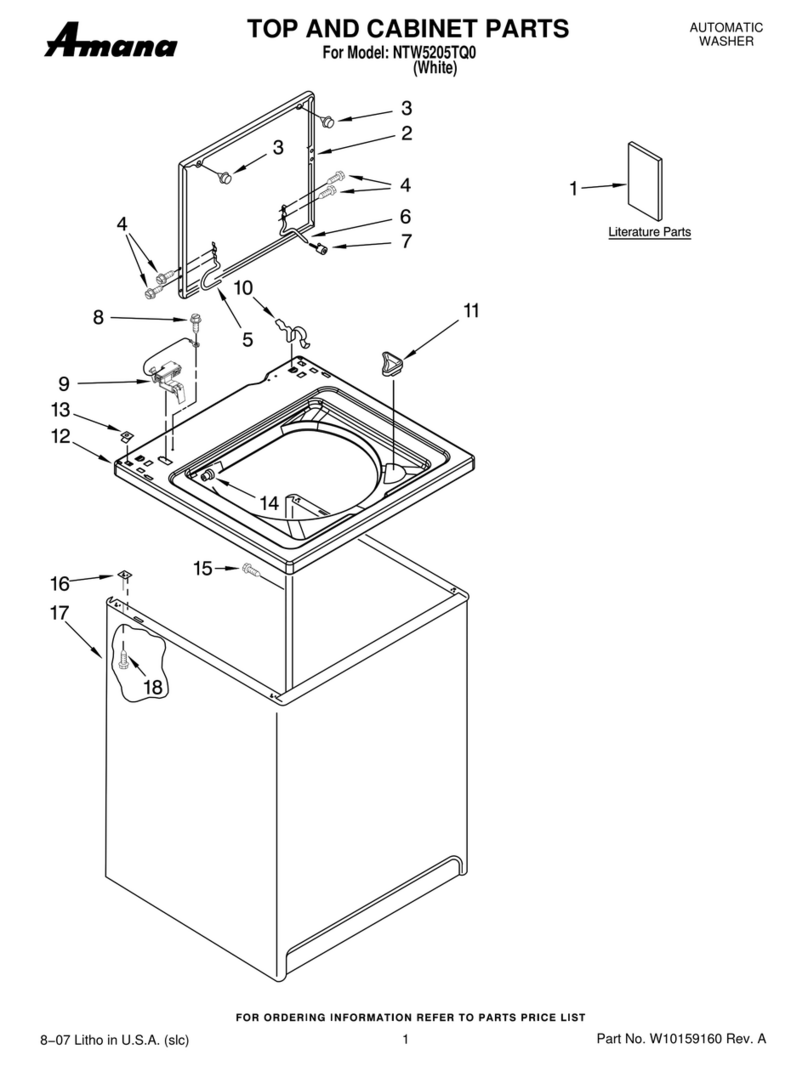

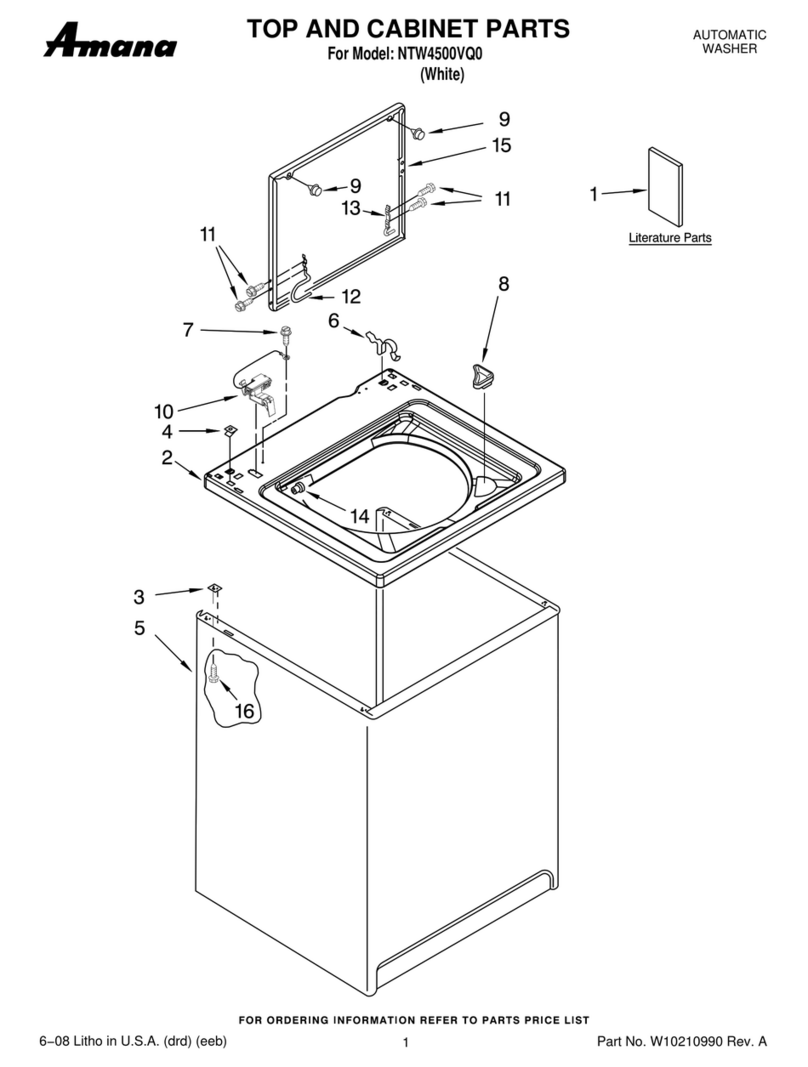

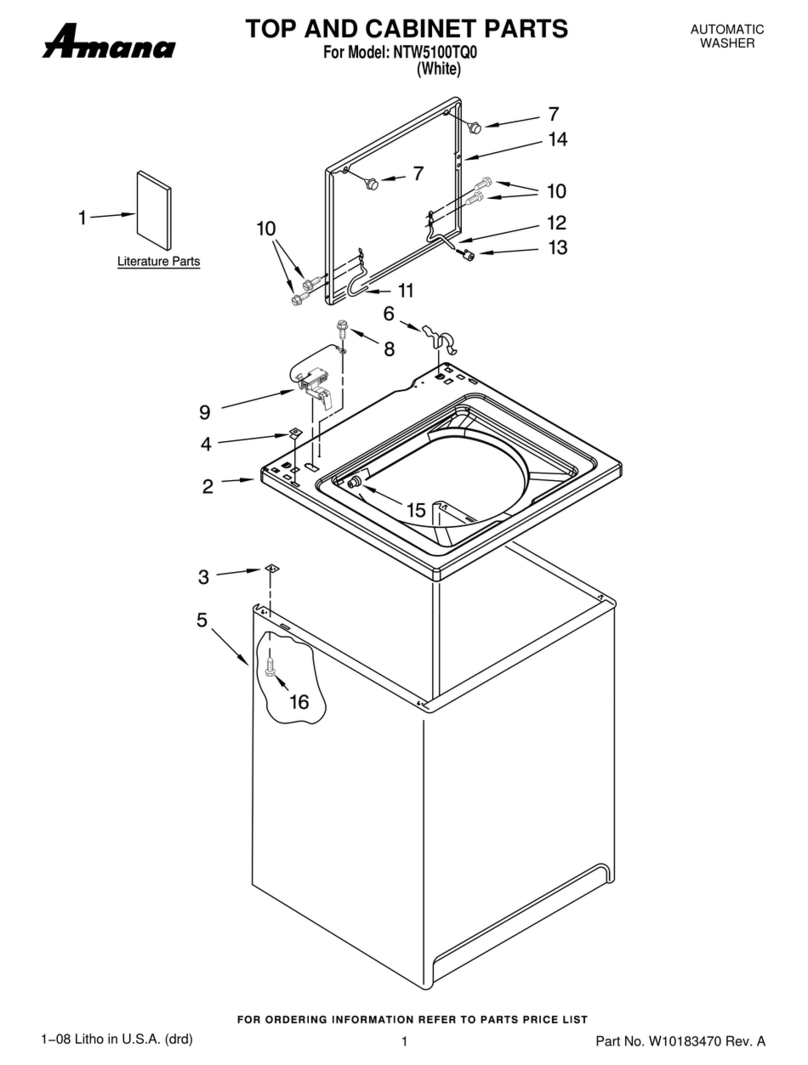

18. Cabinet

Top

Assembly ......................................24

19. Out-of-Balance Switch Assembly ..................... 26

20. Mixing Valve Assembly .....................................

27

21. Washtub and Clothes Guard ............................

28

22. Hub and Seal Kit Assembly ..............................

32

23. OuterTub .........................................................

38

24. Drive Pulley and Helix ......................................

41

25. Brake Assembly ...............................................

44

26. Lower Bearing Housing....................................

46

27. Transmission Assembly ...................................47

28. Balance Ring ....................................................

54

?9. Upper Bearing Assembly .................................

54

30. Snubber Pad and IsolatorAssembly ................

55

3

SECTION Ill -

Adjustment

31. Leveling Legs ...................................................

57

32. Pressure Switch ...............................................

58

33. Belt (Agitate and 3pin) .....................................

58

34. Out-of-Balance Switch .....................................

59

SECTION IV -Service Helps

35. No Hot Water ..................................................

61

36. No Cold Water ..................................................

61

37. No Warm Water ................................................

62

38. Water Fill Does Not Stop at Proper Level .........

62

39. Timer Does Not Advance ..................................

62

40. Motor Does Not

Run

.........................................

63

41. No Agitation .......................................................

64

42. Constant Agitation .............................................

64

43. Unit Smokes, Overheats, Cycles

on

Motor

Thermal Protector, Switch Actuator

Kicks

In

and Out...............................................

65

44. Slow Spin or No Spin ........................................

65

45. Constant Spin ...................................................66

46. Unit Stops

in

Cycle; Quits After a

Couple Loads;

Is

Intermittent ............................66

47. Washer

is

Locked Up or Binding .......................66

48. Outer Tub Does Not Empty ...............................67

49. Excessive Vibration ...........................................67

50. Water Leaking From Outer Tub.........................67

SECTION V - Test

Procedures

Emerson Motor Switch .....................................69

Emerson Motor Windings .................................70

SECTION

VI

-Cycle Sequence Charts..............

71

SECTION VII -Internal Wiring

of

Washer

Motor

Switch

..............75

SECTION VIII -

Wiring

Diagrams .......................77

RS3100002 (37400R3)

Rev.

3