23833A200 11/08/12 2

CAUTIONS/WARNINGS

Failure to follow instructions could cause serious

bodily injury and/or property damage. Use only as

a back-up sump pump in residential wastewater

applications. DO NOT run the pump dry.

1. Check local plumbing and electrical codes before

installing to ensure compliance.

2. Battery box must be kept in a cool, dry, well

ventilated area, and battery must not be exposed

to any sparks or flames. An explosion or fire could

result. Battery acid is very corrosive; avoid spilling

on skin or clothing. Eye protection must be worn

when handling the battery.

3. Battery Selection and Maintenance

• Use a new 12 volt, fully charged battery with

top terminals. For maximum performance and

battery life, a deep cycle (marine, group 24, min.

90 to 100 AH) battery should be used. A Group

27 battery may be used if it will fit in the battery

box. The electrolyte level should be checked

monthly and filled as required. Automotive

batteries may be used, but a decrease in

performance and battery life will result.

• Group 24 batteries will fit into the battery box

with maximum battery dimensions of 12" long x

6-1/2" wide x 9" high to the top of the terminals.

• Every three months battery maintenance should

be done as follows:

Unplug the battery charger. On batteries with

removable top caps, measure the specific gravity

of the electrolyte with a hydrometer. If any cell

is less than 1.225 specific gravity or if the cells

vary more than .050 specific gravity, the battery

should be replaced. Check the electrolyte level

and fill as required. Check battery terminals and

clamps for tightness and corrosion and service

as required. Plug battery charger back in.

• Replace the battery if the backup pump operated

for an extended period of time and the battery is

severely discharged. It is also recommended that

the battery be replaced every three years even if

the system is not used.

4. When service is required, proceed carefully:

• Disconnect the power at the main electrical

service box by turning the circuit breaker off or

by removing the fuse.

• Disconnect the battery charger from the wall

after the power is disconnected.

• DO NOT lift the pump by the cord.

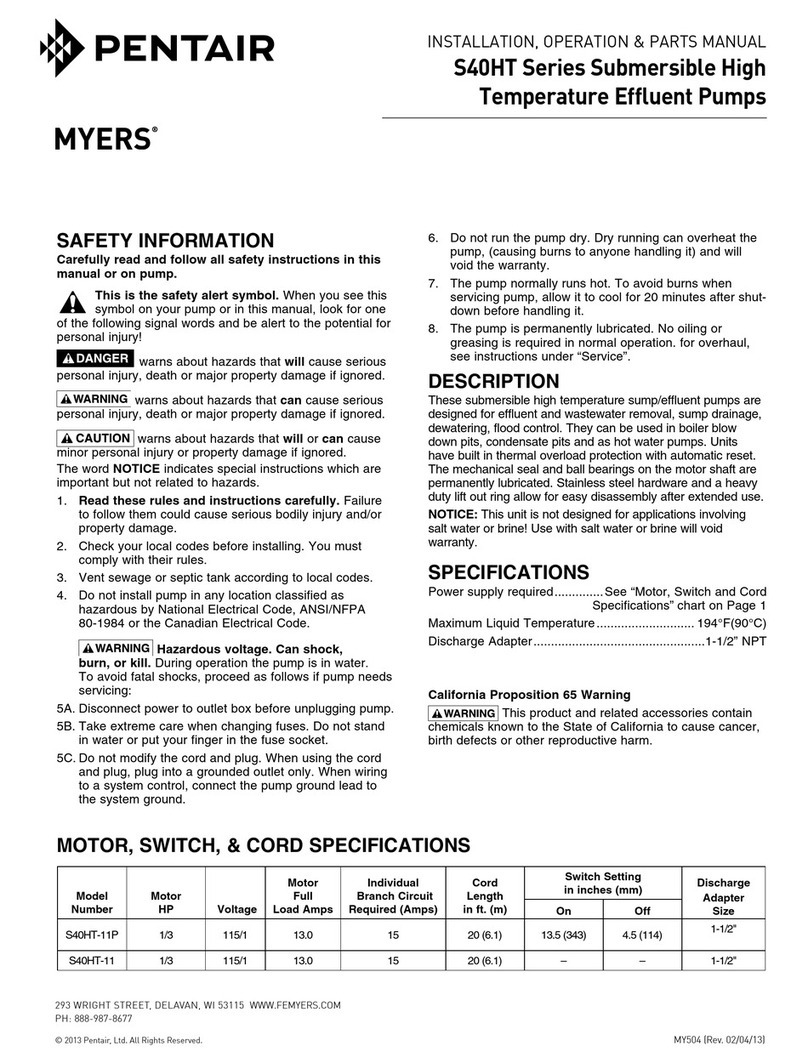

CALIFORNIA PROPOSITION 65 WARNING:

This product and related

accessories contain chemicals known to the

State of California to cause cancer, birth

defects or other reproductive harm.

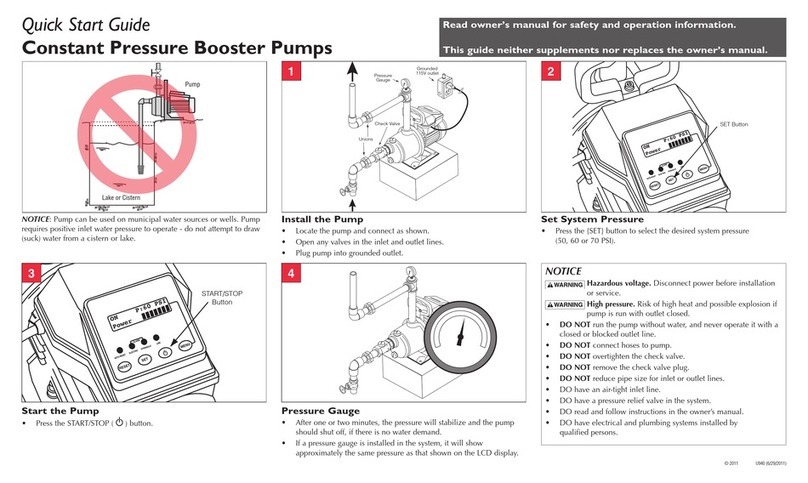

INSTALLATION INSTRUCTIONS

1. Disconnect power to the primary sump pump.

2. Assemble control panel to battery box with four

screws included.

3. Position 12 volt battery (not provided) into battery

box.

4. Assemble the two lead wires from control panel to

the battery with the two battery clamps.

Note: Assemble RED wire to POSITIVE (+) battery

terminal and BLACK wire to NEGATIVE (–) battery

terminal. The RED wire is supplied with an in-line

fuse to protect the battery, pump and wiring should

a short, overcurrent or ground fault occur. If this

fuse must be replaced for any reason, it must be

replaced with one of the exact same rating. Failure

to do so may result in a fire hazard. If the polarities

are connected wrong, the REVERSE battery

indicator light on the control panel will come on.

Correct the battery wire connections. There is an

automatic reset in the panel. A short time will be

required for it to reset. The connections must be

clean and tight.

If voltage of the battery is lower than DC 11 volts,

the LOW battery indicator light will come on and

the buzzer will sound for the ALARM function.

Battery should be checked by a battery shop.

5. Assemble backup pump a minimum of 1" above

the primary pump and rotate 30°.

The enclosed pump includes a built-in check

valve and screws directly into the side of the tee

included.

The other two ends of the tee will accept 1-1/4" or

1-1/2" PVC and ABS pipe. An additional check

valve must be installed between the primary

pump and this pump.

6. Attach the float switch to the discharge pipe with a

wire tie. Be sure that the turn off or down position

of the float is above the suction inlet of this pump.

Tether at 1-1/4". Insert the plug of the float switch

into the SENSOR socket of the control panel.

7. Insert the plug of the battery charger into the

CHARGER socket of the control panel and plug

the charger into an AC-115 volt power outlet.

8. Insert the plug of the pump into the PUMP socket

of the control panel.

9. Push the manual RESET button and the unit is

ready for operation.

10.The back-up sump pump should be checked by

unplugging the primary sump pump and filling the

sump basin with water. When the water level is

slightly above the backup sump pump, it should

turn on. As the water level drops, the backup

sump pump should turn off before the water level

reaches the bottom of the backup pump. If not,

raise the float switch slightly. Press the RESET and

plug the primary sump pump back in.

Note: Be sure that there is a 4" minimum from the

top of the backup pump to the top of the sump.